Photo

In a properly equipped wooden well, natural water purification makes it better and more pleasant to taste than after processing on a water treatment plant. Such a source is permanently available and can serve as a reserve option for failures in centralized or autonomous water supply.

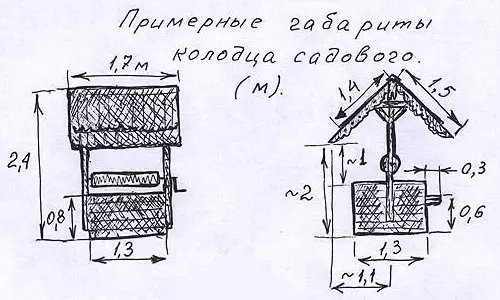

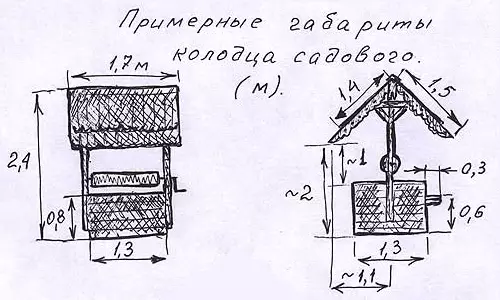

Wooden well drawing.

Underground waters are divided into 3 main types that are located in the depths of the location from the surface: the rigor, soil and artesian. The ridder occurs on a relatively small depth, is not perfectly cleaned from pollution and cannot be used as drinking water. Artesian waters are located quite deeply, the well bored before them pours water to the surface of the gravity. For the water supply of the country area, groundwater is more suitable.

Well design for self-container

The type of the confined well depends on the necessary daily water consumption. If the flow rate is insignificant, the water will begin to stifter and rot. To dig and equip the well with your own hands for individual needs, it is better to choose a mine type.

With a small water intake, a wooden well of an imperfect type is preferred. The inflow of water in this case will be provided through the bottom filter. The mine is plunged on 1/3 of aquifer, the well nutrition from this size will not depend. The arrangement of filters on the walls of the shaft is complex and slightly increase the filling of the well.

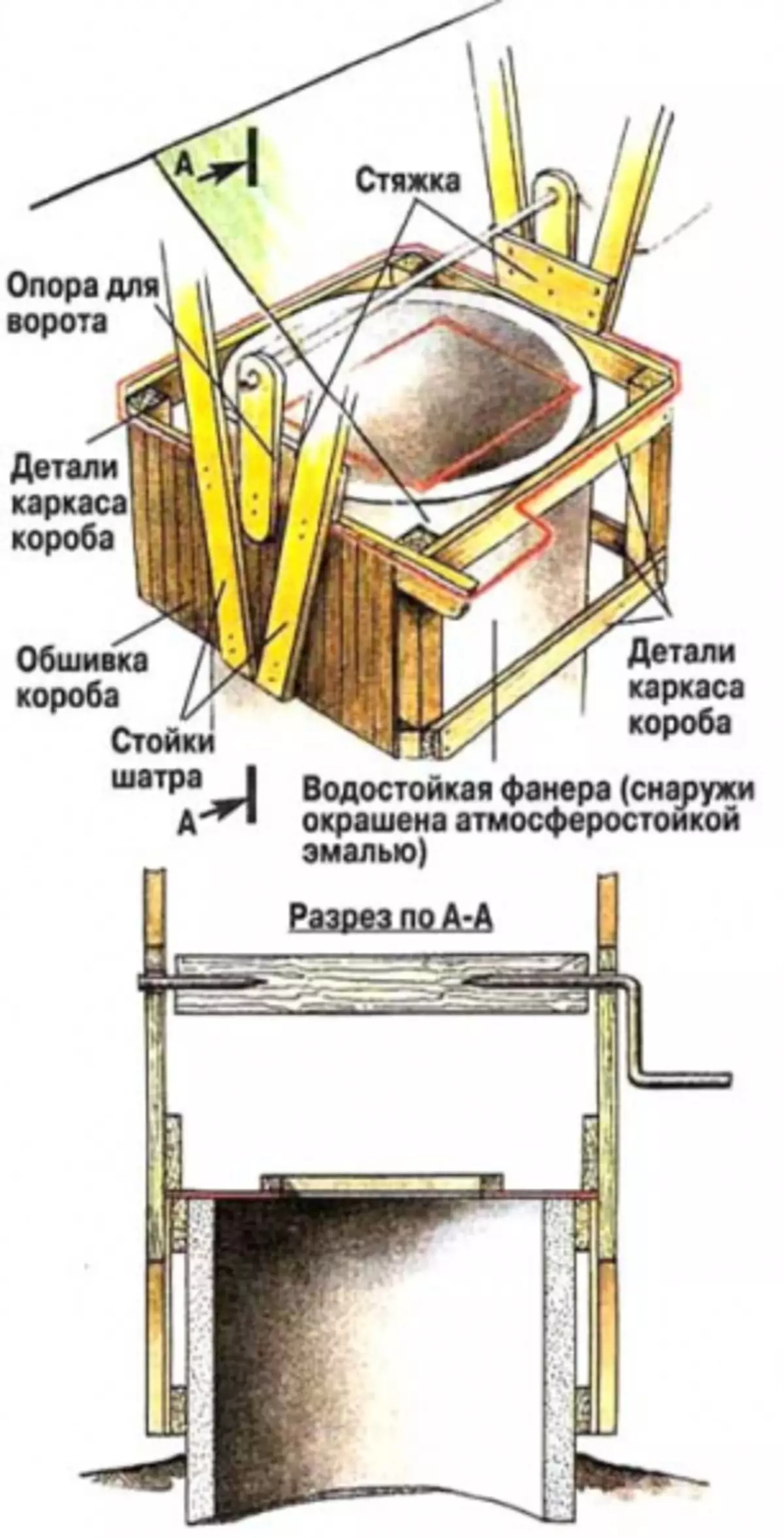

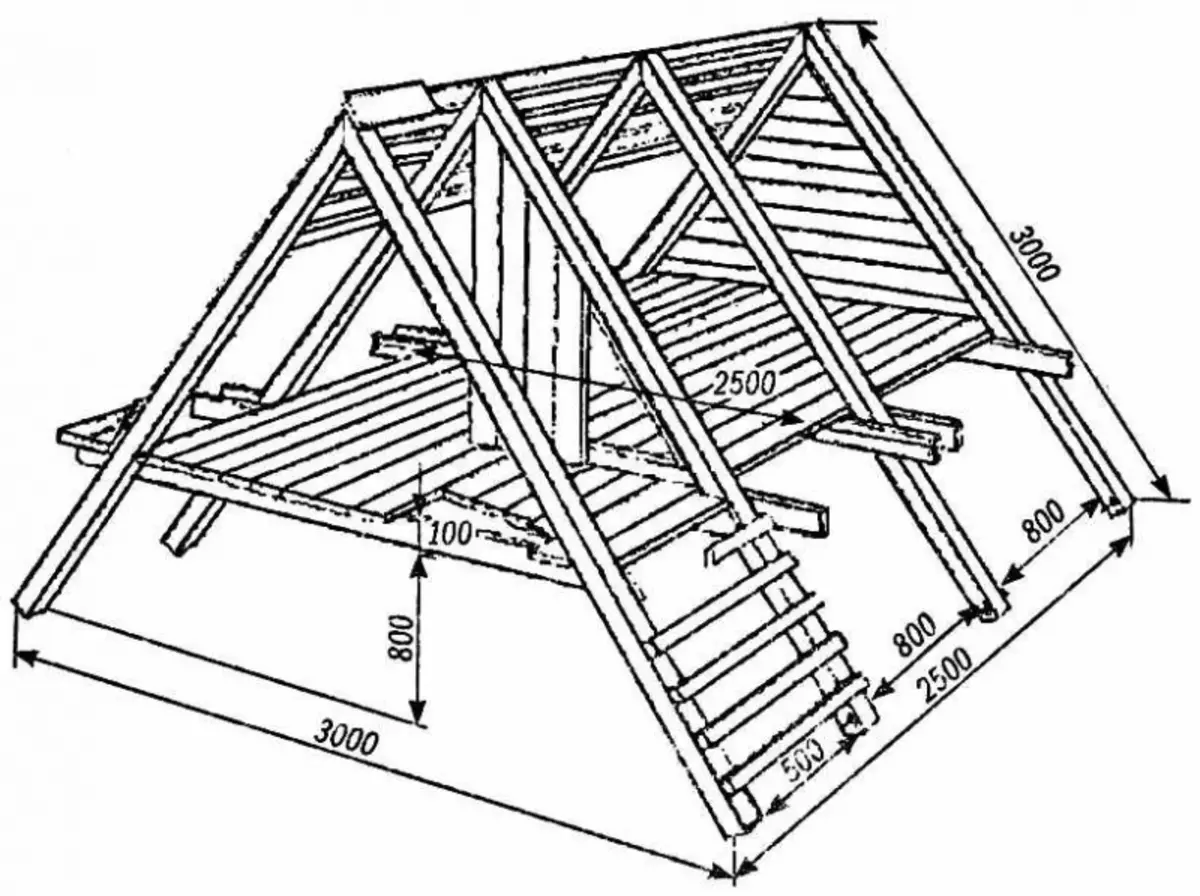

Typical house assembly scheme for well.

When using wood for fastening the walls of the mine log cabin or bars is assembled on the surface. The design is started in the barrel and hesitated to the aquifer with a gradual recess of the soil. The crowns are increasing from the top of the church. With different soil density and the emerging wooden mounting difficulties, other design methods are used.

The water receipt should be equipped with a bottom filter. With a strong dissolument of aquifer (floating) before arranging the bottom filter, the bottoms are resurrected by boards with the preservation of slots or with dried holes.

The well-built well should have a depth of no more than 15 m. With greater depth, the raising of the soil will become difficult. The mine with a depth of less than 5 m is possible to penetrate surface waters polluting the water of the main aquifer.

The transverse dimensions of the mines are accepted exclusively for reasons of convenience in its equipment and reduce the consumption of materials and labor costs. The area of the Well, the well practically does not affect the increase in the flow of water. The lateral section of the bottom matters only when the well is powered by ascending keys. At the best clearing of such a source, the flow rate increases. Optimal for the mine is the size of the parties 0.8-1.2 m, such parameters will allow the use of a manual tramp tool and not produce an excess amount of soil.

Article on the topic: What is better: plywood or plasterboard?

Choosing the location of the well

Scheme selection of a place to install a well.

In order not to dig a well, counting on good luck, it is better to contact the local hydrogeological service, where you can get information about the types of soils on the site, the depth of the occurrence and composition of groundwater. If there are wells on nearby sites, about their parameters and water quality can be asked for neighbors.

For complete confidence in the efficiency of using the future construction, drilling a test well is carried out. It is not recommended to equip the well if the terrain on the plot is swampy. It is possible to reliably find out about the possibility of using water from the existing in the area of the wells for drinking can be in the district SanEpidemstancy.

The well should be removed from septic parts, compost, buildings for livestock and other sources of contamination at a distance of at least 20 m. Do not shift it on the shores of the reservoirs and slopes of ravines to avoid drainage of water. From capital buildings on the site, the well should be removed by at least 5 m.

Earthworks are better spent in summer or autumn. During this period, the groundwater level is the lowest, frequent puming them during the digging of the mine will not be required. If there was late spring, you should wait a month after the melting of snow to sufficient depletion of the aquifer.

Welder Sirway Build Technology

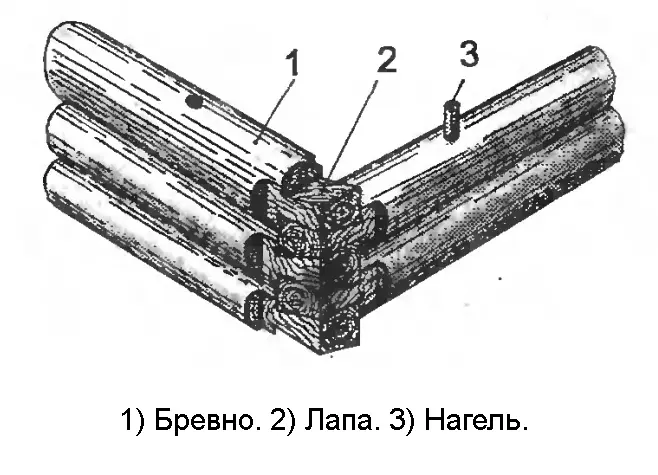

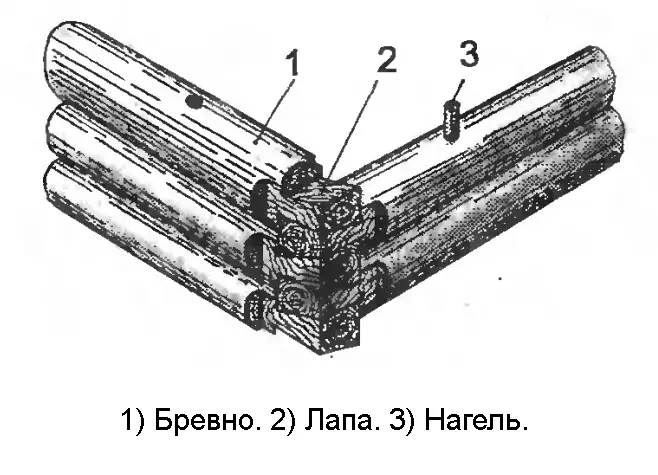

Diagram Connection of the corner of a log of paw.

To build a log, you should prepare the tools:

- benzo- or electric saw, hacksaw;

- ax, chisel, hammer;

- Babel and Tesl;

- plumb, roulette and level.

The log houses take a square shape, more often than 1 × 1 m. Wood for a log cabin is chosen on the basis of the location of the logs relative to the water. The material that is over water is more susceptible to rotting than recessed in it. It is better to combine the use of different forest breeds. Submarine parts should be made of pine, willow or aspen, hanging over a layer of water - from larch, elm, alder or moraine oak. With this combination of material, the well may serve over 20 years.

Oak logs that have passed the filling process, in the underwater part of the well may not collapse over the century. But without specified processing, the tree will give water a bitter taste and change the color to brown. Other types of wood are less durable and affect water quality.

The timber should be straight, disadvantaged. In the logs used, there should not be areas affected by rot or insects. The bark before assembling a log is considered. Processing the material with antiseptics or other protective compositions is not recommended.

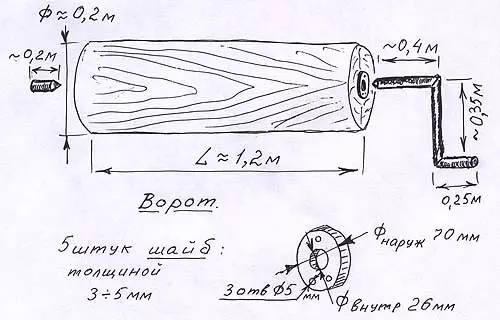

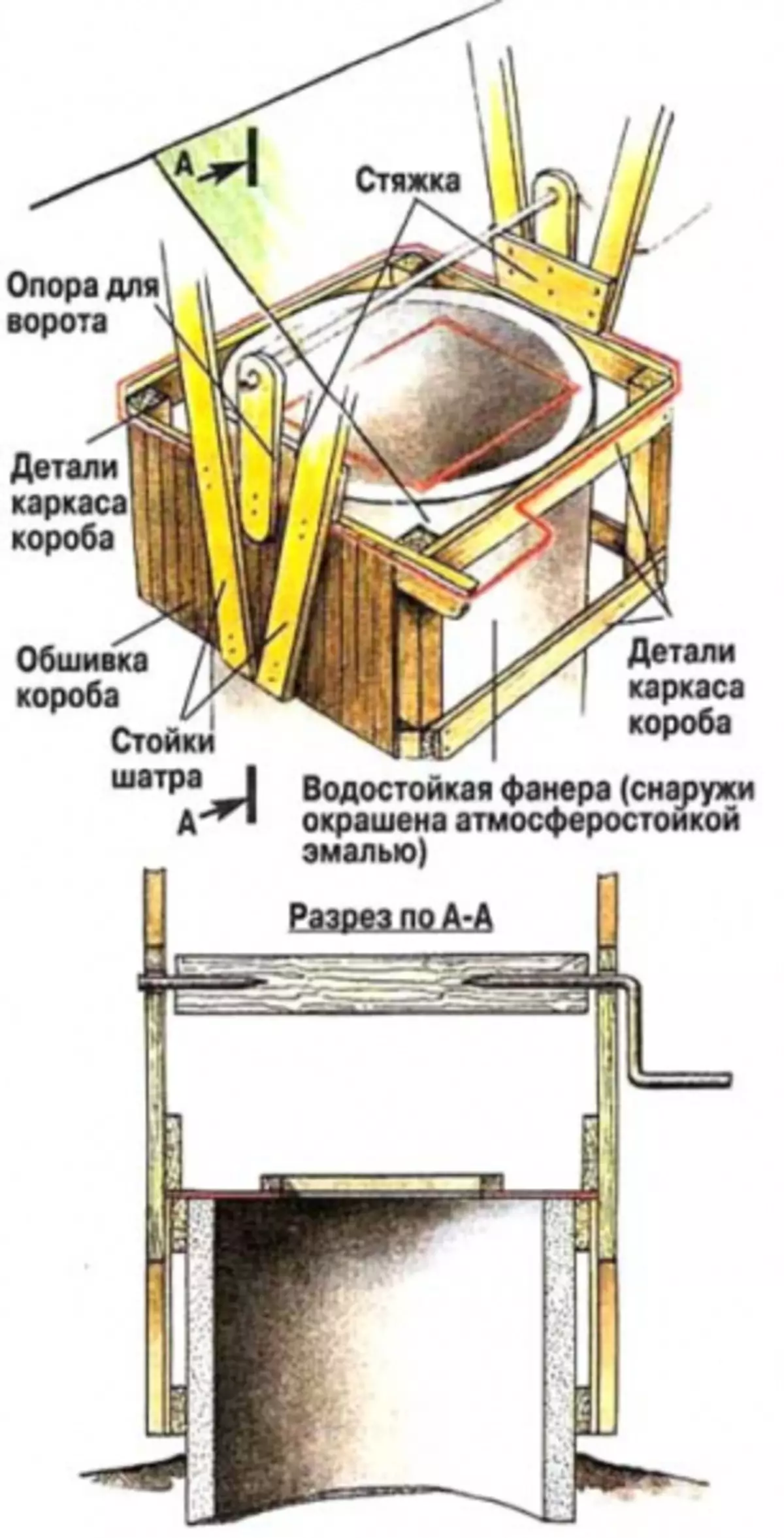

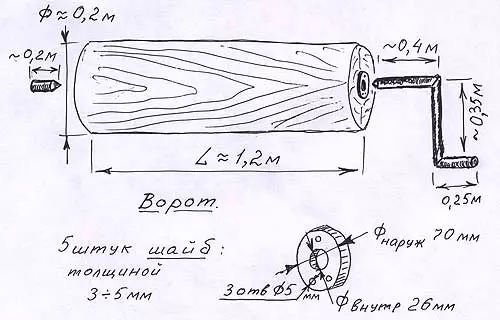

Gate scheme for wooden well.

Article on the topic: Tips for the right glazing of the balcony in Khrushchev

For arrangement of the well, logs are applied with a diameter of 18-20 cm, larger trunks are sawed along. Spiele placed inside the log. Circuit assembly is first made on the surface. If installing inside the mine is planned, the crowns are prepared in advance and place.

In the corners of the cut, the elements are connected in the paw without a residue. The fastener is made of 10 cm in size with a vertical rotation. For the strength of the design, the adjacent crowns fasten with the brackets, they associate in the corners with bars. In the middle of each wall at the installation time nourishes the boards. The logs are customized carefully, as it is not allowed to careen, the paklet will affect water quality.

Fastening the mine logs

For the device mines, the well will be needed:

- Loms and shovels (ordinary and shortened);

- sledgehammer, jack, winch;

- Trenoga, rope and polyspaster;

- buckets and scales for ground removal and sludge;

- soil capacity;

- Rope or Power Staircase;

- pump for pumping water;

- alert or crushed stone;

- Dry clay for "clay castle".

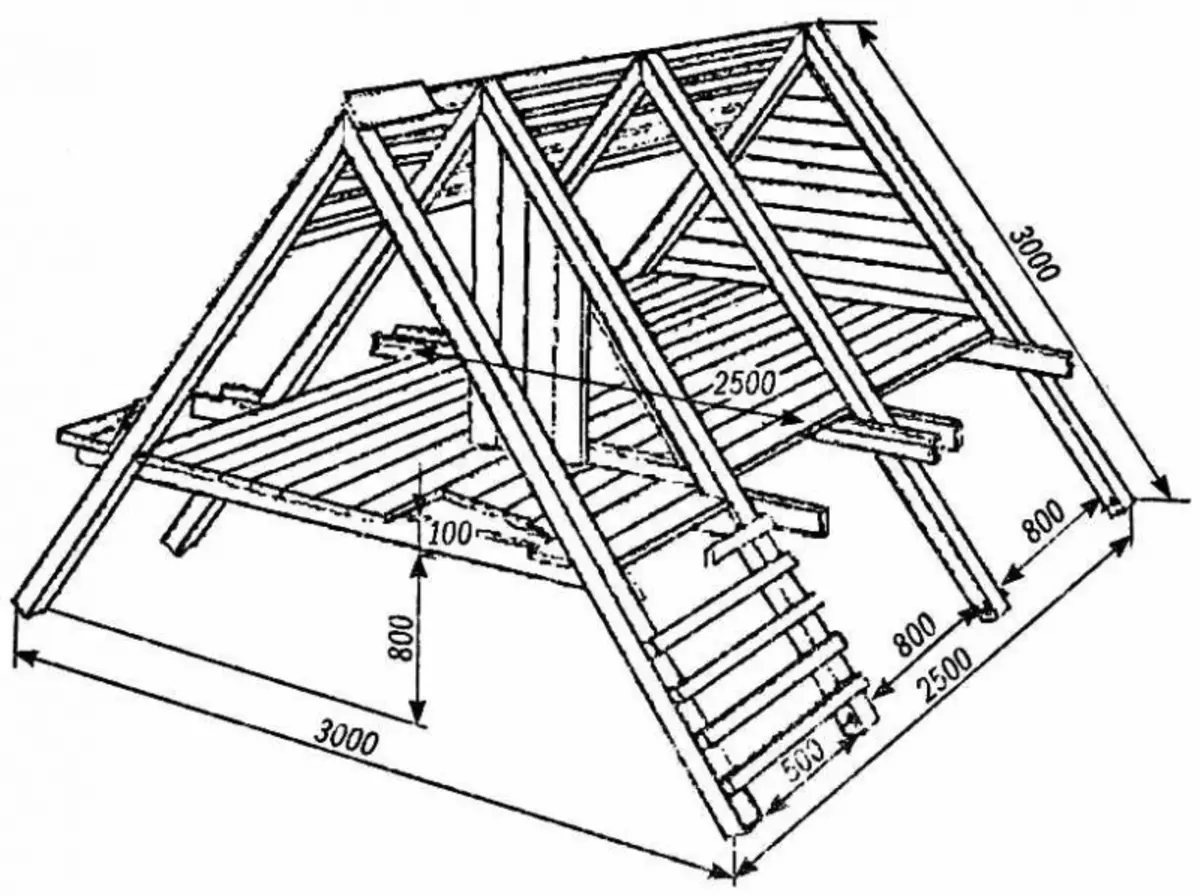

Roof drawing for well.

Fastening the shaft trunk is carried out by various technologies, depending on the structure of the soil layers..

The desired mount is performed at the required depth of the mine more than 6 m. On the surface of the selected site, the future mine of the well is marked. Initially, the ground withdrawal is made by 1.5-2 m. The part is made of a segment with the amount of crown at the initial depth. The protrusion above the surface is made in 3-4 crowns. In the lumen of the mine neatly the collected log houses, not allowing soil collaps from the walls.

The bottom is deepened by about 30 cm, under the frame, the soil is removed from the middle of the wall, but is left in the corners. In a niche for the lower crown, supports are installed (wedge lining). Then the soil is selected from under the corners. Supports are knocked out and the box is uniformly plastered. As the mines are deepened above it is a tripod with a polyaste to facilitate raising the produced soil. For a convenient assembly of a log above the mine in some cases, the framework of logs is erected, the polyspaster is attached at an altitude of about 1.5 m above the ground surface.

The sediment of the bar produce sledgehafts through the subled timber. So that the log house lay down in the mine easier, on its foundation sometimes a special shoe with a cutting knife is mounted. Next, a sequential deepening of the mine and the extension of the upper rows of the crowns is made. The flowing water is painted with buckets, and undermining the lower crown continues.

Scheme of a mine well device.

When aquifer is reached, the mine will gradually fill with muddy water. She pumped out the pump, and the mule is painted with buckets. The log house is lowered before the appearance of water volumes that do not allow further blockage.

After the work on the fastening of the shaft barrel and the removal of the accumulated water is equipped with a bottom filter. The bottom is aligned and falling asleep with a layer of sand (20-30 cm). The filter is formed from the 3-layers of rubble or river alert. The layers are stacked at 15-20 cm with an increase in the fractions from the bottom up. The size of the fragments increases with each layer in about 6 times.

Article on the topic: What to do if the water in the bowl of the toilet is constantly overflowing

Other events for installing a church in the mine

If the sediment of the structure makes it difficult, the flooring is satisfied on the upper crown and the massive cargo is stacked. If the box fails to be precipitated to the desired depth, further extension of the crowns are produced in a mine from top to bottom from the lower edge of the cut.

The crowns added below are made from longer logs, undermining special niches for them (Pecheura). The collateral is mounted every 4-5 of the crowns, the ends of the 2nd logs (fingers) in the Pecheura 0.5 m. The crowns set in this way do not give the design of the structure with further recess of the soil. Sometimes for fastening the part of the barrel left before the aquifer, the box is descended from thick boards.

If the required depth of the well is known in advance and does not exceed 5 m, the extension of the crowns can be carried out from the bottom of the mine.

This technology is applicable if the stem walls are quite strong and the volume of water flow allows you to install. The well rushes to the full depth, the beds are laid on the bottom - painted along the log. The boards are sewn from above, and the grazing assembly begins on them.

With a relatively shallow depth of the well, the log cabin is attached to mounted above the shaft frame and hangs over the bottom at an altitude of 1 m. This will allow you to produce a free recess. With certain hydrogeological conditions, the area there is a need to prevent the influx of water from the rigor. In order to preserve the purity of water in the water receiver, the outer walls of the cut are ridiculous by the headboards.

The head board is constructed with an elevation of 0.6-0.8 m above the ground surface. The clay castle is placed around him. To do this, the trench of 0.5 m and 1 m in depth is digging around the head. A reinforced concrete breakfast is performed on top of the lock to prevent mold and rainwater from entering the mine. The gate is installed for lifting a bucket, the well is equipped with 2 lids.

To protect the ground construction of the well, a double canopy hanging on 0.5 m on each side of the cut. You can build a closed building to protect against atmospheric impact.

Construction well with your own hands, you should be prepared for various freelance situations associated with the special properties of the soil layers. If the problem is not solved with the help of knowledge available, it is better to contact a specialist. Special attention is paid to the safety of this kind of work.