The profession of the cabineturist at all times was in demand and prestigious. Today, the ability to make beautiful carved wood products may not only be a great way to earn good money, but also a fascinating hobby. But in order for wood carving brought joy and was not burdensome, a special tool will be required.

All tools for wood thread should be made of good steel.

To date, a set of tools for a cabineturist must contain devices for the following types of work:

- threads;

- dinking;

- Rings and swallowing;

- planing;

- sharpening;

- Dolbé.

To have a representation, how the tree is processed, it is necessary to consider each of the tools in more detail.

Wood processing tools

Usually all types of devices intended for work on wooden surfaces are called incisors. This may include all cutting blades, saws, axes, chisels, special plans and much more. Each of the tools is intended for a certain type of wood preparation.Each cabinetteer individually selects the tool suitable for its requests and tastes. But if a person has no experience in tree processing and is just beginning to engage in this type of activity, it is advisable to adhere to the recommendations of knowledgeable masters.

Tree cutting fixtures

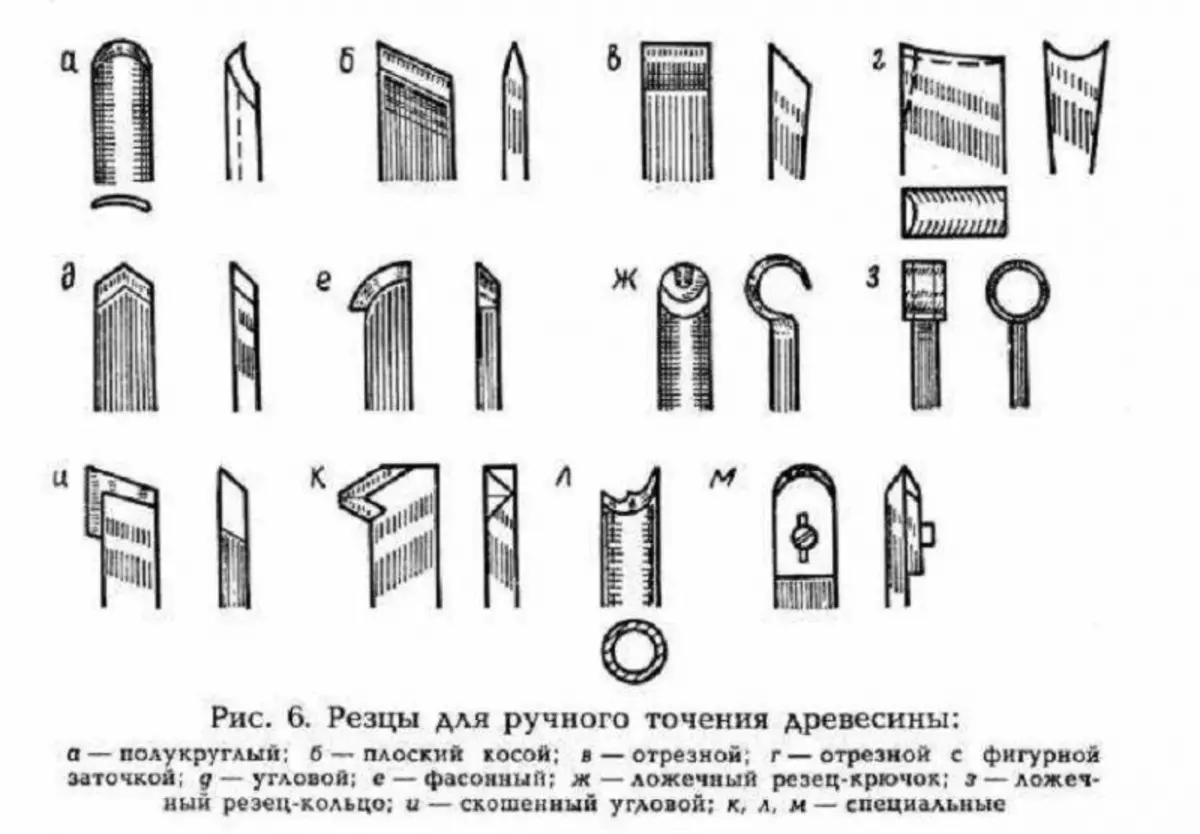

Cutters for wind sharpening.

The manufacture of any items from wood begins with cutting blanks. Cutters for tree cutting are sharp blades that usually form chips or sawdust during operation. When processing wooden surfaces, a manual method uses saws, founds, one-handed plates, and the like. These are tools that allow you to work in the way "from ourselves". That is, the movement of the master's hand goes to the opposite side of the side.

In many foreign countries, wood processing is produced by the way "on itself" when the direction of movement is carried out to the body of the master. As a rule, for this, the tools are specially used for this method - hacksaws, saws, etc. These are bilateral cutters, double-handed stops and spoonful cutters.

At the same time, it is necessary to remember that many devices, such as chisels or knives, cut "on themselves" is extremely undesirable: it can lead to serious injury.

It is also known another rule used by the cabinetries: if a wooden surface is required to handle a large surface, a method "from ourselves" is used, during which the work is facilitated by the energy of moving ax, saws or plans. This is not suitable for such a cutter as the Toll, which only work by the method of "on themselves" using the movements of the brush hand.

Article on the topic: Review and description of bedroom furniture

How to drink blanks

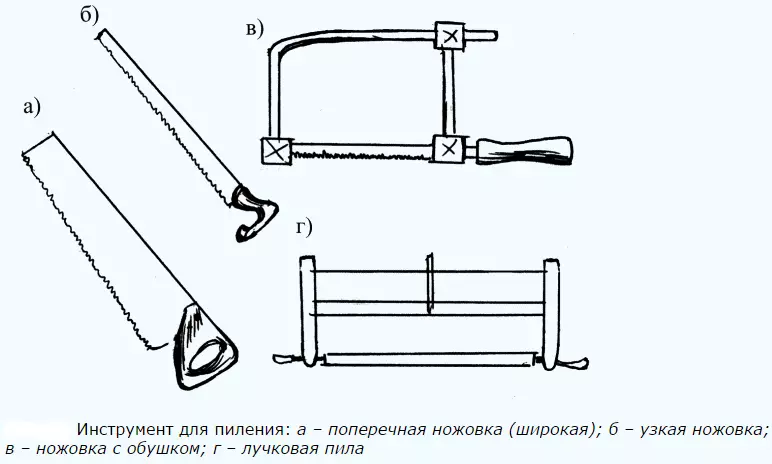

Sawing tool.

In order to sprinkle a tree, multi-cutting devices are usually used, called saws. They, in turn, can be longitudinal, transverse or universal sawing. So, the saws intended for transverse drinks have a sharp triangular teeth, each of which consists of two faces for threads to the right or left. Saws for longitudinal drinking are equipped with teeth in the form of a bit. This form allows the teeth to accumulate sawdust among themselves and make them out of the body of wood. The saws of universal destination have teeth in the form of a straight angle that can cut the fibers as across and along and at an angle.

Each type of saws is divided into the following varieties:

- simple;

- hacksaws;

- one-handed.

Mechanical saws are ribbon, two-way, petrol and circular.

Usually, the cutting of the workpiece occurs with the help of transverse saws, the distortion is one-handed or two-handed, and processing - with hackskeeping, circular or in-like. For rough work on a tree, saws with large cutters are used, for accurate processing - small-scale.

Rolling and sneaking of wood

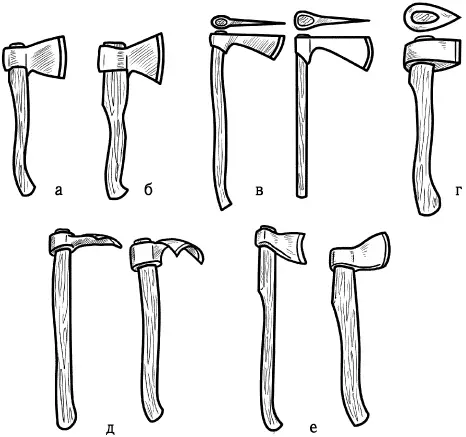

Axes: a - carpenter; b - joiner; in - Rubyatsky; g - colun; d - Tesla for sampling of recesses; E - Tesla for sculptural thread.

For the manufacture of blanks from bars, ridge or trunks, the following types of wood cutters are used: axes and colons. Colong is a heavy ax, which is used if you need to cut the ridge. Together with the kisen, metal or wooden wedges are used, which are driven into the body of wood and make it easier for her splitting. Already made blanks are clothed with household (carpent) light axes that are comfortable to wear on the belt in special covers.

To cut the surface of the wooden billet, the Tesl is used - the type of ax, in which the blade is perpendicular to the topopor. This is a necessary cutter for the manufacture of concave or curly products. If necessary, Tesl can be made with their own hands from the thick steel plate with a sharp and curved edge.

Article on the topic: Curtains from beads do it yourself: Step by step instructions

Planing of straight and curly surfaces

Planer tool for wood work.Planing is called cutting from the surface of the wood of thin layers of chips. This process requires the use of manual or turning cutters of the following type: knives, two-handed colors with straight or semicircular blades, Rubankov, Blyheads. Finishing planing is usually made by branches having a single or double blade fixed in a metal or wood housing. The thickness of the chips depends entirely on how far the blade or housing is extended. The smaller the distance, the thinner the wooden chips.

For the manufacture of curves or rounded parts, such as rivets for barrels can be, special plans are used, having a form of a convex knife. For billets, concave across the plane, Gorbachi Rovenki applies. There are also plans for the manufacture of edges and narrow grooves for fillets or boards.

Types and purpose of chisels

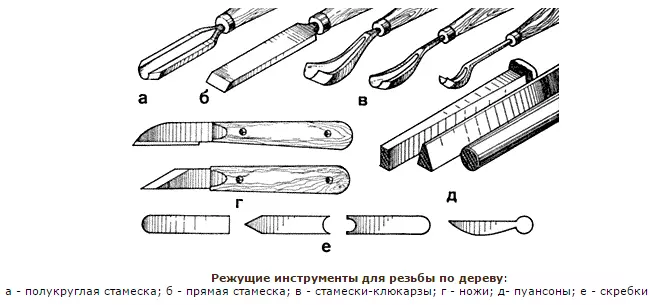

The chisels are the most popular type of cutters for wood processing. Usually for cutting of a tree, devices are used, which are rods of steel, having a flat surface, a sharp cutting blade and a shank. The shank is fixed on a wooden handle with a ring.

Cutting tools for wood thread.

Each variety of chisels has its purpose. So, straight and wide devices are used for stripping or cutting convex or smooth blanks. Narrow tools are designed for wood processing in narrow places of details. To work with wood solid rocks or horny bitch, straight chisels with round blades are used. If you need to clean the tree with a hollow or deep cavity, a chisel is used, having a thick steel rod. In addition, a needed tool in this case will serve as a kiyanka, which the chisel will be buried deep into the wood.

The rocks very well clean the tree from unnecessary fractions, but the main purpose of these tools is to cut the complex products. To create a variety of grooves in the body of various chutes, priests are needed - chisels with curved or gaunt-shaped blades. It is they who allow you to create a deepening of the desired radius and depth. Initially, the hole is cut into the widest clurracos, then the length of smaller can be used, then - even smaller, etc.

Article on the topic: how to align the wall under the tile: preparation and alignment, laying and whether to plaster surface in the kitchen

In addition, the work of the chamber is unthinkable without using the corners. With this tool, triangular recesses and grooves are cut, most often used with flat-strain threads.

Use of special cutters

In addition to all the described devices of the wood carving masters use other equipment. For example, a surround cutting used in the manufacture of artworks requires the use of spoonful cutters. Such tools are designed for centuries ago. The design of the cutters makes it possible to use them by the method "on itself" both along and across the fibers of wood.

As often as a spoonful device, a double-sided cutter is used in the form of the letter "T". This tool usually handle the blanks for the product of large sizes. Cutters of a spoon-type are used to cut out wooden circles, from which plates, other objects of dishes and much more can be manufactured.

The success of working as a lover of wood carving and professional depends largely on the quality of the instrument. That is why it is necessary to initially acquire all the necessary devices, and then start working.