White with a glossy surface plastic slopes are made of material that covers the metal profile of the frame. With the correct installation, they look a continuation of the window. The room becomes lighter and spacious. The apartment is comfortable. Luxuriously look at natural wood. But less light passes, require constant care. Installing wood panels technically complicated. The plaster is a budget option, but is short-lived and poorly clean, loses shine.

Plastic slopes on the windows

Plastic polyvinyl chloride and its use

PVC - polyvinyl chloride, plastic does not release harmful substances. Its main ethylene derivatives and the chlorine binding substance are produced by their oil and salt. To give the material necessary qualities, more than 10 components are added to the mixture. Unlike plastic bottles, polyvinyl chloride during combustion does not secrete poisoning substances. The ceiling and cutting panels are recycled, it is easy to make new things.

In a modern apartment from PVC plastic, Made:

- ceilings;

- window;

- doors;

- Sucks;

- linoleum;

- laminate coating;

- Sucks;

- Insulation on wiring.

In a private house, you can find a hose for watering, a carcass of the greenhouse, the siding facade. The slopes from the plastic can be easily cut with shallow hacksaw, mounted on the windows. Finishing from plastic panels is available to everyone who wants to do it yourself.

Window slopes from PVC

Appointment and features of window slopes

The slopes on the windows are closed with cracks and gaps between the wall and the frame. The decoration by plastic panels is accompanied by the insulation of the walls. By installing plastic slopes with your own hands, it is necessary to carefully close all the pores and emptiness. Plastic protects the surface from the destruction, it is easy to clean. His smooth surface repels dust. If you want to see your windows always shining cleanliness, you need to make slopes from white plastic panels.

The angle of dawn is easier to establish a practical way. The optimal is equal to the ratio of 1:10. The wider wall, the less angle. And the window already, the more you need to deploy window openings. Then it turns out to make insulation simultaneously, protect the surface from destruction, and give the interior a beautiful view.

Very large windows can be visually reduced, mount colored plastic panels at right angles. In this case, the platbands need to do narrow or install the F-profile and stick on top of the wallpaper.

Article on the topic: Types, ways to decorate windows

The slopes on the windows are closed cracks and slots between the wall and the frame

Installation of slopes and illumination of the room

On the windows, the finishing uses often unpainted plastic. It is white with a glossy surface, so reflects partially light. With a properly made angle of dawn - the sole side and top panel due to the expansion of the window opening to the inner side, the space becomes lighter and the space is visually increasing.

The slopes from plastic correspond to the material of the coating of the metal base frame. This finish is harmoniously merged with the window and seems to be continued.

And the windows when finishing use often unpainted plastic

You can make a coating by other materials:

- plaster;

- wood;

- laminate;

- Styrofoam;

- parquet;

- Sheet coated aluminum.

Another color and texture will visually reduce the size of the window. In this case, the room will become smaller and darker.

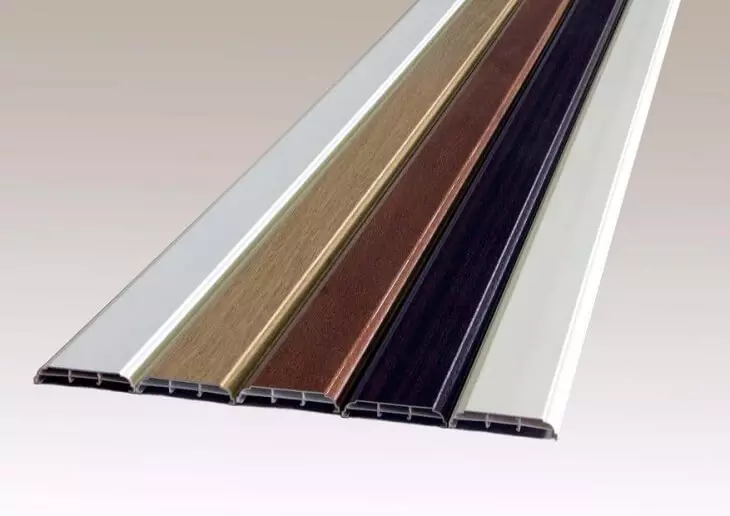

Component profiles for plastic panels

The installation of plastic slopes is made using profiles in which plastic wall or sandwich panel are inserted. Before making the purchase of materials, it is necessary to make measurements and decide on the design and type of finishing.

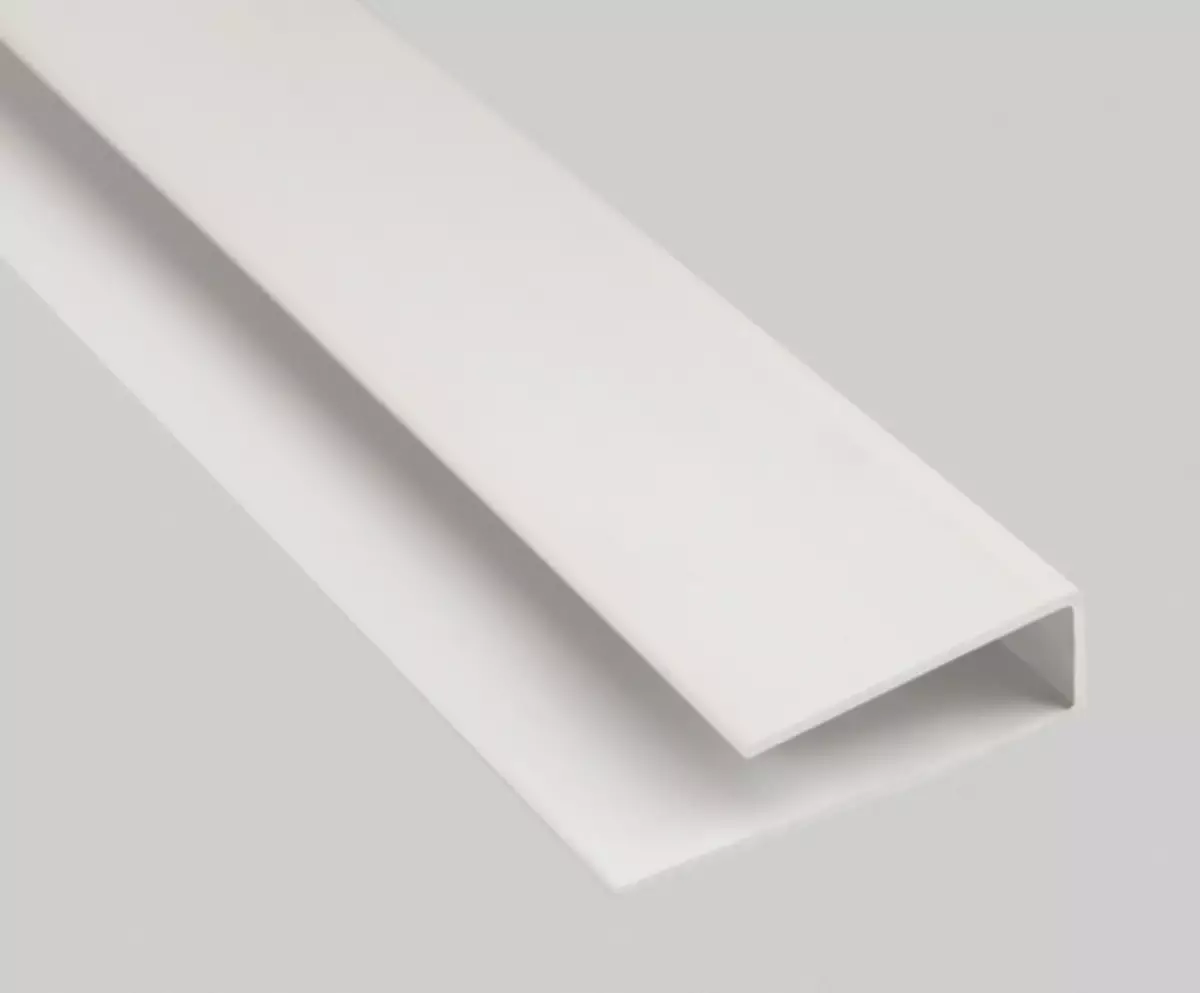

The starting P-shaped profile is attached by self-drawing in the corners directly near the window frame. The width of his groove is selected with the calculation so that the panels come tightly. Calculate profile consumption is necessary, taking into account waste to cut the corners.

You can make a narrow platband using a F-profile. It is installed on the outer edge of the panels after soaring glue and foam.

Plastic slopes are installed and using the starting J-profile. Its installation should be done along the outer edge. It is used in the case when there is no complete platband or perimeter finishing of the opening is carried out by decorative PVC straps.

PVC starting profile - P-shaped

To calculate the materials, I propose a table:

| Profiles | Length calculation parameters |

| P-profile starter | Width + 2 heights of the window frame + 3% |

| J-profile starter | The width + 2 of the height of the discovery on the inner edge of the opening + 3% |

| F-profile | The width + 2 of the height of the discovery on the inner edge of the opening + 5% |

| Decorative cover | The width + 2 of the height of the discovery on the inner edge of the opening + 3 width of the lining + 3% |

| panel | If the break is already panel, the width + 2 of the height of the window frame + 5% |

| Wooden planks | The width + 2 of the height of the discovery on the inner edge of the opening + 3% |

Article on the topic: Electrical Convector ELECTROLUX

If the windows are small, then take more on the cut. To make beautiful windows, plastic is preferably not docked. It is manufactured in width: 250, 380 and 500 mm. Properly flush the width of the wall in the opening, taking into account its increase due to the angle of dawn.

Installation of plastic slopes is made using profiles in which plastic wall or sandwich panel are inserted.

What to pay attention to the installation of the windowsill

The installation of plastic slopes on the window begins with the mounting of the window sill. It can be from PVC or other material: marble, granite, limestone.

For long service it is necessary to make slopes and insulation:

- Well to fit the space under the frame before installing the cooler plate.

- The windowsill should be tight between the bottom of the window frame and supports on the wall under it by about 8 mm. The main load when washing windows falls on the stove near the window. It is necessary to make a substrate durable.

- To flow moisture from dew formed along the boundary of temperature difference - near the frame, it is necessary to make a slope. The windowsill bends 1-2 degrees towards the room.

- All gaps and voids are closed, filled with foam, sealant, put off.

If moisture in the left, even natural stone and plastic will begin to collapse. Especially wall materials. Therefore, close the slots are necessary, first outside. After installing the window, cut off the extra foam and cover it with putty and paint. It is necessary to do it the next day after mounting the window. At the same time, the installation of slopes is made.

After installing the window, cut the extra foam and coat it with putty and paint

External and internal slopes from foam

When the budget option is asked me, I try to disconnect from the foam. I use plates from extruded expanded polystyrene coating. Panels are simultaneously insulation. With proper insulation and installation, they do not absorb moisture. Rodents do not get to them.

Under the panels from the foam, you need to prepare a relatively flat plane of slopes. For this, the coherent plaster from the cement-sand base is suitable. It must be covered with primer in 2 - 3 layers. In addition to improving adhesion, the effect of cement on the panel material is neutralized.

The slopes from foam plane are pasted directly to the plane of the openings. Make installation is necessary under the level using special glue. The cracks close up with a sealant. The surface is sprinkled with the finish line, is ground and covered with paint.

A similar sequence of work and when creating external slopes and platbands on the windows.

Article on the topic: Bedroom for a girl: design and design ideas (41 photos)

Sleeps from foam

Wooden slopes: pros and cons

Wood warm and eco-friendly material. Its lack of hygroscopicity and reaction to ultraviolet rays. When working with wood, it must be processed with antipirens and antitags, isolate from fire.

Wooden slopes are suitable only under certain interiors. They are compatible with styles having a tree in wall decoration, preferably and ceilings. These are Country Folk Styles, Scandinavian and Russian, Country, Sea, Colonial. Wooden floor and at least wall panels must be present in the room. Otherwise, the slopes from the tree will look ridiculous.

Wooden slopes

Installation and fitting angles on boards are more complicated than on PVC panels. Requires a constant renewal of the lacquer coating. The impregnation of wax is better not to use, because from heat of radiators and summer sunny rays it will flow.

To preserve the illumination, use light wood species, make a large angle of dawn. It is desirable to cover wood in Scandinavian style - white varnish. Then the design of the room looks harmoniously. The windows are insulated. The light is reflected and freely penetrates the house.