For a huge number of years from the date of its creation, a power plant was able to reliably consolidate himself in the eyes of professional builders and architects, as a qualitative reliable building material. All this is due to the numerous unique properties of aerated concrete. That is why in our time so relevant laying of walls from aerated concrete blocks, allowing to create robust structures in a short period of time.

Advantages and disadvantages of walls from aerated concrete

I can say that the laying of walls from aerated concrete has a lot of advantages. Let's start with such a third wall cheaper than a brick wall. The fact is that a significantly lower price is installed on the gas chamber than on a brick or stone. Additional savings of consumable material provides weight and shape and dimensions of aerated concrete. The load on the foundation is reduced due to the fact that the walls will be very easy.

The fact is that the construction of the house is a rather long process, one of whose most important and expensive aspects is precisely the creation of a foundation. The easier the built design, the less effort will have to apply when creating a foundation, which is also positively affected by the financial costs.

Another important plus that each wall of the house is made of aerated concrete, this is the lack of the need for plastering, since the material initially has a smooth and smooth surface.

Among other things, aerated concrete has the high properties of thermal insulation due to the fact that on ninety percent consists of air, respectively, has an increased thermal insulation capacity. If the walls of the house are raised exactly from this material, one can safely refuse additional heat insulation, but at the same time it is not bad to save on heating.

Article on the topic: What is better to careen a brusade house?

This is also worth adding the fact that a gas-concrete is a whole and fully ecological and vapor-permeable material, which makes it as similar to the properties with a tree. Due to the unique structure, this material is able to "breathe", which makes it possible to prevent the accumulation of moisture, respectively, the processes of rotting and the development of mold.

Among the no less relevant positive properties of the fuel-concrete walls, it is necessary to allocate their resistance to ignitions. The fact is that the laying of walls from aerated concrete provides the maximum level of security in the house, since this material is not lit. It is also impossible not to mention the unique feature of sound insulation, which is relevant to residents of large cities trying to hide from the noise of the streets in their homes.

Despite such a huge number of positive sides, the use of aerated concrete still has several drawbacks, the main level of which is a low level of strength. This moment makes it impossible to build multi-storey buildings using aerated concrete.

Technology laying

I helped you find out the fact that the cellular concrete is a unique building material that in many properties is many times superior to us building materials - stone, concrete, brick and so on. Let's now deal with the features of construction using aerated concrete.Preparation of solution

The manufacture of aerated concrete blocks implies the possibility of having an error of up to two millimeters, which is being grown due to the adhesive solution. At the heart of the adhesive solution, the factory dry mixture, which includes cement, sand, plasticizers and water-retaining additives.

The masonry can be considered high-quality if the seam thickness does not exceed ten millimeters. When it comes to masonry on a cement-sandy solution, the average seam thickness is accepted for twelve millimeters.

It is necessary to engage in the preparation of the solution directly before construction using ready-made dryness, in a clear accordance with the instructions indicated on the package. To knead the glue, I recommend using a plastic bucket.

Article on the topic: FRONTON roof: species and options

Do not forget to constantly stir the mixture so that in the end it acquired a homogeneous consistency. If the construction occurs during the cold season, in accordance with the SNiP, a mixture with antiorrosal additives should be used.

The first layer of blocks

The finished adhesive solution must be distributed over the entire length of the wall using cells, making it aligning it with a toothed edge. The gas-concrete unit is installed on glue from above. At this point, you need to avoid any horizontal movements exceeding five millimeters.

The globe squeezed at the joints immediately remove the scraper, and then the blocks are rigged with a rubber hammer. I advise you to ensure that the seams are completely filled with glue, thanks to the correspondence to this rule, the madding will be durable and holistic.

Work on the construction of a wall of aerated concrete blocks can be simplified using various devices. For example, you can install wooden slats in the corners of the future buildings. With their help, it is possible to clearly designate the corners of the masonry, as well as the height of laying the following rows.

Special difficulty in the construction process can create end surfaces of blocks. It is worth accepting such recommendations for this case: if the walls are planned to plaster walls on both sides, then the vertical seams should not be filled with glue, as this will increase the uniformity of the masonry and its properties of thermal insulation. In the event that at least one of the sides of the wall will not be plastered, then glue should be filled with glue.

Reinforcement of masonry

The presence of masonry reinforcement, as well as the exact location of the reinforcement in the blocks, you must specify in the building project. If such information in the project is not contained, it is necessary to consider the version of the device of constructive reinforcement in the planes of the masonry. In this case, the wall can be supplemented by armoomas at the level of overlaps.

Consider the fact that reinforcement in household houses should be carried out around the perimeter of external and inland walls using an exceptionally top row of masonry. Extra reinforcement in the zone of the window sill.

If we consider this option in more detail, then in this case, the laying of the reinforcement is produced in advance prepared grooves in the masonry, where it must be completely recessed in the adhesive solution.

If you need to lay the fittings in the selected rows of masonry, be prepared for using horizontal strokes, which, upon completion of the process, it will be necessary to fill in with a masonry solution. The armature in this case is stacked in such a way that the wall does not lose its form, and the solution did not speak above the block surface.

Article on the topic: Green wallpapers for kitchen

Laying walls in two blocks

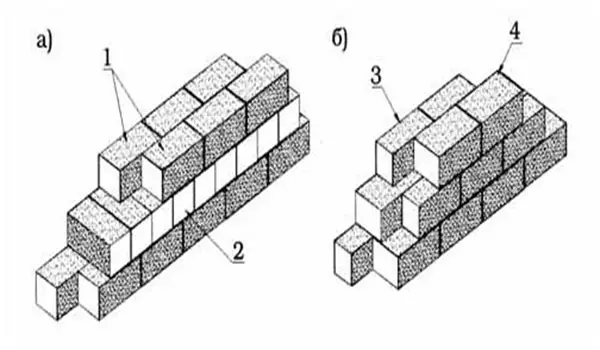

Wall Masonry Scheme and Two Blocks

Any fuel-concrete wall can be laid in two blocks. For this, the piercing bandage of vertical seams is used with a depth of at least ten centimeters. When it comes to conjugate walls that have different directions, the pairing can be created only with the help of inclined stages, the dressing depth for which is at least twenty centimeters. Note that the vertical stranges in this situation is invalid. This rule is applicable to both the outer and interior walls and partitions.

Video "Reinforcement of masonry from aerated concrete blocks"

Video with a description of one of the steps of laying walls from aerated concrete. How to lay reinforcing material, and why it is necessary.