The modern flooring of the roof has a life of up to 25-30 years - the current materials that have been preserved their properties for such a period of time. But this is subject to competent installation of each of the layers. Errors are not allowed, since it is not possible to correct their capabilities. We have to dismantle a piece of roof, if the errors are local or the whole, if they are global. Probably, for this reason, many household owners prefer to do the flooded roof independently, she made it, as a rule, it is worthless longer.

Building materials for the flooring

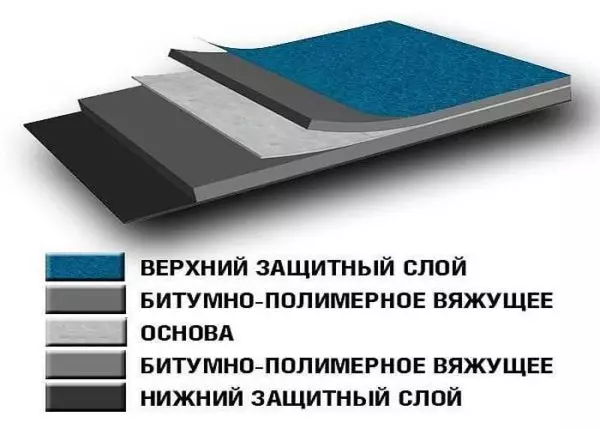

Materials for the flooring roof have a multilayer structure. A binding substance is applied on the basis of both sides, and the protective coating is imposed on it. All these layers have several options. Their combinations and give various properties and characteristics.

Building materials for the flooring

Types of foundations

A significant part of the material properties set the basis for which the binder is applied. If it can stretch, then the material for the flooring roof, too, to a certain extent can change its dimensions if it is deformed tolerates, then the material is torn. There are the following basics for the flooring of the roof:

- Roofing cardboard. A sufficiently strong and inexpensive foundation, popular due to its low price. Based on roofing cardboard make all rubberoid varieties. Therefore, when labeling in the first position, they put the letter "P", which means this material. This is a good choice for the device of the temporary roof - the service life of the rubberoid - up to 5 years. But the area of application of the runneroid is quite limited - it begins to burst and crumble at temperatures above + 40 ° C and less -20 ° C. And this is its main minus.

- Asbestos paper. This basis made hydroizeole. It is used mainly in the lining layer of roofing cake as a waterproofing layer. It has a low price, but also its service life - up to 5 years.

Designation of basic materials

- Glass. A solid foundation that is not easy to break. Materials based on fiberglass during roofs can break away from the surface, but rarely rush. Marked with the letter "C" (in the first position of the designation).

- Glassball. Non-woven material has an average strength, suitable for stable bases on which the movements are unlikely. The glass cholester in the marking is displayed by the letter "x".

- Polyester, durable and elastic fabric. Polyester-based materials can be stretched by 30% of their initial size without disrupting integrity. Denoted by the letter "E" in the first position in the designation.

The most durable materials are made on the basis of polyester. Manufacturers suggest that these materials retain their properties for 25-30 years. So many can be operated by the floral roof without repair, however, with the right installation. The lack of polyester-based materials based on polyester is a high price at the time of the device. But you can save on repair and replacement.

Types of binder

The binder also determines the set of properties of the material for the flooring of the roof, but it is no longer affected by the strength, but on the waterproofing properties and resistance to atmospheric influences. Also, this layer is responsible for the degree of clutch (adhesion) with the base or underlying layer. There are the following types of binders:

- Bituminous.

- Based on tar.

- Bituminous-Degteva.

- Rubber-bituminous.

- Rubber-polymer.

- Polymer.

Characteristics of the flooring materials for the roof wool over the type of binder

The best features of the rubber-bitumen and bitumen-polymer compositions. They have a wide range of temperatures in which they can be operated. When selecting materials for the flooring roof, you must pay attention to this parameter, because the part is well tolerates high temperatures (up to + 150 °), and some are low (up to -50 ° C). And it is impossible to confuse them.

Purpose

The flooring roof is usually multi-layered, and materials for different layers should have different characteristics. Those that at the bottom should provide waterproofing, noise absorption, whenever possible have thermal insulation properties. These materials are called lining and labeling, it is indicated by the letter "P" on the third position in the marking.The installed materials for the upper layer of the roof should additionally have high surface resistance to mechanical damage and weather effects. These materials are called "roofing" and in abbreviations are indicated by the letter "K" on the third position.

Protective layers

Since sticky knitting in the filtered materials, it is necessary to close something. Do it with the help of stone crumbs of various sizes or plastic film. Sometimes foil (pholoisol) is used as a protective layer. Such materials are used in countries with a hot climate. Need a foil to reduce the temperature - the lower layers are heated by 15-20 ° C less than when using conventional materials.

Stone crumb (Running) happens:

- Dusty (P) and fine-grained (m). Used to prevent sticking of layers in roll.

- Coarse-grained (K) or scaly-sali (h). It is used on roofing materials from the front side to protect against mechanical impacts and protection against weather influences. In addition to these tasks, decorative functions - the crumb is painted in different colors.

If the surface is sprinkled by a coarse-grained crumb - it is roofing (finishing) layer

Since the type of protective coating has a significant impact on the characteristics and scope of materials (fine-grained and dust-shaped on both sides are applied to lining materials), then their designation is also in the marking - this is the second letter.

It briefly all the characteristics you want to know when choosing a material that is selected. Before buying, be sure to read the description, study the scope and specifications.

The technology of laying a soft roof without flashing is described here.

Requirements for the base

The weaving rolled roof is most often done by reinforced concrete base, the joints between the plates should be embedded with the M150 and higher brand. Also, reason can be:

- Mineral wool rigid plates (strength limit of at least 0.06 MPa. If the roof is applied directly to them, the surface is treated with hot roofing mastic with a flow rate of at least 1.5 kg / m2.

- Heat insulation from monolithic light concrete with aggregates of type perlite, vermiculite. The screed from the cement-sandy solution of the brand is at least M150.

- Extruded polystyrene foam.

The base under the floors can be rigid mats of mineral wool or high density polystyrene

- The base of asphalt, compressive strength of at least 0.8 MPa.

- Colored screeds of flat asbo-cement and glass chairs, CSP (cement-chipboard). The minimum thickness of the plates is 8 mm, they are stacked in 2 layers with disintegration of seams. One seam from another spaced at least 50 cm. Fastening the layers among themselves - in the center and around the perimeter, the type of fastener is riveted, it is possible to use screws. When mounting on a self-tapping screw, a preliminary screwing of the holes is necessary, the diameter of which is 1-2 mm less than the fastener diameter. For one sheet 300 * 150 cm, at least 14 fasteners are installed.

- Failure from perlite and ceramzit, on top of which cement-sand screed with a thickness of at least 50 mm is satisfied. The screed must be reinforced by the road metal grid.

One of the ways to form a slope - clay

If the flooring roof is flat, it is necessary to form a bias towards the drain or roar of the catchment of at least 1.7%. It is usually done with the help of insulation. Manufacturers of roll-up materials produce insulation slabs with a specified slope. They are simply laid, observing the direction.

Another way to form a slope is to set the guides before the fill of the screed and smooth concrete

The roofing device from bitumen tiles will find here.

The composition of roofing pie

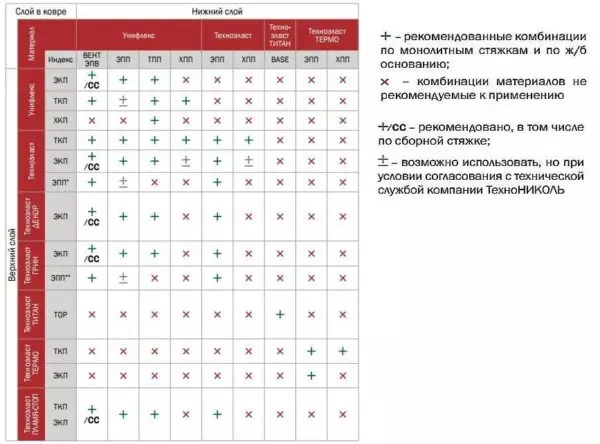

When applying a scope or flat flooring roofing, the cake is the same - with or without insulation, but it necessarily has a vapor barrier layer. The material for vaporizolation is selected under the roofing used, as well as the lining carpet is chosen under it. It's all about compatibility of qualities and characteristics, because it is desirable to use all the elements of one manufacturer on the roof. Solid campaigns even have special tables for which you can choose the required pie. One of the most famous manufacturers in Russia is the firm Tekhnonikol, their table and is shown below.

Compatibility of materials when applying a new roofing

Vaporizolation protects the overlying layers of the insulation from the saturation of moisture, which is especially important when used as a stone wool as insulation. She is afraid of wetting. With increasing moisture, its thermal insulation properties are strongly reduced, and if it freezes in the wet state, then when defrosting it, it will simply crumble into the dulk and your roof will become cold. Therefore, when laying vaporizolation, special attention is paid to the tightness of the joints, the correct cutting of the passages.

Roofing pie of a warmed flat roof with the flooring of the roof

When the flat roof is insulated, it is necessary to remember the need to create a slope towards the drain or receiving funnels (at least 1.5%). The same slope is maintained at the pouring screed. Its minimum thickness is 5 cm, the concrete brand is not lower than M150. Screwing strength (at least 28 days from the moment of fill), the bituminous primer is labeled, which provides a normal adhesion of roofing pie with a screed.

Along the rigid stained wool plates, the materials are allowed without laying a screed. Then the primer is drambled by the surface of the insulation, and the layers of the floor of the roof are mounted on top.

But it is not always necessary to warm the roof. In this case, the layers are smaller (see photo).

Flat flooring roof without insulation

In the device of the scanty kyszy or the band tie (from the plates and sheets), the roofing pie will be the same, only a vapor barrier layer is styled by the room, the insulation is laid between the lag, and the sheets of the team screed are fixed on the lags (sheet thickness of at least 8 mm, laying in Two layers with savings breakdown).

Device of the flooring roof

The flooring roof will serve for a long time if its layers will be laid in all the rules. Work is quite a lot, are located in the article they are in order of priority.Preparation of the foundation.

- From the surface of the roof all the garbage and dust are removed.

- Rust and other low-fat stains are removed using abrasives.

- If there are fat stains, a portion of the solution is removed, aligning the resulting deepening by patch from cement-sandy solution.

- If the surface is relatively smooth (the difference is not more than 5 mm / sq. M. M along the roof slope and 10 mm / sq. M in the transverse direction), cracks and potholes are closed with cement-sandy solution. If the slab overlap is uneven, it is poured with an aligning screed. For the fill, the concrete of the brand is not lower than M150, the minimum thickness of the screed is 30 mm.

Cracks for start expanding, then fill with a solution

- Vertical surfaces must be plastered or covered with CSP plates, flat asbestos sheets. If they have cracks and cracks, they are sealed with a sealant or cement-sandy solution.

- Before starting the laying, the surface of the roof and vertical surfaces is treated with a bitumen primer (primer composition).

In places of adjustment of the roofs to the vertical surfaces to start the floor roofing materials to a height of at least 10-15 cm (if there are no special recommendations). In places of adjoining the flooring roofing to the walls of heated premises (chimney pipes and ventilations including), the occasion to the vertical wall should be at least 25 cm. It is necessary that condensate is not formed in the roofing cake.

Laying vaporizolation

The bituminous steamer vapor insulation material can be laid by the method of burning and you can put freely, but be sure to rush all the joints.

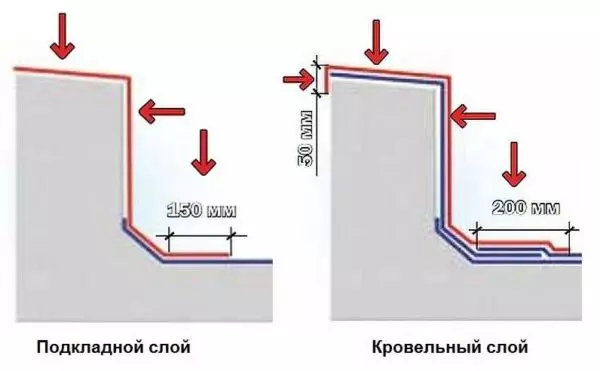

- The material is rolled over the roof so that the side adhesions leave 80-100 mm, the end (points of the joints of two rolls in one band) - at least 150 mm.

Rules for laying rolls of the floor

- The end adhesions on the adjacent bands should be separated at least 500 mm.

- When the device of the insulated floral roof, vaporizolation starts on the wall above the heat insulation layer by 10 cm.

- The places of adjoining to vertical surfaces are enhanced by an additional lining layer, it will start on Seine by 250 mm and so much 100 mm should lie on the roof.

After laying vaporizolation

Layer of thermal insulation

Laying thermal insulation is made on a ready-made vapor insulation layer. The surface must be absolutely dry and clean. Rules are:

- The plates are stacked without a gap, tightly fit together to each other. If the slots are formed greater than 5 mm, they are filled with strips of heat-insulating material.

- When laying two words, the sutures are stacked by a rotary.

- In order not to damage the laid insulation, there are tracks from the plate material (plywood, osp, etc.) on its surface.

- They are attached by special sharply deposited self-draws with plastic hats instead of umbrellas.

Laying thermal insulation in several layers occurs with the displacement of the seams

- With the help of thermal insulation, a bias is formed towards the drain.

Tie device

Through the insulation poured a screed. When using rigid plates from mineral wool (stiffness for compression of at least 0.06 MPa), the flooring roof can be made directly to the insulation, without a screed device. But for greater reliability, it is better not to skip this stage. The order of work is:

- The separation layer is placed on mineral wool or polystyrene - rubberoid or pergamine.

- Metal wire mesh is placed at least 3 mm thickness with 150 * 150 mm increments.

- The grid fragments are stacked with an overlap of at least one cell (150 mm). In the places of the allen, they bind to knitting wire with a step of 300 mm.

Device screed under the roof from the filmed materials

- The railway rails are installed, taking into account the formation of the slope.

- Concrete poured between the rails. He is moving by the rule, resting it on the rail.

- Within two days after the fill, the rails are removed, the formatives of emptiness are filled with cement-sandy mortar.

The screed leaves the strength. It takes an average of 28 days. To preserve the required level of humidity, immediately after laying, the screed is closed with polyethylene film, tarpaulo, burlap. During the first week, the surface is periodically wetted: at high temperatures several times a day, with a low one.

The stuffed concrete strength is treated with primer (and parapet too), wait until it dries (time depends on the brand and weather). Pressing the roofing material for a non-dry primer layer is prohibited.

Adjunction to vertical surfaces: the device of the side, adolescent

In places of roof adjoining to vertical surfaces to ensure tightness, it is recommended to make a side with an angle of 45 °. You can make it:

- With the help of cement-sandy solution (Mark M 150, dimensions 100 * 100 mm)

- By installing special cartoons, which are produced by the same campaigns that produce materials for the floor roof.

The cartoons are installed on bitumen mastic, the stern from the solution after grappling cement is labeled by primer.

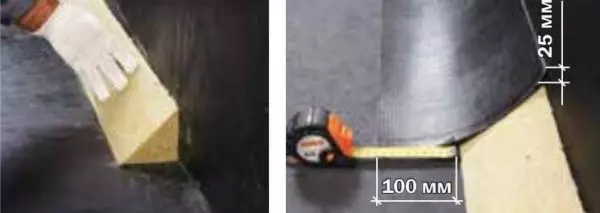

Fishing device on the flooring roof

Bursts are closed with an additional layer of a technoelast EPP type. From the roll, the band is cut off with such a width so that at least 100 mm of the material remains on the base of the roof and at least 25 mm started on the vertical surface. Side backstage stripes - not less than 80 mm. Extruded around the perimeter The material of an additional carpet on flights is filmed across the entire width.

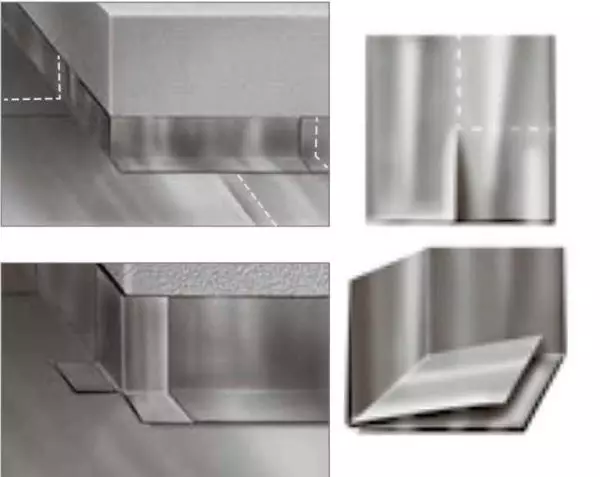

Processing of the angles of the floor roof - external and internal

When laying the following layers (lining and roofing), the lining layer is also first sealed, then the main carpet is fill and removed, bringing it above the side of 80 mm above. The bandwidth of the additional carpet depends on the layer.

Adjunction of the floor roof to vertical surfaces

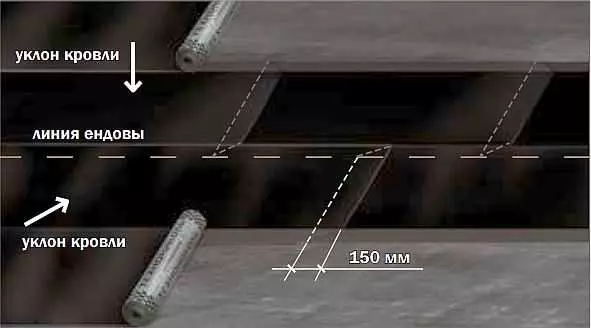

Endow and Konk

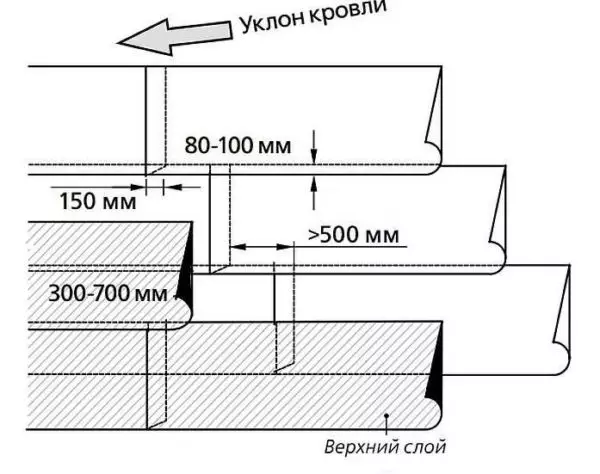

If the scope-pitted roof is satisfied, in the place of the inflection of the roof - the additional lining layer is stacked on the skate. Its width - 250 mm on each side. On complex roofs in the fields of the Unders, the lining layer should be at least 500 mm on both sides of the inflection.

Laying the material in Undova (below the additional layer is still laid

When laying on a skate, the joints are placed against the direction of the dominant winds. The overheet of the cloves is at least 80 mm, the joints are necessarily fused. In Undova, if possible, the lining carpet is placed in a single piece. If the roll lengths are not enough, the rolling starts from below, moving up. The place of the joint is also mandatory.

Claimed roofing: Material laying rules

First of all, it is necessary to determine the direction in which rolls will roll. On flat roofs, this is done along the long side of the roof. On the roofs with a slope, the direction depends on the magnitude of the angle:

- less than 15 ° - roll across the slope (along the skate);

- More than 15 ° - along the slope.

Note! Laying different layers in the perpendicular direction is unacceptable. All layers of the focused materials for the roof are stacked in one direction.

If there are several layers, the longitudinal seams of the layers are shifted by at least 300 mm. When laying, standard adhesions are also provided: side - 80-100 mm, end 150 mm.

Displacement of the panels when appliance

Order stacking

Start the installation of materials of the floor roof from the lowest place. Pre-roll are completely rolled, providing signs for vertical surfaces (parapets, pipes, etc.). It is necessary to roll without waves. In order for the material to not shifted, with a split one side pressed something heavy (you can put an assistant). On the laid rolling, the length is noted, too much cut off.

Preliminary rolls "try on"

On flat roofs roll roll away from the edges to the center. For convenience, you can use the iron pipe. With a slope of more than 8%, this option does not pass. In this case, the pressure starts from above, moving down. A piece of 1.5-2 meters long is not replaced. It is processed after the entire piece is glued.

In order for the rolls with the rolls, there were fewer waves, a couple of days before the start of installation, they are set by "sticking". So they take a round shape, the material then falls smoothly.

Swimming technology

Regardless of how the material is scattered, it is filmed off the "on yourself". So you can control the degree of heating of the bituminous layer: all the pictures have before your eyes. If you push the roll "from yourself", the quality of the roofing will be very low and the roof will quickly leak.

It is necessary to roll "on yourself"

Motion burner smooth and uniform. When laying the place of the allen warm up. In this case, the burner is moving along the trajectory in the form of the letter "g". The burner is placed so that the base of the roof is also heated, and the binder on the surface of the roll. With proper heating, a small roller from the molten bitumen is formed before the roll.

When you find it is necessary to monitor the bitumen evenly, there were no "cold" zones or zones of local overheating. Some manufacturers (TEHNONICK) on the lower side of the flooring materials for the roof are applied. It is easier to control the degree of heating of bitumen - as soon as the drawing "floats", you can roll the roll and move on. If bitumen is heated correctly, it follows the edges of the roll, leaving a band with a size of about 25 mm. That is, on the edge it turns out even seams of dark color.

How to control the degree of heating of the flooring material for the roof

Note! It is impossible to walk according to the welded roof. The sprinkver is in hot bitumen, which worsens its appearance and protective properties.

When laying the flooring of the roof in reduced sites, the coils of rolls in the joints are cut by 45 °. This defines the correct direction of water movement.

Laying of the material of the material in low sections (endowes)

Sometimes when laying the finishing layer of the floor, the roof there is a need to remark the material on top of the coarse-grained or scaly sprinkle. If you simply heat the material and glue to the sprinkling, the likelihood of leakage is great. In this case, it is necessary to preheat the surface of the material with the sprinkler, drown it with a spatula in the bitumen. After that, you can already re-warm and glue.

Article on the topic: Types of sofas