The warm floor is the newest type of heating system. This heating is gaining popularity of both among heat supply professionals and among ordinary residents of private houses and apartments.

Warm floors are not a simple heating system, they have certain nuances when installing and during operation.

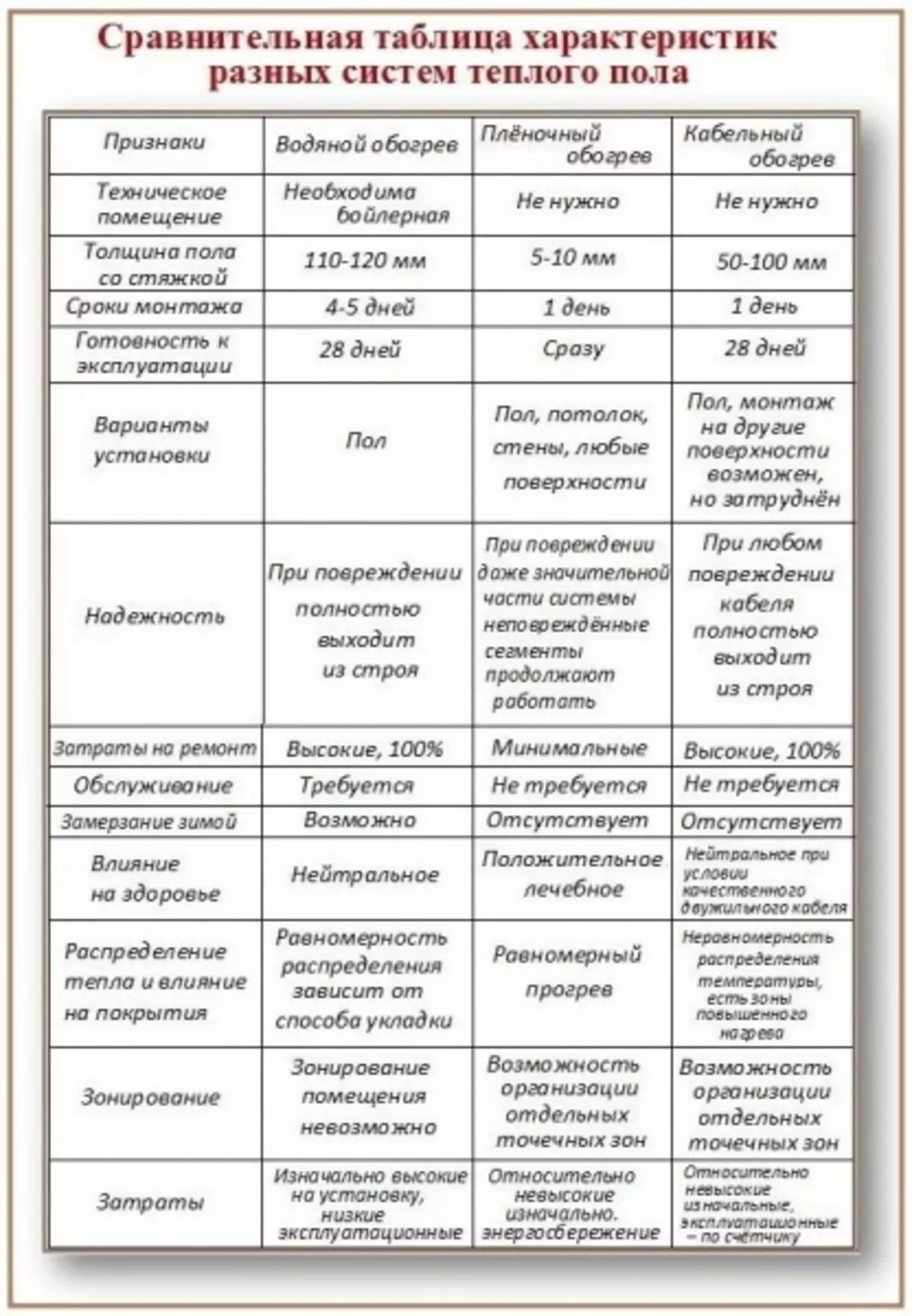

There are two different varieties of a new type of heating: water and electric warm floors. The electrical flooring device is diverse, since there are several types of flooring having power supply.

Electric warm floor: principle of operation and device

By turning his eyes towards electric warm floors, as a basic or additional heating system in your residential room, you need to be prepared for various difficulties associated with the choice of one of the varieties of heating flooring, as well as the organization of high-quality power connection.

Since the warm floor is an electrical device that can be installed in places with high humidity, it is necessary to thoroughly examine all the requirements for this electrical safety equipment and constantly observed them.

Failure to comply with the installation requirements can lead to undesirable consequences, such as a short circuit of the wiring, the consequence of the fire and the electric shock of the residents of the room.

To make these events, it is worthwhile to mount all contact connections and be sure to install a separate circuit breaker in aqueous distribution electrical shield. This "machine" will be individually defended by the system of warm electric floors.

Termaomats

Electric warm floors have a number of varieties of floor flooring for heating:

- cable warm floor;

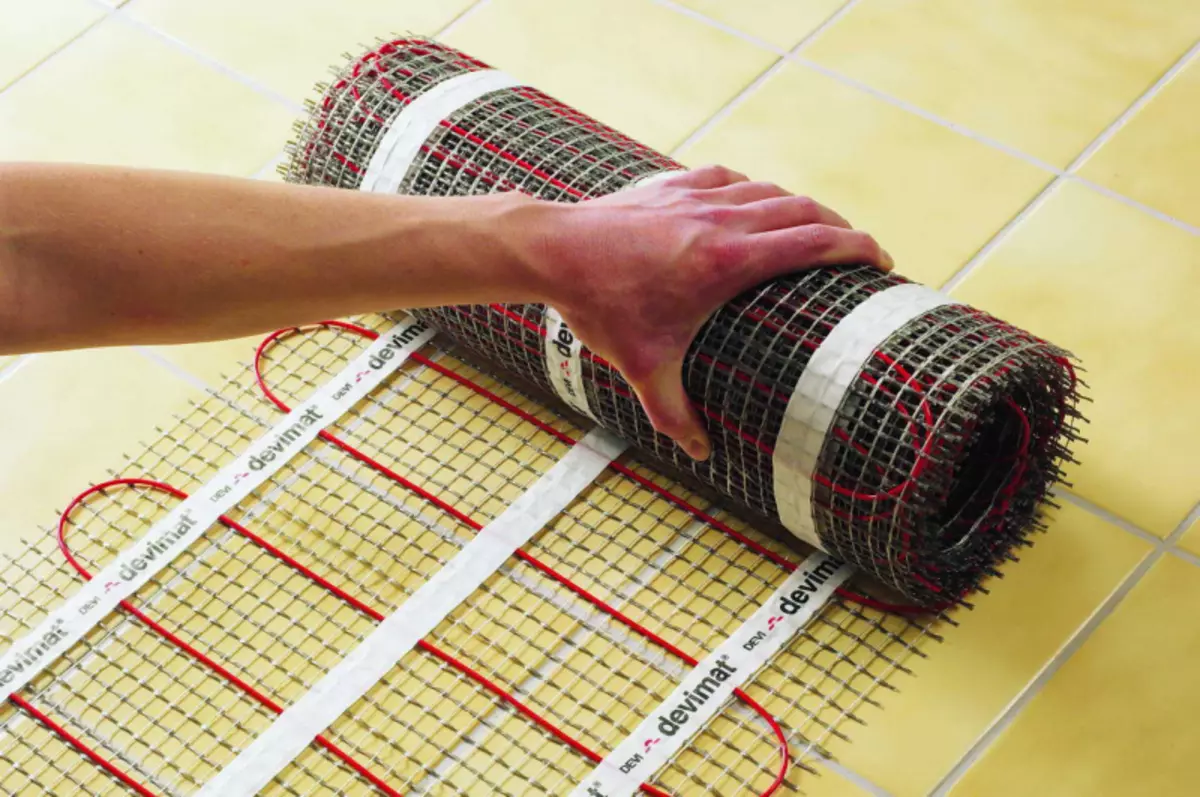

- flooring in the form of mats;

- Infrared warm underground.

Choosing your type of heating system installed under the finishing sex, it is necessary to learn each electric flooring in more detail.

Choosing an electric warm floor for its room, it is necessary to remember the thickness of the "cake" of this design, because it turns out that the modern heating system prevents the move of doors or built-in wardrobes.

It is not necessary to reduce the thickness of the screed, this often leads to the destruction of the flooring and damage to the design of the warm electric floor.

Varieties of warm electric floors

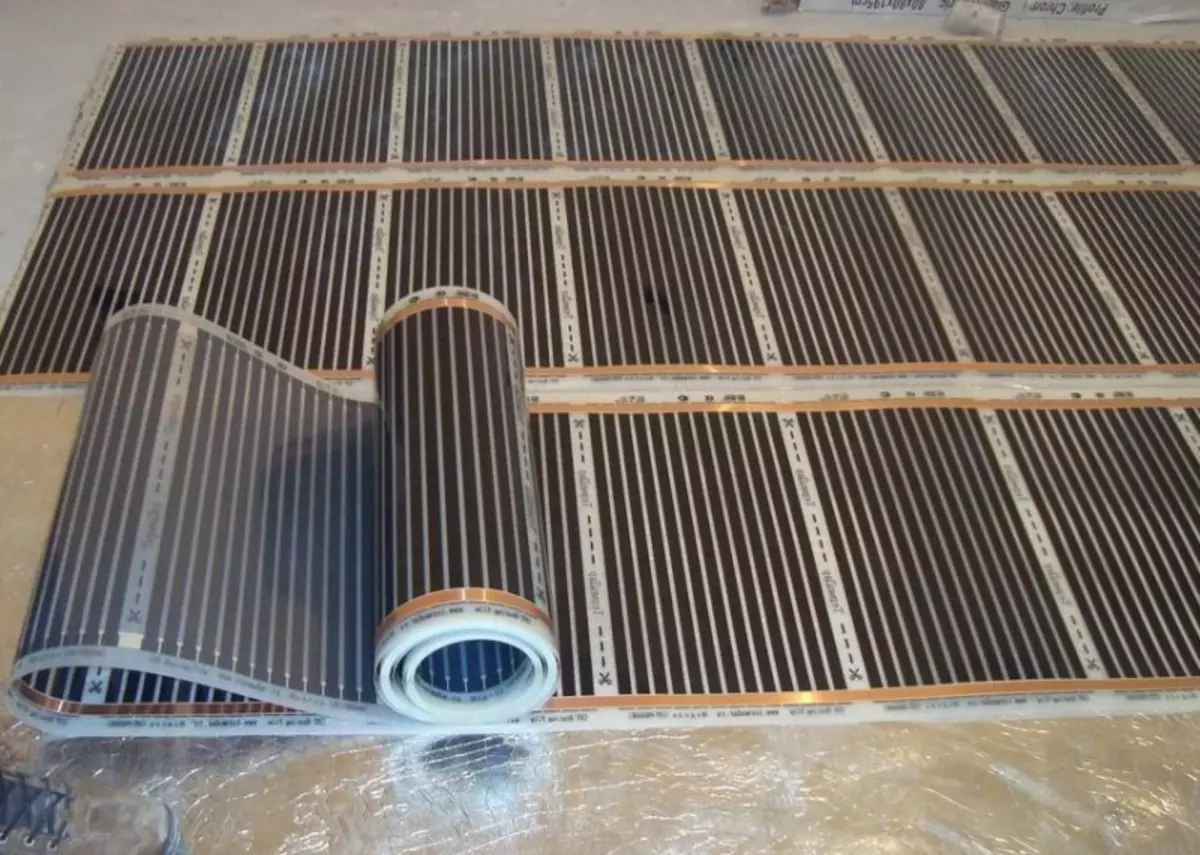

At the IR film you can immediately lay the finish coating

Electric warm floor has several varieties, which will allow each client to choose its own version suitable for certain conditions and meets the requirements.

To date, the following types of electric flooring are exist:

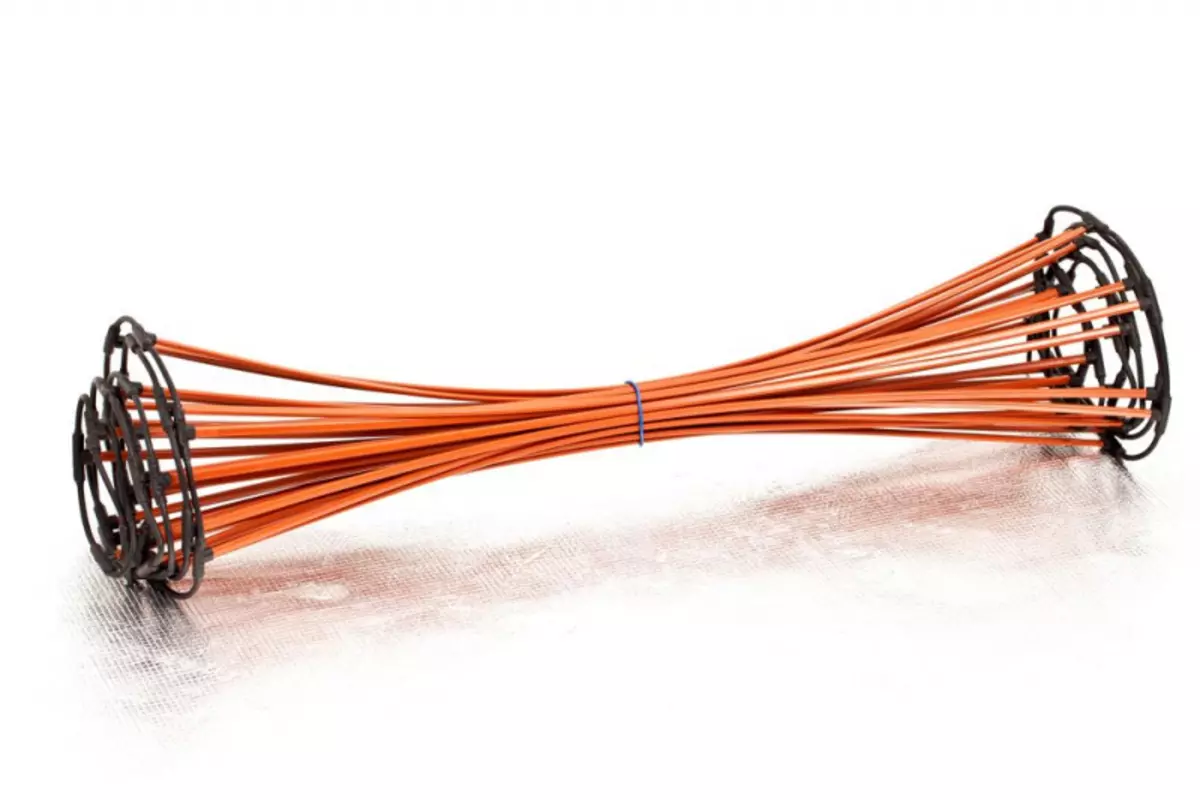

- Cable thermal cover. The heating system of this species is based on one or 2 vein electrical cable, which has several layers of insulation. The advantage of this type of heating system is that you purchase all devices for the flooring individually and can independently plan the length of the cable, to connect which there are special hermetic clutches. Choosing cable products for a warm floor, you should choose high-quality products, since you organize heating for yourself.

- Infrared warm floor. Infrared cover is the most new underground heating system. For its installation, the organization of the screed is not required, which allows to reduce the thickness of the layers of the "Pie" flooring. The work of this heating system is based on infrared radiation, as a result of which items are heated, and not the air, due to which heat in the room is delayed for a longer period and does not eat so quickly. The device itself is represented as a film on which special cuts of cuts are applied, so individual pieces of heating elements can be placed arbitrarily around the room, as the owner is required.

Choosing cable heating, follow the quality of the acquired wire

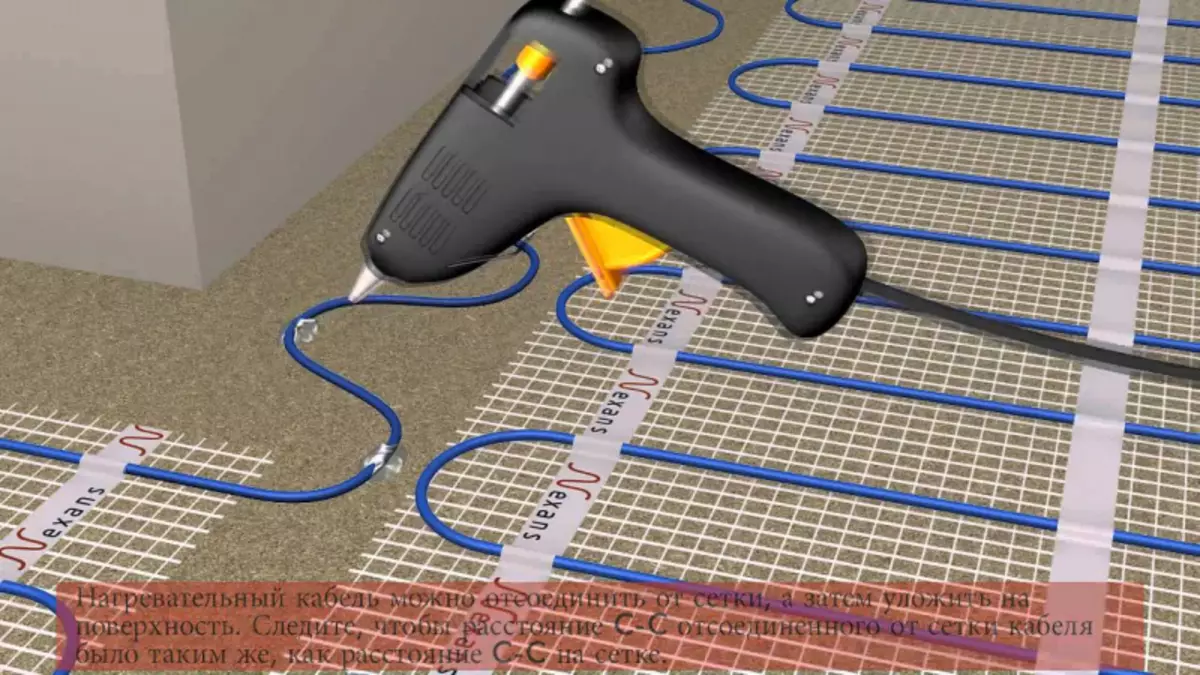

- Electric floor in the form of mats. Electrical mats have a similar device with a cable warm floor, since the mat is the same cable, fixed on a plastic grid, which serves to fix the cable and reinforcement of the surface screed. The mats come in different sizes and have a connection point, which are designed in such a way that you can connect both the power cable to the output and additional items.

The system of electric heating floor consists not only of heating elements.

The most important role in this kind of heating of the family hearth plays the thermostat with an attached thermal sensor, which is located at one level of flooring with heating elements.

Thermostat for electric heating floor

The thermostat configured for a certain temperature will independently support the required heating level

Today it is hard to imagine any kind of system of electric heat floors without a thermostat, since this device is considered to be a "brainstorm" of a new type of heating. "On his shoulders" leads to the control of temperature indicators in the room.

It is the thermostat that helps to switch the system in a timely manner, without creating electricity recalculations and maintaining a comfortable environment. The device reacts to the data from the thermal sensor, which connects to it using a special thermal protection cable.

The thermostat is made with mechanical and automatic temperature adjustment. The automatic thermostat may have a digital display, which displays the existing room temperature and other parameters.

Adjustment and control of the process of operation of the heating system can be performed using the remote, which is convenient, but significantly increases the cost of the device.

The mechanical thermostat has an adjusting knob, with which you independently exhibit (on a graded scale) the temperature value suitable for you, since the "comfortable temperature" of each person has its own.

The thermostat is in operation constantly and, as soon as the sensor feeds it a deviation signal from the set temperature value, switches the power supply system, starting a current to heating elements or stopping.

The thermostat is constantly under voltage and performs switching work, so it is not necessary to save on this device.

It should be made of high-quality material and have reliable contact compounds, as they place the main load.

Principle of operation and features of electric warm floors

As mentioned above, a warm electric floor device has a number of features. The principle of operation of the heating system is to transform electrical energy into thermal. At the same time, the properties of the conductors are widely used, namely their resistance.

For a more understandable description, you can cite an example with a light bulb. In the AC network, the voltage 220 into the light bulb connect to two conductors, which in commoner are called "phase" and "zero".

In our case, the bulb is the heating element, and the connection point is the thermostat, it is on its outputs that the heating cable and power wiring is docked.

Features of cable and matte flooring

The number of joints should be minimal

Cable and matte warm floors have a similar design. In both types of devices, the heating element is cable.

Choosing a cable or mats for its premises, you need to calculate the required amount of materials in advance. Since the number of joints should be minimal, since it is the places of compounds that are weak points of the entire system.

Choosing a warm floor, it is worth considering the size and purpose of the room in which the flooring will be applied, as well as the power parameters of the heating element itself, in this case of the cable.

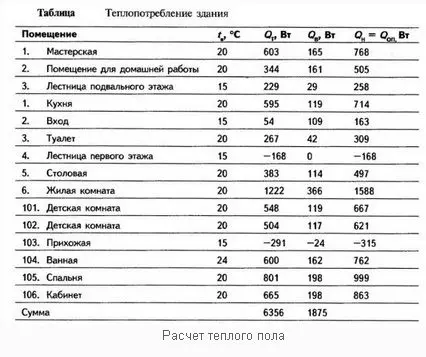

Knowing the room, its type (kitchen, bathroom, balcony) and the purpose of the wall-mounted floor (main heating or auxiliary), according to the table below, you can determine the power of the device as a whole.

Infrared warm floor

The thickness of the IR panels is not more than 2 mm

The technology of manufacturing infrared warm floors is the most modern. This thermal flooring is created as a film that has a two-layer structure. The total thickness of the product is 1-2 mm.

Inside the film, the heating elements of bimetallic plates are arranged, which are connected to each other with thin copper-silver conductors (materials with better conductivity are used).

This product may be partitioned, separated by the corresponding lines applied to the material. This allows pieces to have sickens in the right places, each of which has contacts to attach the conductors.

When heating the plate, located in the film, emit thermal energy, which is transmitted using infrared radiation from the surface of the product due to the upper carbon layer.

When organizing the connection of any type of warm floors, the total power of heating elements with thermostat is compared.

The permissible parameters specified on the device should not be lower than the overall power of the floor, as the result may be the fire of thermostat and short circuit.

Installation of electric warm floors

After you finally chose the type of warm electric floor used, you can prepare the base and directly by installation. For details on the installation of thermomats, see the video:

Before laying the electrical cable, mats or film, you need to prepare a qualitative basis.

An obligatory requirement when applying a different type of warm floors is the alignment of rough overlap or its repair. If in the initial moment of installation, do not align the surface, then in the future, the organization of the cake of the flooring may arise problems associated with uneven warming of the entire floor area.

On top of the draft overlap, it is customary to make a layer of waterproofing. To do this, it can be used both a special film and rubberoid. The next layer of "cake" is a heater, which is used by foam or polystyrene foam 2-3 mm thick.

Plates of material must be laid tightly to each other without cleansings and gaps. On top of the insulation, you can already lay the heating elements and connect them.

Features of the organization of electrical flooring with cable and mats

Insulation will not give heat to scatter down

The first layers of flooring flooring for all options are the same. With a recent appearance of a specialized insulation - polystyrene foam, intended for a warm floor, it became convenient to mount water pipes and heating cable, since each sheet has special grooves where heating elements are inserted.

This invention allows you to lay an electrical cable as a zigzag and a spiral with a different step (the grooves are removed from each other by 5-8 cm). On top of the laid cable, a thin layer of bulk floors can be organized (at the top level of the heating element) or cover the design with sheet material (moisture-resistant plywood, OSB-stove or CSP). The next layer is already finishing flooring.

The cable is connected to the thermal sensor

Electrical mats cannot be laid on the polystyrene discussed above, as they are a cable fixed on the grid, so for the matte floor it is recommended to use a conventional flat polystyrene foam.

Rolling mats and laying the cable, do not forget to install the thermal sensor (so as not to touch the heating elements) and output from it the wire that binds it to the regulator.

All couplings and connecting parts of the heating elements must be installed in the same level with mats and cable.

The output is done in one place strictly under the thermostat, while the thermostat should be installed on the floor at a height of at least 1 m.

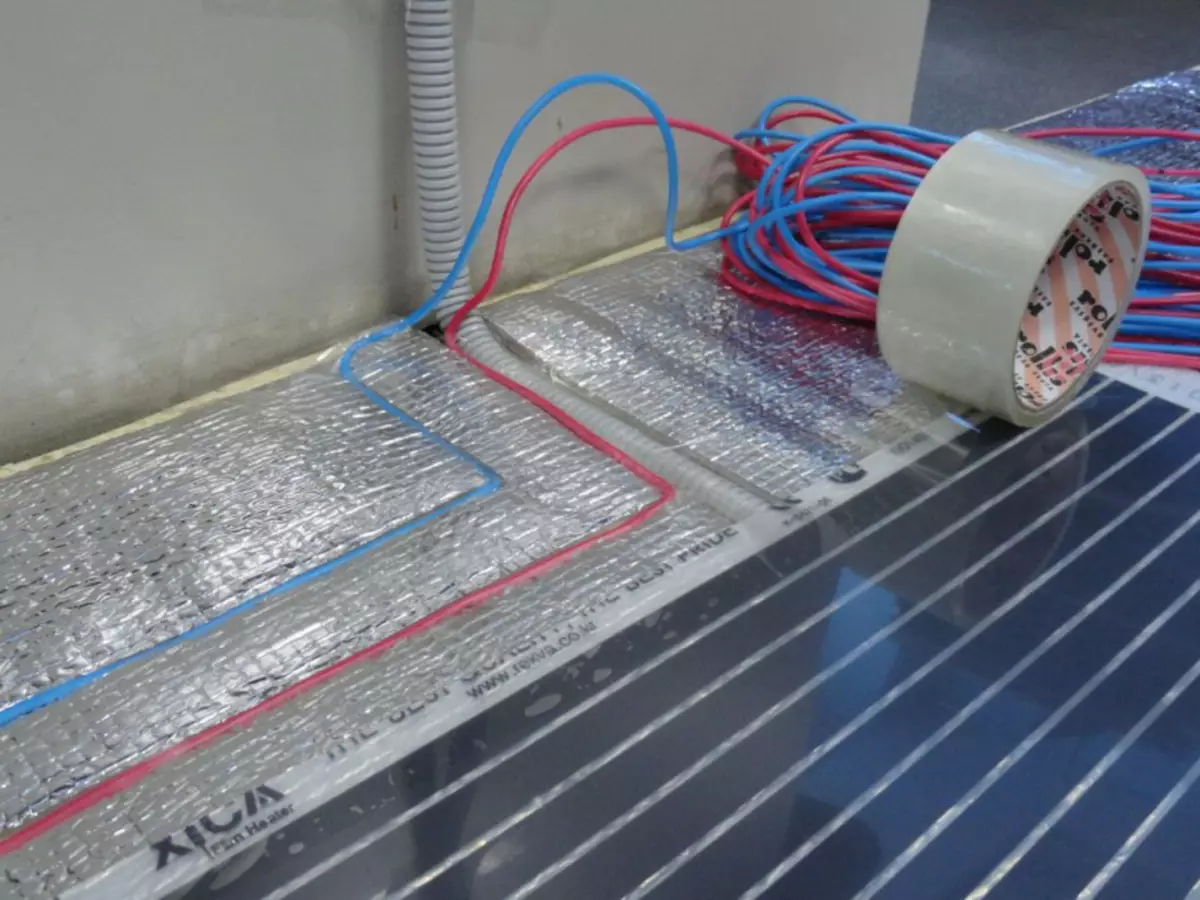

Installation of infrared warm floor

One of the advantages of infrared warm floor is the thickness of the cake. This flooring is considered a homogeneous device (without convex surfaces), the OSB sheets or plywood are immediately mounted on top of it, which further laminate, carpet or linoleum are placed on top of it. The thickness of the "cake" of infrared flooring is from 2 to 4 cm. Read more about the process of laying, see this video:

As a heater, it is customary to use a special polyurethane substrate with a reflective surface (thickness 0.4-0.8 cm), to which the film is stell.

Above it was said that all segments of infrared film have contact exits, the conductors are connected to them, which are subsequently connected in one coupling, from where it is derived to the thermostat.

When installing infrared flooring, it is necessary to take into account the places of laying the film, because it is not recommended to establish this heating system under heavy objects (cabinets, washing machines, couches).

Summing up the article, it must be said that various types of warm electric floors have both similar features of the installation and principle of operation and differences. Choosing a "sample" of the heating system, each owner can use the stated material.

The selection process is very important, because before buying a product it is worth familiar with all the advantages and disadvantages, as well as learn the power parameters for the room where the heating system will be installed.

Article on the topic: Decor of the old door with their own hands: Stained glass window, decoupage, cracker (photo and video)