Ukuqhubekeka kweplanga le-sawn, iipokotshi, ukuveliswa kwemingxunya yetekhnoloji kunye nokufunyanwa, ukuthwala iinkuni- konke oku kunokuba sisixhobo njengemitha. Ngapha koko, ayinakuphela kuphela izixhobo zobungcali, kodwa nazo ikopi ezingenaxabiso. Kodwa umsebenzi ongumthi wokugaya i-Migaga ifuna ulwazi ngeendlela ezithile zobuchule kunye nemithetho. Ngayo yonke le nto - kwinqaku.

Yintoni i-milling kwaye yintoni efunekayo kuyo

Isigayo sisixhobo sokuqhutywa komthi okanye isinyithi. Baqhuba indawo ethe tyaba kunye neflethi, ikwayintloko yokufunyanwa kwetekhnoloji - i-Grooves, iComb, isuswe phantsi kofakelo lweelogo, njl. Ngendlela yokufaka, kukho oomatshini bokumisa (kukho iintlobo ezahlukeneyo zokwenza imisebenzi eyahlukileyo), kwaye kukho ii-milling margation. I-elektroniki ze-elektroniki sisixhobo sendalo esivumela nayiphi na imisebenzi. Ukutshintsha ukusebenza, kuphela ufuna ukutshintsha i-nozzle-Mill kunye / okanye indawo yayo ngeenkcukacha.

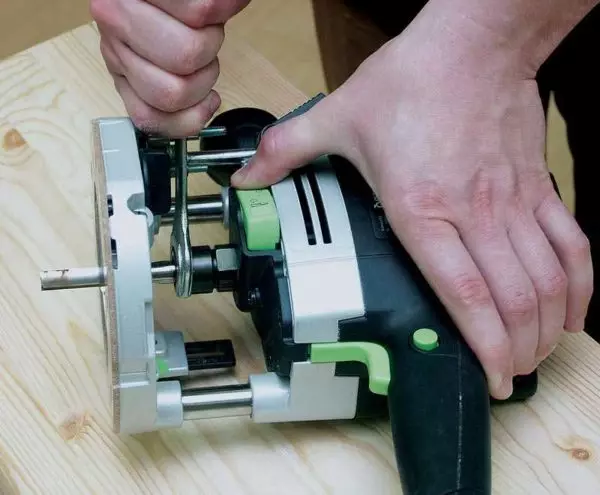

Oomatshini basetyenziswa ikakhulu kwimveliso yobuninzi. Isikizi sokugaya sifakwe ngokungakhathali, kwaye i-godpiece ihamba-ngokwendlela ethile. Xa usebenza nge-Milling Master, le meko yinto eyahlukileyo - lungisa i-Worpiece, hambisa i-Milling Gome. Xa iqhubela phambili imiqulu emikhulu yeenkcukacha ezifanayo, ilungele ukulungisa i-Mill yesandla kumphezulu othe tyaba ngokwenza into efanayo nakumatshini wokugaya.

Umatshini wokugaya wasekhaya - iplanethi ethe tye ngomngxunya phakathi, apho i-milling yesandla ifakwe apha ngezantsi

Zininzi iindlela ezahlukeneyo zoomatshini bokugaya, kodwa kwi-Master yasekhaya okanye i-Semi-Memi-Memidical Service ifanelekile ngakumbi. Bafakelwa amasikilo ahlukeneyo kunye nezixhobo ezizodwa, ezivumela ukuba wenze nayiphi na imisebenzi. Ukubulawa kwabo kufuna ixesha kunye nobuchule kunamatshini owodwa.

Yintoni enokwenziwa ngoncedo lwelitye lesandla:

- i-grooves kunye ne-grooves yayo nayiphi na imilo (ijika, inxatangi, iifom ezintsonkothileyo);

- Ngemingxunya nemfama;

- Inkqubo yemiphetho kunye neziphelo (zinokuthengwa nkqo, curly);

- Nciphisa iinkcukacha ezihlanganisiweyo;

- Faka isicelo sebhalo, iipateni, imizobo ebusweni;

- Khuphela iinkcukacha.

Iinxalenye zekopi-enye yeempawu zamandla ombane

Imisebenzi enjalo isetyenziswa kwi-carpentry, kwimveliso nakwindibano yefanitshala. Nokuba sinciphise isitshixo okanye iilogo emnyango - inokukwenza ngesandla Kwaye iyakwenza ngokukhawuleza kwaye ibaluleke ngaphezu kwemisebenzi efanayo, kodwa yenziwa esebenzisa isixhobo ngesandla.

Ukulungiselela umsebenzi kunye nokukhathalela

Ukujongana nemithetho-siseko yokusebenza kunye nokugaya isaziso, kunqweneleka ukuba nombono ngokubanzi wesakhiwo kunye nenjongo.Ukwakhiwa kunye nokuqeshwa kweendawo eziphambili

Inama-elektroniki yesandla evela kwizindlu ezifihlakele ngazo imoto. Ukusuka emzimbeni kukho umnini apho ikhoyo i-collet ifakwe khona. I-Canggi zii-adapter ezincinci ezivumela ukusetyenziswa kwezisikithi ezinemifula yedayimitha eyahlukeneyo. Isikithi sokugaya sifakwe kwi-collet kwaye sibambezele nge-bolt ebukhali (kwezinye iimodeli zilungisiwe ngeqhosha).

Ii-node eziphambili zokumaza kunye nenjongo yazo

Enye yeenkcukacha ezibalulekileyo zokumiswa kwemali yiqonga eliqhagamshela nezindlu usebenzisa iintonga ezimbini. Iqonga lihlala lenziwe ngentsimbi. Kwicala elingaphantsi leqonga kukho isitovu esityibilikayo. Yenziwe ngento egudileyo eqinisekisa ukubaluleka kwesixhobo xa ishukuma ngaphaya kwenxalenye.

Ukuseta iiparameter ze-freeomier yenzeka nge:

- Iipeni kwaye zithambisa ubunzulu bokugaya. Ukuseta inyathelo - 1/10 mm.

- Ukulungelelanisa inani leenguqu. Itshintsha isantya sokujikeleza komsikisi. Ukuqala, kufanelekile ukuzama ukusebenza kwi-turnover encinci okanye ephakathi - kulula ekuqaleni ukukhokela isixhobo.

Iyimfuneko kwityala ukuba kukho iqhosha elikwi / off, kunokubakho elinye iqhosha lokubhloka. Apha, ngamafutshane zonke iindawo. Ukongeza, kusekho ugxininiso olufanelekileyo. Isenokuba lula okanye ibekho ukubakho kohlengahlengiso-ungatyibilika inxalenye yokusika ngasekunene okanye ngasekhohlo.

Ukhathalelo

Ukusuka kumzi-mveliso, izixhobo zihamba ngooyile, ngoko kumgaqo, akukho misebenzi eyongezelelweyo iyafuneka. Kodwa kuyimfuneko ukuxhasa izixhobo kucoceko-kunyanzelekile ukuba ziqwalasele uthuli rhoqo, tshintsha nge-qubirication ukuba kukho imfuneko. I-Lubrication iyadingeka impahla yokuhambisa-izikhokelo. I-Liquerosol I-Aerosol I-Aerosol Inokusetyenziswa (ichanekile), kodwa iintlobo zokungaqhelekanga zelitywina zinokusetyenziswa. Kodwa, xa usebenzisa i-librick eqinileyo, kuya kufuneka uzicime amaxesha ngamaxesha, njenge-chips inamathele, kuya kuba nzima ukusebenza. Ngokusetyenziswa kokukhanya kwe-aerosol eyongeziweyo, akukho ntweni.Ukwenzela ukuba i-lid kuphela, ungayithambisa nge-silicone ioyile. Oku kuluncedo ngakumbi xa usebenza neetemplate. Emva koko isixhobo sezilayidi, sihamba kakuhle kwaye ngaphandle kwejezi.

Isantya esijikelezayo

Umsebenzi wokuSebenza, ukumangalela, iPlywood, njl. Iqala ngokubekwa kweeparamitha ezisisiseko. Qala usete isantya sokujikeleza. Ikhethintelwa kuxhomekeka kumjikelo onyuliweyo kunye nokuqina kwento kunye neempawu zesigayo, ukuze iingcebiso ezichanekileyo kufuneka zisayinwe kwincwadi yemiyalelo.

Isantya esifanelekileyo xa sisebenzisa ii-cutters ezahlukeneyo

Ukugcwalisa ukusika

Okulandelayo kukufakwe isikithi semiganga. Uninzi lweendawo zokusikelwa kwenkampani, kukho iithegi onokuthi uhambe ngazo. Ukuba abakho, ubuncinci kufuneka bubethwe ubuncinci i-3/4 yobude be-shank (inxenye ye-cylindrical). Faka isikithi kubunzulu obufunekayo (ukuba kukho imfuneko, emva kokufaka i-collet-Ikhatriji ye-adaptha yedayitha eyahlukeneyo yomsikisi), qinisa isitshixo sesondo de uyeke (kodwa ungathuki).

Ukusebenza kwee-Milling zeenkuni kunye nezinye izinto ziqala ngokutyibilika

Ukuba imodeli ilula, izitshixo ezibini ziyafuneka. Ababoneleli ngendlela yokubhloka yeshaft, isitshixo sesibini siya kufuna ukuyibamba. Kwizixhobo zeklasi ephakathi apho kukho iqhosha lokutshixa. Ukutsala, qinisa iqhosha le-carkin. Kwimodeli ebizayo ngaphandle kokuvalwa, kukho iratchet apho ungahamba khona.

Ukuseta ubunzulu bokugaya

Imodeli nganye ye-freresser yesandla inomthendeleko othile-obu bunzulu kakhulu apho le yunithi ikwazi ukuqhubela phambili izinto. Ubunzulu bokugaya akusoloko kufuna ukuba ubuninzi, ke kufuneka uhlengahlengiso lwayo. Nokuba iyimfuneko kwi-Mill ukuya kubunzulu obukhulu, ukuze ungalayishe kakhulu kwaye iyunithi, ungayibetha ngamanqanaba aliqela. Kule nto kukho ugxininiso oluguqukayo. Le yidiski encinci phantsi kwe-barbell enenani elithile lokuma kwezikali ezahlukeneyo-imilenze. Inani lemilenze-ukusuka kwisithathu ukuya kwesixhenxe, nangaphezulu-ayithethi ngcono. Kulula ngakumbi ukuba kukho ukubakho kokuhlengahlengisa ukuphakama komlenze ngamnye. Oku kubonisa ukubanakho kwezixhobo. Ukukhusela ukuma okutsha kwindawo oyifunayo kwindawo oyifunayo kukho ireyithi, edla ngokwenziwa ngohlobo lwebhokisi yokukhangela.

Ubunzulu obunomvuzo bokugaya kwi-Milling yaseMasimini yenzeka ngamanqanaba aliqela:

- Esi sixhobo sibeka kumphezulu othe tyaba, sikhulule amaqhinga, cofa umsikisi wokuphuphuma kumphezulu.

- Khupha ugxininiso olujikelezayo, ukuphinda ulayishe itshixa.

Khetha umlenze womqolo wokumisa

- Kuxhomekeka ekubeni kufuneka ubunzulu bokugaya, umlenze wendawo yokumisa ikhethiwe. I-disc ngemilenze ijikelezisiwe kwisikhundla esifunayo.

- Isikere asizinzisi, kodwa sibambe i-bar ngomnwe, hambisa isikhombisi esishukumayo ukuze udibane ne-zero (kwifoto engentla).

- Ibar iphakanyiswa kwisithuba sokugaya, emva kwengxelo yerekhodi yendawo yokumisa ihlisiwe (kwifoto engezantsi).

Bonisa ubunzulu besikali

Ngoku, xa ufaka i-rimeriece kwaye uphosa phezulu, umsiki uya kungena iinkcukacha kumgama obonisiweyo.

Ngoku iya kuba yinto engekhoyo kubunzulu obufunayo

Kwiziphelo ezifanelekileyo apho kukho ivili lohlengahlengiso oluchanekileyo lobunzulu bokugaya. Ikuvumela ukuba ungayitshisi useto (awudingi uphinda-phinda ukusebenza yonke) ilungisa ubunzulu, nangona imida emincinci (kwifoto engaphezulu kwevili eliluhlaza).

Ukusika i-Milling Master

Izisitho zizixhobo ezisikiweyo eziquka kwaye ziyibeka umphezulu. Ziqukethe inxalenye ye-cylindrical, egqunywe yimibala kwi-HORDEARE yeyunithi, kunye nenxalenye yokusika. Inxalenye ye-cylindrical inokuba yidayitha eyahlukileyo. Khetha i-collet enjalo apho kukho isixhobo sakho. Ubume kunye nendawo yesanti yenxalenye yokusika ichaza uhlobo lokuba iinkuni ezifunyanwa emva kokuqhubekeka. Kwezinye ii-mills (zemiphetho) kukho i-roller eqhubekayo. Ibeka umgama ukusuka kumphezulu wokusika ukuya kwizinto ezenziweyo.

Umsebenzi womthi onomthi wokugaya umthi kubandakanya ubukho benani elithile lokusika. Le yinxalenye encinci yento ekhoyo

Yenza abaguli ukusuka kwiintsimbi ezahlukeneyo kunye ne-alloys. Ukuphatha iinkuni ezithambileyo - ipine, ipruce, njl. -Sebenzisa i-nozzles eqhelekileyo (HSS), kumatye anzima - i-oki, i-beech kunye nabanye-ukusuka kwi-Aldys ye-hard Allos (HM).

Isikithi ngasinye sokugaya sinomthombo othile kunye nesantya esiphezulu apho kusebenza okuqhelekileyo kubonelelwa ngokubetha okuncinci. Isantya esiphezulu sokucetyiswa asikufanelekanga- oku kunokubangela ukwahlukana kokugaya. Akwenzanga qondo lokunyibilikisa imitha, ukuba ithe yaqinisa. Kwenze kwizixhobo ezizodwa (zixabisa malunga ne-1000), apho unokubeka khona i-engile ebukhali. AMANQAKU AKUKHO nto iya kuphumelela. Ke loo nto igxile ngokulula (kwaye ihlawulwe), njengoko zimbalwa.

Iintlobo ezithandwayo

Kukho iintlobo ezithile zempompo zesigayo, ezisetyenziswa rhoqo.

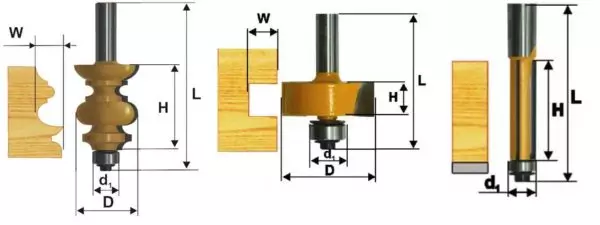

- Umda. Khonza ukuphatha indawo ka-Olks. Ngoncedo lwabo, unokwenza imiphetho egudileyo okanye egudileyo, unokwenza ii-i-i-i-i-Infches kunye ne-Spikes yeNdawo yokuKhwela. Luhlobo oluyisikizi olusenzekayo kunye neflethi ekugqibeleni-iphumle kwinxalenye, icela umgama ukusuka kumda we-odriece kumjikelo.

Ezinye iintlobo zemiphetho

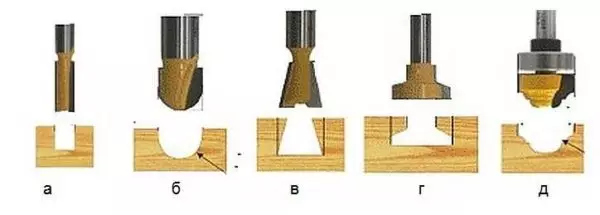

- Groove. Khonza ukwenza i-grooves kunye nokwamkelwa kweemilo ezahlukeneyo. Bazi:

- I-Spirals (a) isetyenziselwa ukwenza i-rooves yobugcisa, umzekelo, i-joyint / groove;

- Igalari (B, E) -Ukuhombisa umphezulu ngoncedo lweemilo ezahlukeneyo, zinokujikelezwa, i-v-viled okanye icingelwe;

- I-Swail Twiil (B, D) - ukwenza i-roove ngendlela ye-trapezium, le Groove isetyenziselwa unxibelelwano oluvulekileyo lwamalungu;

- I-DEARD (D) -Ngalo ngoncedo lwabo lubeka umphezulu kunye nemigca yeefom ezintsonkothileyo.

Iithayitha zokucheba-zokuqulunqa ukufunyanwa kwayo naphi na

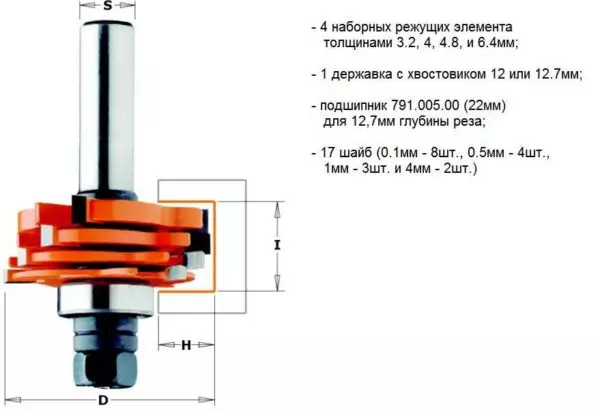

Kukho izinto ezinkulu ezilula, zenziwa kwisiqwengana sesinyithi, siqhelekile. Iiseti zine-shank-isiseko, ezinye iindiza ezahlukeneyo zokusika, iseti yeehehers zobukhulu obahlukeneyo. Ukusuka kula macandelo onokukwenza ngokukhululekileyo.

Umsikisi osetiweyo-Iseti yemiphezulu yokusika kunye nehehers, apho unokwenza khona ifom yefom efunekayo

Ezi zezona ntlobo zithandwa kakhulu zabasika, kodwa eneneni zininzi. Ukongeza kwiidayamitha ezahlukeneyo, kukho iidayamitha ezahlukeneyo zemiphezulu, ukuphakama, ukucwangciswa kwezinto ezinxulumene nomnye, njl njl. Ngokubanzi, ngenxa yokugaya ngezandla zabo, ihlala ifuneka malunga nezona zihlanu ze-chassis. Zihlala zikho rhoqo, kwaye ezinye zithengiwe kwiindidi zomsebenzi.

Imigaqo yokusebenza kunye ne-Milling Mastersing

I-eletcroter yinto eyingozi kakhulu-ijikeleza kwizantya eziphezulu ezibukhali zinokubangela ukwenzakala kakhulu, kwaye iitshipsi zibhabha phantsi kwesixhobo. Kwaye ubuncinci kwiimodeli ezininzi kukho iflegi ekhuselayo, ebonisa i-chips ephambili yeetshipsi, iiglasi zokhuseleko aziyi kuphazamisa. Ke umsebenzi onenkuni yemitya yeminzi ifuna ingqalelo kunye noxinzelelo.

Enye yeemodeli-ngesicoci esidibeneyo sokucoca i-chip

Iimfuneko ngokubanzi

Umsebenzi onomthi wokugaya i-Milling kuya kuba lula kwaye kube mnandi ngakumbi, imveliso iya kuphuma okuqhelekileyo, ukuba wenza iimeko:

- I-milly kufuneka ibe yinto enzima. Kunzima ukuqikelela le parameter "kwiliso", ke kufuneka ukuba senze ixesha lokusebenza: ukuba i-motor ishushu kakhulu kwaye / okanye ingcolile i-"okanye ingcolile"), emva koko isidenge . Kufuneka itshintshwe.

- I-Billet eSebenzayo kufuneka ilungiswe ngokuqinileyo. Awuyi kufumana nantoni na elungileyo ekutsaleni nasekugomeni.

Ii-billets kufuneka zimiselwe ngokuqinileyo. Sebenzisa kakhulu i-clampps

- Ubunzulu obuncinci bokususwa okukhoyo. Okukhona iinkuni ozithobayo, kokukhona umthwalo omkhulu kumsikisi. Oku kukhokelela ekwehliseni isantya sokujikeleza, oko kunyusa ngakumbi umthwalo. Ngokulandelayo - kwisangqa. Kungenxa yokuba ukuba ufuna ubunzulu obuphezulu bokuqhubekeka, kungcono ukuyiqhekeza kwiidlule ezininzi.

- Xa ithatha indawo yokusika, kufuneka uchithe iyunithi. Hayi iswitshi, kodwa susa intambo kwi-Cord. Oku kuyakuphelisa ukubakho kokungena ngokuzithandela.

Ayizizo izinto ezinzima, kodwa ukuphunyezwa kwazo sisiqinisekiso somsebenzi olungileyo kunye nokhuseleko. Ewe, eyona ifunekayo, kufuneka iqhutywe kakuhle, ngaphandle kwejezi, ijezy. Ukuba ukubetha okwethu kuvakala-tshintsha imvana yokujikeleza. Uninzi luhlala luncitshisiwe, kodwa ngokubanzi kuyimfuneko ukuze ugxile kumenzi womenzi (kukho iphakheji).

Ukulungiswa komda-Ukusebenza nge template

Ukulungisa umda webhodi eqhelekileyo kulula kwaye kukhawuleze ukubhabha, kodwa ukuba akunjalo, i-Milling Shoma Sum Gomes iya kujamelana nexesha elininzi. Zimbini iindlela: Ngaphandle kwetemplate kunye netemplate. Ukuba eli ngamava okuqala nge-milling myoy-kungcono ukusebenzisa itemplate. Xa kuqhutywa imiphetho yeebhodi, indawo ethe tye ayisebenzi, kwaye inokwenzeka ezimbini - kunye nefuthe ekuqaleni nasekupheleni kwenxalenye yokusika (kwifoto).

Ukuqhuma komda-yenza indawo egudileyo

Njengetemplate, unokusebenzisa ibhodi esele igqityiweyo okanye, umzekelo, umthetho wokwakha. Ubude betemplate kufuneka bukhulu kakhulu kunexesha lomsebenzi-kwi-5-6 radeters kwicala ngalinye. Oku kuya kunika ithuba lokuphepha i "VAKA" UKUSETYENZISWA "KWI-DEVST kwi-Ekuqaleni nasekupheleni. Inqaku elinye elibalulekileyo: Indiza ethe tyaba (i-perpendicular ukuya kwi-on oding) kufuneka igudile. Ngayiphi na imeko, i-curvature yayo ayifanele ibe mkhulu kunomsantsa phakathi kwengqungquthela kunye nenxalenye yokusika, kungenjalo umsiki uya kuchukumisa iipateni, kubangela ukungasebenzi kakuhle kuya kubonakala kwezinye iikopi.

Ukuba ububanzi bendawo engasayiki imiphetho

Inxalenye yokusika i-Miles Mills kukho ubude obahlukeneyo, kodwa eyona nto inqumlayo, kokukhona kunzima ngakumbi ukusebenza-kuya kufuneka kusetyenziswe iinzame ezininzi ukubamba i-aggregate. Ke ngoko, kulula ukuqala nomsikisi ophakathi. I-oda yokulungisa umphetho nge-mill (nge template) yile:

- Itemplate ifakiwe ukuze isebenze indawo efunwayo-ibuyisela umgama owufunayo emphethweni.

- I-propierce nge template inokuqhotyoshelwa ngokukhuselekileyo etafileni okanye nawuphi na umphezulu othe tyaba.

- Faka i-mill kunye ne-roller kwindawo ephakathi. Ibonisiwe ukuze i-roller iqengqele kwipateni, kwaye inxenye yokusika yinkcukacha. Kule nto, isigayo sifakwe kwi-template engenanto netemplate, bafaka i-milling ekhutshiwe kwinethiwekhi, lungisa indawo ye-nozzle, ikhwele isikhundla se-nozzle, siyiqhekeza.

- Faka isigidi kwindawo yokusebenza - bayithoba ityala, i-clomp.

- Quka umatshini wokumila yeShumi, ubakhokele ngokwe template. Isantya sentshukumo sigqitywe bubunzulu bokuqhubekeka. Nonke niziva.

- Kwaye njani ukuqhuba igaya? Tsala okanye tyhala? Kuxhomekeka ekubeni umi phi. Ukuba i-risoet ye-Wordpiet-puseling, ukuba ngasekunene-kutsala. Ungahambahamba ekuhambeni kweetshipsi - kufuneka ibhabhe phambili.

Ngale nto, eneneni yonke into. Emva kokuba igqitywe isiqendu, vavanya iziphumo, susa amakhonkco.

Oku, ngendlela, iseyindlela yokuthatha ikota ecaleni komda womsebenzi okanye kwinxalenye ethile yalo. Ukususa ikota, bonisa icandelo lokusika ukuze ukuqhubekeka kobunzulu obunikiweyo.

Igcwalise ikota kwifanitshala

Itshintsha umsikisi kwi-curly (Gallop) kunye nokutshintsha itemplate okanye ukusebenzisa indawo yokumisa, ungawusebenzisa umzobo omde kwi-Odriecce (kwifoto engezantsi).

Umgaqo wokusebenza nge-Milling yencwadi

Ngokubanzi, ubuchwephesha obugayo bukhululekile kakhulu. Ngamanyathelo okuqala kwi-Woodring-Le yeyona ndlela "yokugcwalisa isandla", emva koko unokude uphakamise phesheya ngaphandle kwezikhokelo.

Umphetho ogudileyo ngaphandle kwesikhokelo ufuna amava

Ububanzi bungaphezulu kakhulu

Kuthekani ukuba ubukhulu bomsebenzi abuphelele kunenxalenye yokusika? Kule meko, umsebenzi womthi wokugaya isamasa uyaqhubeka:

- Susa itemplate, dlulisela umjikelo ofanayo kwakhona. Kule meko kuphela le template iya kuba yinxalenye yenkqubo yomsebenzi - i-In Eves iyakroba kuphela kwenxalenye yenxalenye. I-Milling Parrarange ukuze ukwazi ukuqhubekeka kangangoko kunokwenzeka. Ngamandla ukukushukumisela kuwe awuyivumeli ukuhamba komnini, kodwa inxenye isaya kuvela.

- Emva koko, sithatha enye i-nozzle - kunye nefuthe lasekupheleni, jika uqhubeke ukuze icandelo eligqityiweyo lingezantsi. Qinisa etafileni kunye ne-clamps. I-nozzle ene-roller esezantsi ifakiwe ukuze i-erline iqengqele ngaphezulu kwenxalenye ephathwayo. Yiyo loo nto, ukukopa ngokupheleleyo inxenye esele igqityiwe.

Iqela lokuqengqeleka ngaphezulu kwenxalenye ephathwayo, inqanaba lokusika icandelo lokuphumla

Ngoku umda uyenziwa ngokupheleleyo kwelinye icala. Ukuba kukho imfuneko-phinda-phinda neqela lesibini. Ngokubanzi, ukuze akwazi ukwenza umsebenzi ngomthi wokuthintela i-SUMIT, 'idrafti' ezimbalwa "ziya kufuneka. Khetha abo AKUFUNI UKUZIPHATHA NGOKUGQIBELA - KWI-PORES YOKUQALA ZOKUGQIBELA ZIYA KUFUNA, KUPHELA NINI.

Ukufumana umda oqiqayo kunye ne-curvilinear

Ukuba awufuni kwana, kodwa ijikelezwe okanye nayiphi na enye imilo yomphetho, kuya kufuneka ujonge imeko yomda okhoyo. Ukuba i-billlet ingaphezulu okanye incinci igudileyo, thatha indawo eyimfuneko yokuganga, uyifaka kwaye uqhubekeke umphezulu, njengoko kuchaziwe apha ngasentla. Ukuba umphezulu ujikeleze kakhulu, kuqala uhlengahlengiso kwimeko yesiqhelo, kwaye emva koko ugime.

Umphetho ojikelezileyo

Kuyimfuneko, kuba i-roller yezathuthutho iqengqele ngaphezulu kwaye ukuba kukho iimpazamo, ziya kutyunjelwa. Ke ngoko, yenza ngokungaguqukiyo - ihla, emva koko inike i-curvature.

Ukuba i-nudna ngokubanzi ingumphezulu we-curvilinear-iphethini inqunyulwe. Umzobo usetyenziswa kwi mpamaer ngobukhulu be-8-12 mm, kuqala ingagcwaliswa yi-electrolybiz, kuba umphetho uza kuzisa kurhulumente ogqibeleleyo ngomgca ofanelekileyo ngomgca ofanelekileyo ngumgca wokugaya.

Kwi-plywood Zoba umzobo ofunekayo

Kule meko, kuya kufuneka sisebenze ngegayo, kodwa ukuza kuthi ga ngoku ngaphandle kwetemplate. Xa umphezulu ogqibeleleyo, itemplate icwangciselwe umsebenzi wokusebenza kwaye ichazwe kwakhona ngaphezulu komsebenzi wokugaya incwadana yemithetho. Inqaku elinye kuphela: ukuba ufuna ukudubula kwezinye iindawo uya kufuna inani elikhulu lezinto, kungcono ukwenza ijigsaw, umzekelo. Ngaphandle koko, isikiti sokugaya siyakhawuleza.

Izifundo zeVidiyo yokuSebenza ngokugaya iMastersi

Xa ufaka iminyango, kuyafuneka ukusika ii-lops, indlela yokwenza ngoncedo lwegaya-kwividiyo elandelayo (kukho malunga nendlela yokwenza i-groove, phantsi kofakelo oluhle).

Uwenza njani umatshini wokumakazi wasekhaya ovela kwiisampulu ze-lamote (inokuba yi-plywood) kunye nendlela yokwenza unxibelelwano oluhlekisayo lweebhokisi (iitafile, umzekelo) - kwividiyo elandelayo

Umsebenzi owenziwa ngumgca we-Milling Woom Wood ubonisiwe kwividiyo elandelayo, kodwa ngesiNgesi. Nokuba awusazi isiNgesi, ungazisoli ngexesha, jonga. Imisebenzi emininzi iya kucaca.

Inqaku lesihloko: Ungayifaka njani i-Lams Lamps