Ii-radiators kunye nokulungiswa kwazo

Kwihlabathi lanamhlanje, i-radiators yenza umsebenzi wokufudumeza kunye nemisebenzi yokupholisa. Bakhupha amaza e-shirmal kwaye batshabalalisa ubushushu emoyeni. Izixhobo ezenziwe ngeentsimbi ezahlukeneyo kunye ne-alloys yazo. Amehlo e-radiators uhlala enetyala elinjengempazamo, eqala ukuyihamba. Oku kuqhekeke kupheliswe ngeendlela ezahlukeneyo, kokukhona kuya kuba yinto ethembekileyo kuyo kunye nokurhweba.

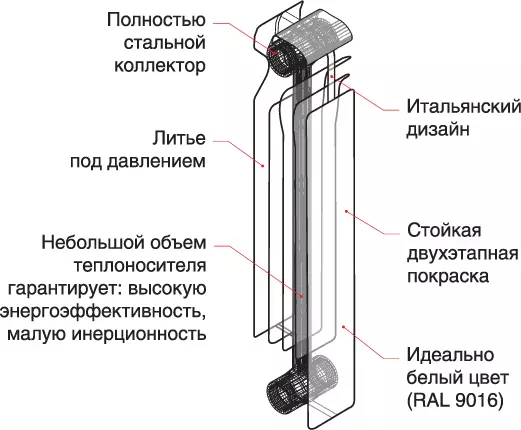

Isixhobo se-Alumumim radiator.

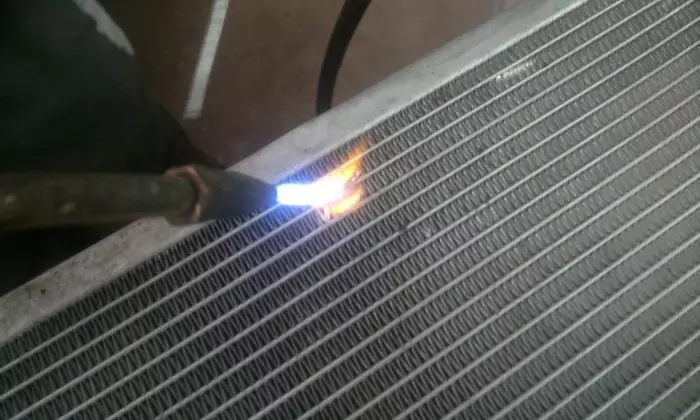

I-welding (i-argon) ifuna ubuchule, amava, izixhobo, ezisebenza kuphela kumaphepha aphezulu entsimbi, kwaye, ke, kunzima ukuyicebisa ngokulungisa i-radiator. Ngelixa ubuthengi (uqhagamshelo lwecandelo elifunayo kunye neThuthi) yinkqubo ekhoyo yokuphunyezwa. Oku kulungiswa kwezixhobo zobhedu kunye ne-aluminium kwenziwa kakuhle ziitekhnoloji esele zingqine.

Lungisa i-aluminium ye-aluminium radiator

Ukusetyenziswa kwe-radiator kunokwenzeka, umzekelo, ukupholisa iinjini zemoto, ukufudumeza kwikhabhathi emoyeni, ekufudumeleni izakhiwo kunye nenye indawo. Sebenzisa i-aluminium radiary rhoqo, njengoko ukuhanjiswa kobushushu e-Alumnum kuphezulu kwaye, ke, izixhobo zipholile ngokukhawuleza kwaye zishushu, ubunzima bazo zincinci.

I-Aluminiyam radiriator (ngokuchasene neemveliso zobhedu) Akulula ukugalela, kuba umphezulu wawo ukhawuleze kwaye ugutyungelwe yifilimu eyomeleleyo ethintelayo kwintsimbi.

Icandelo le-radiator.

Ngaphambi kokulungisa i-radiator, kufuneka ususe kwaye unciphise ulwelo, lowo lome kakuhle. Ukuthengiswa kwezixhobo ze-aluminium kufuneka ziveliswe, zinezixhobo:

- I-Ceramic ibe buhlungu;

- ifayile;

- i-sandpaper;

- Ukurhweba i-iron (ukusuka kwi-100 w).

Kunye nezixhobo:

- rosin;

- Umthengisi okhethekileyo (umzekelo, p150, p250, p300A);

- intsimbi yentsimbi (ebhedini);

Emva koko, senza imiyalelo ngokweenkcukacha.

- Silungiselela indawo yokuthengiswa, ukuyicoca ngesanti kodwa, ngaphandle kokukrola umphezulu.

- Sinyibilike kwi-rosin enqamlezileyo kwaye silungiselele umxube (iRosin 2 kunye ne-Wamdust 1 Icandelo), esiya kuyisebenzisa (emva kokupholisa) njenge-guble.

- Intsimbi ebandayo icocekile ifayile yetyuwa kwaye iguqukele kwinethiwekhi. Ngoku shemula indawo elungiswe, ngoncedo lwensimbi elithengisiweyo, lenza umxube waseRosin. Sisebenzisa iRosin kwindawo efudumeleyo, kwaye hayi kwi-iron ethengisa isinyithi, njengoko inokuthi iqale ukungcungcutheka (nge-315 ° C) kwaye iphulukane neepropathi ze-fulx.

- Umphezulu weLudim, uyihlikihla kwaye wenze intshukumo yesetyhula.

- Ukubona ukuba i-rosin isasazeka, siyaqhubeka nokuxhaphaza, ukongeza igram yeThuqu (i-tin-tin), apho intsimbi yentsimbi iqatshelwe, iyichola i-iron ethengisayo. Izibhengezo ze-Wandslills zicoca umphezulu kwifilimu ye-oxide, itshabalalise (emva koko i-tin yenza unxibelelwano ne-aluminium), kunye neRosin, ukukhusela i-oxidotion.

- Okulandelayo sithengise ubuqhetseba bomthengisi.

Inqaku ngesihloko: Ukubekwa kumgangatho wokufudumeza ngombane phantsi kwelemina kunye nethayile

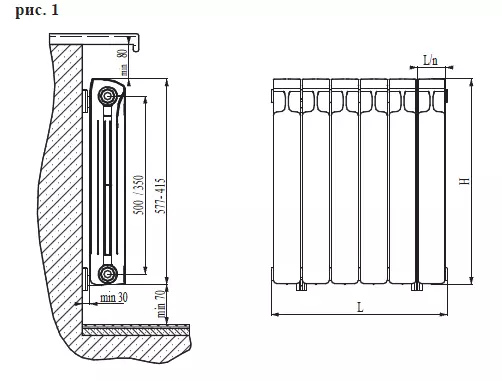

Umzobo we-diagonal wokudibanisa i-radiator.

Ngale ndlela, kunokwenzeka ukuba uvale i-rack encinci kwii-aluminiyar radiria, kodwa ukuba inkulu, umthungo omkhulu onamandla unokufunyanwa usebenzisa umxube we-tim nge-bism endaweni ye-bism. Ukupheka i-cowder: Sinyibilikisa kwi-biscable, yokuxuba, i-bismuth kunye ne-tin (5 kunye ne-55). Senza iiglasi: Greya ngokwahlukeneyo, emva koko uzixube, izithako ezinjalo:

- I-potassium chloride (i-56%);

- I-Ciltite (i-10%);

- I-chloride yeLithium (23%);

- I-6.5% yetyiwa ityiwa;

- I-Sodium sulphate (4%).

Inqanawa enomxube itshixiwe ngokuqinileyo, njengoko ikhawuleza ifunxa umswakama. Ngoku kufuneka ufake isithambeka sento yonke yesakhiwo sokusebenza, dumbisa umphezulu nge-iron esingekho mthethweni, kunye nomthengisi, ukongeza inxalenye yomthengi oza kuvala umngxunya.

Sisebenzisa olunye ukhetho lokurhweba

Indawo eyonakeleyo ngaphambi kokufaka impahla ethengiswayo inokuvalwa ngomaleko wobhedu. Lungiselela izixhobo:

- Ukurhweba intsimbi;

- i-sandpaper;

- Ibhetri.

Ubungakanani be-radiator ye-aluminium.

Izixhobo ziyafuneka:

- Isisombululo se-Copper Sulfate (Cuso4);

- ucingo lobhedu;

- i-flux;

- Ithembeko.

Benza ngolu hlobo:

- Icocwe kakuhle indawo ekufuneka ndiyifune.

- Emva koko wawukhuphela ngononophelo kuyo ngenyameko yemozulu (isisombululo) ukwenza "ukuhla" ezinkulu.

- I-pole engalunganga yebhetri iqhagamshelwe kwi-radiator (umzekelo, ukusuka kwipokothweni), kwaye isibonda sayo esihle siqhagamshelwe kwisiqwenga sobuqhetseba (1 MM

- Elinye icala locingo kufuneka liphindwe "ihla" loMphunga, kodwa hayi ukuchukumisa intsimbi. Kungekudala phantsi kwethontsi, kumphezulu we-radiator, umaleko omdaka uya kuvela ubhedu olubomvu, oluvela kwimozulu.

- Emva koko, umphezulu uhlanjwe kwaye womile, emva koko bavelisa i-tinesel kwi-iron ethengisayo kunye negosa eliqhelekileyo lisebenzisa igosa. Ngoku i-rack iya kuvalwa ngokukhuselekileyo, njengoko umthengisi ehamba kakuhle kwindawo yobhedu.

Isidingo sokulungisa i-radiator kwizinto zabo zinokubonakala ukuba olu hlobo lomsebenzi aluqhutywanga ngobungcali, ukuba isiphene sincinci, nakwisiganeko sentsilelo yexesha. Ukujikeleza i-aluminium radiator ngokuzimeleyo, ngaloo ndlela ufumane imveliso ehlaziyiweyo, yandisa ubomi bayo, yongeza imali ngokulungisa kunye nokuthengwa kwezixhobo ezitsha. Kukwabalulekile ukuba izakhono ezifunyenwe ngexesha lokulungiswa, ukunceda ukwenza umngeni wensimbi "ye" i-ron "enje, njenge-aluminium, inexabiso lokwenyani kwaye linokuba luncedo kwixesha elizayo.

Inqaku lesihloko: I-GIFA YOKUGCINWA KWEENKONZO ZESITHATHU ZESITHATHU