Table of contents: [Hide]

- How are 3-D panels do it yourself?

- Advantages and disadvantages of gypsum panels

- How to make similar panels with your own hands: manufacturing technology

- How to paint similar panels with your own hands?

With the help of 3D panels, you can create a decor for every taste. They are perfectly combined with different designs of plasterboard sheets. The problem is only that they are quite expensive. It is for this reason that people are interested in how to make such panels with their own hands.

3D panels are recommended to be attached to the perfectly smooth base.

Perform a 3D panels from various materials can even at home. You can use the material in order to separate administrative, residential and other rooms. In order to have the opportunity to strengthen the visual effect of 3D, it is necessary to use lighting with point lights. Panels can have a rectangular and square shape. It is applied a three-dimensional pattern. This material is fixed on the walls. In some cases, oval and round models are manufactured, which can be attached to an even base, and necessarily leave the gaps.

Square and rectangular 3D panels can be exclusively on an even base that must be previously prepared.

Corners in the room must be smooth, for which it is recommended to use the construction level. Ideal for the walls of plasterboard sheets. If you ignore everything that has been said above, then the kennels of the panels or pattern pattern can diverge.

If there is no possibility to achieve a smooth surface, it is recommended to use artificial stone from plaster. A similar option of the room finishes can be hidden almost all the irregularities of the walls and corners due to the relief, which mimics the natural stone.

How are 3-D panels do it yourself?

Mounting diagram 3D panels with decor.

As the basis for three-dimensional panels, in most cases, MDF, bamboo, plastic and gypsum are used.

The cost of such panels depends on the dimensions and the material from which they are manufactured. The average price of material is 2-10 thousand rubles. For 1 m².

For the production of 3D panels, you will need to purchase a special form, which will cost approximately 2500 rubles. Provided that the form will be used daily, it will last approximately 1-2 years.

Back to the category

Advantages and disadvantages of gypsum panels

The 3D plaster panels have the following advantages:

- Invisible joints between the material. This can be achieved using the use of finishing putty and sandpaper. In the future, even a specialist will not be able to see the places of compounds.

- They are easy and convenient to restore. If during the installation process 3D panel will be damaged, it can be easily restored using finishing putty and sandpaper. This panel will not be able to distinguish from the new one.

- Low cost.

The 3D of the gypsum panels have the following advantages: invisible joints between the material, easy and convenient to restore, low cost.

The only disadvantage of such products is a low level of strength. It should be known that the strength can be enhanced by adding fiber or polymer additives. Panels are also recommended to cover lacquer.

If you need to strengthen the solution used, then it is recommended to produce a 3D plaster meter panels.

Gypsopolymer is a unique material that has all the advantages of a gypsum binder and can eliminate its disadvantage that is associated with strength. The panel that was made of a plaster emergency will become strong enough, in connection with which it will be possible to wash. This is achieved through the modifying additives that will completely change the properties of the gypsum. This method of production of three-dimensional panels is recommended to use for mass production to sell products in specialized stores and on the Internet. Gypsum panels will not be damaged during the transportation process.

If you plan to use the panels at home or sell them in local stores, it is enough to use an ordinary solution from the gypsum with the addition of fibrovolok. Fiber fiber is artificial fibers that are present in a mixture for strengthening.

Back to the category

How to make similar panels with your own hands: manufacturing technology

Installation scheme wall panels.

Elements that will be needed to make 3D panels with their own hands:

- 7 parts of water.

- 1 part of lime.

- 8 parts of molding gypsum.

- Fiber fiber, which is soaked in water.

- Polypropylene Fiber.

Prepare a mixture for the panel with your own hands as follows:

- In the prepared capacity you will need to put fibrovolok and lime.

- All this should be poured with water.

- The mixture must be stirred by a drill that has an appropriate nozzle.

- Next you need to fall asleep plaster.

- The mixture should be stirred to avoid the formation of lumps. It will take to achieve the consistency of sour cream.

- The solution is poured into a form for a 3D panel. The process will need to vibrate the table.

- After 35-40 minutes it will be possible to disband.

Fibrovolok can be replaced by sand. In this case, you will need to remove some water and gypsum.

In order for the manufactured panels with their own hands faster, it is recommended to make a chamber for drying.

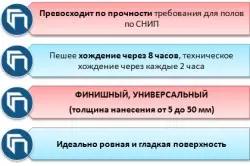

To make a durable 3D panels, it is necessary to use a gypsummer.

Technical characteristics of the plaster emergency.

Gypsopolymer can be made as follows:

- One part of the gypsum will require 10% of the M500 cement. White Turkish cement can also be used.

- Next is added Mataakolin-Putzzolan in the amount of 10% of the mass of cement.

- The C3 plasticizer is 10% of the cement mass.

- 1% of the total weight of the mixture is fibrovolok.

- The finished mixture must necessarily be treated with a hydrophobizer.

Installing the panel with your own hands is practically no different from the installation of an artificial stone. Everything will depend on the basis for which the material is planned to be installed. In most cases, special glue is used to secure the material, which is intended for drywall.

Back to the category

How to paint similar panels with your own hands?

Coloring material is necessary after installing it on the wall. Painting technology Next:

- First of all, it will be necessary to sharpen the seams between the panels. To do this, use the finish putty made of plaster.

- After drying, the putty of the seams will need to be stolen by sandpaper.

- All base panels are processed by primer, which is intended for mineral bases.

- Next, you need to wait until the primer is dry. After that, the material is covered with several layers of water-emulsion paint. You can do this by using a bruster or other tool.

- If necessary, color pigments can be added to the paint. Panels can be painted in one or more colors.

- After painting, you will need to take a rag, after which the beefs from the tassel are stuck.

- After the water-emulsion paint is completely dry, 3D panels can be opened with several layers of varnish. To do this, it is best to use glossy or matte varnish for water-based panels. This must be done in order for the material to be saturated color and shine. A similar layer will give the opportunity to perform wet cleaning.

It is possible to use lacquer for the initial application of paint in the process of initial paint to use varnish for water-based panels in a ratio of 1 to 3. If necessary, you will need to add some water. Thanks to these actions, the water-making paint after drying will not be able to blur. After that, you can apply only one layer of varnish.

The cost of one panel of plaster is approximately $ 1, while in the store the finished panels will cost up to $ 10. During the day you can make approximately 10 m². Making this material with your own hands from the gypsum, you can save a sufficiently large amount of cash. Manufacturing technology is quite simple, you should only purchase all the items necessary for work.

Article on the topic: Dutch style in the interior