Inzuzo ye-compleckan enjalo ukuqina kwayo noma ngaphandle kokusebenzisa imali eyengeziwe, njengokubenza ama-sealants, izimpawu zezimpawu noma izimboni noma izimboni. Ngekhompiyutha esongelayo, asikho isidingo sokuhamba ngensimbi kwikhreyithi, okungukuthi, azikho izimbobo eziku-canvases ezingaba ngumthombo wokukhulisa. Imisipha ngokwayo idlala indima yezimbambo eziyingqayizivele zokuqina, yandisa amandla ophahleni futhi ibone ukubukeka okuhle.

Uphahla lukhuni lube kanjani?

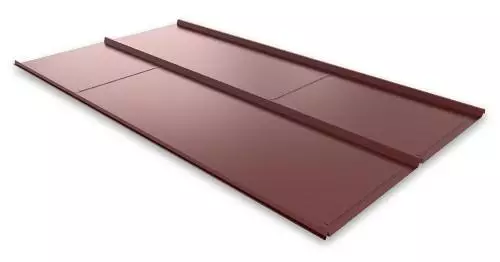

Uma ubheka uphahla olugoqiwe ohlangothini, kubonakala sengathi ama-canvas aqinile anamathele kwikhreyithi ngaso sonke isikhathi, okungukuthi, amalunga avundlile phakathi kwawo awabonakali. Ukuthola umphumela onjalo, kusetshenziswa amafolda asetshenziswayo. I-canvas exhunyiwe yakha isithombe. Phakathi kwawo, imidwebo ibekwe eceleni kwezinhlangothi ezinama-folds amile, okwakha izimbambo ezilukhuni. Ngokuqina, kusetshenziswa imishini ekhethekile ye-elektrolokhethi, yize ungabathwala futhi ngesandla ngosizo lwamabha okhuni nesando. Amafolda amanga ahlwitheke ngaphandle kwamathuluzi angeziwe. Ukugoqa okuphindwe kabili kubhekwa njengokuhlala isikhathi eside, okuthembekile futhi okubekwa uphawu. Yilo mthungo othandwa kakhulu lapho ufaka ophahleni lokugoqa phesheya.

Insimbi esetshenziselwa uphahla iguquguqukayo impela, evumela ukuthi isetshenziswe hhayi kuphela ku-pitched, kodwa futhi nasephahleni olune-conical noma lwe-arcuate. Ukuphakama kwesibaya kuvame ukuhlukahluka kusuka kuma-30 kuye kwangama-70 mm, kuya ngokuhlangana kwesiketi, ubukhulu bungu-5 mm.

Yikuphi insimbi esetshenziselwa uphahla lwensimbi?

Cabanga ngemininingwane eminingi ngezinto zophahla ezisongelayo. Okuvame kakhulu Khawunk - Ishidi lensimbi, lapho ungqimba oluvikelayo lwe-zinc lusetshenziswa khona zombili izinhlangothi. Phakathi kwezinzuzo zayo kunesisindo esiphansi, inani elingabizi, ukufakwa kalula, amandla okusebenzisa ophahleni lwamafomu alula. Okubi kuhlanganisa ukungasebenzi kahle kokuhlobana okuvikelayo, okwenziwe ngokuhamba kwesikhathi kuphela ngaphansi kwethonya lomswakama nokubhubhisa.

Isihloko ngesihloko: Izindwangu zendwangu emafasiteleni ngezandla zazo

I-polymer coating insimbi Kungasebenza isikhathi eside. I-Pural, i-polyester noma i-plastisol, ngalinye linesibopho sekhwalithi ethile yegazi lisetshenziswa njengezinto ezihlanganayo. Isibonelo, ngokuthembekile kuvikela i-Metal kusuka kumvula, umoya, amazinga okushisa wesikhathi sonyaka, i-polyester yenza ophahleni lucishe lube lungazwela ku-ultraviolet, kahle, i-plastisol inesibopho sokuzama. Lapho ukhetha ukunamathela, udinga ukunquma ukuthi iyiphi imfanelo ebonakalayo ebalulekile kuwe. Ngaphezu kwalokho, izimbangi ze-polymer zinikeza uphahla olubukeka ngokwengeziwe futhi lube nemibala ehlukahlukene.

I-Alucycline - Lokhu kuyinye indlela entsha yamashidi ensimbi enziwe nge-galvanized. I-Aluminium Alloy (55%), i-zinc (43.4%) ne-silicon (1.6%) isetshenziswa ebusweni bensimbi esikhundleni se-zinc. Ezimweni zayo zokuvikela, i-alloy enjalo ingcono kakhulu kune-zinc emsulwa, ukumelana kwayo ukugqwala kwandisa okungenani amahlandla ayisithupha, okudlula kakhulu impilo yenkonzo yophahla lonke. Ukuthola imibala ehlukene, i-aluzink ingambozwa ngaphezulu kwesendlalelo sama-polymers.

Ukuphunisa Kubhekwa njengomunye wethembeke kakhulu futhi muhle kakhulu. Ngophahla olunjalo, kusetshenziswa umhlanga we-alloy, equkethe ama-99.9% ethusi amsulwa. Ngenxa yeplastiki yayo ephezulu, i-zethusi ingasetshenziswa kunoma iyiphi indawo etholakala nanoma yiliphi ifomu, futhi yenza izinto ezahlukahlukene zokuphahla okuvela kuyo, njengeziketi, ama-drains, njll. Ukungcola Lapho ufaka okuncane, futhi ukulungisa akunzima kakhulu, ngoba ithusi lishintshiwe, futhi lingathengiswa nge-tin. Uma kungazelelwe, ukuqhekeka noma omunye umonakalo owenziwe ngophahla ophahleni olubekiwe, udinga ukusika eshidini ukuze ukhokhe osayizi abebekiwe kanye ne-weld noma umthengisi. Uphahla, olwenziwe ngethusi, lukwenza lula ukunakekelwa kwalo, ngokungafani nezinye izinto ezidinga izindleko ezithile ekusebenzeni kwalo. Ngokuhamba kwesikhathi, ingaphezulu lethusi liqala ukuba luhlaza ngenxa yokubonakala kwe-patina, enikeza uphahla luhlobo olubukhali lwe-antique lakudala. Abanye abathuthukisi, bafuna ukuthola umphumela onjalo ngokushesha, basebenzise izingoma ezikhethekile ezisheshisa ukubonakala kwe-patina.

Isihloko esihlokweni: Ukubuyekezwa kwephrofayili yomenzi

Phambilini, i-zinc yayisetshenziselwa ukugoqa ophahleni, kepha okwamanje kwanqunywa ukukwenqaba, ngoba bekungafaneleki kahle ophahleni lwamafomu ahlanganisiwe we-curvilinear. Esikhundleni se-zinc emsulwa, i-alloy yayo isetshenziswa ngezinto eziningi ezesalisayo: titanium, ithusi kanye ne-aluminium. Le alloy ibizwa Titan-zinc , D-zinc noma i-zinc eshintshiwe. Izakhi ngasinye sezinto ezihlanganayo zinikeza ama-alloy izimfanelo ezithile: i-aluminium ne-zethusi - i-plastiki, ne-titanium ukumelana nokuthuthukiswa kokukhulisa. I-Titan-Zinc, ukuba ne-coefficient ephakeme kakhulu yokwandiswa okuqondile, kuyazwela amaconsi okushisa ngesizini, okudingeka ukuwakhumbule, ukushiya izikhala zokushisa phakathi kwamashidi lapho kufakwa. I-Alloy, ukuxhumana ne-Iron noma izinto zethusi, kwakha ama-galvanic ngababili nabo, okugcwele ngokuvela nge-electrofosion endaweni yokuxhumana. Ukuze lokhu kungenzeki, kuyadingeka ukuhlukanisa izinto zensimbi noma zethusi, futhi lapho unamathisela kuphela ama-fasteners ensimbi nge-galvanized ebusweni. Njengesisekelo sophahla lwe-titanium zinc, kusetshenziswa isabiso esiqinile, futhi umthambeka wesiketi kufanele okungenani ube ngu-5%.

I-Aluminium Njengoba impahla yophahla inezinzuzo eziningi: ukumelana nemithelela yemvelo nokukhanya kwelanga, impilo yenkonzo ende, isisindo esiphansi kanye nokwethenjwa. Ithengiswa ngendlela yama-rolls. Kuhlanganiswe ngokuphelele ne-Metal Siding, esetshenziselwa ukusetshenziselwa umhlobiso wangaphandle wezindonga zendlu.

Ukwenza isiphetho kulokhu okungenhla, kungaphawulwa ukuthi izinto ngasinye ezifakwe kuhlu zilungele amacala athile. Ukukhetha kuncike ekubumbeni kophahla ophahleni, ukwakheka kwalo, izimo zokusebenza, kanye nezindleko zezinto zophahla. Ukuthenga kweshidi lokuthenga noma ufunde ngakho ngokuningiliziwe ngabamele abakhiqizi, kwiwebhusayithi yabo noma kumaphoyinti wokuqalisa.

Uphahla lwensimbi yedivayisi

Manje cabanga ngedivayisi yensimbi yophahla. Okokuqala udinga ukukhetha izinto zokwakha kanye nezinto ezidingekayo. Uyacelwa uqaphele ukuthi ubukhulu bamashidi ensimbi ama-solets nama-drain kufanele abe mkhulu kunobukhulu bamashidi ophahla oluphambili, ngoba bathola imithwalo esindayo. Ubukhulu bamashidi ajwayelekile bungama-5 mm, futhi amashidi ama-soles kanye nama-drains angama-6 mm.

Isihloko ngesihloko: Ukufakwa esikhundleni senqaba emnyango wensimbi

Uphahla lwensimbi lungafakwa ophahleni, umthambeka wesikhwanyana okungenani ama-degree ayi-10. Ikhekhe lokuphahla ngaphansi kwensimbi kufanele libe nesendlalelo sokufaka ngaphansi kwamanzi (ama-membrane we-membrane) kanye nezikhala zokuphefumula ukuze ama-condensate awaqongeleli endaweni yensimbi. Ngokuqondene nekhreyithi, kufanele iqine noma ivame kakhulu (Isinyathelo 250 mm) ukuze amashidi wensimbi angasindiswanga futhi angawonakali. Kusetshenziswa amakhreyithi wokhuni, kusetshenziswa izigaba zesiphambano se-50x50 mm.

Njengoba kushiwo ekuqaleni, amashidi wensimbi awabethelwanga izipikili ekhreyini, ngakho-ke ingaphezulu alinazo izimbobo. Zinamathele ku-crimeset ngosizo lwama-curmones, kanti ububanzi bemidwebo kufanele bube ngu-50-60 cm. Usayizi ojwayelekile weshidi uvame ukufakwa izingxenye ezimbili ngesikhafu noma i-guillotine (ayikwazi isetshenziswe). Amashidi asikiwe angathengwa ngasikhathi sinye, esizokonga isikhathi namandla lapho sifaka. Futhi amashidi anjalo ophahleni azoba nezikhiye ezibushelelezi nezicocekile zosayizi ajwayelekile, okunzima ukufeza ngesandla.

Amashidi aphumayo anobukhulu baka-0.5x2 m axhunyiwe ezithombeni eziseduze kwazo zonke izikebhe ngosizo lwamapholi amanga agobhozayo. Ama-Clammers asikwa ngokwahlukana namashidi afanayo. Ngokuyinhloko, yimichilo yensimbi enobukhulu be-50x150 mm. Ukukhwehlela okuqediwe kufakwe ekhreyithi ku-50 cm Perpendicular kuma-Shellboards. Izithombe ezikhuphuka ophahleni, ukhiye wazo ohlangothini uxhuma ngokuphela komshini we-beammer futhi ukhishwe nge-Double Stand Fold. Ungakhipha izingidi usebenzisa ama-fasteners kanye nezando ezimbili, noma imishini ekhethekile. Ngakho-ke, amashidi wensimbi anamathele kuhlaka naphakathi kwawo.