If it is decided to put the laminate, then it should be proceeded primarily from what the floor is available: with the draft finish in the newly purchased new apartment or the floor with the old finish.

Laminate laying technology.

Laying the laminate with the entire sequence of works and the purchase of related materials will depend on the initial state of the floor.

Consider how to put the laminate on the new floor and on the old coating.

Laying of laminate on the draft floor

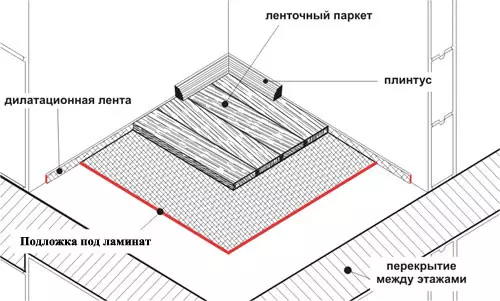

Structural scheme of flooring parquet on a draft floor.Laying of laminate is just one of the final stages of work, which takes 10% by time.

Most of the time is the preparation of the base for laying.

You can align the draft floor with one of two ways: make a bulk sex or to align the floor with sawn timber.

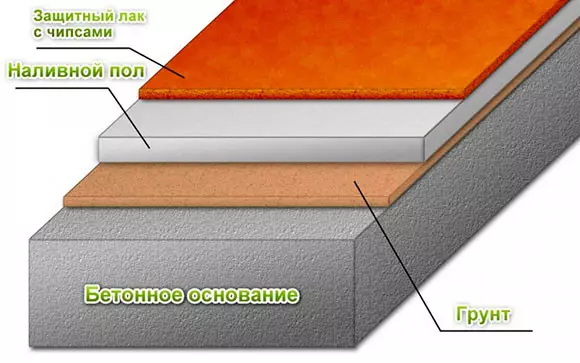

Device of bulk

About the concrete screed says a lot. The screed can be laid from the finished mixture for bulk floors or prepare a solution independently from cement and sand (1/3 ratio). A substrate is placed on the finished tie - foamed polystyrene foam, and after which the laminate.

Device of bulk floor.

Before the filling of the floor with a solution, the surface of the floor should be cleaned, close all the deformation seams, cracks and chips, apply a layer of waterproofing and primer. Only then pour the main layer. To premise small sizes, you can prepare a solution at once on the entire area. For example, breed a whole bag of dry mix. For large rooms, the solution is prepared by parts. The prepared solution is poured into the floor and leveled in 30 minutes. Wooden rails, a wide spatula and toothed roller on a long handle will be required. Complete drying of the screed occurs in 5-7 days. After this time, you can continue work.

If the solution is prepared independently, then surely will be interested in the question associated with the materials used. Recommendations for self-preparation of concrete:

- Typically, the cement grades 400 and 500 are taken for the solution.

- The cement grade 400 is the proportions of cement and sand 1/1, 1/2, 1/3.

- Brand cement 500 - the proportions of cement and sand 1/2, 1/3.

- The solution is poured with a layer of 20-40 mm.

- If the floor is poured in 15 m² in 40 mm, then 15x0.04 = 0.6 m cube mixture will be required. With a 1/3 sand ratio, 0.5 cube of sand and 0.1 cube cement will be required.

Article on the topic: Curtains for giving with their own hands - simple options

Flooring Floor based on sawn timber

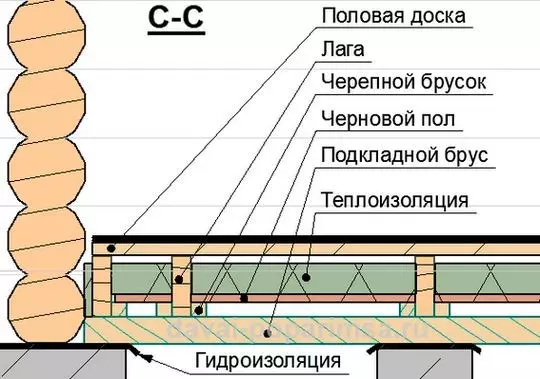

Wood floor circuit in section.

Consider the variant of the alignment of the draft floor under the future laying of the laminate, which is to use sawn timber. What are the advantages of such a floor under laminate?

- The complexity of laying sawn timber is small compared to the manufacture of a concrete screed, for which it is necessary to mix concrete, after that it immediately fill it and wait for some time until the screed is dry. Put the sawn timber is much easier.

- The presence of an airbag between lags and chipboard allows you to make the floor in the room warm. The floor becomes warm even without using a special warm floor system. Additionally, for insulation, the space between the lags can be filled with sheets of mineral wool, glass gambles or foam. And you can do without these measures if the financial capabilities are limited.

- Finance to get a warm flooring of this type is much more profitable if you resort to this technology.

So, here is the most important thing - to choose a suitable base surface to which the laminate can be laid. Consider as the formative of the chipboard. Why not Faneru? Firstly, Plywood is more expensive, secondly, in quality it is somewhat inferior to the chipboard (during operation, plywood sheets can crack, which will become a very negative point for laminate).

How to put laminate on chipboard?

Laminate in the context.

Sequencing:

- Install lags.

- Located on the lags of the chipboard using the level. This will allow you to get a smooth floor. If the skews are observed, then the lags are aligned with pieces of foam polyethylene.

- Attach chipboard sheets to lags using self-tapping screws. So that the hats of the screws are not exhibited, the chipboard is pre-drilled. Lags to the floor Self-storms are not fixed.

- After styling, the chipboard is putting a gasket using a substrate for laminate.

- On the substrate is a rack laminate.

All, the floor with the basis of the chipboard is ready.

Article on the topic: How to pour a warm floor with concrete - step by step instructions

Features of laying laminate on the former finishing coating

How to put a laminate on top of the previous coating?

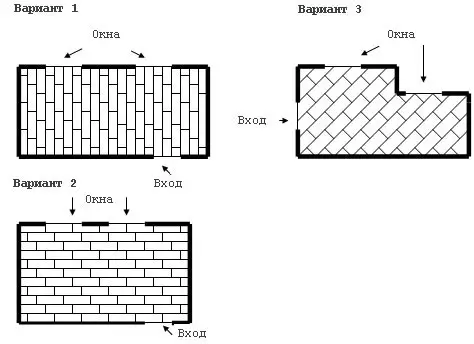

Laminate laying options.

Laminate can be put on top of absolutely any old coating, with the exception of one - long-haired carpet. The latter must be dismantled before laying the laminate and use one of the ways of alignment of the floor, both for the draft version (or with a lifting or sawn timber).

Consider several coatings on which you can lay a laminate.

Wooden floor (boards, parquet).

In this case, you need to make sure that the old ridiculous floorings are still suitable. For these purposes, they are diagnosed and in the case of need restored. Small defects (cracks, holes, chips) close up with a putty, in order to exclude the further flow of the processes of destruction.

Aligning wooden boards by cyclishing or laying sawn timber (plywood or chipboard 15 mm thick) - the next stage of work. Sheets need to be put with a displacement, that is, that the seams are not sharpened. Dust is cleaned so that it does not in the future causes the irritating embroidering of the laminate (as it can get into laminate locks).

On top of the cooked wooden floor lay a layer of dense polyethylene film, the substrate, that is, the laying scheme is repeated.

The chipboard acts not only as a layer for alignment, but also as an excellent equivalent of a concrete screed. To laminate to the chipboard can be put without problems, you need to adhere to the above actions.

Linoleum

The structure of household linoleum.Linoleum must be thoroughly inspecting and identifying all the depressions and protrusions that can be eliminated using another layer of substrate under laminate in those places that need "raise".

One or two layers of polyethylene film layer are put on the old coating before laying the substrate to provide an additional layer of waterproofing. Its fixation is performed by painting scotch. It is impossible to leave too worn or soft linoleum, it should close to the floor surface.

Article on the topic: The membrane for the gas column

Ceramic tile

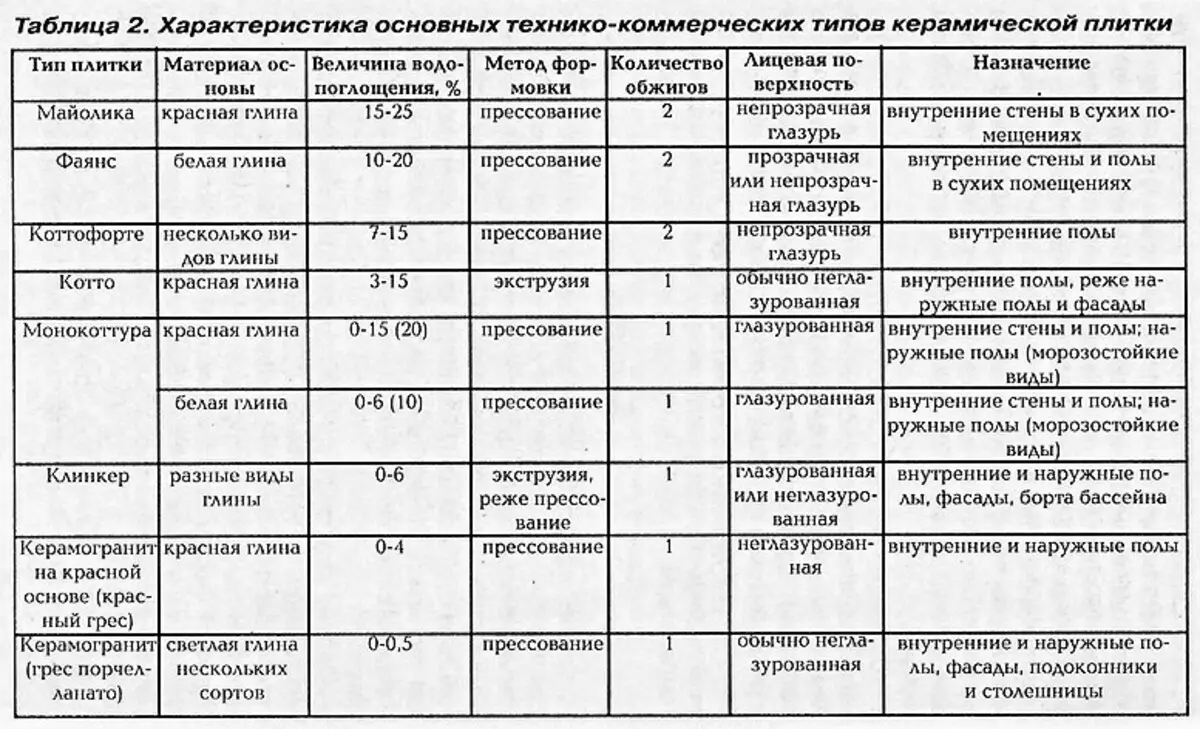

Technological characteristics of ceramic tiles.

The tile is already in itself a fairly flattened coating, and the installation of the laminate will not require any additional actions. It is important here more to pay attention to the substrate, since the tile for the substrate is a very slippery surface. The substrate must be firmly fixed on the tile with painting scotch.

The optimal option is to use the substrate from extruded polystyrene foam. This material is elastic, does not frown, it is a reliable fixation with the help of painting tape. And since the tile is a fairly cold coating, then the device of a film warm floor system can be provided on top of it, specially designed for laminate.

Which substrate for laminate is better to choose?

A large role in high-quality operation of the flooring will be played by lining, which is placed under the laminate. Today manufacturers offer substrates under the laminate of several types.Polystyrene foam

The most common type of substrate.

It is moisture resistant, resistant to mold and mushrooms, is endowed with good insulating qualities. But with mechanical exposure, it is strong.

Bung

The material is environmentally friendly, with good insulation qualities, resistant to the development of mold and loads. Such material is the most expensive of all in the construction market.Composite materials

Bituminous-cork or rubber-cork - is among the average between the first and second type of substrates both at its price and according to the characteristics.

The selection of the substrate must be made by relying on its purpose and resistance to mechanical loads. The assembly of the laminate on the previous finishing coating is provided by the flooring of polyethylene, and it makes sense to lay a substrate from the tube on a concrete screed. Composite materials are universal.

Substrate laying technology:

- The layer of a substrate with a thickness of 0.2 mm is covered with a cooked surface;

- Sheets or canvas are put in the transverse direction of the future laminate masonry, slightly capturing the walls (height 3 cm);

- Separate elements of the substrate connect with scotch with painted;

- The substrate with a corrugated side is put on the book, and fooled - up.

Laying of laminate is possible on the draft floor, and on the previous coating. In the first case, you need to prepare a reliable base for laminate.