The infrared film for a warm floor appeared on the domestic market relatively recently, but in a short period of time she was able to conquer thousands of fans.

Every person who at least once in his life had to lay the floor with heating, knows that this is a rather complicated and long-term procedure, worthwhile money. Installation of infrared thermal floors can be performed on absolutely any floor coverings.

Basic principle of work

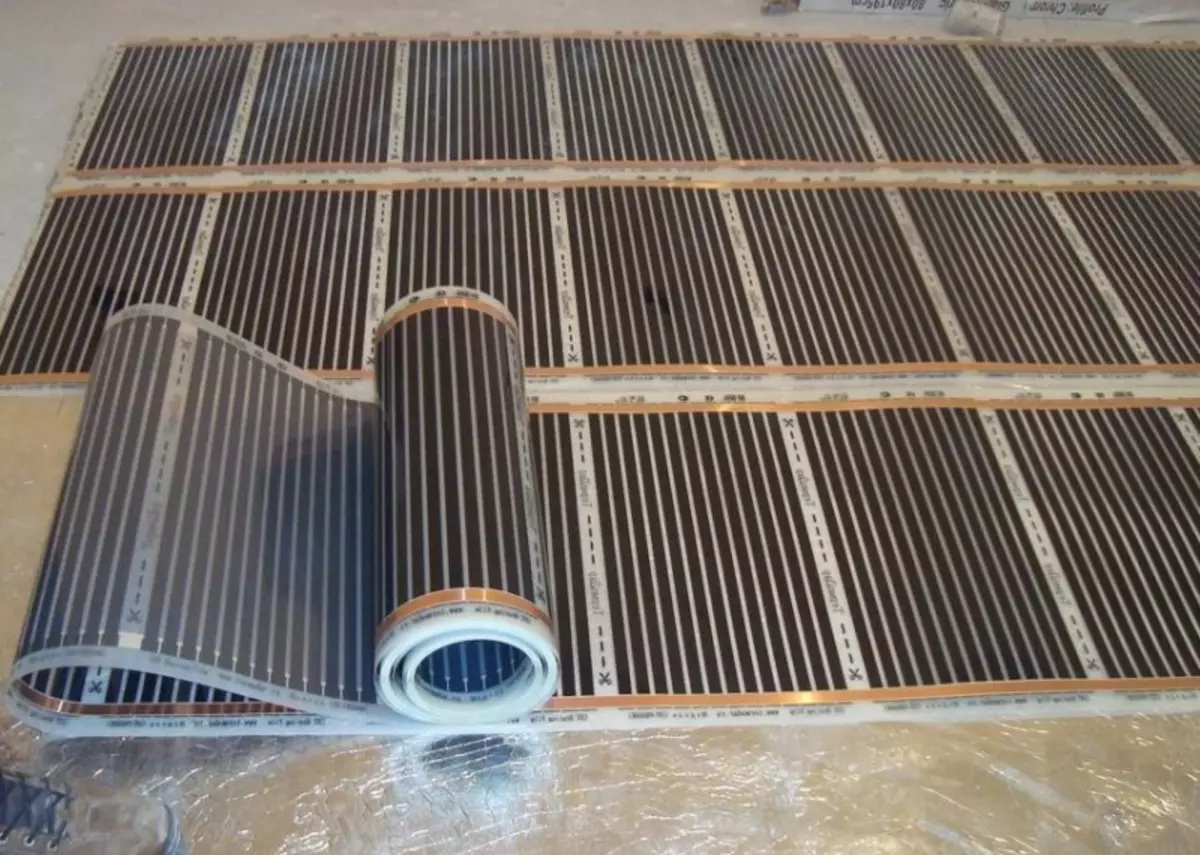

Heating elements are inside the polymer matter

Despite the fact that the electric and film warm floor is very thin, they consist of 5 layers, 3 of which are located inside a very durable polymer matter that does not allow damage to the heating elements.

The latter, in turn, consist of a copper track (tires) and numerous carbon strips (carbonstik). These composite materials consist of polymer and carbon fibers.

The heating element is inside the roll and is located in the transverse direction. The average width of the bands 1 is 1.5 cm connecting with copper conductive tires with silver contacts.

At the edge of each band, the contact group is placed, with which the main power is connected. The protective upper and lower layer passes the infrared radiation and protects the heating elements from moisture and mechanical damage.

Rolled warm floor is not dangerous for a person. As an example, the IR rays can be successfully used in modern medicine (dentistry, surgery).

Specifications

Calculate the amount of material before laying a warm floor

Determine how much material will be needed in order to perform the installation of infrared warm floor with your own hands, you need to get acquainted with its technical data.

Knowing this information will allow you to find out what is still necessary for the proper operation of the system. So, modern filter flooring systems have the following characteristics:

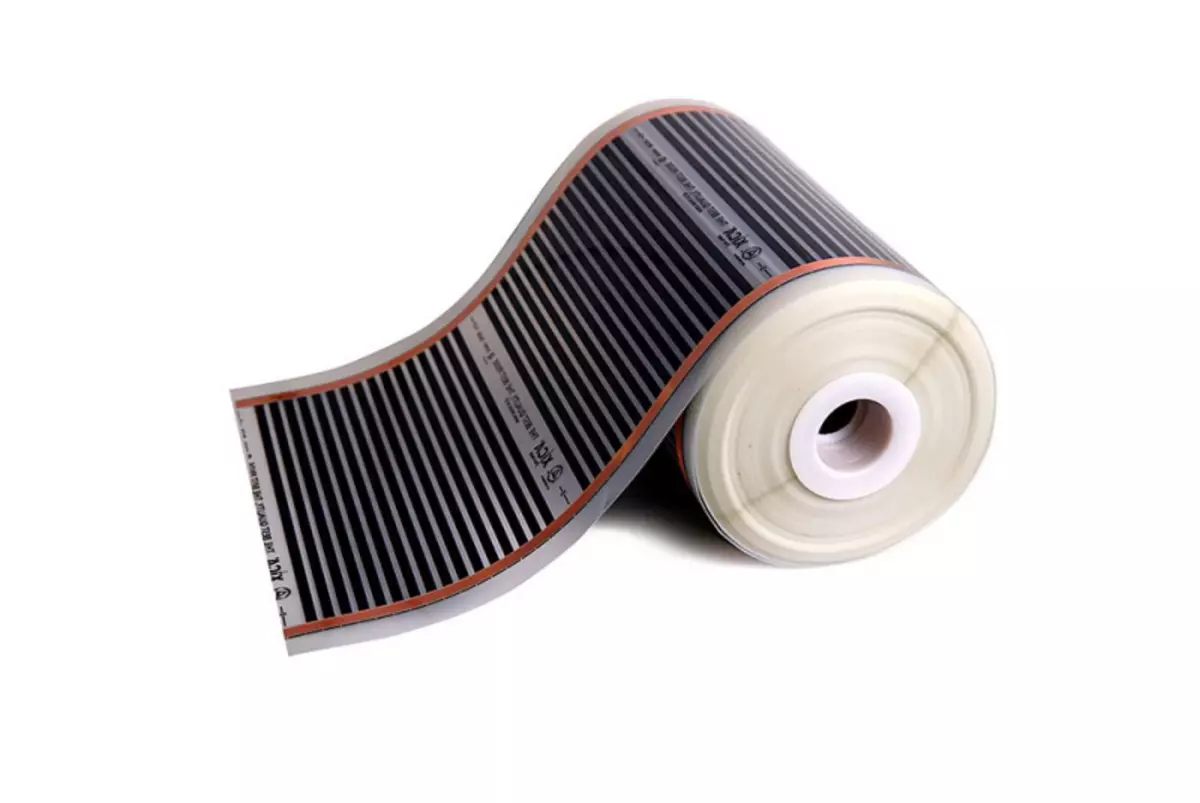

- Modern heating material is sold by rolls whose length can reach 50 m.

- The width is in the range of 0.5 - 1 m.

- The electric floor is connected to a voltage with a voltage of 220 V.

- The minimum consumption per day on average is 20 W / m2.

- Maximum coefficient 21 0W / m2.

- The material reaches the maximum temperature of 50 degrees in 2 to 3 minutes after it was turned on.

- 1 Roll of film floor Weighs about 50 kg.

Manufacturers recommend to adhere to performance, therefore, for optimal heating of the room, it is advised to put at least 75% of the entire floor surface.

In this case, the financial benefit of its use at the expense of savings on another type of heating will be more than 25%.

During the purchase, you should pay attention to the fact that the warranty period of at least 10 years should be specified on the package.

Advantages and disadvantages

Infrared panels easy to mount yourself

Article on the topic: Kitchen interior types 9 sq m with balcony

For several years, during which such systems are successfully used in our country, the relative reputation of the product has already developed.

If we talk about the advantages that the infrared film film differs, the following indicators can be distinguished:

- Install the coating can be independently in a short period of time. For this you only need to prepare the surface.

- The coating does not provide for changes in the height of the ceilings, which in some cases is considered important.

- Outdoor material does not need to pour concrete, which reduces the duration of the installation.

- The finishing coating on it can be put without additional preparation.

- The heating process occurs throughout the area of the room, which eliminates the temperature differences.

With infrared floor, the temperature will be the same and constantly in all parts of the room.

- Installation of infrared gender is allowed even in public places. The material has increased resistance to dynamic loads.

- The reduction in energy consumption is considered guaranteed fact in all cases when an IR film is used.

- Mobile properties allow you when moving to turn it into a roll and install in your new home.

- Immunity to voltage drops.

- At the failure of one element, others will continue to work. Repair will cost much cheaper in comparison with competitors from this segment.

Film floors are afraid of moisture, so it is important to pay attention to the insulation

Despite the fact that the film warm floor is considered an innovative material, it is not devoid of negative characteristics.

Yet it requires careful and careful relationship.

According to the reviews of people who have experienced the quality of the product, you can identify the following statistics:

- Contact with acute or thin surface can damage tightly;

- Electric film floors are afraid of moisture;

- The surfaces in the room have to be treated with antistatic, they are very strongly attracted dust;

- It is not recommended to install heavy furniture on the surface, from this elements quickly burn out;

- The average cost of material and work will cost approximately 650 - 800 rubles / m2, therefore, it is largely used for a small room.

Comparative characteristics of IR - warm and water heating

| Signs | Water Pol | Film |

|---|---|---|

| Room for boiler | Necessary | Not necessary |

| Laying heating pipes | Necessary | Not necessary |

| Floor thickness (excluding flooring) | 110 - 120 (with a screed) | 5 mm (with a substrate) |

| Installation time | 45 days | For 1 day |

| Service | Required | Not required |

| Freezing in winter | maybe | Absent |

| Repair cost in case of breakdown | High (100%) | Minimum (maximum 25%) |

| Ability to replace | Many restrictions | Uncomplicated replacement |

Installation of a warm floor

Installation Instructions IR Floor

Independent installation of infrared warm floor does not require a preliminary dismantling of the old concrete coating and fill the new. The only condition for proper laying is the preparation of the surface related to the repair and cleaning of the base.

To estimate its condition, you need to thoroughly spend the surface. This will allow you to detect possible damage to the plates: cracks, chips, holes.

Everything needs to be sealing with cement mortar. If you do not do this, part of the heat will leak through them and go down. After the solution laid in the niche dries, excess must be removed to create a flat surface. All the subtleties of the filting film floor, see this video:

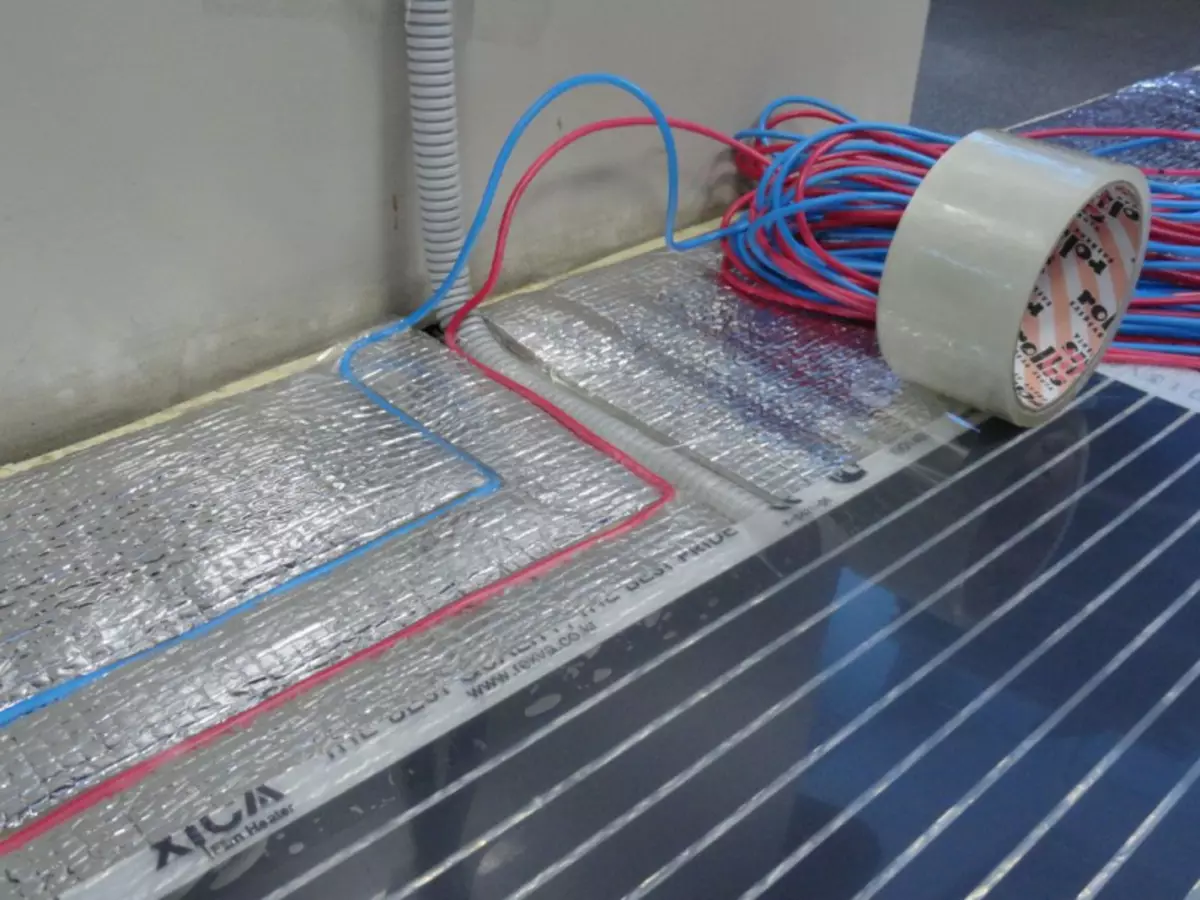

The next action that needs to be performed by carrying out the installation of a film warm floor with their own hands, is the laying of thermal insulation. To do this, it is recommended to use foamed polyethylene. It is spread to concrete, and the seams are connected to a special scotch. Its soft texture will protect possible heat leaks down and protect the surface of film warm floors during operation by smoothing the irregularities of the base.

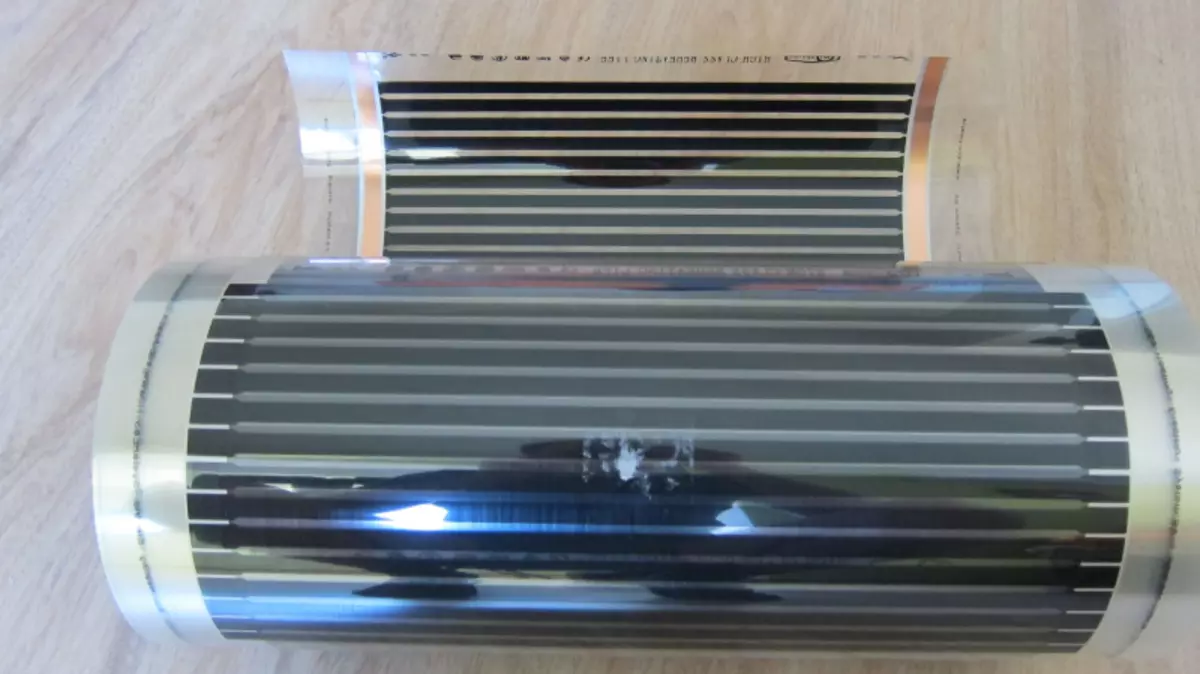

When using a foil insulation, you need to make sure that it is a dielectric, that is, does not let the current through itself.

Laying film

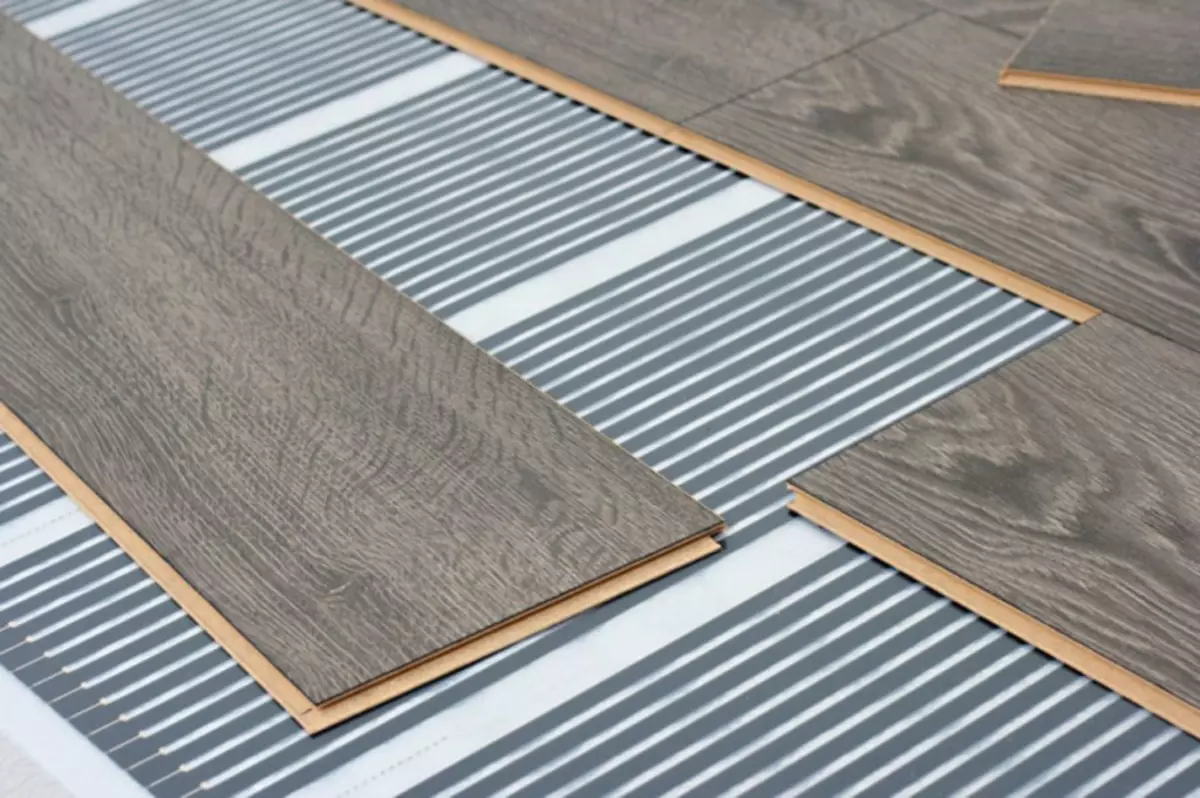

To put the film warm floor with your own hands, you need to roll it down the copper stripe. Thus, the matte surface should be on top, and gloss - down. At the same time, it is necessary to ensure that the air does not accumulate under the film.

If it is necessary to cut the cloth, it is allowed to do this, but only on a special markup caused to the material. It is most practical to roll a warm floor so that the contacts are from the other side where the thermostat will be installed. Details of the floor of a warm floor film, see this video:

Between adjacent stripes you need to save a distance of 1 cm. If in the future installed floor it is planned to be led by linoleum, then this gap should be eliminated. But it is necessary to take into account that the laying of cloths are not allowed. This can lead to their rapid failure.

Connection

Connecting a film warm IR floor can be divided into several steps.

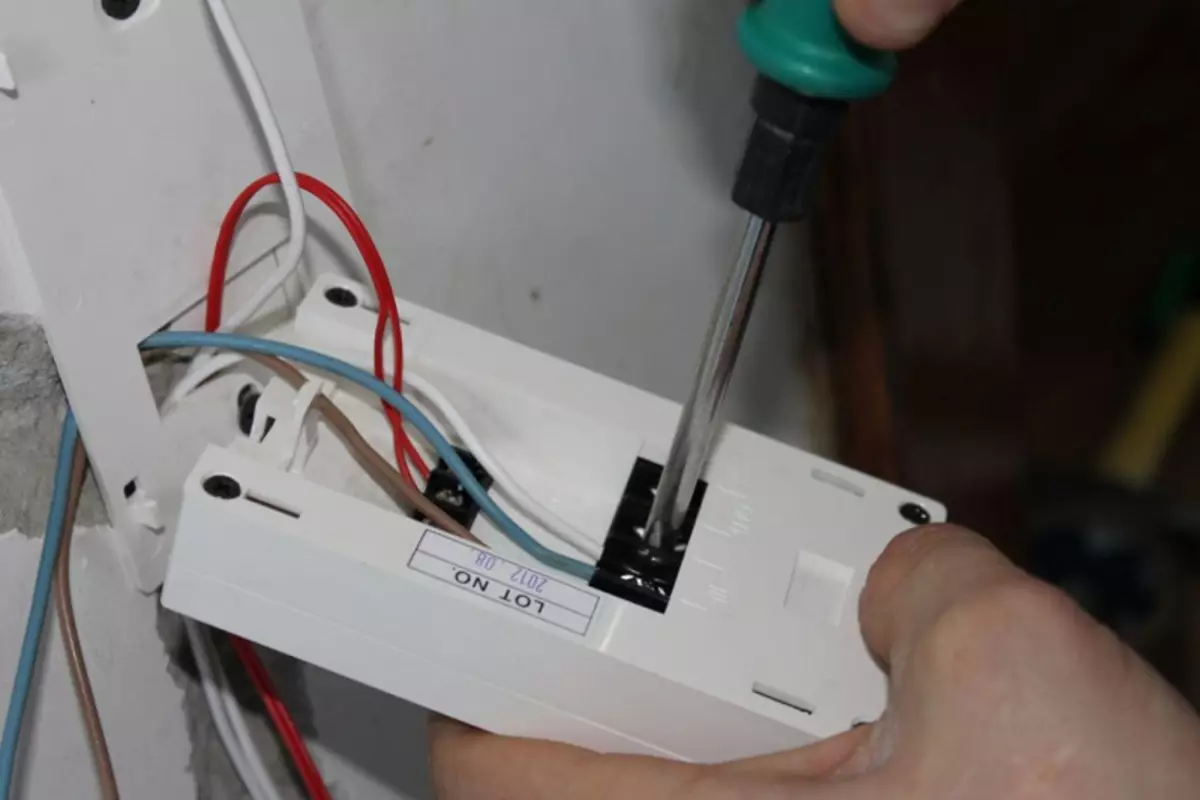

The first is that copper clamps need to be attached at the ends of the tires.

In this case, it is necessary to ensure that one edge is located between the film and the tire, and the second - above the copper surface.

Press the contacts are uniformly and without distortion.

After installing and connecting the floor, you can hide the wires under the canvas

The second stage in the question, how to connect the infrared warm floor, is to install on the wire clamp, its insulation and a dense crimping. In this case, you need to follow the rules of the parallel connection of the wire, and in order not to confuse - it is recommended to use a cable with cables indicated by different colors. After performing all the work, the wire can be hidden under the canvas. To do this, it is desirable to cut a niche in the insulation, the desired size.

Closer to the center of the second section under the film, a sensor adjusting the heating temperature is set. Under it, you can cut a similar hole in the insulation.

Last, the final stage involves connecting the system to the thermostat. Thus, you should get 3 wires:

- Power supply from the power grid.

- The cable with which the infrared warm floor is connected.

- The wire running on the temperature sensor.

The scheme required for the correct connection of contacts must be in the instructions.

Testing

When testing should not be noise and cod

Test the system before laying the finish coating is necessary.

This will allow you to reveal the flaws made during the assembly.

The qualitative execution of work will be confirmed by the following signs:

- No extraneous noise and cod.

- Lack of sparks or other signs of closure of the power grid.

- Uniform heating of the surface.

In addition, it is recommended to make sure that the insulation of contacts in the connecting places are insulated. Only after that the finish flooring can be mounted.

Safety technique

When working with electricity, solzate safety equipment

It should be understood that the wrong laying of infrared warm sex can lead to the rapid way out of the canvas or a short circuit.

Separately, it is worth adding that work with electrical appliances or devices is always less dangerous for life and requires compliance with certain safety regulations:

- Before connecting the electricity line, make sure that the supply of electricity in this chain is terminated and will not resume prematurely;

- Outing the strips to each other can lead to a short circuit and cause a ignition;

- From the edge of the film to the wall should be at least 10 cm. Windows installation is impossible;

- The thermostat must be installed at a height of 10 - 15 cm from the floor surface;

- For warm floors of a roll type, it is not recommended to roll up the web for more than 8 m;

- The cable connecting the film with the thermostat should not intersect;

- Stop material is needed without forming folds and fades;

- The installation of film warm floor is possible only at a positive indoor air temperature;

- Fixation of film is carried out with the help of bilateral scotch. Use sharp objects for this is not allowed.

Electricity consumption in comparison with efficiency

As a result, it is possible to confirm that the use of IR-floor allows you to create an optimal conditions for human life in the premises. In addition, it should be reminding about decreasing payment for heating at home. As an example confirming this fact, you can cite a table in which all the values required for high-quality heating and maintain good conditions in the house with an area of more than 150 m2 are calculated. Read more about saving electricity with IR floors, see this video:

The use of infrared forple sex is beneficial from all points of view. First, it is not only the process of heating, but also a medical course, but, secondly, there is no electromagnetic radiation. Probably, therefore, despite the relatively high cost, IR warm floors are gaining increasing popularity in our country.

Article on the topic: What wallpaper to choose for beige cuisine, examples of interiors