To date, folk craftsmen often use the manufactured equipment provided. At the same time, it can be used to succeed with success with success, making some details of homemade machines from it.

To avoid dust when working with an indoor machine, install a protective fence.

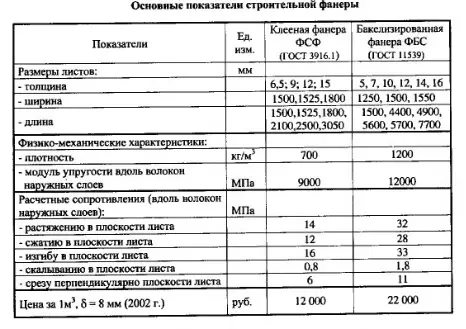

Properties plywood

Plywood - the material is very universal. It has sufficient durability, easy to work, is publicly available and relatively inexpensive. That is why Phaneru often use not only for the manufacture of furniture or decor items with their own hands, but also in order to make homemade machines.

Physico - mechanical characteristics and sizes of construction plywood brands FSF and FBS

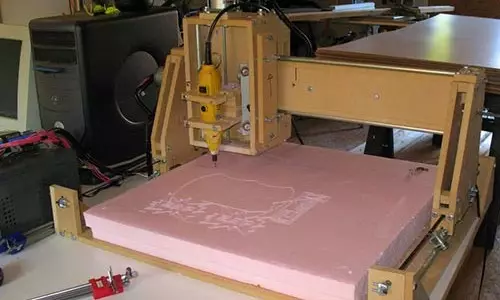

Some parts of the machine can be perfectly replaced with plywood parts made from plywood. For example, a plywood table for cutting material, housings and moving supports made from plywood are perfectly used, are also remarkably proven to be applied. And this is not all the details that can be made of plywood in order to make the machine with their own hands.

When choosing a material, it is worth repelled on which load of plywood and parts are calculated from it. In most cases, manufacturing homemade machine, optimally use the pheaneru of the middle thickness. So, homemade machines are designed for use at home without temperature drops and humidity. Fat is used if the machine or its elements, for example, a table for cutting the material, require an increased fortress, then it is better to use a stronger, thickness of 10 mm. However, making any home machines, initially it is necessary to refuse to use fine plywood, because it is too fragile for such work and is unsuitable for use in the production of a homemade machine.

Article on the topic: Doors Dariano: Brand Overview

When cutting out parts up to 6 mm thickness, you can apply a manual or electric jig. If there is a need to cut a thick sheet greater than a thickness of 6 mm, a disk saw is used.

When sawing plywood across the fibers are made of special cuts with a knife in order to remove the tension on wood.

How to make a homemade plywood machine?

Immediately make a reservation, which means a home machine, which is unlikely to suit for production conditions, but for the home this is the optimal balance of price and quality ratio, taking into account a relatively small load on it. To make a homemade machine from plywood, you need machines for various needs, but the most popular CNC machine is most popular.

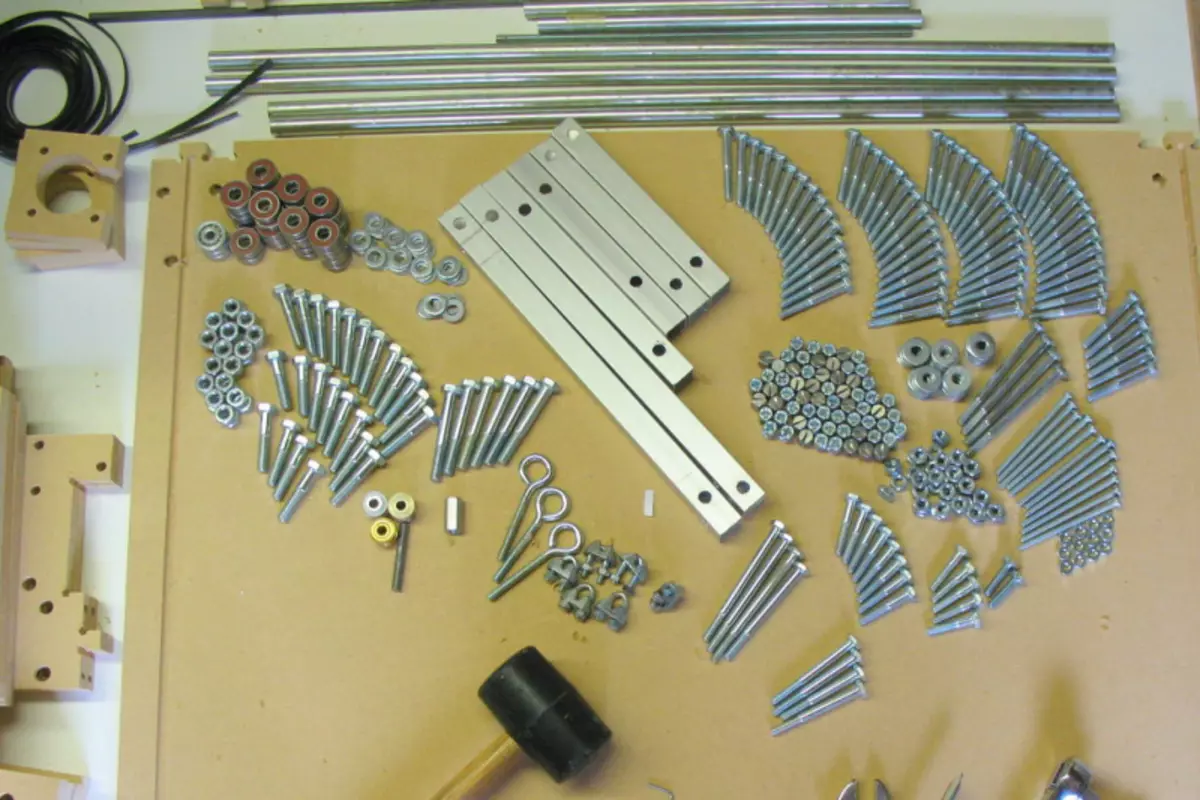

In order to make the CNC of the Plywood Machine, it is not only plywood itself, but also other tools and materials:

Accessories for assembling the machine must be purchased in advance in any construction store.

- Special shafts and holders;

- various bearings;

- screws;

- controller;

- Belts and fixing elements in the form of screws, nuts, screws and washers.

For cutting and cutting, you will need:

- ruler, square;

- knife;

- Lobzik or disk saws based on which thickness of plywood will be applied.

Since the CNC machines suggest the use of parts in which plywood is cut on figurine and must very firmly fit together, so so that there is no slightest clearance, then approach the cutting and sawing, making a future machine, it is very responsible and observing certain rules. .

Making self-contained machine tools for home use, it must be remembered that this material does not tolerate a strong mechanical impact. Therefore, the fastening of parts is carried out using the use of grooves and spikes, which are additionally labeled for the glue fortress. In order for the connection to be reliable, spikes and grooves must be perfectly approaching each other without any gnesks and cracks. No nails or self-tapping screws can be used as connecting elements. Machines and their parts from plywood are exposed to the effects of vibration and with improperly attachment may fall apart in the most responsible moment, because the attachment needs to be paid special attention.

Article on the topic: Inspiration of the day: Homemade gifts for February 14 (90 photos)

Because, manufacturing machines with details from plywood, you have to use the drill, then you also need to observe a small trick so as not to spoil the material. In order for the velocity of the drill in the place of the drill, it is necessary to put on the other side of the same material on the other side of the same material, optimally use the remains of plywood after cutting and cutting.

It's easier and faster to use an electrolovka piece for cutting parts.

After the details are cut, they must be processed, otherwise the plywood can start flaws and collapse. Special attention should be paid to the processing of the edge, which is most exposed to the temperature difference or humidity. As a rule, it was originally every detail to carefully polish sandpaper with small grain, it is necessary to start grinding from the corners along the fibers. The angles are processed by emery paper separately, they are paid to particularly careful attention, if necessary, before processing, they can be stolen.

After completing the thorough grinding of fine-grained emery paper from all parts, it is possible to move to their priming with a special composition, which prevents the effects of temperature and humidity from the effects, as a result of which the plywood can begin to settle and disrupt the operation of the machine. At the final stage, which is done at will, you can spend the color of the parts of the machine from plywood.

Tips for proper sawing plywood

Be sure to cut the dry material, as it is less susceptible to resistance. The use of wet plywood can lead to stratification.

If there are signs that the teeth in the cutting canvase fumbled, it immediately needs to be changed, it will help to avoid the appearance of cracking and the ugly edge, as well as damage.

Along the fibers it is best to operate with an electroller, but a handset is more suitable for cross cut, which will make the edge more uneven, but guarantees the lack of clamping tool or care away from the intended line of propyl.

Article on the topic: put in order an old bath

When working with thick plywood for drinking an arc or a circle, it is best to use a furniture milling mill. In order to quickly avoid chips and other damage, to the place of the future cut the best of all to glue the tape, and then cut the Phaneur.