I-speeti yentsimbi emnandi yingxaki nangona ezinye ii-welders ezinamava. Abaqalayo kwi-wels banzima. Akukho kuyo yonke loo mithetho xa i-welding i-welding iimveliso: Zininzi izinto kunye nobunzima ngenxa yoko kunzima ukukhetha iindlela kunye nee-electroni. Kulula ukwenza oku nge-welding semiling semi-ngokuzenzekelayo, kodwa ikwimihla ngemihla yobomi bemihla ngemihla - yinto enqabileyo, i-anthers ixhaphake kakhulu. Leyo malunga ne-wellting ye-interter yensimbi kwaye iya kuxutyushwa.

Kwaye ubunzima bokuqala kwi-welding yentsimbi yobunzima obukhulu kukuba akunakwenzeka ukuba ubushushu kwaye akunakwenzeka: kuyatshiswa, imingxunya yenziwa. Ke ngoko, basebenza ngokomgaqo "ngokukhawuleza, ongcono" kunye nayiphi na into eyenziwayo i-trajector yentshukumo ye-elecrodes ayikho ngokubanzi. Isinyithi sesinyithi esincinci sibilisiwe ngokwenza i-electrode kwicala elinye - ecaleni komthungo ngaphandle kokuphambuka.

Xa i-welding sheet i-stiles yentsimbi yentsimbi kwaye igobe

Ubunzima besibini kukuba kubalulekile ukuba usebenze kwimijikelezo emincinci, kwaye oku kukhokelela kwinto yokuba i-ArC imelwe kukwenza mfutshane. Ngokuthintelwa okungenakuthelekiswa nanto, uyaphuma nje. Iingxaki zinokuvela kunye ne-ARC, kuba zisebenzisa izixhobo ngohlobo olufanelekileyo lwevolt-Ampere (i-IDling voltage ngaphezulu kwe-70 v) kunye nohlengahlengiso olugudileyo lwangoku, oluqala ukusuka kwi-10 A.

Enye ingxaki: Ngomnqweno onamandla, utshintsho kwijometri yejometri yeshiti lutshintshiwe: batyhafile ngamaza. Ukusuka koku kungaphulukana nobunzima. Olona khetho luza kuzama ukungakhathali okanye ukuthabatha ubushushu (malunga nendlela enobushushu i-swink teet funda ngezantsi).

Xa ucoca i-jack yamashiti amancinci entsimbi, imiphetho yabo inyangwa ngononophelo kwaye icocekile. Ubukho bongcoliseko kunye nobuqhetseba buya kwenza ukuba kube nzima kakhulu. Ke ngoko, lungenisa ngokupheleleyo kwaye uyicoce. Banamaphepha asondele kakhulu kwelinye-ngaphandle komsantsa. Iinkcukacha zilungisiwe ziikhonkco, iikhonkco kunye nezinye izixhobo. Emva koko iinkcukacha zibamba yonke imithi emifutshane ye-7-10 cm-pats. Abayi kuvumela iinkcukacha ukuba zitshintshe kwaye amathuba abo amancinci aya kubaleka.

Inqaku ngesihloko: Indlela yokwenza i-iron esithengisa ngezandla zakho

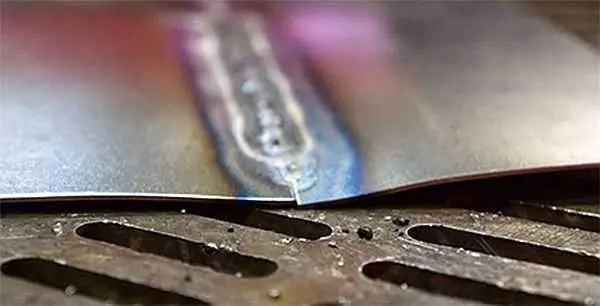

Ukuba icocekile kakuhle imiphetho, inokucima umthungo olungileyo

Ukupheka njani i-inverter yensimbi

Oomatshini bokwenzela i-welding, abasaseleyo ngoku okuhle kuba sinokupheka ekubuyiselweni. Ukwenza oku, qhagamshela intambo kunye nomnini we-electrode, kwaye "-" ubambelele kwinxalenye. Ngonxibelelwano olunjalo, i-electrode igrisi, kwaye isinyithi sifudume kancinci.

Ungayikhetha njani i-Inverter ye-Welding ekhaya okanye i-cotties ifundwe apha.

Ukupheka kuyimfuneko ukusebenzisa i-electrodes e-Encrodes: ukusuka kwi-1.5 mm ukuya kwi-2 mm. Kwangelo xesha, kuya kufuneka ukhethe ngokulinganayo okunyibilikayo: Ke ngee-shots ezincinci, kuya kuba ngumgangatho ophezulu. I-OWFE incinci incinci. Kwi-electros ngobukhulu be-1.5 mm, kufanele ukuba ibe malunga ne-30-5 ye-Amps, kwi "ezimbini" - ezingama-40-60 AMPS. Ngenene ubeke ngamanye amaxesha ngezantsi: Kubalulekile ukuba usebenze.

| Ubukhulu bensimbi, mm | I-0.5 mm | I-1.0 mm | I-1.5 mm | I-2.0 mm | I-2 mm |

|---|---|---|---|---|---|

| Ububanzi be-electrode, mm | I-1.0 mm | I-1.6 mm - 2 mm | I-2 mm | I-2.0 mm - 2.5 mm | I-3 mm |

| Amandla akhoyo | I-10-20 Amperes | Ama-30-35 Amper | I-35-45 mm | I-50-65 mm | I-65-100 mm |

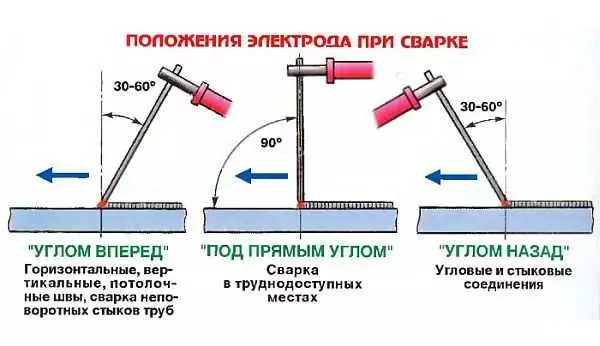

Ukuze intsimbi ifudunyele, iinkcukacha zifakwe nkqo okanye ubuncinci ikhondo elithobekileyo. Emva koko ibilise ngaphezulu, ushukumisa incam ye-electrode ngokungqongqo kolu lwalathiso (ngaphandle kokuphangaza kwaye ungabuyi. I-angle yotyekelo yi-engile phambili, ngelixa ixabiso layo lingama-30-40 °. Ke ukufudumeza kwesinyithi kuya kuba mncinci, kwaye oku kukwizinyithi ezixineneyo ze-welding - enye yeyona misebenzi ibalulekileyo.

Izikhundla ze-electrode ngexesha le-welding kunye nokusetyenziswa kwazo

Ingcebiso ngokubanzi malunga nokukhetha i-electrones zentsimbi ezixineneyo: Thenga i-elektroniki ingenelele kumsebenzi onjalo. Kuya kubakho iingxaki ezimbalwa ngamanye amaxesha.

Malunga nokwenziwa kwebhanti kwisakhelo sensimbi efundwa apha.

Iindlela zobuchule kunye neendlela zokuphuhlisa amashiti anqabileyo beentsimbi

Ngamanye amaxesha amashiti amancinci kufuneka abe ne-waled kwi-engile. Kule meko, kufanelekile ukusebenzisa indlela yokusombulula: imiphetho yephepha iyaliwe kwi-angle enqwenelekayo, iqinile nge-theams emfutshane eguqukayo kwi-5-10 cm.

Ividiyo ibonisa indlela yokupheka i-nyibi yeshithi elicekeceke kunye ne-electrode nge-ining therter. Indlela yokufaka i-flapp isetyenziselwa: imiphetho yamalungu ayaliwe, emva koko inamathele kumthungo omfutshane kwiindawo ezininzi. Emva kokuba kukho i-welding ene-electrode ecekeceke ngobukhulu be-2 mm.

Inqaku lesihloko: amakhethini kwelinye icala lekhitshi kunye negumbi lokulala - isisombululo esifanelekileyo

Akusoloko kunokwenzeka xa i-welding ngaphandle kokwahlukana ukunqanda umthwalo. Emva koko unokuzama ukutshitshisa i-arc kangangemizuzwana embalwa, emva koko ushiye i-electrode kwindawo enye kwaye uyikhuphe kangangeemilimitha ezimbalwa. Ke, ukuncama kunye nokubuyisa i-ARC, kwaye upheke. Ngale ndlela, kuyavela ukuba isinyithi ngexesha lokwahlula i-ARC sinexesha lokuphola. Kwividiyo uyakubona ukuba umbala wendawo ye-wellting Indawo emva kokuba isusiwe i-electrode. Into ephambili ayizukunika isinyithi ukuphola kakhulu.

I-welding yentsimbi ecekeceke iboniswa kwinxalenye yokuqala yevidiyo. Indlela yokude ye-Ismeeche (inxalenye enye iyagqobhoza okwesibini nge-1-3 cm), i-electrode ne-rutile yokuhamba (yezakhiwo kunye ne-steels yesakhiwo kunye ne-steels kunye nesakhiwo esisezantsi. Ke i-welding yentsimbi engenasimo ibonakaliswa yi-electrode engaqhelekanga kunye neqela eliphambili, kwaye ekupheleni kombane ofanayo ukusuka kwintsimbi engenasimo, ukudibana kwentsimbi enesitayile esihle. I-Seam, ngasendleleni, yajika ilunge ngakumbi kunangaphambili xa usebenzisa i-electrodes.

Ukukhetha i-electros ye-Ining Anthenter, funda apha.

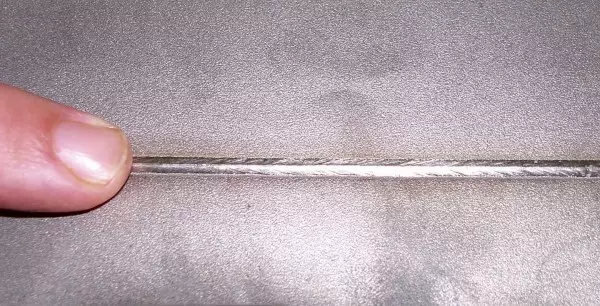

Ukuba ngexesha lokuphela kwentsimbi elungileyo akudingi ukudalwa komthungo oqhubekayo, sebenzisa iSeams yenqaku. Ngale ndlela yokuvelisa ubungakanani obukhulu be-tepi bakumgama omfutshane kufutshane nelinye. Le ndlela ibizwa ngokuba yi-DEAM PERMIT.

Ijongeka ngathi ngumthubi wokuntywila kwisinyithi esincinci

Ngokubanzi, ubilise i-iron ye-welding i-celing inzima. I-Vangst ilula: Iinkcukacha azithathi ntshukumo kwaye zingaphantsi kwamathuba okuba yonke into iya "kuziphatha."

Funda malunga neentlobo ze-wels kunye nonxibelelwano lokufunda apha.

Xa ulwelo lombane lwensimbi, i-jack inokwenziwa phakathi kwamashiti ocingo olucekeceke nge-2,5-3.5 mm (ungayikhupha ukuthuthuzela kwi-electros eyonakeleyo kwaye uzisebenzise). Ibekwe kwindawo yokuba bujongene nayo ukuba buhambe ngomphezulu wensimbi, kunye ne-phantse engasebenziyo phantse i-seameter. Xa i-welding i-ArC ikhokelela kule wire. Kuthatha umthwalo ophambili we-thermal, kwaye amashiti entsimbi ye-Wolds ashushu ashushu ngamaxesha aphezulu. Kwangelo xesha, abagqithisi, abavuni, umthungo iflethi, ngaphandle kwemiqondiso yokugxeka. Emva kokususa ucingo, kunzima ukuqwalasela umkhondo woko wayekhona.

Inqaku lesihloko: Ukufakwa kweplastiki ePlasi yeplastikhi kwi-phaliry ngezandla zakho

Ke ijongeka ngathi ngumthungo xa uvelisa i-jack yensimbi ecekeceke nge-wire ye-thermal

Enye indlela kukubeka iipleyiti zobhedu phantsi komdibaniso. Ubhedu lunengxaki enkulu kakhulu - amaxesha ama-7-8 aphezulu kuneso sensimbi. Ibekwe phantsi kwe-welding. Kuthatha inxenye ebalulekileyo yobushushu, ungavumeli ukugcwala kwentsimbi. Le ndlela yokufumana izinyithi ezixineneyo ibizwa ngokuba "ngamashushu e-frings."

Ukupheka njani i-gazebo ukusuka kwinsimbi. Funda apha. Mhlawumbi uya kuba nomdla wokufunda indlela yokwenza uphawu oluvela kwi-cylinds yegesi okanye isinyithi? Into iyimfuneko kwaye kuphuhliso lwe-welding al.

Welding galvanovka

Intsimbi ye-Galvanited yishiti elilinganayo, ligutyungelwe kuphela ngomaleko we-zinc. Ukuba ufuna ukupheka, kuya kufuneka ususe oku ukuthuka kwimiphetho ye-welding, ukucoca intsimbi. Zininzi iindlela. Eyokuqala kukususa ubuchwephesha: isangqa kwi-rasive kwi-grinder okanye yokugaya, i-sandpaper kunye nentsimbi evuthayo. Kusekho indlela-tshisa i-welding. Kule meko, upasa kabini i-electrode idlule ecaleni komthungo. Kwangelo xesha linye kukho ukuthuma kwe-zinc (iphuma kwi-900 ° C), kwaye izibini zayo zinetyhefu kakhulu. Ke ungachitha le misebenzi nokuba usesitratweni, okanye ukuba kukho i-hood emsebenzini. Emva kokuba idlule nganye, kuya kufuneka udubule phantsi.

I-welding ye-welding ilunge ngakumbi ukwenza ngaphandle ngaphandle: Ukuphuma kwe-ZINC kuyingozi kakhulu

Emva kokususwa ngokupheleleyo kwe-zinc, indalo iyaqala. Xa imibhobho ye-welding ye-GARANS yokufumana umthungo olungileyo, kuya kubakho iindinyana ezimbini kunye ne-electros ezahlukeneyo. Umthungo wokuqala ubilisiwe nge-rutile oahlelos e-electrode, umzekelo, i-MP-3, ANO-4, OGC-4. Kwangelo xesha, i-oscillations ine-ampling encinci kakhulu. I-Seam ephezulu-ejongene nokwenza. Imalunga nelingane nabakwiidayimitha ezintathu ze-electrode. Kubalulekile ukuba ungangxami kwaye uzame ukuphendula kakuhle. Esi sicatshulwa sisetyenziswa ngama-elektrods ngokudibana okuphambili (umzekelo, MODI-13/55, MOI-13/45, DSC-50).

Funda ngakumbi malunga nokukhetha i-electrones ze-Inurester Apha.