Together with the abundance of building materials, the market is constantly updated with new elements that greatly simplify the performance of repair work and, together with this, give an improved look of housing, both inside and outside. We will talk about one such element today - it is corners for slopes. It helps to emphasize the slip line and give it a complete view. Since there are many plastic corners options, you need to figure out which items to use for one or another case.

Finishing of slopes

Varieties and features

Finishing plastic slopes

Plastic corners are an indispensable element of finishing and decor. Their installation does not require special efforts, and after the completion of the installation it is quite possible to hide the shortcomings of plaster. Decorative elements perfectly complement the design of the entire room, but this is not the most important feature that plastic corners perform.

Before you purchase an area for slopes, you need to know in what cases it should be used:

- For window slopes inside the house

- From the outside of the building, when it is necessary to protect the mounting foam and for a favorable appearance

- Doors slopes also need decorative corners

- For arched openness

- Can be used to protect the corner of the wall, after sticking wallpaper

- In order to fix the corners that appear with the help of drywall, and which are subsequently taking

- In the production of furniture

- To form seams when a ceramic tile is used

- Finishing of outdoor and internal seams during plastic sheaving

- Junction drapery when finishing buildings by siding

Decorative plastic corners

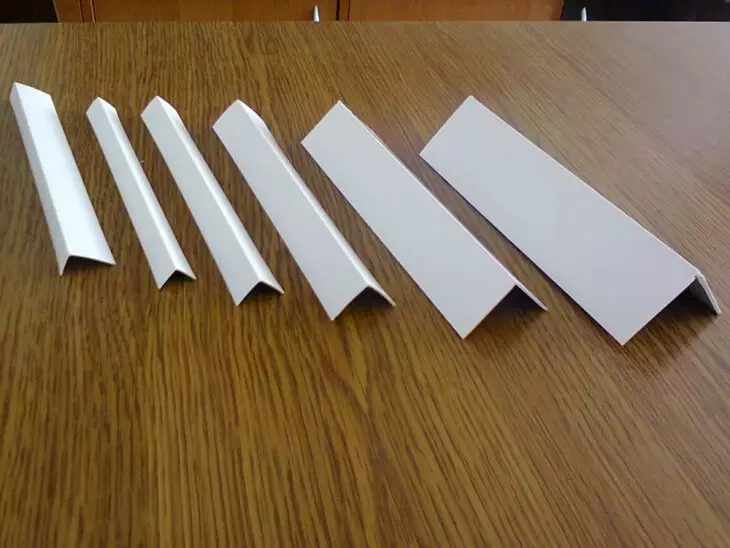

Thanks to this list, which, undoubtedly, it can be continued, it becomes clear that the plastic corner is widely in demand under construction and facing works. PVC sheet is used to produce the profile, which, after severe heating, gentle the floor with the right angle. Thanks to this method, PVC plank remains smooth and has no cracks. PVC corners of the L-shaped species are most often used in the installation work, they separate the angles of slopes on the windows and doors. The sizes of the corners will be prompted, where it is better to apply them.

Article on the topic: How to make noise insulation of walls in the apartment?

| Angle in degrees | Sizes of elements for external finish | Dimensions of elements for interior decoration |

| 90. | 20 * 20. | 10 * 10. |

| 90. | 25 * 25. | 15 * 15. |

| 90. | 30 * 30. | |

| 90. | 40 * 40. | |

| 90. | 50 * 50. |

Construction Corner PVC

Due to the harmful effect of atmospheric precipitation, they advise the profiles for exterior work, the dimensions of which begin with 20 mm. While indoors are less severely, it is possible to install smaller items. Plastic parts are suitable for plastic panels, window slopes and lining.

There is a huge number of advantages that will emphasize all the need to apply decorative glossy corners for slopes. Some of them are below:

- Little Weight does not take away slopes

- There are many forms and varieties of PVC corners

- Colored plastic strips can be combined with different decor

- It is convenient to cut - it is especially pleased when the installation is performed independently

- Installation is possible both with the help of self-tapping screws and glue or putty

- Lines become clear

- Such corners can serve before one hundred years

- Low cost allows you to use the items to all

Plastic corners for decoration of slopes

For the archer, it is used non-unambiguous plastic corners. Thanks to this cross section, they are pliable and easily attached. The cross section of one side makes the fold of the desired radius. PVC strips are used for external and internal works, for the first angle equal to 90 and 105 degrees.

Important! Recently, a self-adhesive corner for slopes has become popular. In addition, it disappears the need to buy glue, they are easily bent and extensible. An interesting feature is that the material is sold in rolls.

Corners and their significance in oxcask plasters

Plastic slope with decorative corner

During plastering work with slopes, the corners processing is of particular importance. The method of applying plaster is known to everyone, but the correct trim of corners and slopes - no. Using this element you can achieve wonderful results. For plastering, the corner serves as a beacon and can be plastic or metal. Such reinforcement does not give plaster to crumble and allows you to make the angle as soon as possible.

Article on the topic: Answers of specialists: Is it possible to glue wallpaper on the OSB plate

During operation with these elements, you need to adhere to some rules:

- Install the bar for plastering is needed for the entire length of the rib surface

- Corners are exhibited using a level or light rail rack - how to work with it I think everyone is familiar

- Such elements are not decorative, so necessarily hide under the layer of plaster

Replacing windows in the house This phenomenon is frequent and not new and everyone understands that the undemanded slopes do not bring harmony and beauty into a general view. It is to simplify the finishing process that produce elements perforated with the grid. They are comfortable in the work and the process of plastering with them, it becomes easy and rapid.

The correct installation of such a corner is that a small amount of solution should be applied on the edge edge. After that install a putty corner and press it into the solution and with the help of the level to check vertical. The extruded mixture is removed by the spatula, and the work after that stops for a while until the solution is grabbed. Then the plastering process occurs, and the corner must be fully hidden under the desired amount of the mixture. In the process of such installation, the angular plate allows you to remove the most even angles of slopes.

In addition to the corners of PVC, there are elements from cork, wood and bamboo. The latter are able to fit perfectly into the interior of any room and even make it even more attractive. In addition, they are also ecological. The only drawback is that they are much more expensive than others and need further staining. However, for someone the opportunity to make wooden corners with color and give them the desired shade is more advantage, not a disadvantage.

Of course, you can trust all the work by qualified specialists who will fulfill the task quickly and you do not have to delve into the installation technology, but in this case it will not be possible to save. If you are accustomed to yourself repair and finishing work in your home or apartment, then you will definitely have the necessary list of tools for trimming and installing plastic corners. Such are:

- Mounting glue - in the professional language it is customary to call liquid nails

- Painting ribbon - as a last resort, the usual tape is suitable

- Silicone sealant - apply indoors with high humidity

- Pencil and hacksaw - you can use scissors for metal

Article on the topic: Drainage of the site do it yourself on clay soils: from groundwater, how to make yourself

Glue plastic corner on slope

Before buying, you can consult with the seller in the store, it will tell you which item is better to purchase. However, with independent work, all measurements you produce yourself. Just in case, get the material with a reserve - to run once again to the store, I think it does not want to be in case of anything.

Important! In no case do not stick plastic elements on the wallpaper. If the material attaches not to the wall, namely to wallpaper, then it will not work out the desired strength. All irregularities should be removed, nails are elongated. In the future, the surface is subject to degreasing.

RESULTS

Dexted with plastic corners

Definitely the process of installing plastic corners requires certain skills, but with proper observance of the technology of gluing and surface preparation, it is possible to achieve excellent results. A variety of colors and sizes will allow you to choose the most appropriate option and give it a complete view with it. A corners with a special film that is cleaned after the installation is completed, protects the decorative element from mechanical damage during installation. Properly measure measurements and cut off the planks with the necessary tools in order to avoid microcracks.