When sawing the forest, it is important to immediately calculate what consumption will be, as it will have an impact on the cost of sawn timber. The output of finished products may be different. It all depends on how quality the forest is used whether measures to optimize cutting are applied. There are special measures to increase the efficiency of work, make the output better, and the quality of sawing is higher. Before sawing, it is necessary to calculate everything. It is not as difficult as it may seem, but the flow rate of the round forest will be optimal, profitable for obtaining an excellent result.

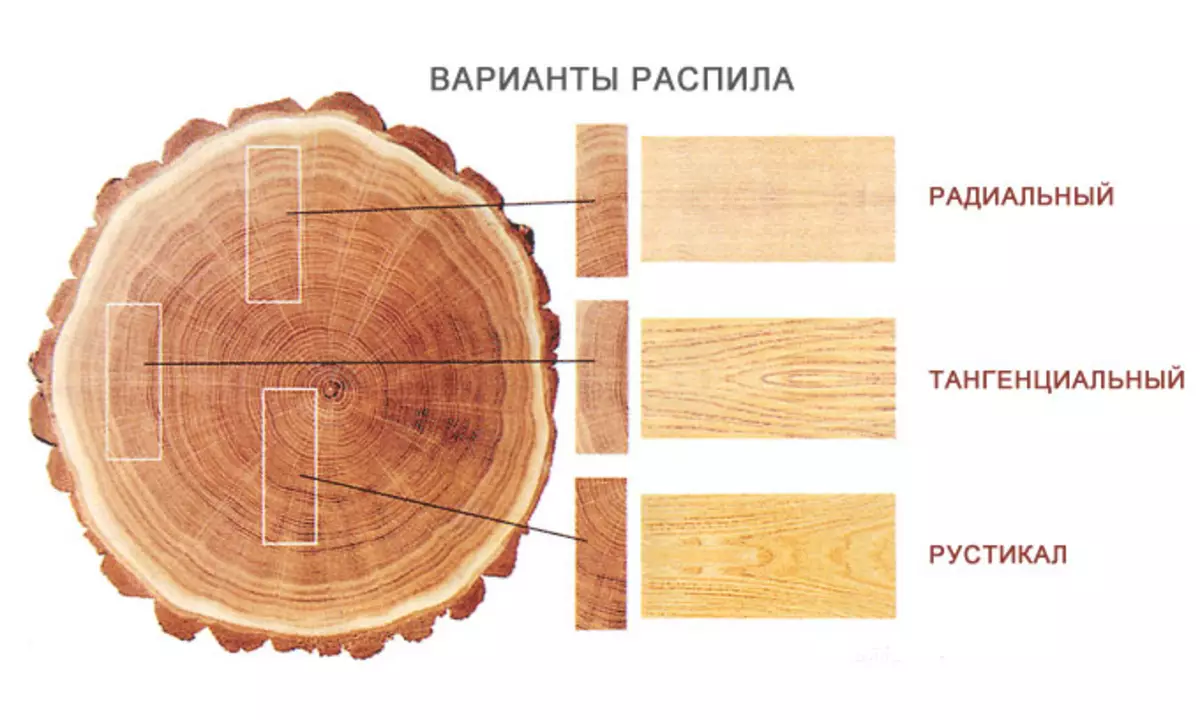

Options for cutting round wood.

How to increase the efficiency of cutting

In order for the lumber output to be significant, it is necessary to use special measures to increase the efficiency of the process:- The calculation should be carried out only when using special programs, manually it will have a low performance, the percentage of marriage will be large.

- Pre-rounding must be sorted so that the processing is carried out correctly.

- For cutting it is necessary to apply high quality equipment. Otherwise, the amount of waste will be large, and the quality of the resulting lumber will become low.

- It is best to first cut a wide sawn timber, the treatment of narrow leaves more time.

- The logs are not recommended to take long.

- Before work, configure the equipment.

The output of finished lumber may be different. It must be remembered that at the first stage the boards are obtained, then they are sorted. As a result, the percentage decreases even more, for example, for deciduous breeds, it can be only 10-20%.

How to optimize the cutting

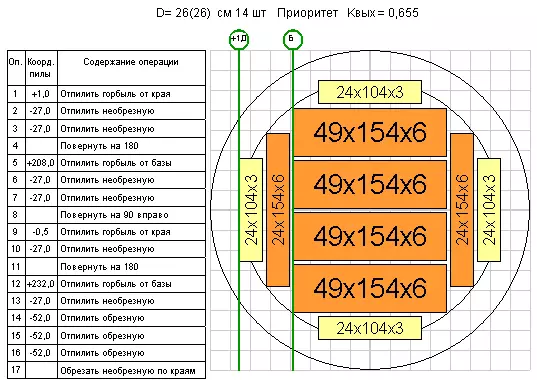

Sequence and sizes of cutting round forest.

To make the output of sawn goods above, the cutting process must be optimized. This applies primarily to those billets that are significant curvature. To cut a round forest curve, you need to perform a number of actions:

- First, only a suitable forest is selected for work. If there are rotes, seedlings, cracks on the ends on the remaining logs, then it is necessary to reflect some sites.

- If a rotten core is detected during operation, then it can be carefully removed, after which it is possible to cut the remaining part. This will avoid large losses, get boards with a length of 1 m with the necessary quality.

- It is recommended to use logs with a large diameter so that the output percentage is higher. The coefficient can be 1.48-2.1, but it all depends on the diameter, the quality of the roundabout, sorting, equipment. For framework workshops, such a coefficient will be 1.48-1.6, and for lines with milling equipment - 1.6 for a large forest. With a diameter of the rounder from 12 cm, the coefficient may exceed the mark of 2.1.

Article on the topic: Bookcase with your own hands: Choosing materials, blank parts, installation

Waste volume after sawing

To make the finished board with a great percentage, it is necessary to prepare everything correctly, work should be carried out only in accordance with technology. Round wood coniferous and hardwood gives a different way out. In the latter case, the volume is less, even if used special accessories. The cutting of sawing is considered more convenient, since she has a straight line, and the log has a larger diameter. The coniferous forest is not as susceptible to rotten, so marriage is less. For deciduous breeds, 2 technologies are usually used:

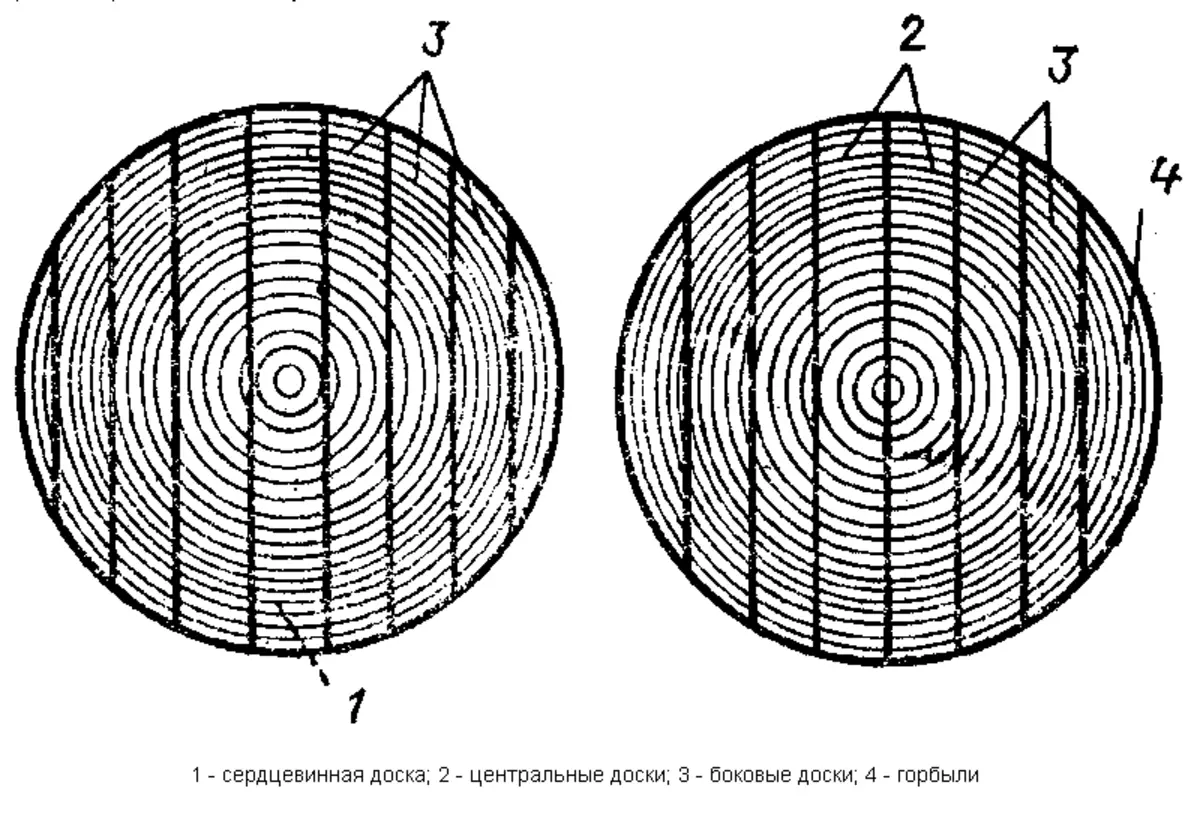

Varieties of sawn timber from round forest.

- with the help of the belt panel on the Z75, Z63;

- In the collapse, when a semicircular is cut into the core of the material, passed through a multi-step machine.

The volume in the belt sawmill is 40-50%. When using the technology into the collapse, the output is different, it can be increased to 70%, but the costs of such work are higher. If a round forest is to be cut, the length of which is 3 m, then you can see that the percentage of marriage is quite large, and the remaining material requires processing. This concerns the bulk of the bulk of 22x105 (110, 115) x3000 mm. There are a lot of such marriage options. For example, it can be wormworm, which is no longer suitable for most works.

After sorting the volume of hardwood material, which refers to a variety of 0-2 will be only 20-30% of the amount that is obtained after sawing. This means that from the total mass of the harvested round forest, the output of a normal board will be only 10-20%. The remaining materials mainly go on firewood. The coniferous rounding the output will be different, but attention should be paid to which the average values of the resulting volume are observed.

Lumber output

To access the lumber is optimal, it is necessary to take into account numerous conditions. For correctly calculations, you can consider an example of the release of round wood. The data was obtained on the real experience of specialists and in the indicators of the pilots. This makes it possible to compare the percentage ratio, calculate the optimal averages.

Article on the topic: how to hide beams on the ceiling

Softwood has the following way out:

Chalk title in a sawn log.

- For unedged boards and other umbered materials during sawing, the yield will be 70%. This is the number of material obtained during processing, the amount of waste will be 30%.

- For edged material when using pylomas at 63, 65, 75, there will be a smaller output of sawn timber, in total in the area of 45%. In belts, the output is usually up to 55-60% of the finished material. If you use the effectiveness to improve efficiency, then 70% can be achieved, although it requires extensive experience.

- From the disk sawmill, it is possible to obtain a sawn timber in an amount of 70-75%, although it may be 80-75% when using efficiency methods. But you need experience.

According to GOST 8486-86, for a grade of 0-3 percentage of output, without taking into account the sorting, is approximately 70%.

Another 30% can be left to the rejection of the finished material. The material being discarded is not discarded, it is used to make other types of sawn timber, which allow for a certain marriage.

At the round forest of hardwood, another percentage of exit is observed:

- Unedged material - 60%.

- At the edged - up to 35-40%, since the curvature of the source forest of hardwood is usually large.

The output can be enhanced, for this applies additional equipment. It can be a special multi-step machine, an edge cutting machine, a subgrile machine. In this case, it turns out the output of the lumber to increase by about 20%. The percentage given is based on the data on obtaining a grade board of 0-4. When sorting varieties 0-1, the percentage of sawn timber is 10%. To obtain a cube of the finished edging material from hardwood, it is necessary to break 10 cubes of the original round forest.

The output of sawn timber from the round forest may be different. It all depends on the starting breed of wood used by the sawmills. Special measures to increase efficiency allow you to get a greater percentage than it is possible, but for this you should have some work experience.

Article on the topic: Topic gardens: Amazing sculptures from living shrubs and plants (45 photos)