Facing brick for fireplace

Introduction

The beauty of the fireplace primarily depends on the quality of the brick, and only in the second, from the quality of masonry. Although, of course, both is very important. The term "facing" if the fireplace is made of facing bricks, not quite faithful. After all, they are not faced, and the fireplace is built from it. But, due to the fact that it is not refractory, but stacked on top of this, this term has taken root. Fireproof stoves in the furnace furnace, and in the fireplace as an arch over the hearth.

Brick-lined fireplace

Facing brick is stacked on top of refractory and should be bright, very smooth and, of course, should keep warm long. Construction of the fireplace Although different from the construction of furnaces, but not very radically. Conventional ovens are built from a special chimney brick, and the decoration is usually produced by tiles. This is at best, usually improving the outer surface of the furnaces occurs by plastering and subsequent whitewash. Processes (plastering and finishing of furnaces) will highly differ with the facing brick. Here you need a narrow profile specialist.

Brick Fireplace Laycast

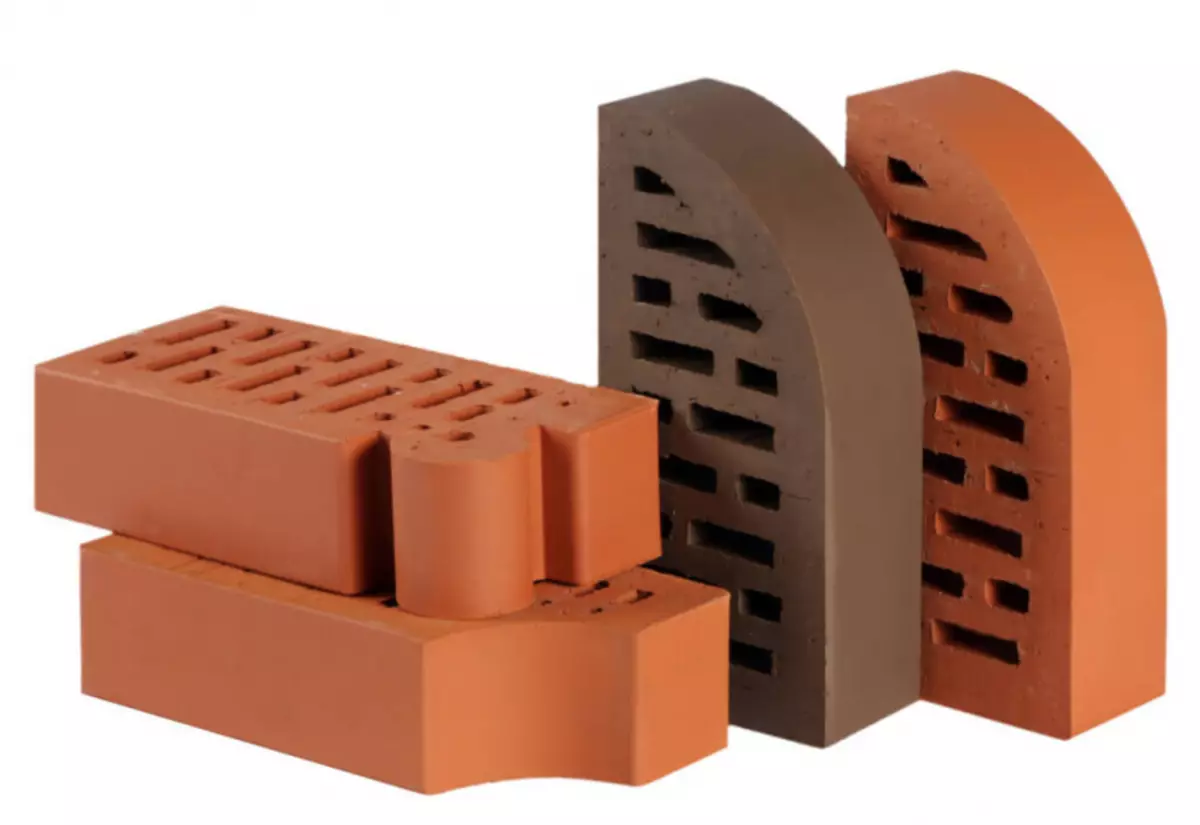

Fireplace, in modern housing, unfortunately, does not fulfill its main role - heating, as in its time the oven. It is rather an aesthetic component of the interior, and only occasionally is used for direct intended. Yes, it is impossible to cook food, as in a Russian oven, but it is not intended for this. But this value of the quality of the facing is only increasing. Brick, which is used for these purposes, in principle may not only be purely facing, but also in any other (antique, figured, full or hollow, manual molding, semi-dry or plastic pressing).

Article on the topic: How to pull the wire?

Fireplace from various bricks

It all depends only on the desire of the owner. It is only necessary to remember that some brands do not withstand high temperatures and can crack. For this reason, a high-class specialist should be made. He knows exactly what brand bricks can be applied, and in what no. As a rule, special facing bricks are used for these purposes, which are used for facing furnaces, the so-called "chims". Here are some of his brands:

- Victory LSR (fireplace brick)

- Brick chimney Vitebsky

- Latvian fireplace Lode (Loda)

- Full-time furnace terca (grater) production concern WIENERBERGER

- Belgian Terca manual molding.

Latvian fireplace brick Lode

Modern technologies allow you to produce a brick of almost any color and any form. How it is done, consider below.

Production of facing bricks for the fireplace and its marking

The production of facing bricks for fireplaces and furnaces has significant differences from the manufacture of ordinary construction. Qualitatively performed surfaces of spoonful and tonch faces, here is a distinctive feature. They are not only smooth, but also textured or even specifically aged. Many species have chamfer on the edges, thanks to which a neat batch of seams is possible. Facing never has cracks, lime inclusions, openings.

Its color is smooth over the entire surface. The dimensions are more accurate than the usual, construction or used furnaces. According to the GOST, the deviation from the standard size should not exceed 4 millimeters in length and 3x in width. Distribution in thickness in plus 3 and in minus 2 mm. As for straightness, the deviation of no more than 2 mm. The color scheme, as already mentioned earlier, can have a variety of shades: from natural light yellow, to dark blue and even black.

Factory brick

Production of facing bricks (both for furnaces and fireplaces), as well as any other production is improved over time. So, in recent years, this production began to acquire other forms. Instead of the formation of clay ribbons, and cutting on bricks, and then firing has become popular dry production, and even from construction waste. With the old way, the moistened mass of sand and clay is burned in the furnace. But the time of the furnaces permanently passes. So, for the dry way only the press is needed. All the necessary components are crushed in the crusher, mix and pressed. This method is called superpressing. Moreover, in order to form bricks there is no need to press each of them or even a batch. Everything happens in a continuous cycle by filing the source products into the bunker connected to the screw press. The press creates the necessary pressure and temperature that are needed to sintering components. At the exit of the mass of their press there is a cutting of the masses (if it can be called mass) into pieces of the desired size. And then, ready-made bricks are cooled in air and acquire the declared vanity.

Article on the topic: how to hang the ceiling eaves do it yourself

Pressing brick production

In the production of such a cladding material, metal waste, slag from the furnace and much more, what was previously considered garbage and was thrown into a landfill. In this case, this is not reflected in the quality of facing bricks. The consumer is usually absolutely not interested, from what material it is all manufactured. Especially if the brick is painted, and the surface is embossed. Of course, such a product can not have natural color and synthetic dyes are used for staining. But the price is so much lower than ceramic. The price of a brick for the construction of a furnace (oven) is about three times lower than refractory (chamotte). Facing, produced by old technology (with a firing in the furnace), is about twice as expensive. And on the new technology (without firing in the furnace) for sale at the price of chamotte. In order for the market to be a choice. And the choice is only for the consumer.

Types of facing bricks

| Classification: | |

| In form: |

|

| By availability of emptiness: |

|

| In size (sizes in mm): |

|

| By color: |

|

| By type of facial surface: |

|

| Form of the product: |

|

Brick fireplace option

Marking

Facing brick has labeling, for example: DIN 105 - VHLZ B 28 - 2.0 - 2 DF. Which means: Multiplass with void in class, with a density class 2, compressive strength class 28, in 2 DF format, which means size 240 * 113 * 14mm.But it is so marked only by a foreign-made brick. Domestic marked as follows. Marking of facing brick 1- NF F50 M25. Where 1 is NF means size F50 means frost resistance on a scale from 35 to 100. M25- means mechanical strength. The greater the number, the stronger the brick.

Article on the topic: Beautiful holders for curtains do it yourself

Conclusion

What material for the construction of fireplaces to choose only the buyer can solve. To suggest or impose your opinion not in our competence. Only one advice, if you allow. Do not make a decision spontaneously, consult with experts. And preferably not with one, but with several. Then your choice will definitely be true. Successes to you in construction.