The finishing floor covering from water heating tile is usually suitable in the sanitary room of private houses and public buildings (hotels, saunas, pools).

The tile floor is an excellent heat transfer and a reliable barrier on the path of moisture penetration, therefore, in private householdings with water heating, the tiles are put in the kitchen, in the bathroom and toilet. Rarely put tiles on the floor in other rooms. In this article we will look at how the water floor should be arranged under the tile.

A gas boiler

Warm floors installed in private houses are connected to gas heating

For heating the water warm floor under the tile, an aggregate is needed, performing a constant supply of hot water into the system of pipelines heating the ceramic flooring.

Boilers are installed in houses located in places with the possibility of connecting to the central gas pipeline system and water supply. If you need to warm up a small area, then it is enough to install a wall-mounted unit of low power.

In most cases, powerful outdoor multi-mounted boilers are set. They cope with the heating of all residential premises, bathroom, toilet, kitchen and provide hot water to the internal wiring system.

The most common option is the installation of an outdoor multi-mounted boiler with atmospheric burners.

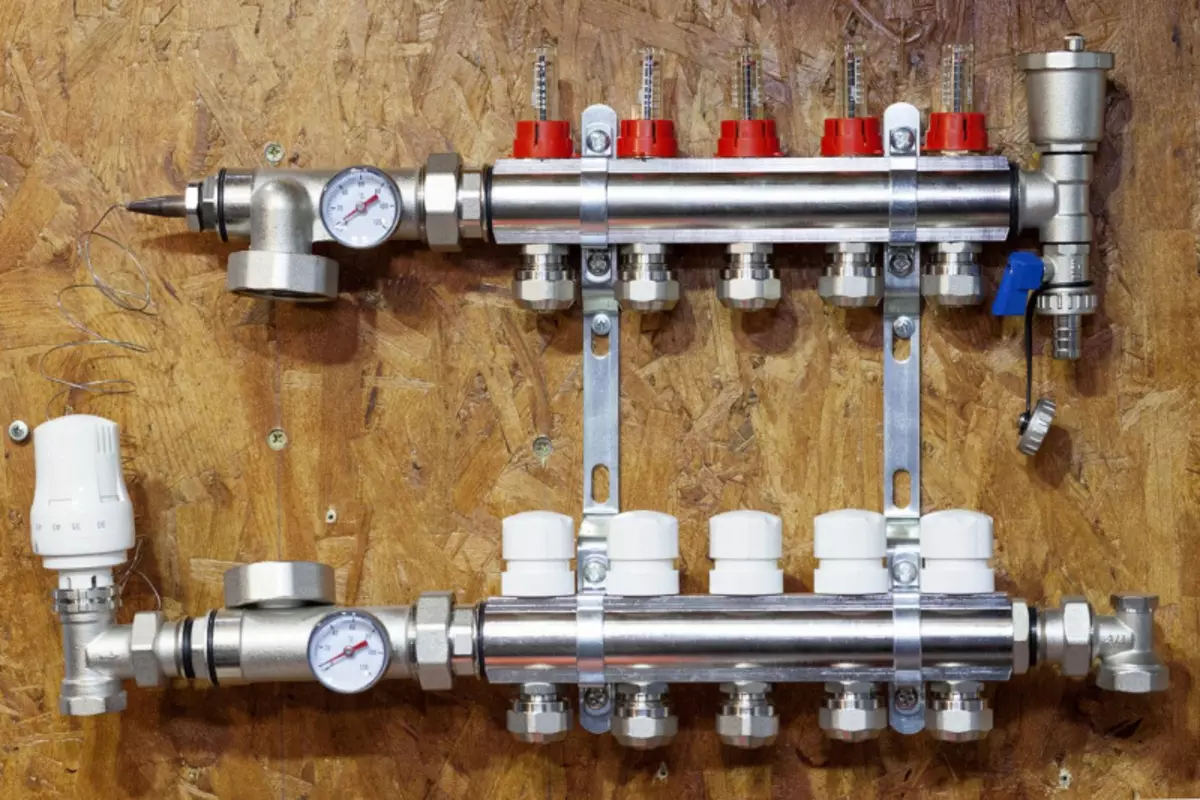

Collector equipment

The collector node is the control device with warm floors. Using the collector, set a specific heating temperature in each circuit.

Collector knot

Connecting the collector node, as well as the commissioning of the gas boiler, is made with the permission of the gas and water supply service.

Water Warm Pipelines

Water warm floor under the tile heated pipes from different material:

- stitched polyethylene;

- Metal plastic pipes;

- polypropylene;

- copper pipes.

Article on the topic: What to close the balcony for the winter

Stitched polyethylene

Polyethylene pipes are famous for resistance to temperature drops

The name of the pipe is obliged to the molecular structure of the polymer. In special equipment, the polyethylene structure is subjected to "bombardment" by electrons.

As a result, molecular chains are formed, which "stitch" the structure of the material, giving it particular strength.

Stitched polyethylene tubes withstand sudden temperature differences and a strong hot heat carrier pressure.

Metal plastic pipes

Metal-plastic strength gives an internal aluminum mesh

Metal plastic on the cut is a three-layer pie. The outer polyethylene layer is fastened with an internal glued aluminum mesh.

The outer surface has increased strength and withstands the effect of the aggressive medium.

Aluminum gasket performs the role of a carrier frame. The inner smooth shell provides the unobstructed passage of the coolant.

Polypropylene

For flexing pipes pre-heat them

Pipelines from this material serve about 50 years.

Pipe compounds are carried out using a special soldering device.

Fiberate the pipe is only under strong heating.

Due to its low price, polypropylene pipes are very popular for the warm water floors under the tile with their own hands.

Copper pipes

Copper tube - perfect material for water warm floors under the tile.

In addition to its high thermal conductivity and flexibility, copper pipes have an unlimited service life and absolutely "indifferent" to corrosion.

Each material from which pipes are made, has its advantages and disadvantages:

| № | Name of material | Dignity | disadvantages |

|---|---|---|---|

| one | Stitched polyethylene | Does not allow internal deposits | Completion complexity |

| 2. | Metal plastic pipes | Special strength | — « — |

| 3. | Polypropylene | Aggressive resistance | For folding need heating |

| four | Copper pipes | High heat transfer | High price |

Methods of pipeline location

The heating pipes are placed on the basis of the floor in the form of 2 forms of position:- Spiral and double spiral;

- Straight sinusoid.

Spiral or snail

In small areas, such laying perfectly provides uniform heating

Laying pipes are made in the form of a swirling spiral.

The spiral can consist of a single pipe, and can also be made from a dual pipeline.

Such a type of laying is most suitable for premises of up to 20 m2 (kitchens, bathrooms and toilets) with ceramic flooring.

Article on the topic: How to make a pond on a plot of plastic bowl?

Straight sinusoid

Laying the sinusoid pipeline

This form of laying has the smallest heat loss in its extension, so this form of laying pipelines use when they arrange water warm floors under the tile on large areas.

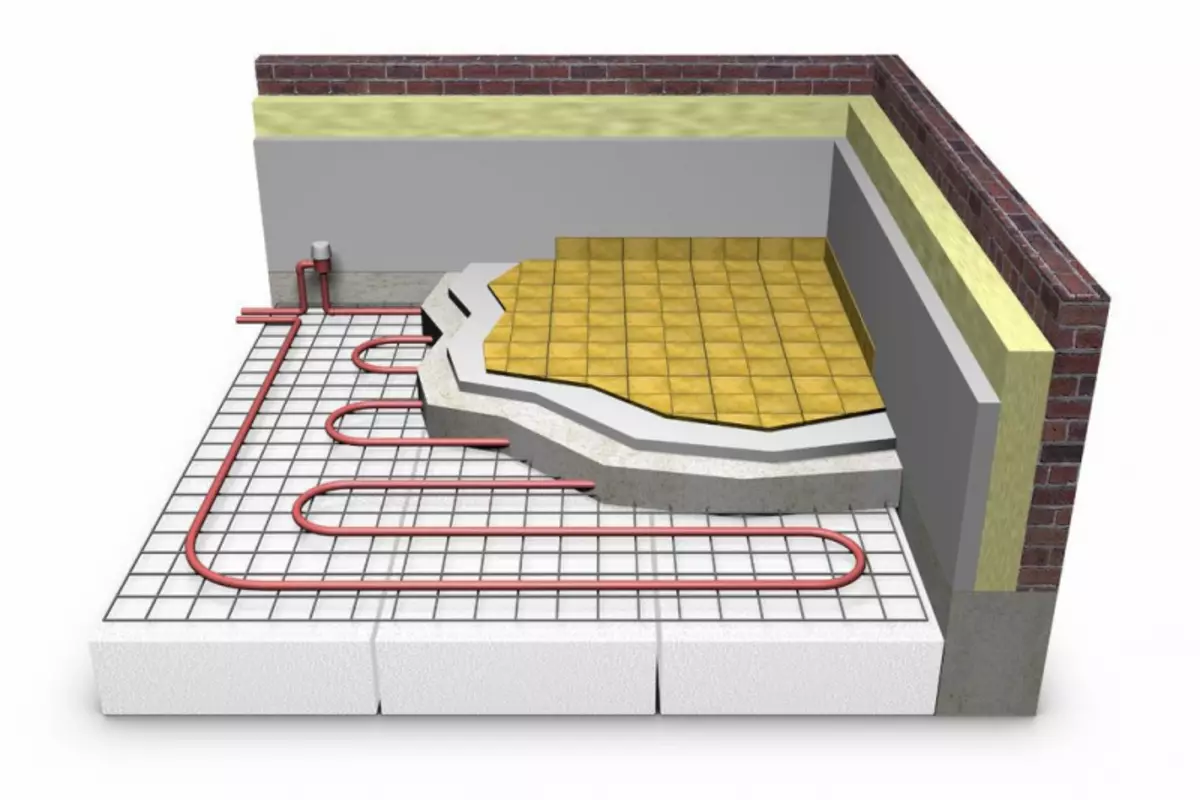

Installation of floor heating

Heavy flooring device

The installation of the thermal circuit is produced in several stages:

- On the concrete base of the steering vapor barrier from the polyethylene film. The edges of isolation are boated on the walls around the perimeter of the room. The edges of the film should be higher ceramic coating.

- The entire surface of the vaporizolation is covered with insulation plates (polyurethane, foam or similar material).

- Then put the reinforced grille.

- Pipes are placed in the form of the desired laying form. The pipeline is fixed to the lattice with plastic clamps.

Warm floor testing

System test connection allows you to find and eliminate leaks

Warm floor test is carried out in two ways:

- In the mounted heating system, hot water under pressure exceeding the standard by 1.5 times is supplied. Reveal weak connections. If you find a leakage, it is eliminated. The test is carried out again.

- The second method of test is that compressed air is injected into the pipe compressor. Places of pipeline connections are coated with a soap suspension. The leak is manifested by the appearance of soap bubbles. After eliminating defects, the tests are repeated.

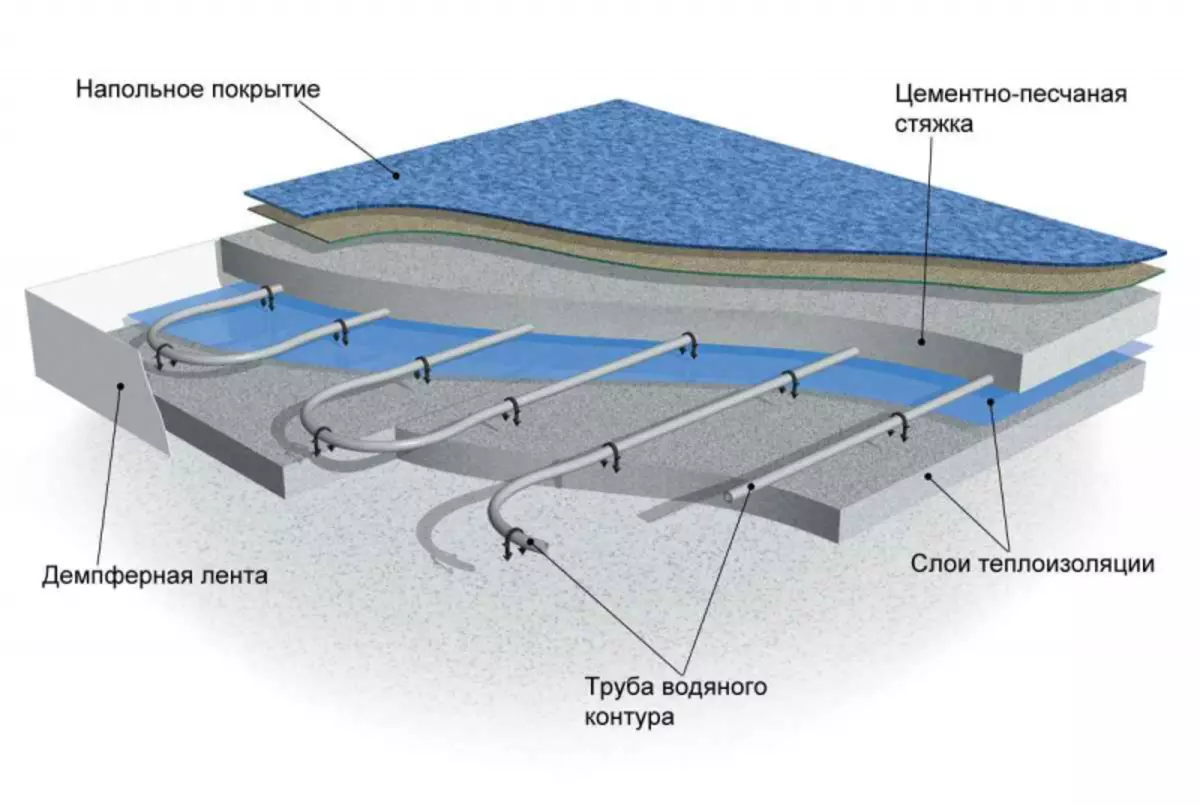

Types of filling water warm floors under the tile

Fill the wall of the warm floor in two ways:- Pouring concrete

- Device dry frustration

Pouring concrete

Standard diameter of water heating pipes 16 mm.

According to thermal calculations, the optimal height of the concrete layer above the pipes should be 30 mm.

With a screed thickness, over 70 mm, the heating inertness of the floor structure increases. The overlap will be slow and cool.

The base of the floor should have sufficient bearing capacity. When the device of concrete fill, it is necessary to take into account that 1 m2 tie 50 mm thick weighs 125 kg.

Device dry frustration

Flooring the dry floor is made of clay crumbs. Under the laying of the floor covering from ceramic tiles, dry floors are not suitable. Read more about Dry Screws See in this video:Article on the topic: Adjustment of the volumetric tank with their own hands

Device coating warm water floor from ceramic tile

Ceramic coating works well heat

Ceramic tile - universal facing material. Tile is used to finish facades of buildings, as well as for lining of walls and floors indoors.

Particularly need ceramic flooring of rooms with high humidity - kitchens, bathrooms and toilets. The tile has the maximum degree of heat transfer from the warm water floors inside the room.

Square tile is most convenient in mounting

Ceramic plates are obtained by firing at a temperature of over 1000 degrees of liquid clay mixture with sand.

Various substances that improve certain types of material are added to the mixture. The mixture is poured into various forms and placed in a firing furnace.

The trading network offers a wide range of ceramic tiles, affecting a variety of colors, patterns and sizes.

Ceramics for a warm floor are chosen mainly square or rectangular shape. It is very convenient and beneficial to lay a square tile with dimensions of 30x30 cm and 50x50 cm. Read more about laying ceramics to the warm floor, see this video:

For kitchens and bathrooms are used ceramics with a thickness of 8 to 15 mm.

The tile is placed on glue, which consists of a mixture of cement, various plasticizers and stabilizers. It is bred by water until the tough mass is obtained. The mixture is applied to the surface of the screed and smash with a toothed spatula. Tile before laying soaked in water. On the back surface of the plate, the adhesive mixture is plugged and pressed the tile to the glue layer on the floor.

To get a flat launching of seams between tiles, plastic crosses are inserted into the gaps, which, after drying, remove and produce seams.

The ceramic coating is a powerful barrier blocking moisture penetration path. Tile withstands heavy loads.

For wet rooms, they choose a tile with anti-slip coating. Ceramics is well clean, which is important for maintaining cleanliness in the kitchen and in the bathroom.

Warm ceramic coating leaves pleasant sensations from the barefoot.