Before finishing the walls, they need to be properly prepared. Experts advise to remove the layer of plaster and level the surface, make reinforcement and then put shnot. The finish putty is one of the main stages, the mixture for which it is worth choosing carefully. Why it is needed, which options are offered today manufacturers, how to apply material to the selected surface - find out right now.

Why it is needed

The finish putty is a special building composition that is necessary for the final stage of wall decoration.

What is the role of such a mixture? It allows you to finally align the surface after finishing works. It can really hide small defects in size. It also protects the walls from possible physical damage. Finishing putty increases the functional qualities of the base. Makes the coating durable, durable and protected from the negative effect of the outside. Such a tool is designed to give the walls aesthetic appearance. After it is applied, the surface look perfect, and the finish is completed. The thickness of such a coating is 1 - 2 mm, so the wall prepared for decoration looks excellent.

Summing up, it can be safely argued that without the finish line, it is not necessary to do without the high-quality finish of the walls and the ceilings indoors.

Types and selection

By types, the finish putty is plaster, cement and polymer. Gypsum to go well on any surface, making it matte. It can be applied both thin and thick layer dries in a short period of time. Cement will be easy to use even for beginners. It is easy to breed, the flow rate per square meter is relatively small, and the cost is acceptable for everyone. The polymer material is expensive, if compared with the first two, but has many advantages. The finished solution retains viability up to 3 days. Allows you to make a very thin layer - about 0.2 mm.

Next, consider the finishing agents of the well-known manufacturers popular to date today, and let's try to determine which one is better to use.

Putthawned prospectors packing 20 kg is characterized by environmental friendliness, good adhesive properties, resistant to negative exposure from the outside, is used without regard to weather conditions. The mixture of prospectors (20 kg) dries quickly and is represented by the manufacturer in a rich assortment.

Article on the topic: Basket for linen from newspaper tubes

The putty prosperity (20 kg) is basic, gypsum and polymer-based. Basic mixture prospectors 20 kg is suitable for finishing the following surfaces: plaster, brick, concrete. The flow consumption of 1m2 is 1 kg, if we apply a layer having a thickness of 1 mm, so that packaging 20 kg is enough for about 20 m2. The mixture of polymer-based prospectors reduces the number of costs of paints and varnishes, creates a smooth surface of the walls, has a white coefficient up to 89%. Another kind - a white-colored finish mixture, made on the basis of gypsum. Allows you to create a high-quality layer under the finish, close small cracks and joints between plasterboard sheets. Puttyer prospectors (20 kg) is advantageous for the price. A mixture of prospectors in packaging 20 kilograms is popular among finishing masters.

Finish putty Hercules is better suited for high-quality wall decorations under painting and wallpaper. The spacure of Hercules consists of polymer additives and fine-dispersed fillers. Hercules perfectly withstands the temperature differences and nature whims. Hercules well lies on a brick, concrete, stone, stucco. The putty Hercules is economical to use, does not succumb. The mixture of Hercules has a high degree of adhesion. The thickness of the applied layer of the finishing agent of Hercules is 3 mm. The putty Hercules in the cooked version should be used as quickly as possible.

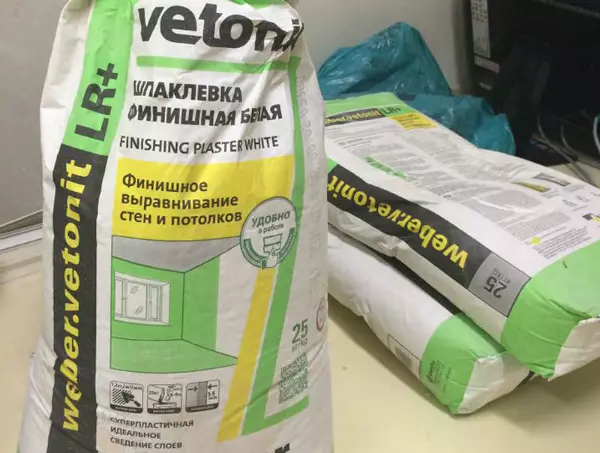

Vetonit putty is easy to use, falls on any surface you need, dries quickly, has excellent adhesive qualities. The finish mix is eco-friendly and is not dangerous to human health. In the composition of Vetonit, there are safe components - polymer and organic adhesive compositions, limestone, mineral supplements. The mixture of the wind is suitable for surfaces such as concrete, plasterboard, brick, chipboard, ceramzitbon. It is not recommended to use Vetonit putter for surfaces that applied aligning and water-soluble compositions. It is impossible to be embedded with a mixture of winds and seams between plasterboard plates.

Before applying a vetonit tool, you will definitely clean the surface and dry. The mixture is monitored sensitive to moisture. Putting a vetonit putter is permissible surface with a temperature of more than 10 degrees of heat. It is necessary to knead a solution with a nozzle, adding a dry mixture to the water. Vetonit finished solution is suitable for 2 days. Manufacturer of putty Womens recommends applying it to its manual way, in which the flow to 1m2 will be small. The seams and the vetonit treated surface is better to handle emery paper. When working with a mixture, we use protective masks from dust. The putty has a democratic price with high quality and reliability. A mixture of unconite is designed to perform finishing works in dry rooms.

Article on the topic: Laminate laying methods: Direct, diagonally, christmas tree

The wet is a putty, which is created by the manufacturer based on plaster, mineral fillers and modifying additives. It can be used in any premises except bathroom. The wrap is suitable for finishing the finishing of walls and ceilings, preparation of drywall sheets and plates to painting and pasting with wallpaper, leveling surfaces, preparation of plastered concrete, aerated concrete surfaces to painting.

The wave mixture is better manifested if the base is dry and purified. The finishing of the volatile is divorced in water with a temperature of 5 - 20 degrees, the flow rate is 0.5 liters of water per 1 kg of the mixture. The resulting solution of the wound should be applied for 60 minutes. The advantages of the wrap putty - the final preparation of surfaces, the high degree of whiteness, during the final processing is not small, it turns out a smooth level surface. A mixture of an eco-friendly vehicle, plastic and dries quickly. The consumption of the mixture at a layer thickness of 1 mm is up to 1 kilogram per 1m2. At a temperature of 21 degrees, frozen after 5 hours.

Rotband CNAUF spacing mixture is suitable for processing plastering, cement, concrete, drywall surfaces. After applying Knauf Rotband, the surface becomes white, acquires elasticity, smoothness, has good adhesion. After the means, Knauf Rotband will not be unpleasant odors, and the solution is suitable for use for a long time. Temperature for working with Knauf Rotband should be from 5 to 25 degrees of heat. A mixture of Knauf Rotband is produced in buckets of 3, 8, 18, 28 kilograms. Consumption of the ROTBAND KNAUF to 1M2 is 1.3 - 1.5 kilograms. A mixture of Knauf Rotband will allow you to get a smooth and smooth surface under painting or sticking even thin wallpaper. Knavuf Rotband should be applied in a dry room where the degree of moisture is no more than 50%.

American putty stitches are perfectly suitable in order to impose a connecting tape, the main layer passing in a metal corner, the second and third finishing layer, when performing lamination, texturing, for seelings of cracks in the structure of plaster, for work on this type of surface and concrete bases. The mixture is applied without problems, perfectly connected with the surface, easy to use even for beginners, resistant to cracking. Logging allows you to make even walls even in a wet room. The tilt of the stroke helps to reduce the amount of incident putty. In the process of applying the mixture, the shrinkage does not shrink, so the finish passes faster and better, as well as seams. The consumption of putty linked is 1 kilogram per 1m2. The mixture of the liner does not have a specific smell, is able to be stored for a long time. The finish putty firm company is available at a price and at the same time characterized by high quality.

Article on the topic: Wallpaper under painting: photo in the interior, what better, pros and cons, how to paint with your own hands, reviews, smooth stencils, structural, fiberglass, video

What is the consumption of each of the putty and for which they are applied, you already know, and what mixture it is better to use - solve yourself.

Application technique

To perform work, it is customary to use 2 metal spatula - narrow and wide.

The cooked solution is placed in a shallow pallet. Choosing a mixture with small portions, should be applied to the surface, pressing the tool at an angle of 70 degrees.

The amount of the mixture and the thickness of the layer is actually adjusted by controlling the angle of inclination of the spatula and the pressure force.

Cracks and other irregularities of the surface are filled with a small spatula. Then the reinforcing painting mesh made of fiberglass is superimposed. It will be completely able to replace it with a medical bandage or gauze. The surface around the slit is lubricated with a solution, a mesh strip is superimposed on top, after drying, the area is sweeping with a wide spatula.

The putty is applied on the surface, by processing small areas. Control the result is convenient with the help of a long line or rule, help and glare on the surface - when the light of irregularity is clearly visible. After the finishing layer is working normally, the surface is grinning. You can still check the quality of the finishes using electrical lamps - their light should be sent in parallel to the surface.

Video