Kumlo wombane wokufudumeza, i-ARC yombane isetyenzisiwe. Yenzeka phakathi kweenkcukacha kunye ne-electrode - isiseko esivela kwintsimbi esebenzayo (ngamanye amaxesha ukusuka kwintsimbi). Intsimbi inyuswe kubushushu be-ARC. Umda wokwenzakala kwindawo yendawo leyo ibizwa ngokuba yi-welded (i-welding) seam. Ngeentsimbi ezahlukeneyo kunye neentlobo ezahlukeneyo zezinto ezidityanisiweyo, ubuchwephesha be-welding, isikhundla se-electrode, isantya sentshukumo saso, i-AMLLLTIT itshintshiwe. Ukupheka njani umthungo, ukuze unxibelelwano alunakuthembeka, kodwa mhle, masithethe.

Iintlobo ze-wels kunye nonxibelelwano

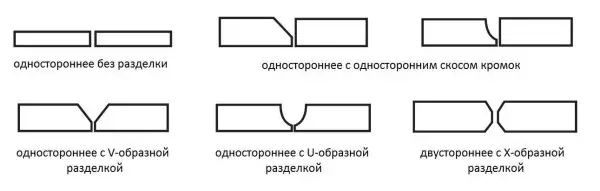

I-SEAMS inesiko elibanzi. Okokuqala, zahlulwe ngohlobo lokwenza. Kuxhomekeka kwiimfuno zokuthembeka, umthungo unokugqobhoza ngelinye okanye kumacala omabini. Ngomntu onamacala amabini, uyilo lufunyanwa ngokuthembekileyo kwaye lungcono lugcine ifom. Ukuba umntu omnye uhlala rhoqo ukuba imveliso iphoswe yi: Suture "i-transls." Ukuba kukho ezimbini zazo, la mandla ahlawulelwa.

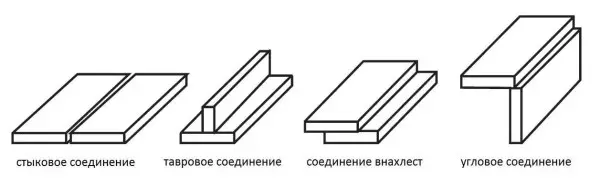

I-Weldid Seams ngokuxhomekeka kuhlobo lonxibelelwano kukho i-butt (kwi-Intanethi), uphawu, ibrawuza kunye ne-angular (ukusondeza kwimouse iphambili)

Ayinakuqaphela ukuba ukufumana i-Wight Cold Weld, intsimbi ayifanelanga ukuba ibe rusty. Ngenxa yokuba iindawo ze-welding zizinto zangaphambi kwexesha okanye ziphathwa ngefayile - de itshiphu inyamalala ngokupheleleyo. Okulandelayo, kuxhomekeke kwiimfuno, ngokungacwangciswanga okanye hayi emphethweni.

I-Butt Cound (Jam-Jack)

Umthungo kwi-welding isetyenziswa xa uqhagamshela i-Shinati yensiki okanye iityhubhu. Amalungu abekwe ukuze phakathi kwabo wayengumsantsa we-1-2 mm, ukuba kunokwenzeka, ilukhuni ilungisiwe ngamakhonkco. Kwinkqubo ye-welding, umsantsa uzaliswe yintsimbi etyhidiweyo.

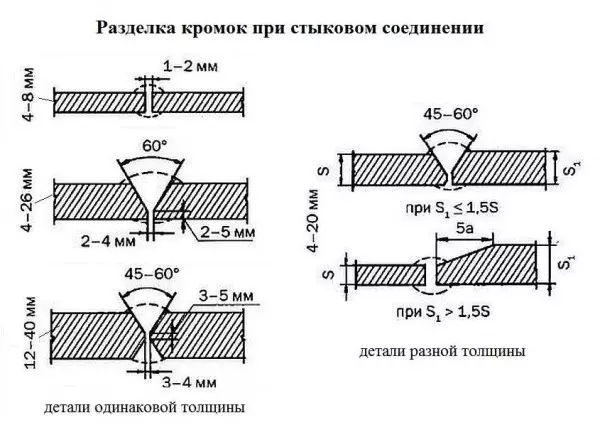

I-timp yesinyithi esincinci-ukuya kuthi ga kwi-4 mm ingu-4 mM Kule meko, ubilise kuphela kwelinye icala. Ngobukhulu beenxalenye ezi-4 mm, umthungo ungatshatanga okanye kabini, kodwa itywina lomphetho lifunwa ngenye yeendlela eziboniswe kwifoto.

Iindidi zokulungiselela iinxalenye xa i-welding

- Ngobukhulu benxalenye ukusuka kwi-4 mm ukuya kwi-12 mm, umthungo ungatshatanga. Emva koko imiphetho icociwe naziphi na zeendlela. Ilungele ubungqingqwa ukuya kwi-10 mm ukwenza amalungiselelo athile, kwaye amalungu amakhulu acociwe rhoqo ngendlela yeleta i-v. I-virper inzima kakhulu ekuphunyezweni, ke ngoko ixhaphake kakhulu. Ukuba iimfuno ezisemgangathweni ziphakanyisiwe, ngobungqingqwa obungaphezulu kwe-6 mm, kuyimfuneko ukuqaqanjelwa kumacala omabini kunye nomthungo ophindwe kabini kunye nakwelinye icala.

- Xa intsimbi ye-welding enobungqingqwa be-12 mm, umthungo ophindiweyo unyanzelekile, akunakwenzeka ukufudumeza ungqimba kwelinye icala. Ukuqhekeza imiphetho iphindwe kabini, ngendlela yeleta X. Sebenzisa kunye ne-v okanye imiphetho ye-v okanye i-U-I-U-I-U-I-U-I-U-I-U-I-U-I-I-DEED yemiphetho ayisebenzi: ukugcwalisa izihlandlo ezininzi isinyithi. Ngenxa yokuba ukuselwa kwe-electrodes kuyanda kwaye isantya se-welding sincitshisiwe kakhulu.

Ukusika imiphetho yentsimbi xa iqhagamshela iinkcukacha zeseti ye-intanethi (ukusondeza ubungakanani bomfanekiso, cofa kuyo i-ITUPE)

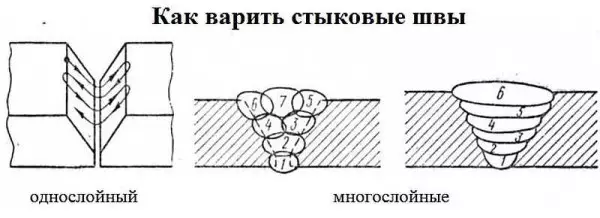

Ukuba iphinde icombulule isinyithi sobukhulu obukhulu bokupheka kunye nokusikwa kwicala elinye, ukuzalisa umthungo kuya kufuneka kubekho kwiindinyana ezininzi. Ii-Sds ezinjalo zibizwa ngokuba zii-Multi. Njengale meko, ukulungiswa komthungo kuboniswa kumzobo ongezantsi (amanani abonakaliswa ngokubeka imigca yentsimbi nge-welding).

Malunga ne-welding yamatshini ongaphakathi wensimbi we-welsting apha.

Ukupheka njani i-butt ye-fuim: Umaleko ongenamanzi kunye ne-andding of the (ukusondeza ubungakanani bomfanekiso, cofa kuyo imouse iphambili)

Unxibelelwano lweVangs

Olu hlobo lwekhonkco lusetyenziswa xa i-Welding Spect ngesinyithi esinobungqingqwa ukuya kwi-8 mm. Yibilise kumacala omabini, ukuze kungabikho mngcipheko phakathi kwamashiti kwaye kwakungekho lumololo.

Inqaku ngesihloko: Ungathini ikhonkrithi ye-Plam-Itekhnoloji yeTekhnoloji yokusebenzisa udonga lweendonga ze-Fom

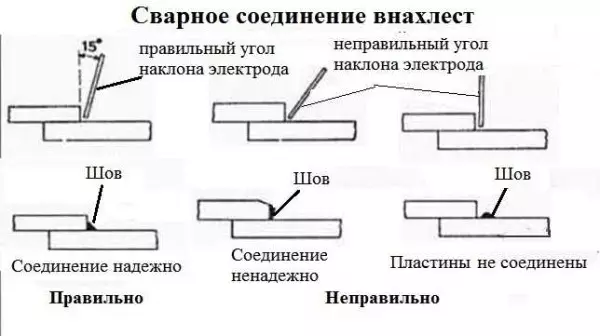

Xa usenza umthungo we-mudey, kufuneka ukhethe i-Englict Engle ngokuchanekileyo. Imele ukuba malunga ne-15-55 °. Emva koko iguqula unxibelelwano oluthembekileyo. Ngokuphambukisa kwicala elinye okanye kwelinye icala, isininzi sentsimbi ye-molten ayikho kwi-cunction, kodwa ecaleni, amandla onxibelelwano ancitshiswa kakhulu okanye amalungu ahlala enxulumene noko.

Ungayigcina kanjani i-electrode xa ifunxa i-mumeeche (ukonyusa ubungakanani bomfanekiso, cofa kuyo iMouse iphambili)

I-Taurus kunye nonxibelelwano lwe-angular

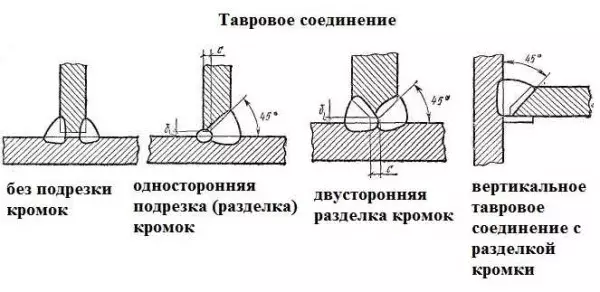

Unxibelelwano lwe-brand kwi-welding yincwadi ethi "T", kwiKomini - ileta "g". I-Brand Counds inokuba kunye nomthungo omnye okanye emibini. Imiphetho inokwahlukaniswa okanye hayi. Isidingo sokusika umphetho sixhomekeke kubungqingqwa bamacandelo edleleni kunye nenani lezitshixo:

- ubukhulu bensimbi ukuya kwi-4 mm, i-Seam ayitshatanga-ngaphandle kwempangelo lokungena;

- Ubukhulu obuvela kwi-4 mm ukuya kwi-8 mm-ngaphandle kokwenza imiphetho ye-Seam kabini;

- ukusuka kwi-4 mm ukuya kwi-12 mm - umthungo ongatshatanga ngokusika kwelinye icala;

- Ukusuka kwi-12 mm umphetho wokuchithelwa kumacala omabini, kwaye umthungo wenza ezimbini.

Iindidi ze-welds: iTaurope iqhinga ngokusika (ukunciphisa) imiphetho ngaphandle

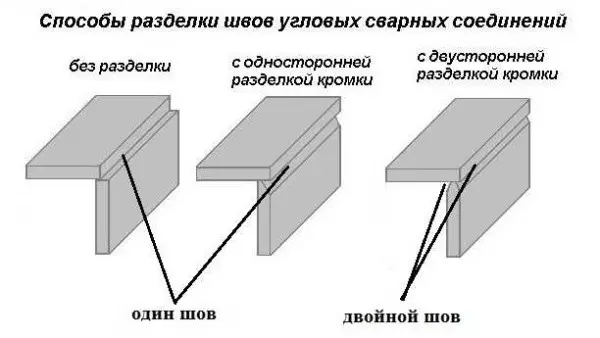

Iikona zekona zinokujongwa njengenxalenye yophawu. Iingcebiso apha zifana ngokuchanekileyo: isinyithi esincinci sinokubekwa i-welding ngaphandle kokusika imiphetho, ubukhulu obukhulu ekufuneka uthathe inxaxheba kumacala elinye okanye amabini.

Ungayilungiselela njani inyibilikhi ye-angcular uqhagamshelo (kunye ne-seams enye okanye ezimbini)

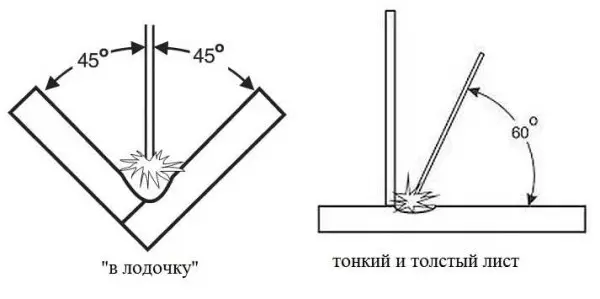

Ikona kunye nokudityaniswa kwe-brass ngamanye amaxesha kuya kufuneka kubilwe kumacala omabini (amathungo amabini). Ukwenzela ukupheka ngokuchanekileyo umthungo onjalo, amalungu ajikeleza ukuze iiplanethi zentsimbi zikwi-angle enye. Kwifoto, le ndlela isayinwe "esikhepheni". Kulula ukubala iintshukumo zombane, ngakumbi umntu omtsha nge-welding.

Ukupheka njani i-Seam: "esikhepheni" kwaye xa uqhagamshela i-metrials

Xa uqhagamshela intsimbi ecekeceke kwaye i-angle yotyekelo lwe-electrode kufuneka yahlukile - malunga ne-60 ° ukuya kwinxalenye engaphezulu. Ngalesi sikhundla, uninzi lwezinto ezifudumeleyo ziya kuba phezu kwayo, intsimbi emangalisayo ayitshisi, enokwenzeka ukuba i-angle yotyekelo lingama-45 °.

I-welding ye-SAMS

Xa ifunga i-Anglar Seams, kuyimfuneko ukubeka esweni isikhundla kunye nokuhamba kwe-electrode. Kuya kufuneka ube nomthungo nge-iyunifomu. Kulula ukuyisebenzisa le nto ukuba ubeka izinto zedysing "esikhepheni", kodwa oku akusoloko kufunyanwa.

Ukuba inqwelo moya esezantsi ithe tye, ihlala ifunyanwa ukuba kwindiza ethe nkqo, nakwikona yentsimbi, akwanele: iphantsi. Oku kuyenzeka ukuba ngaphezulu kwe-angle i-electrode incinci kunexesha lecala lecala layo. Ukuhamba kwencam ye-electrode kufuneka ibe yinto iyunifomu. Isizathu sesibini sikhulu kakhulu ububanzi be-electrode, engavumeli ukuba iwele ngaphantsi kwaye ifudumeze indawo yendibano.

Ukuthintela ukubonakala kwesiphene se-ARC kwi-Arc ethe tyaba (kwinqanaba "), ukuhambisa i-electrode kumphezulu othe nkqo, emva koko kwandule ukubuyiselwa endaweni. Xa i-electrode ingaphezulu kwe-cunction, inesithanga ezingama-45 °, njengoko ihamba iye phezulu, i-engile inciphisa (umfanekiso osemgceni, xa inyuka. Ngale ndlela, umthungo uza kuzaliswa ngokufanelekileyo.

Ikona ye-welding-isikhundla kunye nokuhamba kwe-electrode

Xa uvelisa unxibelelwano lwe-angular, ubeka iliso kwixesha lokufumana i-electrode kuwo onke amanqaku amathathu (emacaleni nakwiziko) okufanayo.

Malunga nokukhetha i-electrods zoomatshini abangena ngaphakathi, bafunda apha.

Isikhundla kwisithuba

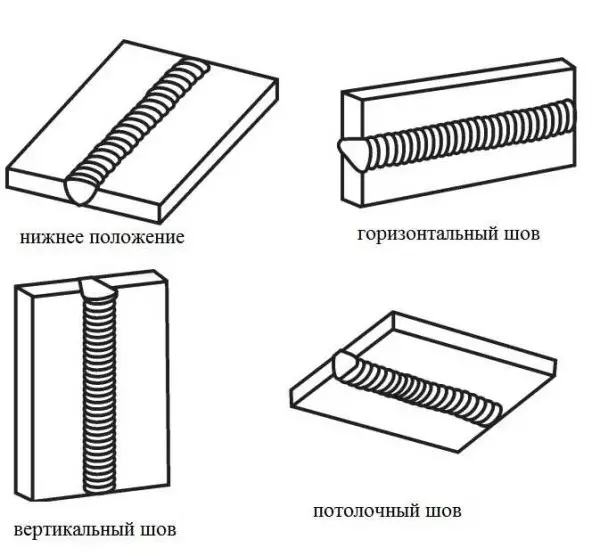

Ukongeza kwiindidi ezahlukeneyo zezinto ezihlanganisiweyo, imigqabi inokuthi ibekwe ngokwahlukileyo kwisithuba. Zikwisikhundla esisezantsi. Kuba i-welder yeyona ikhululekile. Kulula kakhulu ukulawula igumbi lokuhlamba. Zonke ezinye izikhundla zihamba ngokuthe tyaba, nkqo kunye ne-piams ye-phairy-funa ulwazi oluthile lweendlela ze-welding (malunga nendlela yokupheka iisesa ezingezantsi).

Inqaku ngesihloko: Indlela yokuhlamba ii-Alweminium

Iindidi ze-wels kwisikhundla esikwisithuba: nkqo the nkqo, phaling

Ungapheka njani ukutya

Xa unesikhundla esisezantsi, akukho bunzima kwenzeka na kwi-novice ye-novice. Kodwa onke amanye amalungiselelo afuna ulwazi lwetekhnoloji. Kwindawo nganye kukho izindululo. Indlela yokwenza i-Weld ye-WEDD yohlobo ngalunye ithathwa njengengezantsi.I-Welding Sears

Ngexesha lezinto zokugcina amalungu kwisikhundla esithe nkqo, isinyithi esivelayo phantsi kwesenzo somoya. Ukungaphumi, sebenzisa i-arc emfutshane (incam ye-electrode ikufuphi nokuhlamba kwe-weld). Ezinye ii-wish, ukuba i-electrode ivumile (ayinamathela), ngokubanzi basungulwa kwinto leyo.

Ukulungiswa kwensimbi (ukusikwa komda) kwenziwa ngokungqinelana nohlobo lonxibelelwano kunye nobungqingqwa bamacandelo edlelo. Emva koko bahlelwe kwindawo ebiyelwe kwangaphambili, baqhagamshelwe ukunyusa iisentimitha ezininzi ngemithi emifutshane ethe tyaba - "Prots". Ezi zixhobo aziniki iinkcukacha zokutshintshwa.

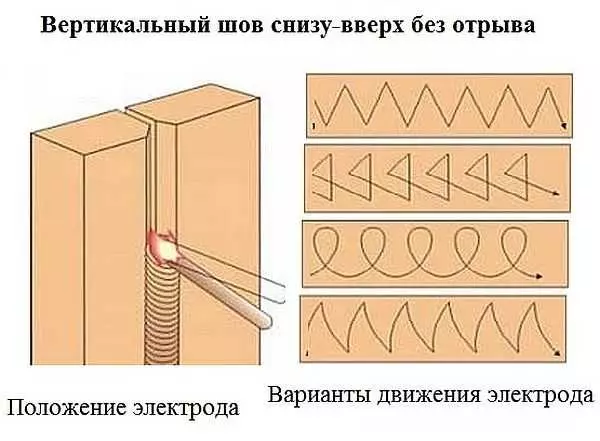

I-seams ethe nkqo inokuthi iphekwe ukusuka phezulu-phantsi okanye ezantsi. Ilungele ukusebenza ukusuka ezantsi-up ukusuka phezulu-up: Ke i-arc ityhala igumbi lokuhlamba i-weldid, lithintela ezantsi. Kulula ukwenza ithungo eliphezulu.

Ukupheka njani imithambo ethe nkqo ukusuka ngezantsi: isikhundla se-electrode kunye nokuhamba okunokwenzeka

Kule vidiyo, iboniswe indlela yokupheka ngokufanelekileyo umthungo othe nkqo wokuhamba kombane kunye nokuhamba kwe-electrode ukusuka ezantsi-phezulu ngaphandle kokwahlukana. Indlela emfutshane yeroller iyaboniswa. Kule meko, intshukumo ye-electrode yenzeka kuphela, ngaphandle kokususwa ngokuthe tyaba, umthungo ufumana phantse iflethi.

Yenza uqhagamshelo lwamalungu kwindawo ethe nkqo kunye nokwahlulahlula i-arc. Ukuze baqale abakhi bezilwanyana, kunokuba lula: ngexesha lokwahlula, isinyithi sinexesha lokuphola. Ngale ndlela, unokuchaza i-electrode kwishaldic yeWelvic. Kulula. Inkqubo yokuhamba iphantse yafana ngaphandle kokwahlukana: ukusuka kwicala ukuya kwelinye, i-lops okanye "iroller emfutshane" - ezantsi.

Ukupheka njani umthungo othe nkqo ngomsimelelo, jonga ividiyo elandelayo. Kwi-tutorial efanayo, isiphumo samandla akhoyo kwimo yoboya umthungo. Ngokubanzi, okwangoku kufuneka ibe se-5-10 engalunganga ecetyiswayo kolu hlobo lwe-electrode kunye nentsimbi. Kodwa, njengoko kubonisiwe kwividiyo, ayisoloko inobulungisa kwaye imiselwe ukuzama.

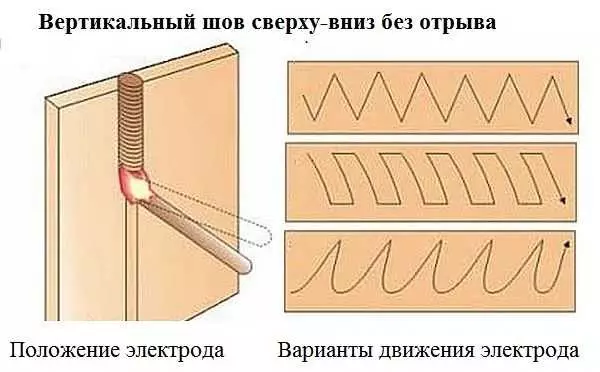

Ngamanye amaxesha umthungo othe nkqo ubilisiwe. Kule meko, xa i-ARC ikhutshiwe, ibambe i-electrode kwi-Prempecular ukuya kumphezulu womphezulu. Emva kokukhutshwa kwesi sikhundla, krwada intsimbi, emva koko ithole i-electrode kwaye ibiliselwe kwesi sikhundla. I-welding ye-Willing ye-Seam ePhezulu ingaphezulu, ifuna ulawulo oluhle lokuhlamba lwedled, kodwa ngale ndlela unokufumana iziphumo ezilungileyo.

Ukupheka njani i-verical verical yombane onqumamileyo: isikhundla se-electrode kunye nokuhamba kwencam yakhe

Ukupheka njani umthungo othe tyaba

I-theam ethe tye kwindiza ethe nkqo inokuqhutywa zombini ukuya ngasekhohlo nasekhohlo ukuya ekunene. Akukho mahluko, ekulula kuye, ukupheka. Njengokuba xa uvelisa umthungo othe nkqo, igumbi lokuhlambela liya kulwa. Kuba i-angle yotyekelo lwe-eleclide lukhulu ngokwaneleyo. Kukhethwe kuxhomekeka kwisantya sentshukumo kunye neeparamitha ezikhoyo. Eyona nto iphambili kukuba ibhafu ihlala ikho.

I-Welding Sears: Indawo ye-electrode kunye nentshukumo

Ukuba intsimbi ihamba phantsi, yanda ngesantya sokuhamba, isinyithi esincinci sokushushu. Enye indlela yokwenza ukwahlulwa kwe-arc. Ngezi zithuba zimfutshane, iipholethi zensimbi kancinci kwaye azihambi. Unokunciphisa kwakhona amandla akhoyo. Kuphela kuwo onke la manqanaba afaka amanqanaba, kwaye ayingabo bonke ngaxeshanye.

Kwividiyo, iboniswe ngezantsi indlela yokulinganisa ngokufanelekileyo isinyithi kwindawo ethe tyaba. Inxalenye yesibini ye-roller malunga ne-Seams ethe nkqo.

Umthungo ojikelezayo

Olu hlobo uqhagamshelo lwe-weldan yeyona nto inzima. Ifuna i-mastery ephezulu kunye nolawulo oluhle lokuhlamba kwe-welding. Ukwenza lo mthungo, i-electrode ibambe kwii-angles ezifanelekileyo kwisilingi. I-ARC imfutshane, isantya sihlala sihleli. Yenza ikakhulu iintshukumo ezijikelezayo, ukwenziwa kweSemms.Ukuqhekeza i-Weamd Seams

Emva kokungena kumphezulu wensimbi, i-splashes ye-SPLAS, i-rop yensimbi kunye ne-slag ihleli. Ithumbo ngokwalo lihlala likhohlakele, lixhaphake ngaphezulu komphezulu. Zonke ezi ntsilelo zinokupheliswa: yicoca.

Inqaku ngesihloko: Iimpawu zokulungisa amaplanga

Ukuqulunqa i-Seams emva kokwenza amanqanaba. Kwinqanaba lokuqala, ngoncedo lwe-chisel kunye ne-hammer inkqonkqozwe isikali kunye neslag ukusuka kumphezulu. Kwisibini, ukuba kukho imfuneko, thelekisa umthungo. Apha ufuna isixhobo: IBulgaria ixhotywe ngediski yokugaya yentsimbi. Kuxhomekeka ekubeni umphezulu ofanele ukusebenzisa ingqolowa eyahlukileyo.

Ngamanye amaxesha, xa i-welding ye-welding, udaka iyafuneka - ukuphindezela kwe-weld ngomaleko omncinci we-molten tin.

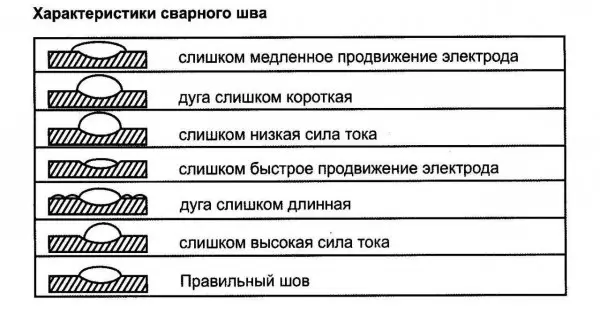

Iziphene zeSeamd Seams

Abaqalayo bahlala belders bahlala benzeka xa besenza imithangamsane kukho iimpazamo ezikhokelela ekubonakaleni kwesiphene. Abanye babo bagxeka, abanye - hayi. Ngayiphi na imeko, kubalulekile ukuba ukwazi ukufumanisa impazamo ukuyilungisa. Esona siphene esiqhelekileyo phakathi kwabaqalayo bububanzi obungalinganiyo kumthungo kunye nokuzaliswa okungalingani. Oku kungenxa yentshukumo engalinganiyo yencam ye-electrode, etshintsha isantya kunye nokuhamba kweentshukumo. Njengoko amava eqokelela, ezi zithintelo ziya kuba zincinci kwaye zingabonakali, emva kwethuba zinyamalala.

Ezinye iimpazamo-xa ukhetha okwangoku kunye nobungakanani be-ARC-inokugqitywa ngendlela yomthungo. Ngamazwi, kunzima ukuzichaza, kulula ukubonisa. Ifoto engezantsi ibonisa ezona ziphene ziphambili zokulinganisa-ukugcwalisa, izizathu zokubangele ukuba zimiselwe.

Iimpazamo ezinokuthi zenzeke xa i-welding

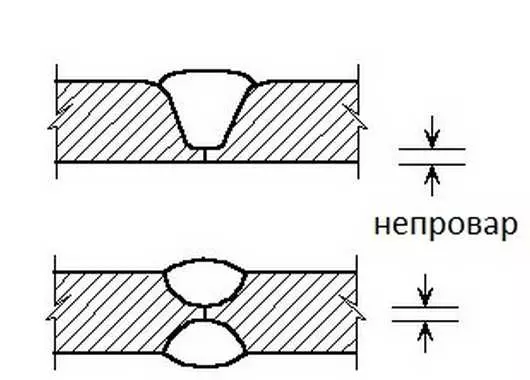

Ukuntywila

Enye yeempazamo eziqala ukuqalisa abaqalayo: Ungaze

Esi siphene sinengxaki yokuzalisa ngokupheleleyo iinkcukacha. Lo mzobo ubuyinge kufuneka uhlengahlengiswe, njengoko ichaphazela amandla onxibelelwano. Izizathu eziphambili:

- ilokhwe engonelanga yangoku;

- isantya esiphezulu;

- Ukulungiswa komda ongonelanga (xa i-welding metals).

Ukupheliswa ngokuhlengahlengisa okwangoku kwaye kuncitshiswe ubude be-ARC. Ukuhambelana ngokuchanekileyo nawo onke amapharamitha, susa into enjalo.

Ngokukhetha umatshini we-ining wilter welding yekhaya kunye ne-cottiges ifundwe apha.

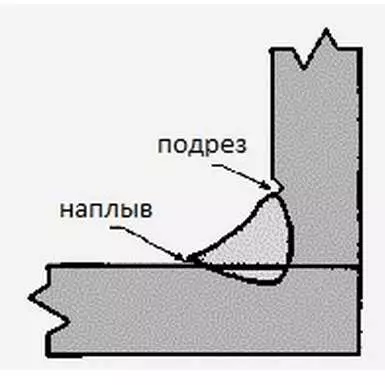

Iplarita

Esi siphene sisiphoso ecaleni komthungo kwisinyithi. Ihlala ivela nge-ARC elide. Umthungo ubanzi, ubushushu be-Arc yokufudumeza akwanele. Isinyithi esijikeleze imiphetho ekhawulezayo sikhawuleza, siyenza le mmandla iGrooves. "Iphathwa" nge-ARC emfutshane okanye uhlengahlengiso lwangoku lwabaninzi.

Kwikona yekona

Nge-angular okanye i-friend computer, i-suble-dension yenziwa ngenxa yokuba i-electrode ibhekiswe kwindiza ethe nkqo. Emva koko intsimbi ihamba phantsi, i-groove yadalwa kwakhona, kodwa ngenxa yesinye isizathu: Ukufudumeza okuqinileyo kwenxalenye yomthungo. Isuswe kukuncipha kwendlela yangoku kunye / okanye ye-ARC imveliso.

Burner

Lo ngumngxunya kwi-shul. Izizathu eziphambili:

- Ulwazelelelo lwe-welding ophezulu;

- isantya esaneleyo;

- I-giap enkulu kakhulu phakathi kwemiphetho.

Oku kujongeka ngathi ngumthungo womlilo xa u-welding

Iindlela zokuLungiswa zicacile - sizama ukukhetha imodi ye-WORL ye-WORL kunye nesantya se-electrode.

I-pores kunye neflow

I-pores ijongeka njengemingxunya emincinci enokuthi idityaniswe kwi-chain okanye isasazeke kuwo wonke umphandle womthungo. Zisisiphene esingamkelekanga, ngokunciphisa kakhulu amandla equla.

I-pores ivele:

- Ngokukhuseleka okwaneleyo kokuhlamba kwe-weldided kunye nexabiso eligqithisileyo leegesi ezikhuselayo (i-elektroniki);

- Idrafti kwindawo ye-welding, ethambisa iigesi zokukhusela kunye neoksijini ziwela kwinyithi etyhidiweyo;

- Phambi kongcoliseko kunye nokungcola kwentsimbi;

- Ukusika i-phedges engonelanga.

I-Slops ivele xa i-welding i-wioyili ejijekileyo ngeemodyuli ezikhethwe ngokuchanekileyo kunye neeparamitha ze-welding. Ziyintsimbi ezibekiweyo ezingakhange zidityaniswe kwinxalenye ephambili.

Iziphene ezisisiseko zeSwitzed Swiss

Ukubanda kwaye kushushu

I-cracks eshushu ivela kwinkqubo yentsimbi epholileyo. Ingabhekiswa kuwo okanye ngaphaya komthungo. Ukubanda kuvela kwi-Seam ebandayo kwiimeko apho umthwalo wolu hlobo lolu hlobo lomthungo uphezulu kakhulu. Ukuqhekeka okubandayo kukhokelela ekutshatyalalisweni komdibaniso we-weldided. Ezi zithintelo ziphathwa kuphela ngokutsha. Ukuba zininzi iimpazamo, umthungo unqunyulwe kwaye ugqithise.

Ukuqhekeka okubandayo kukhokelela ekutshatyalalisweni kwemveliso

Indlela ye-interter ye-welding ichazwe apha.