Plaster walls from aerated concrete - justified measure. Aerated concrete block, like foam block, despite all its advantages, hygroscopic material. This means that it easily absorbs moisture. Consequently, the house of the gas block must be protected from bad weather. If the gasoblock is wetted in the rain, and then he dries, he will not lose its properties. And if it wet in winter, then the water accumulated in the pores of the aerated concrete will freeze and expand. This is fraught with the appearance of small cracks, which spoil the appearance, as well as the emergence of more serious destruction.

Conclusion: protection of aerated concrete outside of freezing, moisture, snow and other atmospheric precipitation - forced measure. During the construction of a house of aerated concrete and in the period of winter conservation (if necessary), a film tensioned on the wall can be performed this function. During the operation of the house, it can be any facing material for the external finish of the facade - plaster for cellular concrete. The main thing is to create the conditions of vapor permeability to the aerated concrete "breathed."

Plaster walls made of aerated concrete

The outer finish of the house of aerated concrete in addition to the protection of the blocks allows:

- strengthen the heat and sound insulation of the walls;

- eliminate the likelihood of wetting walls;

- protect the house from sharp temperature drops;

- Decorate the facade of the house (decorative stucco for aerated concrete).

One of the most popular ways of external decoration

Aerated concrete house is to apply plaster. Therefore, often arise

questions, for example, how and than plastering aerated concrete, reply to which we

We will try as much as possible. We will conduct a comparative review of the characteristics of the best mixtures for finishing the facade, as well as we describe the technology of plastering walls in the form of step-by-step instructions, understandable beginners without construction experience.

Plaster for aerated concrete

Generalizing the experience of builders and owners of aerated concrete housesIt can be concluded that for plaster walls from aerated concrete

Varieties of finishing materials:

Cement-sand plaster for aerated concrete

This is the most famous solution that has proven itself.

On other materials, but not suitable for aerated concrete blocks.

Is it possible to plaster aerated concrete mortar?

No you can not. No matter what made masonry

Gas blocks on cement or glue. Generally, plastering aerated concrete cement

The solution is extremely undesirable, because the aerated concrete is very smooth and the solution on

It does not hold, and also strongly absorbs water from the solution.

Causes why not plastering a house of aerated concrete

Cement mortar:

- Cement mortar has a lower indicator

Parry permeability than gasoblock. This is the most important reason why it is not

It is worth using. In the case of finishing walls from aerated concrete

There is a rule, you can only apply that finishing material that

the vapor permeability indicator does not differ from the aerated concrete or has

larger compared to it, indicator. Only in this case will

Save the optimal microclimate of the aerated concrete house.

Note. For the same reason, tough insulation (foam

And polystyrene foam) it is undesirable to use a housekeeping house for insulation.

- The cement-sandy solution has an increased moisture content.

To knead the components in the sandy-cement mixture you need to add water.

It is also obvious that aerated concrete, having a significant indicator of moisture absorption,

It will strive to absorb this water from the solution. This, in turn, reduces

The quality of the applied solution and its ability to stay on the wall. After all, concrete

Visits strength only under the condition of uniform and slow drying.

Remember, the foundation must be able to periodically moisten and

Turn the film to ensure uniform drying. So why on the wall

Does he behave differently? The primer saves the situation, but not much.

The appearance of the cage of small cracks on the plastered surface of the aerated concrete

to avoid.

Note. In order to save it, you can mix cement-sand

a mixture and a special mixture for finishing aerated concrete blocks in proportion 1 to 1. But

whether such a save is needed, which will significantly reduce the speed of work, and the trimmed

The surface will not be high-quality at 100%.

- In cement mortar for plaster Low adhesion. He is not

It can provide high-quality adhesion with aerated concrete. One of the reasons may

It is considered the weight of the solution and the presence of large impurities in its composition.

Article on the topic: At what height correctly hang a floor TV

You can increase the adhesion indicator (sticking, clutch of surfaces) by adding lime to the classic recipe for cement mortar (proportion: 8-10 kg of lime per 100 kg of concrete).

Cement-limestone plaster can be purchased as a finished dry mixture.

For example, a dry construction cement-lime mixture Solo Extra Light (240

RUB / 25 kg), the start of the startwall T-21 (208 rubles / 25 kg), Baumit Handputz 0.6 (300

rub / 25 kg).

Plastering Straight Spass Extra Light

Facade Plaster Bases Starwell T-21

Facade Plaster Baumit Handeputz 0.6

- Mandatory applying the finish layer. Because It's hard to do

A smooth surface using a sandy cement mixture.

Is it possible to plaster aerated concrete glue for aerated concrete?

Also undesirable. Despite the fact that the adhesive mixture is designed to take into account the specifics of the aerated concrete, it is designed to applyThe thin layer and formation of seams, and not for the outer decoration of the walls.

Violation of the violation of the aerated concrete will lead to such

problems as cracking the finishing layer, manifestation of traces of seams (disappear

After drying), the appearance of mold.

Gypsum plaster for aerated concrete

Advantages of plaster based plaster:

- High drying speed;

- Selfless solution;

- the ability to make a smooth surface;

- No need to apply the finish layer.

Disadvantages of gypsum plaster:

- mediocre vapor permeability;

- more compared to a special mixture, content

Water required for mixing mixture (10-15 liters per bag);

- rapid wet during rain or snow;

- the probability of appearance of spots on the surface, which

You have to paint.

Despite the minuses, plaster walls by plaster - acceptable

Option for decoration of aerated concrete. Well proven itself: gypsum

Velvet G-567 winper permeable high-fast plaster mix (earlier

Win-aegis TM-35 for 320 rubles / 25 kg.), Knauf Rotband (360 rubles / 30 kg) and Bonolit

(290 rubles / 30 kg).

Plaster mix Win Velvet G-567

Plastering mix Knauf Rotband

Plastering mix Bonolit.

Facade plaster for aerated concrete

The most effective material for plastering outdoor andInland walls from aerated concrete. Stucco for facade works has near

characteristics, including record indicator identical

Aerated concrete indicator (for most types of plasters), good adhesion based on

Beautiful appearance.

Choosing than plastering aerated concrete, it is best to stop

on a high-quality special mixture. In addition, the use of facade

Plasters simplifies the finish of the house of the aerated concrete.

What plaster is better to stucked the walls from aerated concrete?

The market presents a variety of Ready-made mixes for

Plasters walls from aerated concrete. To make the right choice, you should pay

Attention on the characteristics of plaster:

- vapor permeability;

- Required amount of water for mixing mixture (no more than 0.2 l. per 1 kg. mixtures);

- Boundary values of plastering thickness (minimum and maximum);

- adhesion with the base (minimum of 0.5 MPa);

- resistance to low temperatures;

- cracking resistance;

- The time of the viability of the solution. The more, the easier it is to work with him beginners.

Stucco for aerated concrete Ceresit CT 24I only choosing between two equivalent mixtures, one should be guided by the price, it solves in this matter not the last role, but not the key one.

According to the reviews, the plastering of walls from aerated concrete is popular among users from the outside of the room - dry mix with Ceresit CT 24 plasticizers (380 rubles / 25 kg), the price / quality is leading in terms of price / quality.

Material prepared for site www.moydomik.net

When can you stucked the walls from aerated concrete?

Since the aerated concrete absorbs moisture, it is better immediately

same to protect from wetting. Repeat, not critical if the material wureswards, but

Do not allow moisture freezing in the gas pack. It can lead to it

Weakened and the appearance of unwanted cracks.

Hurry in facing is also nothing. After laying aerated concrete

Walls must be good. That is why plaster walls of aerated concrete

Performed only in the warm season. In case of use

Concrete-sandy solution as a binder element when laying

aerated concrete blocks, the drying time increases, since such a seam in

Several times thicker than seam made by a special adhesive mixture.

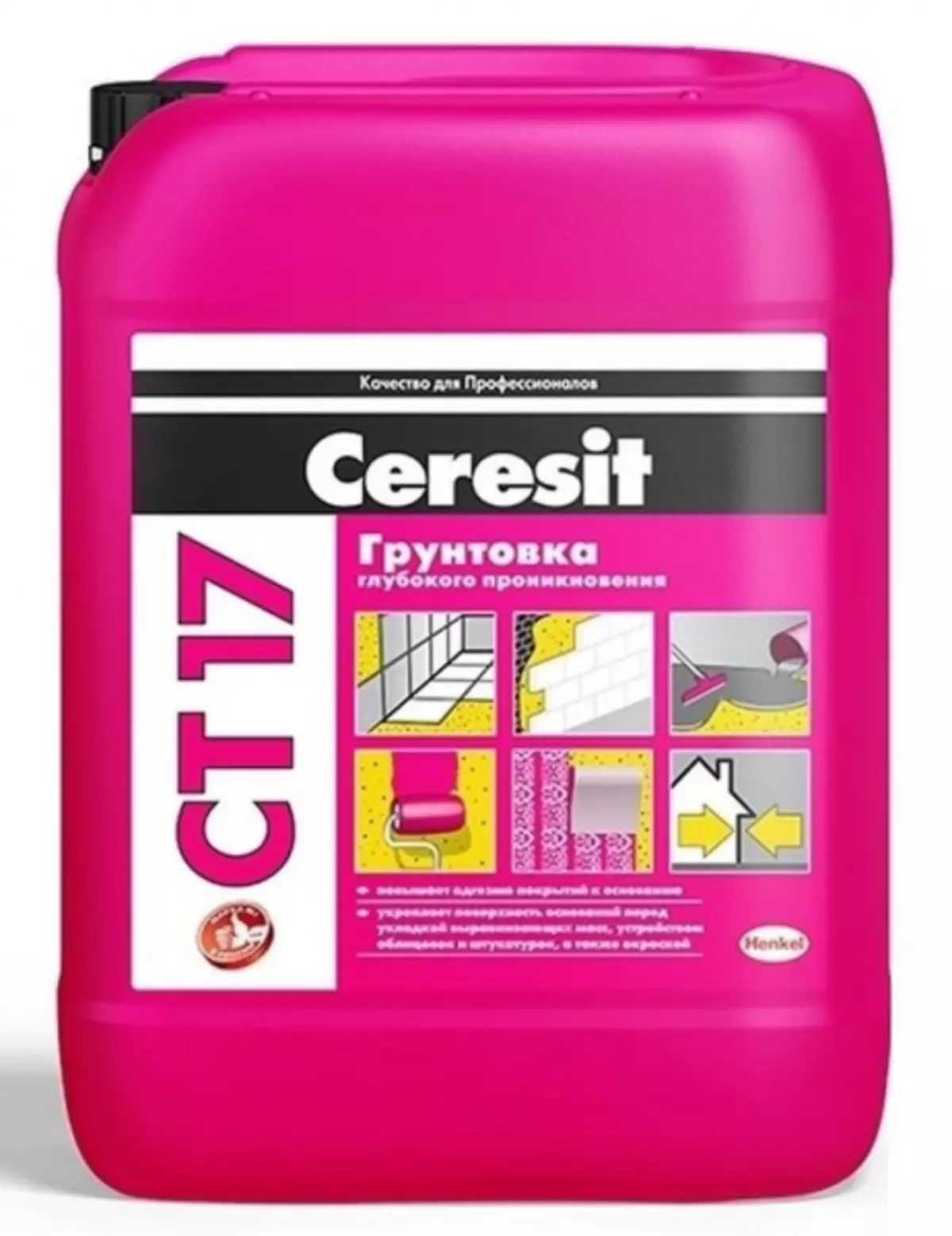

Primer for aerated concrete Ceresit St-17Exi perform a finish of the house during the warm season is not possible, you need to cover the walls of any grinding of deep penetration. For example, Cerezite ST-17 (549 rubles / 10 l).

The primer will reduce water absorption. It is also desirable to cover the walls with polyethylene, which remained from the packaging of a pallet with aerated concrete.

According to the masters, the most preferred time for

Performance of finishing works is a period when the night temperatures exceeds

0 ° C. For the middle strip of Russia, this time from the end of March to the beginning of October.

What part do you need to start the finish of the house of aerated concrete?

We will conduct a comparative analysis of several popularvariants of the priority of finishing walls.

Article on the topic: Rectangular design: Recommendations, interesting techniques

Option 1

First, the outer decoration of the house of aerated concrete

There is an opinion that the most important thing is to protect the gasoblock with

Streets, because He gains moisture. However, it is not, even stood without protection (but

Trunk) whole winter, gasoblock in the spring "give" the accumulated moisture. BUT

If it is closed outside, where will the pairs be directed? That's right, inside

premises. This will not only increase the drying process and delay the implementation of the inner

Finishes, but also fraught with the appearance of cracks indoors.

Note. Exception in the order of finishes are at home,

Which are built on the seashore, river or lake. Here as a priority

Protecting the outer walls from the effects of moisture and wind.

Option 2.

First, the interior decoration of the house of aerated concreteWith this approach in the process of finishing work partially

The pores of the gas-concrete block are closed. And if they are attached first from the outside,

I just have nowhere to make a copying water pair. Settling inside the block

Moisture will contribute to its destruction. Stucco walls from aerated concrete inside

The premises will avoid this situation.

After the plaster touched the inner walls and

It can be faded, you can proceed to the finishing of the outer walls.

Option 3.

Simultaneous finishes from the inside and outside the house

The method is the least preferred. The moisture that "pulls" the gas-block at the same time outside and from the inside will not be able to have the ability to quickly exit.

Despite the fact that the plaster for aerated concrete has good record indicators, the speed of this process is not so high. What is especially critical in the cold season (at night temperatures below zero). In this case, water vapor will fall in the form of condensate and in the end can lead to peeling layer of plaster from aerated concrete. In practice, this option will quickly lead to the destruction of the gasoblock.

Theoretically, each option has the right to implement. But, the second is right.

How to stucked the walls of aerated concrete with your own hands

With a question, it is possible to plaster aerated concrete. Now it is important to understand how to do it right, without prejudice to the aerated concrete moisture.

Shuttering of aerated concrete blocks does not have a fundamental

Differences from the performance of such a species on other materials. Technology

applying putty differs only by several details on which

Made accent.

Internal plaster walls from aerated concrete

Technology finishing aerated concrete plaster indoors -Sequence of work:

1. Preparation of the foundation

Starts with alignment of walls - removal of irregularities

Made by planer or grater for aerated concrete. This work is recommended

Perform at the stage of building a house, but many of this neglected, saving

time. In principle, this stage can be omitted, which will lead to a significant

An increase in the flow rate of the mixture and an increase in the thickness of the application layer. In turn

This is fraught with peeing plaster and cracks.

2. Applying the primer

Recommendations are often found that

The primer with water 1 to 1. This is rooted incorrectly, because Reduces its ability

Increase the adhesion of the surface. There are more reliable ways to save.

For example, remove dust from the surface by applying clean water to it.

Water is applied with a brush or roller so if it was a primer. And then,

After drying, the primer is applied.

The choice of primer depends on the purpose of the room, which

shall be finished. For a corridor or an entrance hall, any universal

Primer, for example, Unis (250 rubles / 5l). For bathroom and kitchen, preferably

Use deep penetration soil, for example, prospectors (450 rubles / 10 l).

Applying primer on aerated concrete with a brush

Application of primer on aerated concrete with roller

3. Installation of Mayakov

Lighthouses, as follows from the name, determine the thickness of the application

Solid. They are installed on the width of the rules. Installation accuracy is determined

Building level.

Installation of beacons for plastering aerated concrete

Lighthouses for plastering aerated concrete

4. Plugging "Shub"

This is the name of the method of applying the first layer of plaster.

Work is underway. Next you need to drink the rule on the lighthouses and align (pull)

Differed layer on them. If voids appeared, they need to immediately close.

The main thing is that the plaster from the base does not happen. If that

It happened, you need to remove the plaster, handle the surface of the primer and again

Apply a solution.

Packing plaster

Plugging of plaster - fur coat

5. Processing of the first layer

After drying out the first layer of plaster, it needs to be slightly

Moisten (with a pulverizer) and to dissolve. Since lighthouses serve as bridges

The cold is desirable to remove them at this stage, and the places (recesses after dismantling)

solution.

Pulling plaster for lighthouses

Dismantling of beacons for plaster

6. Corners formation

For the device and enhance the outer corners, a perforated corner with a grid is used.

Mesh for plastering angles

Mounting Mounting Scheme for Corner Stucco

Article on the topic: Ideas for organizing storage in the bathroom (25 photos)

7. Finish finish

Grout is performed (if necessary) and staining of walls

from aerated concrete. In the case of pasting wallpaper, the finishing finish is not required.

Sturgating Technology Stucco

Finish stood plaster

Requirements for aerated concrete paint

Regarding vapor permeability. These properties have paints for

internal works based on PVA, latex, acrylic emulsions, on organic

Solvents and cement paints.

As an example, you can bring Eskaro Akzent

(Antibacterial paint, 325 rubles / 0.9 kg). At the same time, for rooms with elevated

humidity should use special paints, such as Aquanova Premium

(282 rubles / 2.8 kg)

Paint Eskaro Akzent.

Paint Aquanova Premium.

How to plaster aerated concrete walls - video

Outdoor plaster walls from aerated concrete

Decorative facade house facade can provideApplication of plaster for outdoor work with a thick layer (Tolsti-layer finish)

or several layers (thin layer plaster).

Consider a multi-layer application of thin layer

Facade plaster for aerated concrete. Its feature in creating three thin (not

More than 10 mm) layers.

Plaster Application Technology Outside:

- Preparation of the wall. Includes surface alignment

To reduce the consumption of the mixture and the thickness of its application;

- priming surface;

- Applying a thin layer of plaster mixture (up to 5 mm). His

Purpose - serve as the basis for fastening the grid;

- reinforcement of plaster grid;

How to reinforce plaster

As a reinforcing layer, a metal mesh with small cells can be used, for example, a steel mesh with a wire diameter - 0.1 mm, and a cell pitch - 0.16x0.16 mm (average price of 950 rubles / m.KV = 2,850 rubles / roll) or a fiberglass mesh (for example, a reinforcing fiberglass with a cell packet 50x50 mm (approximate price of 17.60 rubles / m.kv = 880 rubles / roll).

Reinforcement of plaster Setures the grid with an overlap in 50 mm. At the same stage, building angles are formed using a perforated corner with a grid. The grid helps prevent cracks on the plaster due to a building shrinkage. Thus, the plaster of the facade from aerated concrete will not cover the cobweb of small cracks. The grid is taken to the applied solution with a spatula. It is especially important to install the grid in the places of high voltage, near the windows and doors.

Council. Mounting mesh on a dry wall will not give any

Results because the grid will be fixed on the basis of self-drawing. IN

the case of its installation on the solution, it forms a monolith with a solution, and will

Move with him.

- Alignment of the plaster layer on the grid;

Next you need to wait until the first layer dries

Fully. Otherwise, it can disappear under the weight of the second layer.

Since this method provides for thin layer application of the solution, wait

It will be necessary 3-4 days. The thicker layer - the more. Check whether the layer can be dried

With water. If you splash on the wall and water is absorbed, then it's time

Bring out work.

Note. When drying, the plaster needs to be protected from

The effects of environmental factors (from moisture, snow, rain).

- Applying the second layer of plaster. This layer is considered

aligning, so high attention is paid to the smooth apparent and

forming a smooth surface;

- drawing a third (finishing) layer of plaster mix with

subsequent grouting if necessary;

- Staining plastered walls from aerated concrete or application

Texture plastering mixture, for example, win-cored (340 rubles / 25 kg).

For dyeing aerated concrete, only paints are used for

outdoor work. For example, Nova-facade (590 rubles / 7 kg), GasBetonBeschichtung from

Dufa (2674 rubles / 25 kg), Rolplast Gordianus (3700 rubles / 10 kg), dyotex

(Concentrate, 5500 rubles / 15 kg).

- Application of the hydrophobizator. This is a special solution that

Professionals recommend to apply one year after staining, after graduation

All facing works. The hydrophobizer will give any surface

Additional water repellent properties. Well established himself

Special hydrophobizer for aerated concrete "Neogard" (350 rubles / 1 l).

Putty aerated concrete

Deciding than placing aerated concrete, you need to know that in the market

Presented three varieties of material for finishing finishes similar to

appointment, but differing in its composition. All this, stucco for aerated concrete

Facade, sold in the form of a finished mixture. Designed for thin-layer finishing of the plastered surface.

Silicate Plaster Baumit Silikattop Kratz Reprogota Silicate Plaster, for example, Baumit Silikattop

Kratz Repro 3.0 mm (3700 rubles / 25 kg)

Silicone Plaster Baumit Silikattop Kratz Reprosylconic Plaster, for example, Baumit Silikontop (3300 rubles / 25 kg)

Acrylic plaster Cerezit CT 77 acricle plaster, for example, Ceresite CT 77 (3800 rubles / 25 kg)

Facade "fur coat" Weber.pas Akrylated Weber.Pas Akrylat Shuba 615С 1,5mm (1800 rub / 25 kg)

Conclusion

Consistently performing work on plastering walls from

Aerated concrete and applying only paropropic materials can be provided

A reliable finish that will decorate the facade of the house for more than one year. And planned

Repair work will be reduced to periodic staining, to restore

Colors of paint and eliminate small cracks.