Ceramic tile is one of the most non-additive coatings. It is not afraid of moisture and sharp change of temperature modes, easy to maintain and laying. True, assembly works suggest trimming tiles. So that the sections gently looked need to use special equipment, which is called stovetur.

Types of plotkores

To date, several variants of machines are presented on the market, which are designed to trim the tiles. Conditionally, they can be divided into two groups: mechanical and electric. The first are used in the event that it is not about industrial work scale.

Let's say, to repair in your apartment, it is enough to arma with a mechanical instrument. But if the repair is professional activity, it is better to purchase a good electric tool once.

When using a mechanical tool, the power supply is not needed. All the work is carried out by a person, leading to an easy mechanism. Such machines are not recommended to be used if the tile thickness is greater than 1.5 cm. There are models designed to work with ceramic tiles, the length of which does not exceed 40 cm.

As a rule, such a tool without problems copes with a wall tile, the width of which is an average of 8 mm. But cuts are far from perfect. There are multifunctional machines, with which you can not only cut the tile on the part, but also cut round holes.

Mechanical tiles, in turn, are divided into desktop and manual. Table machines are designed to make straight cuts. They can be fixed on the table and use as a stationary tool. The small weight of the equipment allows you to use it and as a portable machine. With the help of manual stoveturis, you can make curly cuts.

Electrical machines are advisable to use if you need to work with thick tiles or work is not limited to cutting 10-20 tiles. Electric stoves have a fairly large weight, which complicates their transportation.

Article on the topic: Strings for curtains and string curtains: secrets of installation and features of operation

When choosing electrical equipment it is worth paying attention to the presence of water tank. If there is no such, then during cutting ceramic tiles there will be a lot of dust. The presence of container with water partially solves this problem. In addition, this tool will serve longer.

Platekores have a different pricing policy. This is a tool on which you should not save. Cheap machines will not be durable. Yes, and a slice made on such machines, it looks not particularly aesthetic. If you do not want to give a round sum, you can make a slab barrier with your own hands. Moreover, you can make both a mechanical machine and electric.

We make mechanical tiles with your own hands

Manual stoves is a safe tool, and does not require connecting to the electrical network. These two factors ensure the popularity of this model. In addition, such a tool in view of a sufficiently low weight is easy to transport and the manufacture does not have to spend a lot of money.

The manual tiles consists of a platform on which the ceramic tiles, guide, cutting element and knobs are directly located, with which the entire mechanism is activated. The main element of the design is a cutting element.

It is advisable to use the most common glass cutter as the latter. But, it is necessary to pre-remove the head on which the cutting element is located directly.

In addition to the cutting element, it is necessary to prepare:

- 2 bearings and shaft for them;

- tube made of steel, the diameter of which is identical to the shaft diameter;

- 2 steel corners, measuring 40x40 cm and 4 corners with a size of 20x20 cm (the length of each element should be on average 60 cm)

- material for the manufacture of the working surface;

- Rubber and glue.

In addition to building materials, you need to arm the welding machine. Without it, make mechanical tiles do not work with your own hands.

From 1 corner with dimensions of 40x40 and 2 corners with dimensions of 20x20, half the required device is constructed. We take a bigger corner and to its ends from the outside welding smaller corners. Similarly, you need to make the second part of the device.

Article on the topic: Interior doors made of black glass in the interior

The first and second part of the slab should be symmetrical in relation to each other. These elements are fixed on the platform. They need to be consolidated in such a way that the cutting part of the design moves freely between them.

As a platform can be a regular board. But since the tree is unstable to mechanical damage to the operating part of the platform, metal strips must be installed. To install them use a hinge element. Since the cutting element will fall below the ceramic tiles itself in the middle of the platform must be a deepening. Otherwise, at the first use, the platform is damaged.

The last stage is to create a cutting design element. To the steel tube it is necessary to welcome the handle on one side, and on the other - the retainer for the cutting element. By and large, on this work is almost completed. When you click on the handle, the diamond disk should get to the ceramic tile.

Then, smoothly moving the rolling part of the structure for the same handle, the diamond disk leaves a smooth incision on the tile. In order for the designs freely moving part to the rolling part, it is necessary to equip the bearings. For better fixation of the tile on the working surface of the equipment, it is possible to glue the rubber strips by its edges.

Making electric tiles

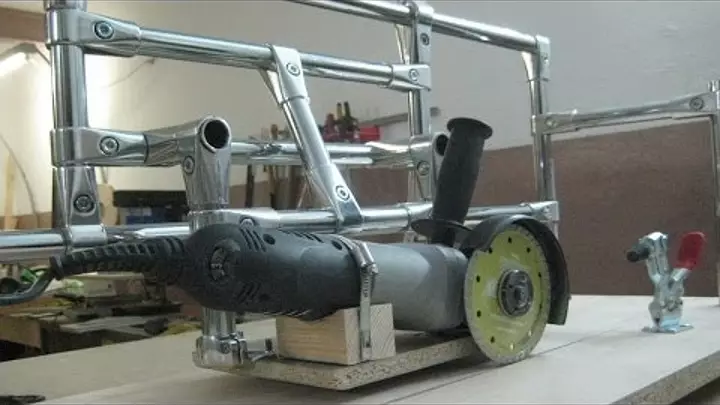

Make electric stoves with your own hands much easier than it seems. You need to cook metal and cutting electrical tool. It is better to use the Bulgarian as the latter. Start work from the manufacture of the working surface. As the latter, the most common table can act.

You can cook a table yourself. In this case, the tabletop is made of metal sheet. Since the cutting element will be a circle from the electrical instrument used, the operating surface center should be a deepening. It will allow you to move the cutting element and at the same time not to damage the platform. Such a tool will be stationary.

Article on the topic: Swedish wall do it yourself

Bulgarian is installed on the attachments that you need to pre-install on the platform. Also, the limiter will also be installed. It will not give ceramic tiles in the pruning process. This is the easiest option of electric stovetur created by yourself. An alternative to the Bulgarian can perform an electric motor.

The resulting equipment will resemble the circular floor. The electric motor is installed under the platform of the stoveturis. The work platform is cut. After installing the disk, which acts as the cutting element, it must be above the platform for several centimeters. After the equipment is connected to the electrical network, the disk will rotate, which makes a smooth incision on the surface of the ceramic tile.

A tool for cutting ceramic tile make yourself quite simple enough. At the same time, its creation will take at least funds. Buying the same factory equipment will cost a considerable amount. And the equipment is flaw fast enough.