Warm water floors for a private house are the most preferred option from all types of outdoor heating systems. The main advantage of their advantage is in economy and ability to effectively heat large areas.

Usually, a solid pipe from polyethylene is used in systems on which the coolant circulates. However, often homemade masters use polypropylene pipes, of which standard wall heating systems are usually mounted. Is it possible to use them in floor heating systems, and if yes - how to assemble the warm floor of polypropylene pipes correctly?

Polyethylene and polypropylene: advantages and disadvantages

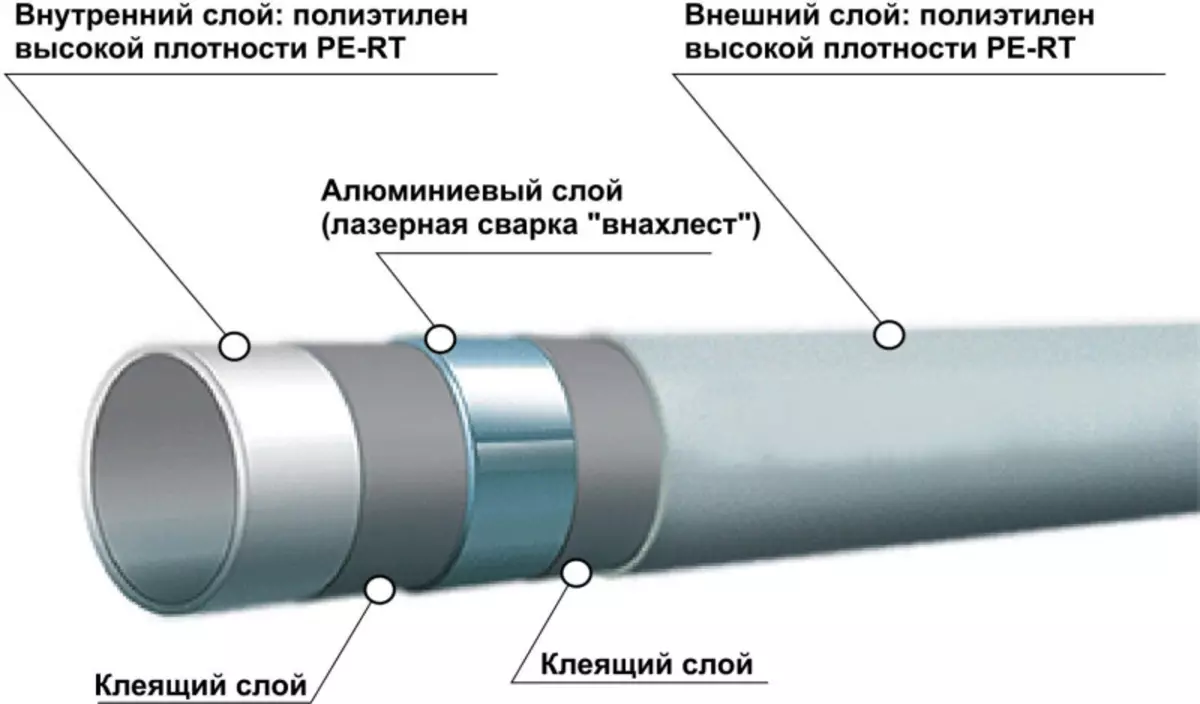

Before you give preference to one or another option, we will consider more details from stitched polyethylene and polypropylene.Stitched polyethylene

Modern polyethylene pipes do not have a seam

With the word "polyethylene", and even stitched, most of ordinary ordinary people immediately arises the image of something fragile and short-lived, but this is not at all. Modern technologies allow you to cross the materials in such a way that there is no seam on the surface of the pipe, weakening the strength of the structure.

Most recently, polyethylene hoses were welded by a longitudinal seam, which did not make them particularly durable. As a result of the most common area of their use, summer cottages and households were used, where they were used for watering plantings.

But polyethylene, stitched with modern technologies, has increased strength. This is especially true of the plastic pipe re-RT, that is, with increased heat resistance. The structure of the wall of such a pipe is a three-dimensional mesh with strong molecular bonds. This is achieved by the fact that the welding of the pipe goes at the molecular level, as a result, a practically monolithic compound is formed.

Such pipes, according to manufacturers, can withstand pressure up to 20 atmospheres. Such strength is achieved in part in the fact that in warm floors systems, a solid flexible tube is used that does not have butts.

Among the minuses of polyethylene warm floors, their insufficient resistance to external physical influences can be noted.

The pressure from the outside can take the pipe, which will cause problems with the circulation of the coolant on the system, so the polyethylene heating elements are recommended to be covered with a concrete screed, which plays the role of a peculiar shell that protects them from pressure from the floor covering.

Polypropylene

Pipes made from this material are known today almost everyone. It was over the past decade that in the last decade, in the construction of "classics" in the form of metal water pipes.

Polypropylene tubes have a whole range of indisputable advantages:

- Long service life, reaching with the right installation up to 50 years.

- High resistance to various chemical reagents. In this regard, not only water, but also antifreeze or ethylene glycol can be used as a coolant.

Polypropylene is less corrosive and less noise when water passes through pipes

- Resistance to corrosion and sediments of salts and rust. Polypropylene is absolutely indifferent to water molecules, so the pipes do not threaten neither corrosion, nor rust, and the smooth inner surface prevents deposits on the walls of various precipitation contained in the coolant.

- Reduced noise level. When circulating fluid on pipes, noise is almost completely absorbed by thick multi-layer polypropylene walls.

- High mechanical strength. The polypropylene tube is almost impossible to transmit unlike soft polyethylene species, so it is not necessary to hide the heating elements from polypropylene into a concrete tie.

Have heating systems and their drawbacks. First of all, these are limitations in the loads that make up 7.5 atmospheres of pressure and + 95 from the maximum temperature. The recommended operating temperature is + 75 C.

In order to bend such a material need special equipment

If these parameters are exceeded, polypropylene begins to deform and significantly increase in volumes. Another minus of such pipes is excessive rigidity.

The polypropylene "snake" or a spiral, like polyethylene pipes, is unlikely to succeed, so when installing a warm floor from polypropylene, it will be impossible to do without the "iron" for welding pipes and adapters-corners for connecting individual elements.

From how qualitatively welding will be made, the strength of the entire heating structure depends, therefore it is necessary to pay special attention to the strengths and tightness of the compounds.

After familiarization with all the advantages and disadvantages of polypropylene and polyethylene, you can make the most suitable choice for you.

If you decide to use polypropylene tubes as a material for a warm floor, you should familiarize yourself with the main criteria for their choice.

Choosing polypropylene pipes

There are several types of polypropylene pipes in the modern market. In order for you to have a durable and efficient system of outdoor heating, it is necessary to approach the choice of the polypropylene brand.Single-layer

Designation RRN. This type of polymer is made of the so-called homopolypropylene. PIR-polypropylene pipelines are intended for ventilation systems and cold water supply systems.

Mounting from it water heating floors is not recommended due to low resistance to high temperatures.

Standing material to pressure and high temperatures

Designation of RRV. Such single-layer pipes are made from a polypropylene block copolymer. They are distinguished by increased resistance to pressure and temperature, so it can be used for warm floors.

RRS designation. Fire-resistant polymer option designed for use near open fire sources. According to the characteristics, the RRV polypropylene is similar, but is characterized by a higher cost.

Multi-layered

Two-layer pipes have aluminum or fiberglass layers

Such pipe variants are enhanced by the reinforcing layer located between two layers of the polymer.

Reinforcement is a thin leaf of aluminum or fiberglass thickness not more than 1 mm.

Thanks to him, pipelines made of multilayer polypropylene are capable of functioning at a coolant temperature to + 95 ... + 100 s (briefly - up to 110 s).

The pipeline made of multilayer polypropylene is best suited for the manufacture of warm floors, due to its increased stability.

Installation of heating system

After you have chosen and purchased suitable material, proceed directly to the installation of heating elements.Preparation of the foundation

Waterproofing will protect the neighbors from the bottom of the neighbors

Works on laying the heating pipeline should be started with the preparation of the base. First of all, the insulating layer should be asked.

This will help you avoid troubles with neighbors from below in the case of force majeure in the form of a pipeline breakthrough.

For these purposes, it is possible to apply both liquid moisture-repellent mastic and a conventional rolled waterproofing material: rubberoid and materials similar to it. In the first case, the waterproofing is applied using paint brushes or roller. Liquid mastic fills all the pores and microcracks of a concrete base, not leaving moisture paths of penetration through inter-storey floors.

Waterproofing joints Mastics

Rolled waterproofing is laid on a blanket on each other, gluing to the roughing floors by means of bitumen mastic. The joints of the insulation sheets are also thoroughly labeled with mastic, and, if necessary, the rolling insulation cannons are laid on each other in 2-3 layers.

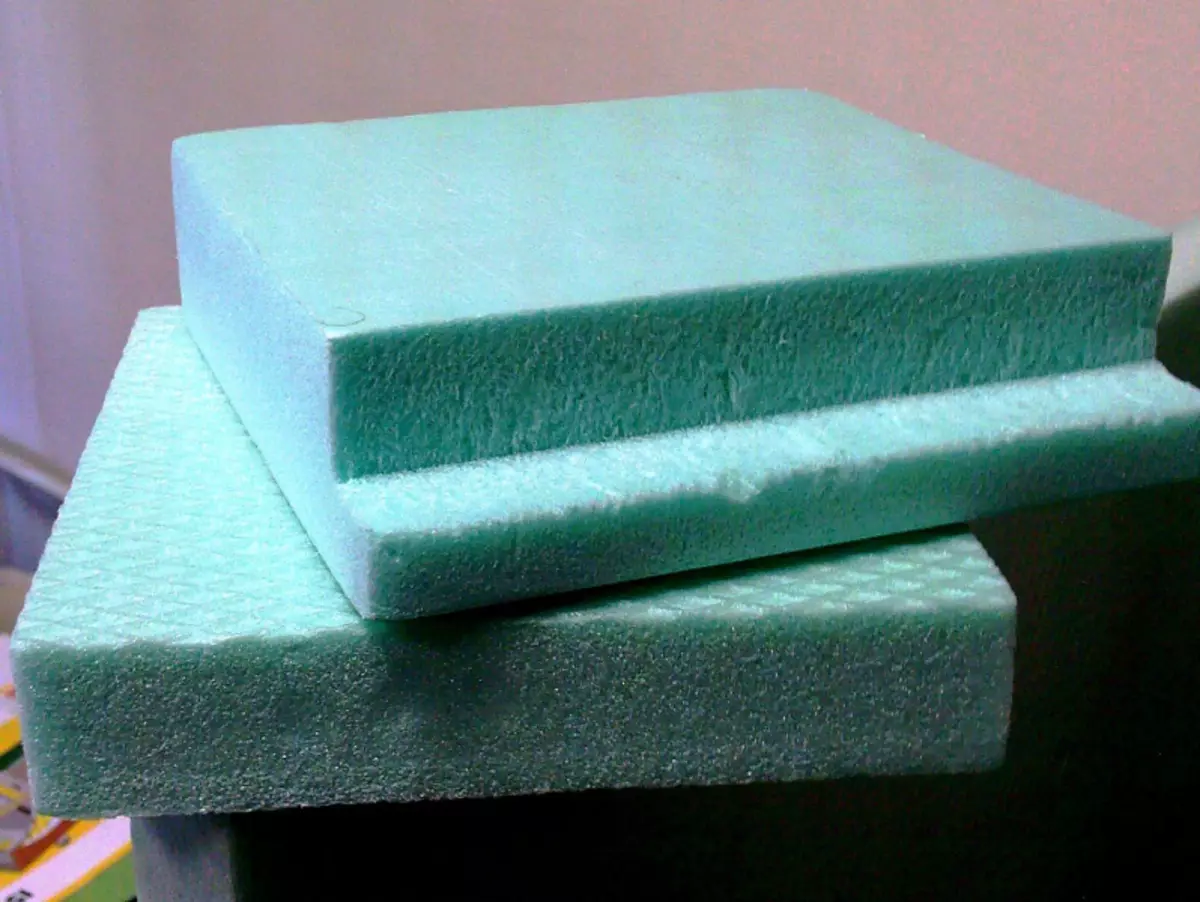

The next step is the insulation of the base. If you do not make this work, then your outdoor heating design will only warm the room. The remaining 50% heat will go to heating the ceiling by the neighbors from the bottom or basement.

Polystyrene foam

To optimize thermal energy costs over the waterproofing layer, lay heat insulation.

For this, the lists of dense material are suitable, preferably not fearing moisture.

The ideal option will be dense expanded polystyrene (extruded foam) Penoplex, etc. You can also use a foam polyethylene insulation with a foil surface.

It should not use the Martpit for the flooring of thermal insulation under the warm water floor. First, the Ministry of Service is afraid of moisture and with possible wetting will lose its insulation qualities. Secondly, the minilate under the weight of the pipeline, the flooring of the floor and the furniture standing on it doubt and it is broken, which will also adversely affect its properties.

Project preparation

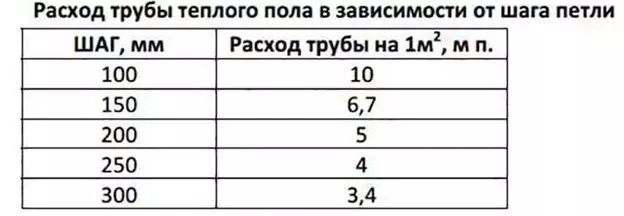

Next, you need to decide how the pipeline will be laid. From whether it will be mounted "snake", spiral, "double snake", etc. Its longest length depends. For details on how to design the water floor, look in this form:

Pipe floor length should not be more than 50 m

When drawing up a project, it should be remembered that polypropylene tubes are quite rigid, so you should not lay sharp turns and bends in terms of too much.

For the effective functioning of heating, a distance between the threads of 25-30 cm is quite sufficient.

At its length, the pipeline should not exceed 50 m - otherwise, in its distinction, the heat transfer will be extremely low, and this will lead to uneven heating of the room.

To calculate the total length of the heating pipeline, you should lay out its outline on the floor with a thread or twine. After it remains only to measure the length of the thread, to find out the exact merar of the future pipeline.

The table shows the flow consumption depending on the distance between the loops.

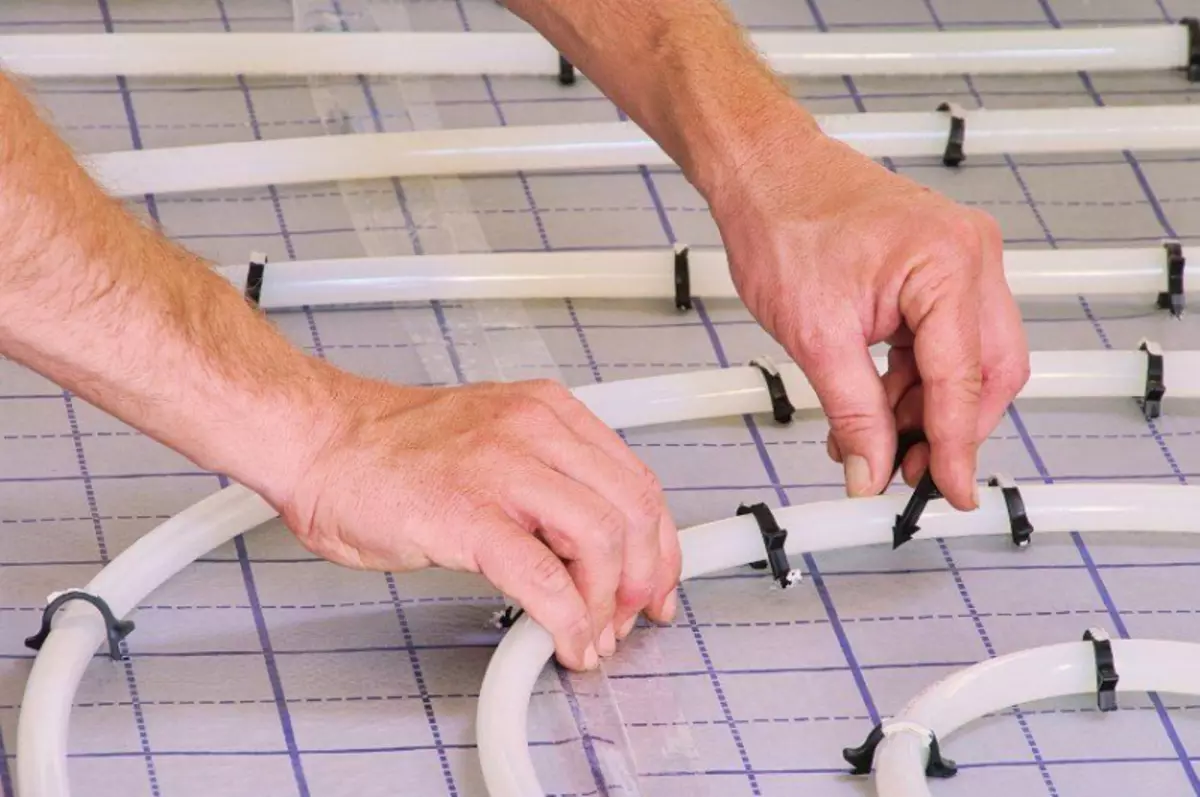

Laying pipes

Snake the easiest to put the contour

After all preparatory work, you can proceed directly to laying the heating circuit. The most effective in terms of thermodynamic parameters is to lay a contour with a spiral.

However, such a scheme may be too difficult for not too experienced homemade master, so if you decide to install warm floors with your own hands, it is better to stop your choice on the "snake". It is much easier to design, and the items in this case should produce only two sizes: a large segment of the pipe - for a long side, and a smaller cut is used to connect two long pipes.

To give bending pipes, use corners coupling

Also, when installing, we will need corners-couplings to impart a bend of design and iron soldering iron for polypropylene pipes. For a more hard fastening of the pipeline under it, a metal or fiberglass mesh is placed, to which heating elements are tied in several places, on each bend.

The next step is to create a protective layer over the mounted heating circuit to facilitate the pressure on it from the furniture and home appliances. To do this, you can use a concrete screed. This option will perfectly protect the pipes, and will also create a perfectly smooth base under the finish coating. On how to make the floor from polypropylene, see this video:

As an option - a pavement device. In this case, there are rains or shelters between the pipeline coils, which should rise by 1.5-2 cm above the pipe. They form the base on which the plywood layer is placed on top of which the decorative flooring is already laid - linoleum, laminate, carpet.

An option with a concrete screed is more preferable, since concrete is an excellent heat conductor from heating elements to the environment.

PVC manifold device

The rack floor is significantly inferior to the concrete according to this indicator, so it should be mounted only if it is impossible to install a concrete screed or when water floors are planned to be used as auxiliary heating.

We produce a finishing flooring flooring as the final stroke. At the same time, it is necessary to prefer materials without the heat insulating effect, so as not to reduce the efficiency of the heating system.

Article on the topic: Options Curtains for gazebo and veranda: species and features