Laminate is considered a half-quality floating and wear resistance with excellent properties. It is easy in laying, and properly completed laminate laying is the key to long-term operation of the coating. The content and distribution of formaldehydes is significantly lower than the regulations prescribed by the laws. Laying laminate on the floor is possible without restrictions. At its heart, the coating contains wood products, therefore its properties are largely similar to the properties of natural wood. This fact will not be discounted in the process of use and in care.

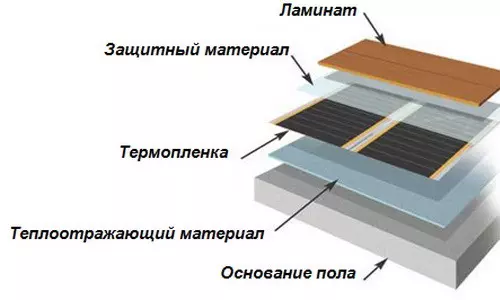

Laminate laying scheme on a warm floor.

Benefitability:

- The laminated floor in the assembled form resembles a parquet, although in terms of cost it is much lower than the latter. And the installation of it is much easier.

- Laying of laminate is possible absolutely to different surfaces (all varieties of linoleum, tile, short-haired carpet, wooden boards).

- Laminate is easier than a simple board, and more durable.

- Special care for it is not required: enough vacuuming occasionally and make wet cleaning on it.

- The strength and wear resistance of the laminated coating is confirmed by a long utilization - is able to perceive intensive loads for 15-20 years.

- It is safe from an ecological point of view.

Secret of intraceability and thermal resistance: panel structure from the top to the bottom layer

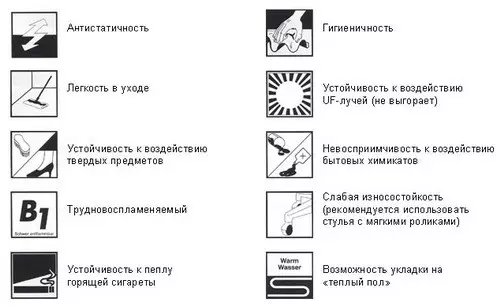

Laminate marking.

- Corundic application (powdered state of stones) couple with resins with the absence of impurities dangerous to humans. Direct Pressure Laminate (DPL) - Special Technologies Extinguishing Coating on Laminate Floor Cars.

- Recreation of natural stone or wood decorative material treated with resins.

- The coating complementary (products of simple does not happen) - it serves to enhance the impassability of the surface coating and its wear resistance.

- Compressed sawdust (HDF) - do not absorb moisture.

- The opposite side with impregnation from the resin, preventing the wigging and allowing the form to be preserved.

Over 20 patterns include the palette of colors of laminated parquet panels of different series - from cherry blossom to maple. Laminated coating provides the ability to experiment and with color and with its form. When using various color strips Laying the laminate is possible. You can lay out the decorative edging. It looks very peculiar and unusually laying the laminate at an angle of 45 degrees, but also a lot of work hard. Although the result compensates for all the efforts spent.

Article on the topic: Mold under the wallpaper manifests itself on the walls of black spots

Tools

Laying the laminate will require the presence of: devices of stretching (30 cm), wedges, hammer, belt, saws, adhesive strip 5-8 cm wide, smelting, resistant to moisture (consumption - 0.5 l by 12 m).Features of mounting laminate

The technology does not provide for the use of coverage outside or indoors with high humidity. But the laminate is perfectly adapted for laying indoors with warm floors. It will ensure a uniform temperature distribution on the floor surface.

The simplicity of laminate laying is this moment as the lack of need to remove the former coating from the floor.

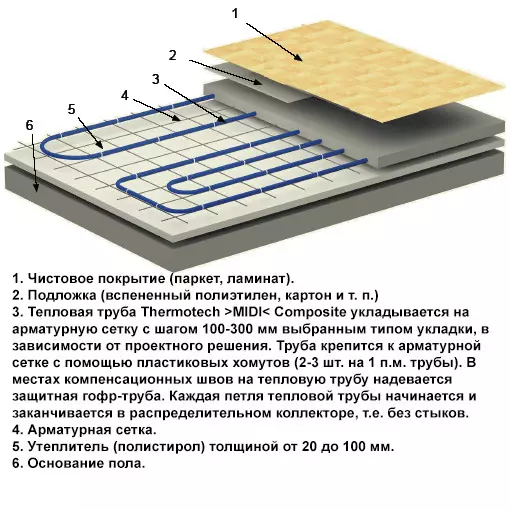

Laminate laying diagram for warm water floors based on a concrete screed.

Laminate dice can be put on the base: Fiberboard or chipboard, on the tile, on the wooden floor, linoleum, even possible installation of laminate on the tie.

The assembly of the laminated boards in time is short. The technology is quite accessible to anyone who knows how to cope with the hammer. Naturally, you need to adhere to a clear sequence of work.

Sequence of action when assembling laminate

- Unpack panels, examine them for integrity and quality. Leave for 48 hours indoors where their assembly will be made. Pricing temperature - 18 degrees, relative humidity - 75%. Passing the acclimatization procedure, the laminate will take the necessary dimensions in accordance with the atmospheric conditions of the room.

- To reduce the visibility of the joints between the panels, it is necessary to walk on all edges to walk with grinding paper 320, easily pressing them.

- Prepare the base for laying is necessary in advance. The surface to the beginning of the work should be dry, purified, dense and smooth.

Linoleum, polyvinyl chloride and any other solid material can be left, but the fibrous coating is required to dismantle. Flooring with short wool and soft linoleum is permissible to apply under the base for the laminate floor.

Laminate laying scheme on a screed.

Placeing the laminate on the tile from the tile, the wood board either on the hijacked linoleum, you need to take care of the additional layer (at least 2 mm) from the soft material. Such may be a foam or a special substrate from foamed polyethylene. It must be accurately put and glued. For gluing, you can use the adhesive film (4-5 cm wide).

Article on the topic: Homemade shock and moose shoes for hunter

To eliminate the penetration of moisture under the floor, it is necessary to smoke the angles of the room and the walls at a height of about 2-3 cm. In the future, the plinth will close all unnecessary elements.

On the cement screed or floor of the tile, you need to lay a polyethylene film in such a way that it is superimposed onto a part of the wall. It will serve as insulating layer of vaporizolation.

The irregularities of the seamless floor must be aligned with a spacion grout intended for the floors.

- Decide on the direction of laying and provide deformation seams for large rooms. At the entrance to the room you need to provide a place, delaying dirt and moisture.

Before you start stacking parquet, you need to estimate whether it will be possible to freely use the interior door if parquet will be laid under it. It is necessary to remove the platbands from the door jambs and the former plinth.

Laying of laminate is made in the direction of rays of light. In an elongated room, the laminate must be laid regardless of the direction of illumination perpendicular to the long wall. To ventilate the room in the process of laying should not be.

- The laminate panel laying is always performed by a floating option without the use of gluing or any other clutch with the surface of the floor. The dies are not glued to the floor and nails are not fixed. Printed to the semi grooves and spikes. The dies glue only among themselves. Clauses should be 0.1-0.2 mm. With a dry climate in the room you need to provide in the future an increase in gaps.

Do not forget that the basis of the products is a tree having a "breathe" property. In accordance with seasonality, the humidity in the room may vary. Therefore, for the floor should be provided for the possibility of stirring and shrink in 4 directions. In the process of laying, it is necessary to leave 8-10 mm gaps on the entire floor area. Such gaps need to be left near heating pipes and next to the threshold. At the end of laying the laminate, all intervals will close the plinth, which is not attached to the floor. Stop starting with the angle of the room.

Article on the topic: Fresh ideas for decoration of the hallway in the apartment

Laying laminate on a warm floor system

How are the warm floor with laminate combined? The laminate coating is perfectly combined with a heap system, personifying the reliability and safety of heating the floor surface. The advantage of this interaction is that the screed in the process of operation of the warm floor is heated evenly, increasing the use of laminate.

You can not labeled laminated coating on the warm floor, you will not like, but with the existing permission from the manufacturer.

The residual humidity of the dice should be checked additionally. Prepared cement solution on the floor to put evenly.

Preparatory work of laying laminate on the warm floor is as follows.

The screed with the mounted warm floor should achieve a certain degree of humidity provided by drying. To achieve this level, the flooring is triggered to work (after 2-3 weeks after drying the concrete), gradually increasing its temperature. 3 weeks it should be in the on state. And consider what is included not immediately at full capacity, but with raising periods by 5 degrees. This procedure is carried out regardless of the time of year, that is, in the summer too.

When the maximum temperature is reached, you need to warm up the floor 72 hours, being at such power system.

For 1-2 days before laying the laminate, the floor heating system is turned off and allow the floor to take the temperature of the room.

The surface of the screed should be sucked on the basis of the requirements of manufacturers of laminate. And the level of drying is checked before laminate laying.

The surface of the floor at the time of assembly of the laminate should be warm (18 or 20 degrees).

In order to avoid penetration of moisture on the floor, the polyethylene film, which is glued with scotch. After that, put the substrate (you can use in its quality foamed polyethylene with a thickness of 2 mm). The substrate is stacked by joking it all over the area of the room. After that, the rack laminate.

The process of laying the laminate on the warm floor does not have differences from the usual ways of laying. It is important to follow the instructions created by the manufacturer.

A day after the installation is complete, it is possible to turn on the warm floor, its temperature should not be above 26 ° C.