Plasterboard sheets are firmly entered into our lives as universal finishing material, characterized by its excellent performance. But even such a good material can be replaced by an improved option, namely, dry-fiber plates.

Characteristics

What is gypsum solid sheets? This is a finishing material produced from plaster and reinforced reinforcing components and cellulose fibers. Thanks to these additives and pressing GVL becomes very strong and reliable, and also does not need to close the surfaces of cardboard sheets. In addition, the material is not afraid of the fire, protects well from the cold and not bend under the action of mechanical loads.

There are two varieties of GVL: the usual and waterproof gypsum cooker. Both of these options are monolithic and do not scatter as a layer of plaster in drywall.

Gvl plates have the following advantages:

- simplicity, speed and dry installation of material on the floor;

- lack of waste and minimum construction garbage;

- better resistance to moisture than in GCL and DVP;

- monolith;

- density;

- Security for ecology and health;

- insulation qualities;

- fire safety;

- Not expanding under the action of temperature.

Cons of dry-fiber material are insignificant: increased value, compared to drywall, and probability of breaking with incorrect circulation. To reduce the probability of damage to the material during the installation process, it is necessary not only carefully examine the installation process and observe accuracy when laying, but also to choose products only proven manufacturers.

When buying a waterproof type GVL for the floor, you need to check the appropriate marking on each sheet, since sometimes they are mixed with conventional plates.

Scope of application

Used GVL as a dry screed for floor alignment. It is usually stacked by this material on the insulation, which serves as a ceramzite. Such a screed has many advantages, the main of which is not to wait for the drying of the coating, which usually takes from a month to 45 days.

Article on the topic: Crafts from stones and sea pebbles (40 photos)

In addition, the mass of the dry screed is significantly less than cement-sand, which reduces the load on the overlap. This is important if the floor is mounted on fragile concrete floors or on wooden lags.

You can also additionally align and strengthen GVL slats with cement or polymers. The main disadvantage of any plaster material is the fear of moisture, which requires careful thinking of waterproofing measures.

The leveling properties of the coating of gypsum fiber sheets are complemented by excellent insulating qualities. GWL will play the role and sound insulation, and insulation. Such a coating helps to balance the microclimate in the room, absorbing the excessive moisture out of the air and highlighting it back when the air becomes overwhelmed.

Types of gypsum fiber sheets

GWL is produced in the form of sheets polished, on the one hand. All sheets are soaked with substance that repulsion water, as well as primer, which counteracts the loss of color. The size and power of the GWL is divided into two types.

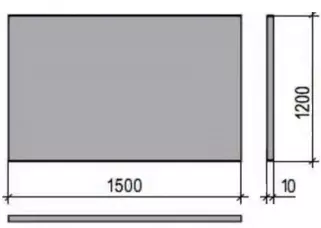

Standard plates similar to ordinary plasterboard sheets. The size is 1200x1500 mm. This type of material is applied not only to cover floor surfaces, but also for finishing other elements of the building design - alignment of walls, creating partitions, arches, niches and other architectural parts.

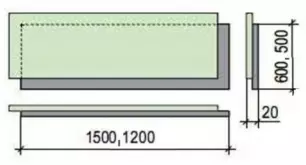

Little-format sheets are glued slabs of non-standard sizes with intersecting axes. Due to the offset of sheets relative to each other, Falk is created - a locking system that facilitates the fastening of the floor covering elements. There are two formats of such sheets: 1200x600 and 1500x500 mm.

Standard gypsum fiber sheet

Little-format GVL for the floor

All types of GVL meet the total characteristics: no more than 1% humidity, density up to 1200 kg / m3, bending strength from 5.5 MPa, hardness from 22 MPa. When buying, you need to check the availability of appropriate quality certificates.

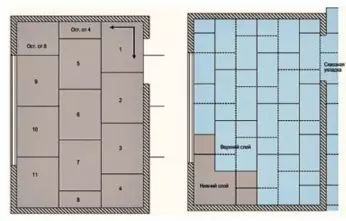

For greater strength, the HBLE sheets are usually placed in two or three layers, and it can be used both single-format plates and sheets with different linear dimensions. For example, the first layer is formed from low-format sheets, and the second is from standard. At the same time, it is necessary to comply with the inconsistency of the direction, that is, to lay the leafs of the cross-cross.

Article on the topic: how to make a doors from wood: materials, tools

Features of laying

There are special sets of building materials for dry floor alignment, including a set of GWL plates and the necessary fasteners for mounting one or multilayer coating. Large manufacturers also provide detailed instructions for assembling floors from gypsum fiber material.The founded feature of this process is the installation of the coating should be made with the displacement of the plates relative to each other, as a result of which the floor resembles a brickwork. Due to this, the area of docking increases, which increases the friction force between the coverage elements. As a result, the maximum durable and durable design is obtained. The offset should be made at least 20 cm, and better - by 25 cm.

GWL flooring device technology

Before starting work, the usual preparation of the main surface of the floor is made. Concrete base should be repaired and ground. After that, the dust and concrete crumb are removed by the construction vacuum cleaner, the floor ished away.

If the dry screed is mounted on the floor of a wooden bar or on the lags, all the elements of the design and the strength of the fasteners are checked, and also need to make sure the horizontal of all wooden beams.

The order of installation of a screed of a gypsum fiber leaf is:

- The small differences of the base heights (up to 5 mm) are eliminated using a self-leveling mixture or filling the removal of the floor with cement mortar with the additive sealant. Large irregularities are filled with a layer of clay, which is also useful in what is an excellent insulating material.

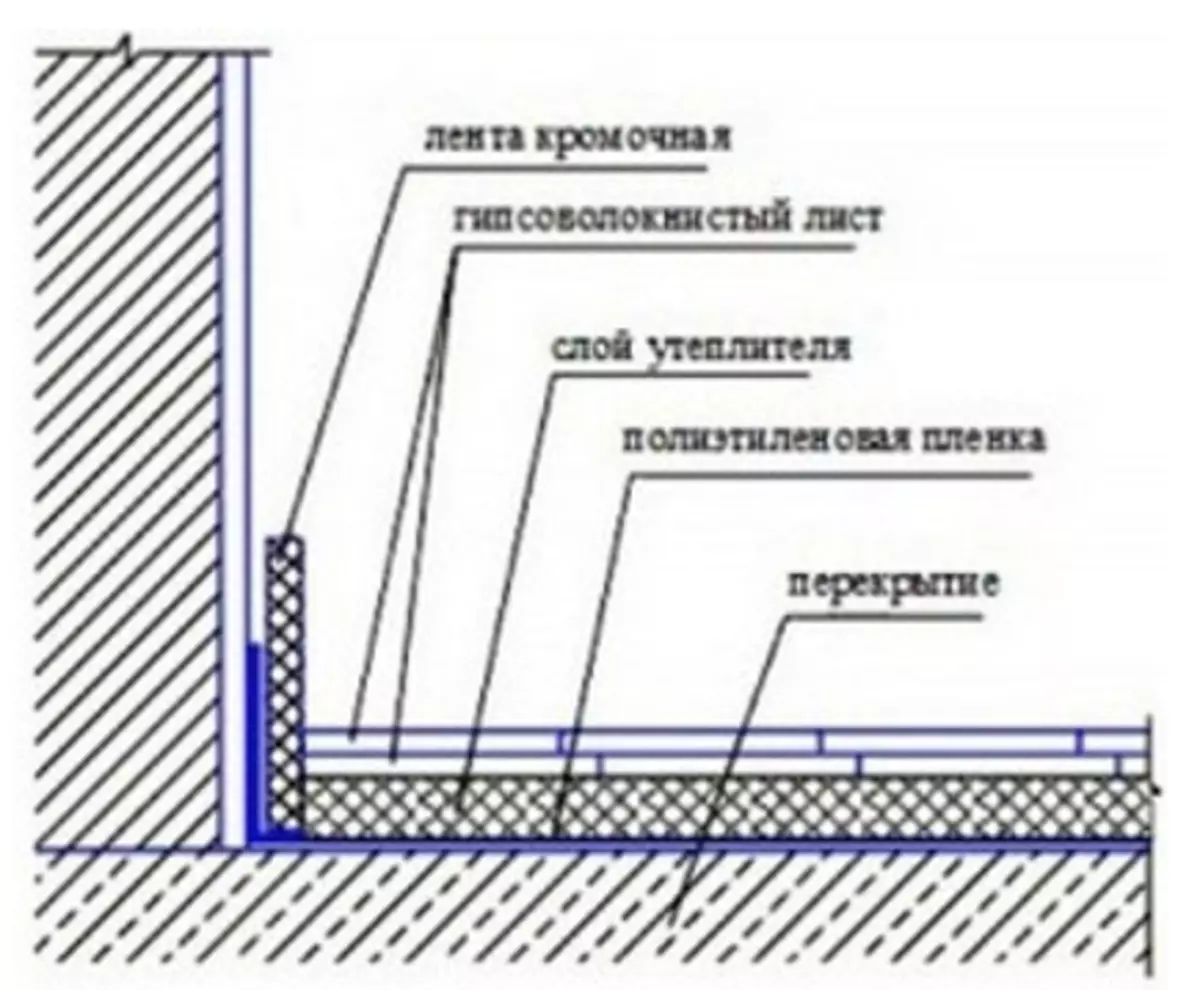

- The base is covered by a layer of waterproofing. As this material, a polyethylene film is usually performed, which is spilled by the flask, slightly entering the walls around the perimeter of the room. The film thickness should be about 0.2 mm. It is worth considering that when laying GVL on the wooden floor, insulation should be vapor-permeable - paraffinated paper or pergamine is suitable.

- On the perimeter of the future screed, a damper tape of foam or mineral wool is laid. Thanks to this element of the design, the material is not deformed when shrinking, and will also be improved sound insulation.

- Sheets of gypsum fiber material are reproduced by the project, taking into account the creation of the gap of the edges.

- The layer of insulation is poured - small grains or washed sand. This insulation is recurrected by the Rule of Lighthouses. The layer thickness should be at least 20 mm. If it exceeds 100 mm, the plates of GVL should fit into three layers.

- If the floor is placed on wooden lags, you can use mineral wool or glass gambler as insulation, as well as foam.

- On top of the insulation, the GWL layer is stacked. The gaps between the elements should be the size of no more than 1 mm in width.

Article on the topic: Mosaic plaster for the base - the best solution

Dry screed device diagram

The leveling coating is stacked, ranging from the far wall of the room. The first layer of the screed is covered with an adhesive substance, then the second layer is placed on top of it, perpendicular to the direction of the elements of the first and necessarily with the displacement of the joints.

In addition to glue, self-tapping screws are used, which should be screwed at a distance of at least 30 cm each other, if the sheets are standard, and not more than 20 cm when using small-format plates of GVL.

Laying of GBL floors in two layers, sheet placement plan

For fasteners, special screws with double fasteners should be applied, since conventional tapes for drywall can independently get out of the coating. As with the installation of plasterboard sheets, the hats of self-tapping screws need to be dragged into the surface of the GWL plates.

Upon completion of the installation, all joints and spuning offices of screws are embarrassed by putty. If the HBL plates fit indoors with high humidity, the joints of the joints should be additionally treated with a sealant or other waterproofing substance. After that, the protruding edges of the polyethylene film and the damper tape are cut. Since there is nothing to dry here, it is possible to start laying the decorative coating on the same day.