Abayili abaninzi basebenzisa udonga lwe-semicircular ye-plasterboard kwizifundo zabo zongenelelo ngaphakathi kwindlu. Umzobo 1. Ukuze uzenze ngokwakho, kuya kufuneka usebenze kancinci. Ukwenza lula inkqubo yokwenza i-septum enezandla zakho, ngaphambi kokuqala komsebenzi, kufuneka ukwazi ukuqhelana neengcebiso kunye nenkqubo yomsebenzi wokuvelisa, oya kuthi unikwe ngezantsi.

Udonga lwe-semicircular lukhangeleka lungaqhelekanga kwaye lunomdla, kunokwenzeka ukuba luyenze luphume.

Yintoni ekufuneka uyazi ukuba wenze udonga lwe-semicircular ye-plasterboard

Eyona nto iphambili ekudaleni nasekufakweni kuyilo olunje lubandakanyiwe koku kulandelayo:

Amanqaku odonga awenziwe yipensile usebenzisa intambo efana ne-comper.

- Ngamandla olwakhiwo, kuphela iprofayile yentsimbi kufuneka isetyenziswe.

- I-Plasterboard inamandla amanqamli asezantsi, ngenxa yoko imfuneko ukusebenzisa iitemplate ezikhethekileyo zokugoba.

- Ukuba udonga oluvaliweyo lune-radius encinci, emva koko ngaphambi kokufakelwa i-plasterboardboard kunyanzelekile ukuba imanzi-iya kwenza ukuba ikwazi ukugoba nangayiphi na i-angle.

- Kuyanqweneleka ukuba ukuphakama kodonga kukuhlihla, kulula ukuyicombulula.

Ukuba ayifikeleli, emva koko yokwandisa uzinzo kuya kuba yimfuneko yokufaka iiprofayili zentsimbi ukuze ikhusele i-semicircle ukusuka phezulu.

Itekhnoloji yemveliso yomsebenzi

Ilele kwezi zenzo zilandelayo:

Isiseko sezakhelo senziwe kwiprofayili ye-U, siyinqumle kwaye sigobe ububanzi obunqwenelekayo.

- Phantsi Zoba umgca apho udonga luya kwenziwa khona. Kule nto ufuna intambo kunye nemakishi (ipensile). Isiphelo esinye sentambo (indawo yokuqala yesalathiso icinezelwe phantsi, kwaye enye itsalwa ngobude obulinganayo noyilo lwexesha elizayo. Kule ndawo umphawu omakishi ulungisiwe kwaye, ukugcina intambo kwindawo yolwazi, chitha isemilcle phantsi.

- Kumsebenzi olandelayo, ufuna iprofayili kwiseti yokuseta. I-cuted ngesikere sensimbi. Kwiindidi ezininzi zeeprofayili ezinjalo kukho umvelisi wesikihlo, ukuze baqhubeke nenqanaba elifunayo.

- Into egqityiweyo kufuneka ilungiswe kumgangatho we-screws ende okanye i-stals yentsimbi.

- Ngoku kufuneka senze uqikelelo lwendawo yokuqala ukuya kwisilingi. Ukwenza oku, sebenzisa i-plub okanye i-rack egudileyo. Ukuphawula imarike efunyenwe ngokulungelelanisa, chitha kwisilingi ngentambo kunye nepensile (njengakwisiqendu sokuqala) semicrosoft.

- Ukufaka inkxaso ethe nkqo, olunye uhlobo lweprofayili yensimbi isetyenziselwa ukomelela, oko kukuthi, utshintsho lwalo lwe-C ekufuneka luqhagamshelwe kwi-U-Roby Screws ngokwaziwa phantsi. Ukuqinisekisa isikhundla esichanekileyo serack ethe nkqo, isikwere okanye isikwere sensimbi ngama-90 degrees.

- Lungiselela iprofayili ye-U-Celish, ulunqumle kwiindawo ezifanelekileyo. Idityaniswe ngezikrelemnqa kwi-rack ethe nkqo, kodwa ayigcinwanga kwisilingi, ukuyidibanisa isiphelo sesibini kumtshato wesibini. Ngokwesikimo esinjalo, kuyimfuneko ukudibanisa enye i-U-Rail embindini we-rack ethe nkqo.

- Umngxunya uyatywina kwiprofayile ye-semiconductor kwisilingi kwaye isukhwe nge-dolisowel yentsimbi.

- Sebenzisa iiprofayili ze-c-profiles, kuya kufuneka unyuse ii-racks ezithe nkqo. Inyathelo likhethiwe kuluhlu lwe-18-25 cm. Ziqhagamshelwe zizikrelemnqa kuzo zonke izilonda ze-UURE ezimile phantsi, ezimbilini nakwindlela yoyilo.

- Isakhelo esibangesiseko sisetyenziswa njengesiseko sokuqinisa amashiti ombane. Umsebenzi kufuneka wenziwe ngecala le-convex ye-semicircle. I-screws i-screws kufuneka iphakathi kwe-12-16 cm.

- Emva koko, amashiti anokuqulunqwe eludongeni oluvela ngaphakathi. Ukuba kukho imfuneko, ukuze ingaqokeleli ingxolo, emva koko phakathi kweengxolo zezinto onokuthi ulungiselele uboya bezimbiwa kwiiprofayili okanye nakweyiphi na enye i-abufunsi yesandi. Xa ufaka ngaphakathi, umsebenzi uqala ukusuka embindini wesemicircle kwimiphetho yayo.

- Zonke iindawo ezikrwada zinqunyulwe kwaye zisigqubuthele.

- Inxalenye yokuphela koyilo isondele yi-GCL imivimbo.

- Amalungu kwi-trim kufuneka afakwe isampuli yegridi ekhethekileyo.

- I-DOTTY yenziwa kuwo onke amalungu oyilo kwaye ifakiwe kwikona eqhotyoshelweyo. Emva koko, wonke umntu uhambelana ne-angular spatula. Umsebenzi ofanayo wenziwa phantsi kwesilingi, kwindibano. Ukuqulunqwa kwempahla kusetyenziswa kudonga olwenziwe, kwaye emva kokuba kutshiswe, yonke into ithethwe ngenenombolo ye-sandpaper.

- Inqanaba lokugqibela liyindawo yoyilo kunye nebala kwibala elifunayo.

Inqaku ngesihloko: Ukukhetha iveranda esitratweni. Sikhetha izixhobo ezifanelekileyo.

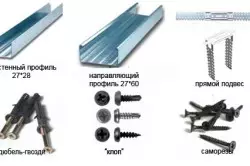

Izixhobo kunye nezixhobo ezisetyenzisiweyo

Iindidi zeprofayile ezifunekayo ukufaka isakhelo sodonga.

- Amaphepha e-glkl.

- Iiprofayili zentsimbi.

- Isikere kunye needosi.

- I-PATTY.

- Primer.

- Ipeyinti.

- I-Drill yombane.

- Isikere sentsimbi.

- I-Spatulas - Eqhelekileyo nekona.

- Roller okanye ibrashi.

- Ummesi wokwakha.

- Isando.

- Inqanaba le-plummb, inqanaba lokwakha.

- I-screwdriver.

- IRoulette, umlawuli, ipensile.

- Intambo kunye nemakisha.

Ukuveliswa kwezimeleyo koyilo lwe-semicircular ukusuka kwi-GLC Sheet- Umsebenzi usonjululwe ukuba uzifaka ngokuchanekileyo zonke ezi ngcebiso zingezantsi kunye neengcebiso kwaye ungabuyiseli kubuchwephesha bokuhlangabezana netekhnoloji yolo mbhalo.

Uyilo olwenziweyo luya kusebenza iminyaka emininzi.