Circular saw saw blade consists of steel sheet (disk body) and plate with carbide attacks in the form of incisors, the form of which can be different. To correctly sharpen the disk, you need to know the geometry of the tooth and the basic rules of sharpening.

For proper disc sharpening, you need to know the geometry of the tooth, as well as the basic setting rules.

Teeth geometry of saws

The disk saws are made of durable steel grades, on the body of which carbide plates are mounted using high-temperature spikes. Alloys for the manufacture of these attacks may be different. Domestic manufacturers are used mainly toolfram alloys with cobalt. Foreign manufacturers use their technological formulations. The characteristics of one or another composition will depend not only on its chemical characteristics, but also on the size of the grain of the carbide phase. A small graininess will provide the greatest parameters of hardness and strength that material will be posted.

Disk saw blade can have different geometric shapes. Among them are distinguished by several basic forms:

Different discs for different materials.

- Tooth straight shape.

- Oblique shape of the tooth.

- Trapezoid shape of the tooth.

- Tooth conical shape.

Saws that have a tooth straight shape are used to perform rapid longitudinal sawmills. At the same time, the quality of such cut will be low enough.

The tooth oblique form can have the right or left angle of inclination. Very often, disk saws can be made with alternately beveled tooth, i.e. When the teeth with the left and right angle will be repeated in turn. Such saws are used for sawing chipboard in the longitudinal and transverse direction. A similar constructive form will help to avoid the appearance of various chips on the surface of the material being processed. Poured, the tooth of which is made in the form of a trapezium, can be used to dry the MDF material. The peculiarity of such saws lies in the small wear of the tooth material and in a sufficiently low cutting speed. Very often, the teeth in the form of a trapezoid alternate with straight, which are used for cleaner cut.

Article: Septik Yunulos Astra: Characteristics, and negative reviews

Saws having a teeth of conical shape are used for auxiliary work when trimming the upper or lower laminated layer. Such a saw will protect against the appearance of chips and retain the surface of the material being processed.

Sharpening rules

The tooth oblique form can have the right or left angle of inclination.

To understand how to sharpen the disk correctly, you need to know that the main wear of his tooth falls on the upper cutting edge. This edge during work is subjected to rounding. The size of the rounded layer can reach up to 0.2-0.3 mm. The front face of the surface is rapidly wearing.

To perform such works, you will need the following equipment:

- Sharpening machine.

- Pendulum courier.

The process of performing a sawing saw having a straight tooth must be performed on a plane located in front. To do this, it must be installed in the mandrel in a horizontal position.

Then, using the adjusting screws located on a sharpening machine, you must set the desired angle under which the sharpening will be carried out. The saw blade should move in such a way that the most dense adjacent to the surface of the abrasive circle is provided.

The thickness of the layer removed from the material will be adjusted by the force of the clamp. After the first tooth is sharpened, the disk must be allocated from the sharpening circle. After that, it must be rearranged one step and continue the process. So consistently need to sharpen all carbide plates.

Circular saw sharpening.

The sharpening of the beveling surface of the carbide attack can be performed both by the front of its plane and back. The difference from sharpening the attack disk having a straight surface will be that such a saw disk must be placed at an angle that will correspond to the angle of inclination of the tooth.

To determine the necessary angle of installation, you must use the pendulum tilter. Initially, it is necessary to set an angle with a positive value (+8, +10, etc.). Sharpening needs to be performed through the tooth, thus the first half of the disk plate is processed. After performing this work, the desired angle of inclination is changed to negative and produce the processing of the second half of the teeth.

Article on the topic: How to build a house from sip-panels do it yourself

The rear plane of the attack sharpen a little more difficult. To do this, a machine is needed, the design of which will allow you to install a circular saw so that the rear plane of the saws of the saws was parallel to the plane of the sharpening circle.

Work without machine and quality of work performed

You can roll the circular saw not only with the help of a special machine, but also with utilization. In this way, you can use when there is no money and the desire to acquire a sharpening machine. Most of the people use a similar hand tool infrequently, so buying additional devices is not necessary.

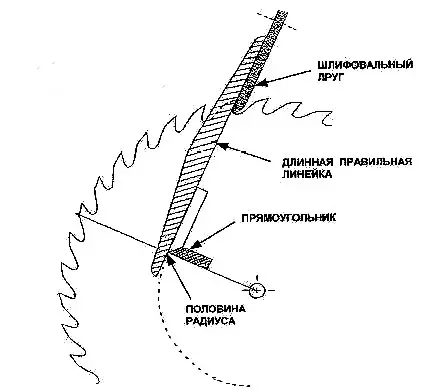

In the event that there is a regular emery machine, you can perform all the required procedures using it. For convenience, you need to make a device that allows you to fix the saw in the desired position relative to the abrasive element. For this, the usual metal stand is suitable, the surface of which will be located at the same level with the axis of the abrasive circle.

On this stand, you need to put the circular saw disc in such a way that it lay in the required plane relative to the surface. It can be performed using bolts that simultaneously help to adjust the angle of inclination.

Make sure the absence on the surface of the saws and various cracks on the surface of the saws and various cracks will help. Radius of the rounding of all cutting edges must be in the following borders: 0.012-0.015 mm. When conducting a visual inspection on their surfaces, there should be no glare.

Observing the rules for performing work, you can confidently use a circular saw without frequent replacement of saw disks. And the cutting part of them will perform high-quality cutting of the necessary products and materials, not spoiling their surface.