Ukuphakanyiswa kwezakheko kweyona ndlela iyo eyomileyo yeyona ndlela ithandwayo yesixhobo esimiselweyo sezinto ezinqunyanyisiweyo, izahlulo, ii-arches kunye nezinye izinto ezivela kwezi zinto.

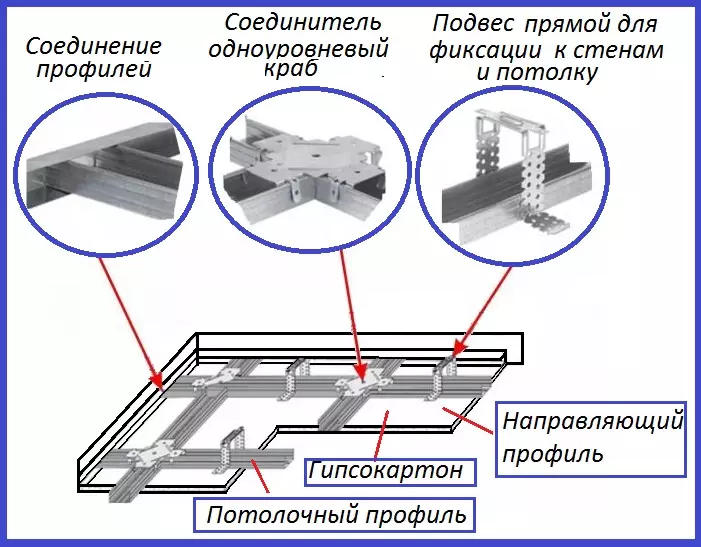

Iskimu sensimbi yensimbi ye-plasterard cleard.

Ukuba itekhnoloji yomsebenzi kunye ne-GLC iyaqondakala kwaye iyakhutshwa, ngezandla zabo unokwenza yonke into ekwaziyo ukuyifumana kwakhona igumbi.

Kodwa eyona nto ibaluleke kakhulu-ifunda ukuba yenze isakhelo se-Plasterboard. Sisiseko salo naluphi na uyilo, ke iimfuno ezizodwa zibonakalisiwe kumiselo.

Izixhobo kunye nezixhobo ezisetyenziselwa isikhokelo

- Iprofayile yentsimbi:

- Iprofayile yesikhokelo. Imelwe yimveliso ye-PN28 / 27. Isetyenziswe njengenxalenye ephethe i-rack kunye neeprofayili zephangi kumgca ofanayo.

- Iprofayile yoCeliling PP 60/27. Isetyenziselwa ukuphakamisa iiracks ezithe nkqo kunye nezothe nkqo, ii-jumpers ezahlukeneyo kunye neenxalenye zoyilo ezivavanyiweyo.

- Iprofayile yoLwimi. Ngaphaya kobude bonke bemveliso kwicandelo eliphakathi kukho i-grooves ekhethekileyo eyenzelwe ukwenza izikrikhi ngexesha lofakelo ekulula kakhulu ukulungisa. Ingasetyenziselwa iintlobo ngeentlobo zeeracks, i-jumpers kunye neenxalenye ezigobileyo.

- Ukunqunyanyiswa ngokuthe tye okanye ukufutshane. Kucacile ukuba yenzelwe ukulungisa iiracks zeprofayili yazo zentsimbi ezindongeni kunye nophahla.

- Isinxibelelanisi senqanaba elinye. Yenzelwe ukonakalisa i-node kwiindawo ezihamba ngee-angles ezifanelekileyo zeprofayili.

- Izinxibelelanisi ezahlukeneyo zeprofayili eyilelwe ukuba ijoyine amacandelo alo.

- Ukumiswa kwentwasahlobo. Kuya kuthatha ukuba xa unyusa uphahla olunqunyanyisiweyo, uyilo luya kucelwa ukuba luthobe ngaphezulu kokusetyenziswa komiso.

- Izikrelemnqa ozingcayo kwi-SMM yensimbi 3.5 / 51, ezona ntlobo zimbini: zibukhali kwaye zisiphelo ngendlela ye-drill.

- Imivalo yomthi.

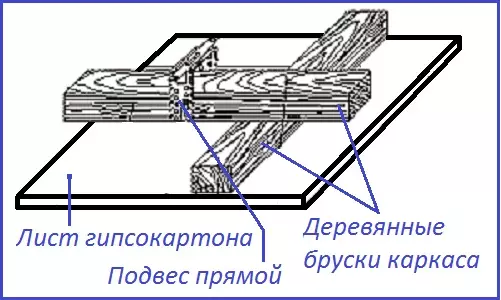

Inkqubo yefreyimu yokuyila iplastiki ukusuka kwimivalo yomthi.

Ngaphambili, i-plasterboard yaxhonywa kwiifreyimu zokhuni. Ngokuqala kweprofayili yentsimbi, imfuneko yokusetyenziswa kwemivalo inyamalala ngenxa yenzuzo engahlelwanga yentsimbi:

- Inkqubo-sikhokelo yentlawulo ayikho ngokujikeleza;

- Ayizukwenzakalisa iingxowa zenkuni;

- Ayifumani mtyumbo kwaye ayiphelelwanga ngenxa yoku;

- Iiracks zentsimbi aziyi kusilela, musa ukuqhekeza, awuyi kukutywina ngexesha kunye nezakhono zesini;

- Iprofayili ngamaxesha amaninzi ngaphezulu komthi oqinileyo, ophantsi kwaye unenqanaba elincinci kakhulu.

Ke ngoko, ukunyuka izandla zakho isakhelo sekwwwnikhithi okwenziwe ngamaplanga kuyavakala ukuba unebhar eyomileyo eyaneleyo, engenakwenzeka eyenzekileyo. Kwelo bar, okwintengiso yasimahla, akunyanzelekanga ukubala: ikwisininzi samatyala, kunyibilika kwaye kunomswakama omkhulu. Ukuba isakhelo seso sixhobo sifakwe, kungekudala siya kuba sekupheleni, njengoko umthi uqalisa ukomisa kwaye ugobe.

Izixhobo zokuphakama kwefreyimu.

Izixhobo eziya kufuneka ngexesha lomsebenzi:

- I-perforator okanye i-drick drill.

- I-screwUtor screwdriver.

- Amanqanaba: amanzi, ulwakhiwo, i-laser.

- IRoulette, iMakishe, ipensile, isikwere.

- Isitshetshe sokusika esomileyo.

- Isikere sensimbi okanye i-bulgaria enediski encinci yentsimbi.

- Ukuba kuthathwa isigqibo sokwenza isakhelo esivela kwi-bar, uya kufuna isaw kunye ne-electrolybiz.

Inqaku lesihloko: Ungayigubungela njani umgangatho kwigaraji evela kwikhonkrithi

Itekhnoloji yokuphakama kwenkuni ye-plasterboard

Olu kuyilo lulula ukulwenza ngokwakho. Kodwa unokwenza lo msebenzi ngeendlela ezimbini: uthambile kwaye unzima.

Iskimu sesixhobo sesakhelo somthi sokwahlulahlula i-plasterboard.

Indlela yokunyuka enzima:

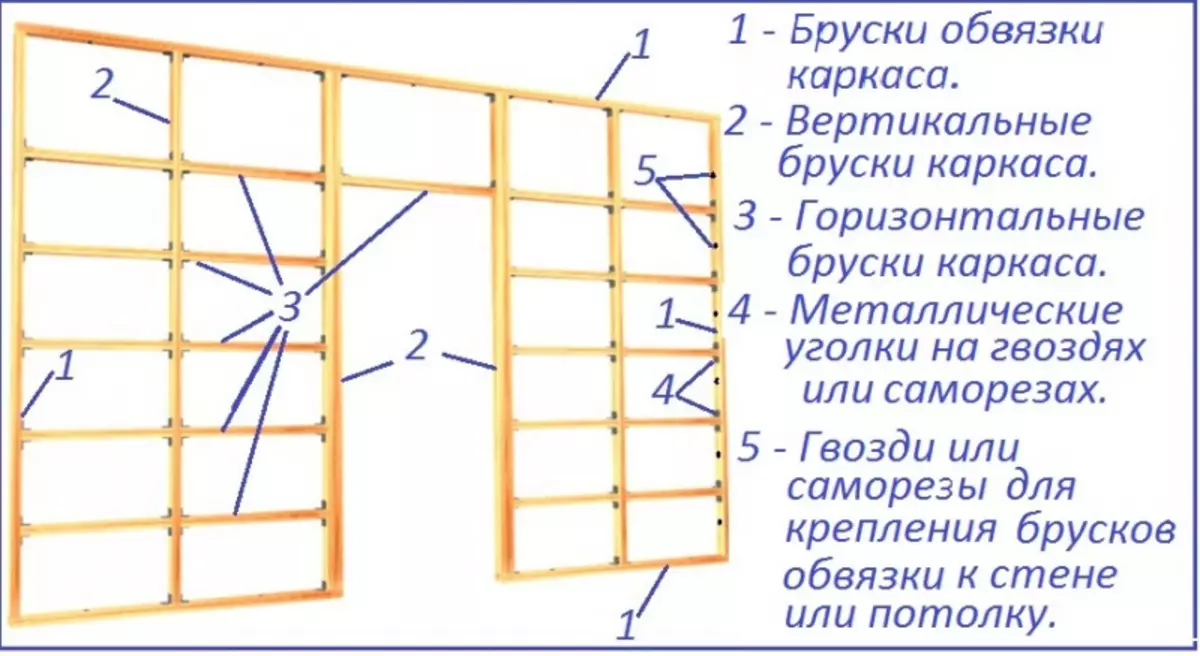

- Le yeyona ndlela yakudala nelula, apho unokukhumbula ngokufanelekileyo isakhelo somthi. Imisebenzi iqala ngokumakisha. Ukuba isakhelo siyadingeka isilingi, emva koko ngeendonga usebenzisa inqanaba lamanzi kunye nentambo yokupeyinta kunye nentambo ethe tyaba. Emva koko, isilizi sitsalwa kwimigca apho amaplanga aya kuqhotyoshelwa khona. Inyathelo phakathi kwabo yi-40-60 cm. Ukuba isakhelo kufuneka sibekwe eludongeni, emva koko kukhangelwa okufanayo.

- Siqala ukwenza i-trapy ngezandla zakho: Amaptimbe anyuka kwi-compaur yomphezulu, ekufuneka ibonwe yi-plasterboard. Ukuba isixhobo esisigxina esisigxina sicwangcisiwe, i-track ifakwe kwindawo yodonga lodonga. Ukuba isahlulelo sakhiwe okanye udonga luhambelana, ke imivalo kufuneka iqhotyoshelwe kuyo yonke imilinganiselo ye-GLC ye-GLC.

- Ukulandelelana kwezi nkonzo kulandelayo: Kusebude bonke imivalo kwinyathelo le-30-40 cm imingxunya yomiswe, enkulu kunezipikili esiya kwenza iindonga eziphawulayo. Imitya yamaplanga isetyenziswa eludongeni kunye nesikhonkwane kunye nesikhonkwane sifumana iithegi. Ezi ndawo zikhutshiwe kwaye iplastiki zeplastiki 40/60 okanye i-40/40 ifakwe kwimingxunya, okanye i-ctroppers eqhelekileyo. Ngenxa yoko, siya kwenza isandla sakho izandla.

- Phakathi komtya wolula umgca okanye umsonto, oya kusebenza njengendawo yokubonisa ireferensi yokufakelwa kweeracks ezithe nkqo okanye ezithe nkqo.

- Ngendlela efanayo, njengakwimeko yokutsala, sifaka ngokuchanekileyo iplanga elifunayo.

Itekhnoloji "yokufakelwa" ngokufakelwa kwesakhelo somthi:

- Umahluko ophambili wale ndlela yokuhlangabezana nesakhelo esivela kwi-bar ukuze usebenzise ukumiswa ngokuthe ngqo: "P" -ibakaki ezisebenza ngemveliso yensimbi. Ngenxa yabo, isantya sokufakelwa kwezakhiwo esonyuka kakhulu.

- Ukunqunyanyiswa kuqhotyoshelwe ecaleni kwemigca ye-palack ye-racks enenyathelo le-40-50 cm.

- Amaqhekeza aqhotyoshelwe kubo ngoncedo lwezikrelemnqa ezifanelekileyo.

- Itekhnoloji yokufaka isakhelo iyafana nokudibanisa iimveliso zensimbi.

Ungazenzela indlela ekwinkqubo yokufikelela kwi-Pondocpril kwindonga okanye phapha

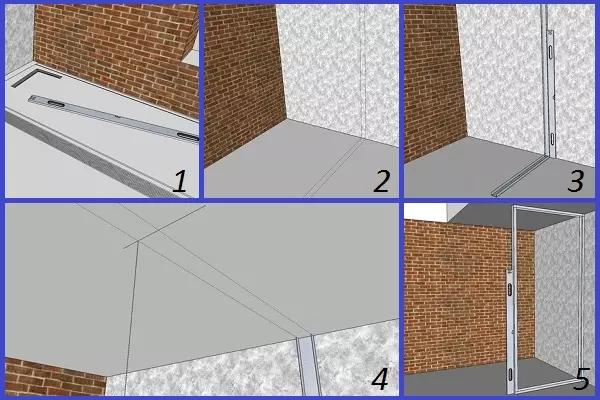

Isakheko sokumakisha kwi-Plasterboard Yilo: 1 - Lungisa ipensile, umlawuli kunye nenqanaba; 2-Sebenzisa inqanaba kunye nepensile kufuneka lwenziwe ngokumakisha kwiiprofayili ezibonakalayo; I-3-Iprofayile isebenza kwi-markup kwaye ikhuphe iprofayile phantsi komgangatho kunye nodonga; 4 - Ukumakisha indawo yokuncamathisela iprofayili, sisebenzisa isitshixo; I-5-Qokelela isakhelo kwaye uyikhangele kunye nenqanaba.

Ukumakisha

Ukugqibezela kwakhona eli nqanaba libalulekileyo lomsebenzi, kufuneka uqonde izinto ezimbini: ukuba ifowuni yezahlulo ze-interher, uNiche, ukulungelelaniswa kweendonga, uphawu luqala kumgangatho. Kukho imigca apho iiprofayili ze-PN 28/27 ziya kuqhotyoshelwa. Kufuneka balingane ngokungqongqo, kwaye umgama phakathi kwabo kufuneka ulingane nobungqindilili bokwahlula okanye ukufunyanwa kudonga olusekwe.

Inqaku ngesihloko: Iindlela kunye nokukhethwa kweekhathini ezintle zenziwe ngokwakho

Inqanaba lesibini

Ifanelekileyo yokudlulisela ukumakisha kumgangatho ukuya kwisilingi. Apha uyakufuna isakhiwo sokwakha. Ngayo, senza iprojektha eyimfuneko yokuphuculwa: Kukho amanqaku aliqela kwisilingi, edityanisiweyo kwimigca eqinileyo. Emva koko, ukubala indawo iiracks ezithe nkqo ngomsebenzi odongeni, kwaye ethe tyaba - ngenxa yesilingi. Iiracks zepitch-40-60 cm. Kule migca, senza amanqaku esiya kwenza isondo. Umgama phakathi kwabo yi-40-50 cm.

Faka iProfayile ye-PN 28/26

Ukuba wenza ngezandla zakho izilonda ezinqunyanyisiweyo zesonga, emva koko iprofayile ikhuselekile ezindongeni ezindongeni. Bafuna ukuphakama kwenqanaba lokuqala lokwakha. Kufuneka ihlolwe ukuba uphawu lusetyenziswa ngokuchanekileyo, nokuba luyahambelana nendawo ethe tyaba. Ukuba sinxibe udonga, ke izikhokelo zikhuselekile kwimigca emgangathweni kunye nophahla.

Faka i-rack okanye iprofayile yophahla

Isikere sentsimbi sifaka i-rack yobude obufunayo. Kumanqaku ophawu lokumiswa, imingxunya ye-Drill phantsi kwedowel okanye i-anchors. Ukuba isakhelo sibekwe entlungwini yokumiswa, ke akukho tyala lingekafakwanga iidosi zeplastiki zokwenza ufakelo olukhawulezileyo. Inyani yile yokuba imizobo yowomileyo iphakamileyo kwaye ngokuhamba kwexesha, izikrikhi ezivela kwiplastiki ziphuma kwaye i-phals iphela. Iiracks ezilungisiweyo ezivela kwiprofayile yesilili okanye iprofayile yeRack ifakwe kwikhokheli kwaye ilungiswe kwizikrelemnqa ze-SMM 3.5 / 51. Amacala asecaleni ("i-mumele") agoba kumphezulu osisiseko.

Itekhnoloji yentsimbi yentsimbi yentsimbi yeFomu

Itekhnoloji yentsimbi yentsimbi ye-curly izinto: 1 Isikere sensimbi senza yonke i-CM; 2 -Yisebenzisa emgceni, siqala ukuyibeka ngenyameko kwisikhundla esinqwenelekayo kunye nesikrelemnqa; I-3-i-glk eyomileyo eguqukayo ngokusika kokuncitshiswa kwexesha elide; 4 -Cwangcisa i-glc kwisakhelo.

Okokuqala kufuneka ufunde ukuba ungayifumana njani iprofayile ngokuchanekileyo. Ukwenza oku, ezindongeni, phala okanye ezomileyo, kufuneka uzobe umgca wejika. Senza isikere sentsimbi qho nge-5 cm. Amandla kwiindonga ezisecaleni ze-PP 60/7. Ukuyisebenzisa emgceni, siqala ngokulumkela ngobulumko kwisikhundla esifunekayo.

Kwizinto ezincancisayo: Ii-arches kunye neenxalenye ezahlukeneyo ezigonjisiweyo kufuneka zifunde ukuba zenze njani i-Platestalboard. Oku kuyakwenza ngezandla zakho kuYilo oluphezulu. Kule misebenzi, iphepha le-GLC kufuneka libe nobungqingqwa obungaphezulu kwe-6 mm.

I-Plestalboard eguqukayo. Kwelinye icala, senza inani elifunekayo leendawo ezingekhoyo, malunga nesinye kwisithathu sobukhulu bezinto ezibonakalayo kumgama phakathi kwamanqaku 1.5-2 cm. Sebenzisa isiponji okanye ibrashi ethambileyo, imanzi umphezulu weshithi. Siphinda inkqubo de ukufuma kuphele i-gypsum. Sibeka i-GLC kwiphethini elungiselelwe kwangaphambili kwaye siyilungise. Emva kweeyure ezili-12 ukuya kwengama-20, i-plasterboard iya kuthatha isimo esifunayo kwaye some.

I-GLC eyomileyo ye-GLC. Le ndlela ifuna ukhathalelo kunye nokuchaneka. Kwelinye icala leshiti, ukusikwa kwe-ixesha elide kwenziwa, kubunzulu kwikhadibhodi ngasemva kwe-GLC. Le miso inyibilika. Oko kukuthi, ngesitshetshe esibukhali, i-chamfer isuswa, i-angle enqunyulweyo exhomekeke kuthi ga ngoku i-Deameter ifunelwe ekwenzeni inxalenye yenxalenye oyifunayo. Ibanzi kwaye inzulu i-Groove, kokuthathwa ngakumbi kwaye igorha iya kuphola. Emva koko, i-Plasterboard iqhotyoshelwe kwitemplate, kwaye i-roooses ezisikiweyo icocwe uthuli kwaye isuswe.

Inqaku ngesihloko: Iingcamango zedefur ye-veranda yelizwe kunye ne-terrace kwaye zinokuxhotyiswa (iifoto ezingama-31)

Itekhnoloji yokufikelela kwi-ART

Okokuqala, ephepheni owomileyo, sitsalela ukugoba ngokwayo, siphawula ukuphakama kwayo nobubanzi be-canvas esecaleni. ELizwini, zoba icala langaphambili le-arch esiyifunayo.

I-Eleclillzik i-cutsike le nto. Siyithwale esipilini kwelinye iphepha le-plasterboard. Ke, sifumana iinkcukacha ezimbini zokuvula.

Kwiindonga okanye ekuvulekeni kwangaphakathi senza uphawu.

Kwimigca yophawu, qinisa iprofayili yesikhokelo.

Okokuqala, i-insultise ibekwe kwi-intermedio, ukuba iyimfuneko.

Ngeenkcukacha zabantsundu ezomileyo, imigca eliqela ibekwe ngokuthe tye: kwicala le-ARC. Babonisa iindawo zeeracks eziqinileyo. Sibeka iprofayili ye-PP 60/27 kwi-Skick kwaye inqunyulwe kwimigca yokutshixa yobude obufunayo. Ibalulekile: Amazantsi eeprofayili kufuneka ajikelezwe ngokwe-ARC.

Iiracks ezithe nkqo faka izikhokelo kunye nenkqubo ekhutshelwe.

I-roulette ilinganisa ubude be-Bend Arch kwaye ngokomlinganiso onqunyulweyo kwiprofayili ye-PP 60/7.

Sika kuzo zombini iziphelo qho kwi-5 cm. Ukusika i-rack ngetemplate. Qinisekisa kwisakhelo sokuzibopha.

Ngoku umgca wemisebenzi kwikhava ye-ARC Plasterboard.

Sinciphisa isakhelo sephepha le-glk

Akukho nto inzima kulo msebenzi. Okokuqala, i-insultise ibekwe kwi-intermedio, ukuba iyimfuneko. Emva koko i-trowall ikhuliswe isebenzisa izibonda kwi-GVL. Kuyimfuneko ukuyibeka kwisakhelo ngendlela yokuba i-voltage kwizinto ezenziweyo. Oku kunokufezekiswa ngeendlela ezimbini: ukulungisa amashiti, ukusukela phakathi kwaye ngokuthe ngcembe ukuya kwimiphetho. Okanye uqale ukufaka kwenye yeekona kwaye kwaye kwaye ulukhusele iphepha kumacala omabini.

Akunakwenzeka ukuba uhaduke amashiti omnye komnye. Kuyimfuneko ukushiya i-gap kwi-2-3 mm. Ukuba akukho chamders ejikeleze imiphetho, kufuneka yenziwe ngokusika phantsi komphetho kwikona esezantsi. Kwenzeka ukuba abantu abatshatileyo baya kukulibala ukwenza ngexesha, kodwa le meko ilungiswa. Kuya kuba yimfuneko ukwandisa izithuba phakathi kwamashiti e-HCL ukwandisa i-slot. Ekupheleni komsebenzi, umphezulu we-plasterboard kufuneka ususwe ngerag emanzi.

Ukubetha. Yenziwa ngokuthe ngqo kule njongo ngemixube: I-Rottert, iKnauf, uFegefühlor, njl njl. Kubalulekile ukuthoba zonke iindawo zokuzibopha izikrelemnqa. Imithi ende kunye ne-anglar igula sisiguli kwaye kuphela emva kokuba yenziwe ngumxube we-spasi. Emva kokomisa umphezulu, siqala ukusitshisa ngegridi ekhethekileyo kwaye sibambelele kuyo. Kodwa ungasebenzisa i-sandpaper entle.