The floor arranged in all the rules is a complex design that includes a draft base that levels the screed, the finish coating. A special role is played by the alignment of the floor with a screed, which can be made with a wet or dry way. The latter became increasingly used in the construction and repair of buildings. Dry technology of floor arrangement is different in the installation of flooring of GWL. Having under hand all the necessary materials and tools, make the floor from GWL will not be much difficulty even a master-newcomer.

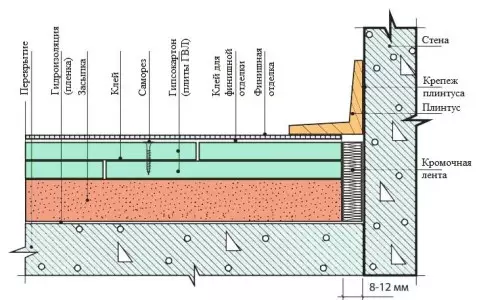

Mounting scheme of GVL slabs per floor.

General Paul Scheme Floor from GWL

Gypsumless sheets (GWL) are modern building material, which consists of flourishing cellulose and reinforced gypsum, has a high density and homogeneous structure.

Even such a demanded finishing material, as plasterboard, loses to him in many major indicators.

The general scheme of the device of the floor from GVL is as follows:

Floor diagram using drywall.

- surface preparation;

- waterproofing floor;

- leveling frustration;

- Floating GVL;

- Finish coating.

The essence of the dry method of the floor device lies in the alignment of the floor by any small phrase material, for example, with a clay, to which two layers of GVL are installed. After that, on top of the sheets, the finishing floor finish is performed on the perfectly smooth prepared surface.

In order for such a floor to serve for a long time, some conditions must be followed:

- The flowing surface must be brought to the perfectly level state;

- Use only solid finish coating: laminate, parquet, porcelain stoneware, etc.

To understand well in all the intricacies of the floor of the floor from GWL, it is necessary to stop at each of the work stages in more detail.

Preparation of the floor surface, materials and tools

So that the basic works were performed qualitatively, it is necessary to spend thorough preparation. It includes:

Article on the topic: How to choose a suitable laminate to doors?

Dry screed circuit with GVL application.

- surface preparation;

- Proper selection of materials and tools.

First, it is disassembled by the old flooring and cleaning of the construction trash. After that, the floor is inspected for various cracks, chosel, cracks and other damage. To eliminate them, depending on the size, clamzite of the shallow fraction, crushed stone or brick battle can be used. It is necessary to remove the damage to the specified damage in order to subsequently in these places, under the mass of the mounds, waterproofing would not be destroyed.

To arrange a floor from GWL, it is necessary to prepare the required materials and tools:

- Ceramizite shallow fraction;

- crushed stone;

- brick fight;

- polyethylene film (for concrete);

- Construction Scotch;

- Parchment (for boards);

- edge ribbon;

- building level;

- measuring instruments;

- marker;

- lighthouses;

- cord;

- rule;

- Hypanoloconse sheets;

- screwdriver;

- self-tapping screw;

- PVA glue;

- toothed spatula.

After the preparation, you can proceed to the fulfillment of basic work.

Waterproofing and floating flooring

Floor screed styling technology.

The next obligatory stage of work is the floorproofing of the floor. It should be done in order to preserve the GWL and the finishing coating from the destructive moisture. If the base of the floor is made of concrete, a polyethylene film is well suited as a waterproofer, and if the base from the boards can be used pergamine. The entire waterproofing material is stacked with a special care, with overlap bands at 10 (cm) and with a bend it on the wall. For fixing the material strips, construction tape can be used. To improve sound insulation around the perimeter of the room, the edge ribbon is sized.

With the help of measuring instruments, cord, marker and construction level on the walls make restrictive marks to which you need to navigate during the backfill. The thickness of the leveling swelling will depend on the irregularities of the draft floor and can be up to 6 (cm). Prepared bulk material, for example, clamzite, poured on the floor and rallied on the walls on the walls. Instead of clay, and fine-grained slag, and quartz sand, and explorer production, etc. can be used. All specified materials have good flowability, high porosity, low hygroscopicity. IMPORTANT Material for filling the floor before use is good to dry, so that in the future it does not happen the unwanted deformation of the floor.

Article on the topic: Installation of fasteners for blinds to the ceiling and wall

Flooring shests of gypsum fuel to the floor

For flooring to the floor, you need to use two layers of sheets of gypsum fiber. Also produced special GVL glued together with a small displacement. To cover the floor, it is best to use small-sized plans of the gypsummer having dimensions of 120 x 60 (cm).

The laying of the first layer of GVL on the dry tie begins strictly from the door, otherwise the leveling belling will be broken. During work, it is impossible to walk on the screed. It is important to achieve flatness of laying so that the sheet will not plunge into the backfill.

The second layer of sheets is stacked with the displacement of the joints by about 20 (cm) according to the brickwork method. The sheets of the first and second layer are glued together with PVA glue, applied to their surface with a toothed spatula. As a result of the displaced location of the sheets, there is a place to fasten them between themselves with the help of a screwdriver and self-tapping screws. It should be noted that the self-screws are screwed in 15 (cm) throughout the perimeter of each sheet. Their hats must be dried into the surface of the material.

After laying sheets of gypsum and their reliable bonding, you can start installing the finishing coating.

Thus, the GWL floor is a perfectly smooth surface obtained by fast, clean and convenient way, with whom even a newcomer can cope with their own hands.