PVC windows today can be found in almost every apartment, a private house. Installing them, the owners are trying to protect against noise, give a housing aesthetic appearance. However, many of them do not think about the fact that these windows are with the advantages have a disadvantage. They do not breathe, which leads to a greenhouse effect indoors. This shortage is deprived of wooden windows.

The windows of wood give the room to breathe and do not lead to the greenhouse effect.

A tree is not easy breathing, it can create a special microclimate in the room and maintain it in the room. Modern production produces wooden windows from various wood breeds, different shape and color. However, wooden glazed windows do it yourself quite possible. For this you need skill and patience.

Materials and tools

For faster and high-quality windows, you will need power tools on wood.

In order to make wooden double-glazed windows, oak wood, pine, ash, birch. Oak frame will be the most durable, however, it is difficult to work with this wood because of its hardness. At the same time, it can later give any shade. Any selected wood for making windows should be carefully dried to avoid the windows of the ready-made window. When drying, the frame can crack, explode. These deformations can lead to the need to replace the window, it is unlikely to be able to repair it. And these are additional costs.

In addition to solid wood for windows, glued bar can be used as a starting material. It is produced by gluing individual thin lamellas with special glue. Such a bar is not subject to deformation and does not require additional time for drying.

Article on the topic: The simplest 5 ways: how to remove wallpaper from the walls

To large extent will accelerate the work and make it easier for its power tools:

- plane;

- a circular saw;

- Lobzik.

Of course, with their absence, you can do the manual inventory: a chisel, hacksaw. Preferably, when making wooden windows with your own hands, use good electrical instruments that allow you to perform a high-quality adjustment of the grooves.

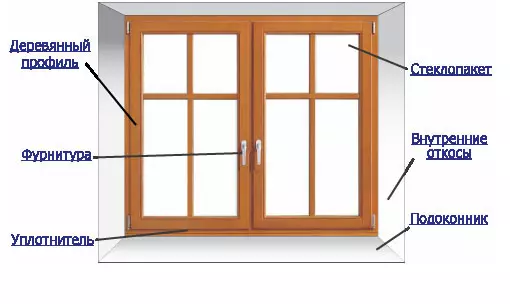

View and overall window diagram.

Therefore, for the manufacture of windows, you must take a quality material and a great tool.

Also do not forget about:

- roulette;

- chisel;

- level.

Framework: Features

Before starting work, it is necessary to measure window openings. This can be performed using a roulette. It should be noted that if the wooden windows are performed for a private structure, then the size of the windows can be completely different. But even the windows in the standard apartment may differ slightly in size. Therefore, regardless of the structure, measurements must be performed at each window opening.

The windows with triple glazing retain more heat in the house.

Brucks of the window frame are connected by a spike-groove method. This is the most dense connection that will last long. For its execution on the vertical side of the frame, the groove is drilled, and the spike is cut on horizontal. The depth of the groove corresponds to the width of the bar.

As a mark of the required size, you can make a shallow gun with a knife. From the end there is a slot with an electric bison and wood is removed. Using the caliper, the axial line of the groove is determined - the center of the bar. A hole is drilled on this line using a drill and drill to work with wood. After marking the shape of the groove, it is cut with an electric bike. According to the same principle, 4 grooves are performed.

Further on the bars that will be a horizontal part of the frame, it is necessary to perform a spike. The thickness of the spike should be slightly larger than the width of the groove, for a more dense connection and an accurate fit of the parts when assembling. All marking must be performed using a caliper. For spikes from the central line, the bar are measured with a spike width and cut off the spike with an electroll bison or use a saw and a chisel. The surface of the spike that will border the groove with the bottom of the groove, it is necessary to round the chisel.

Article on the topic: How to stroke the curtains from organza without spoiling?

In addition, it is necessary to cut the groove grooves.

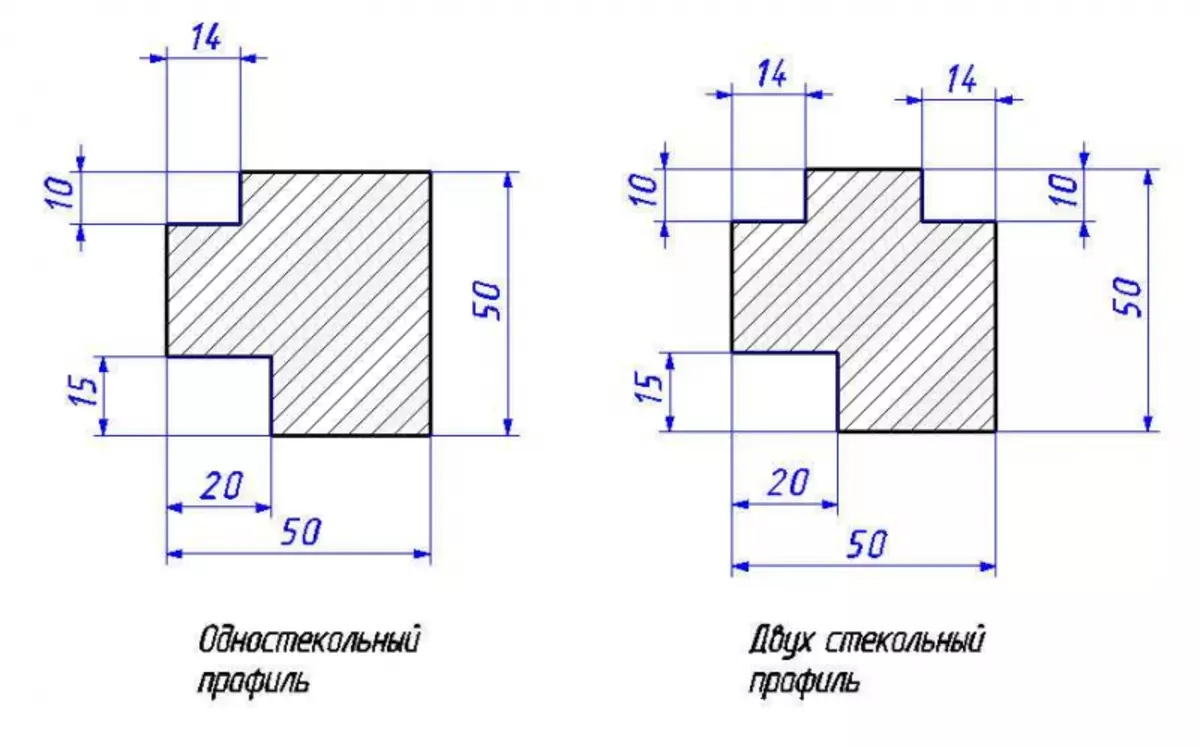

The most acceptable dimensions are the grooves with a height of 10 mm and a width of 14 mm.

After the preparatory work performed, you can proceed to assembling the frame of the future window. Additional strength to the connection will be given to apply glue in the joints of the joints. Excess glue must be removed before it is frozen.

Glass cutting: Practical recommendations

Scheme of profiles with one and two glasses.

Glass, before cut, should be carefully placed. The size should accurately correspond to the size of the frame. Error is not allowed even in 1 mm.

For cutting glass, you must follow several rules:

- put on gloves and safety goggles;

- Clear, wipe dry glass;

- Apply a thin layer of oil to the surface of the glass in front of a sharp;

- The incision itself must be performed by one confident movement.

The incision will be sufficient depth, if, when you press the glass tool for cutting glass, a characteristic creaking sound will be heard. After the end is performed, the glass is shifted to the edge of the surface on which the cutting is performed, and after pressing the sliced part of the glass will fall.

The edges of the finished glasses must be treated with emery paper.

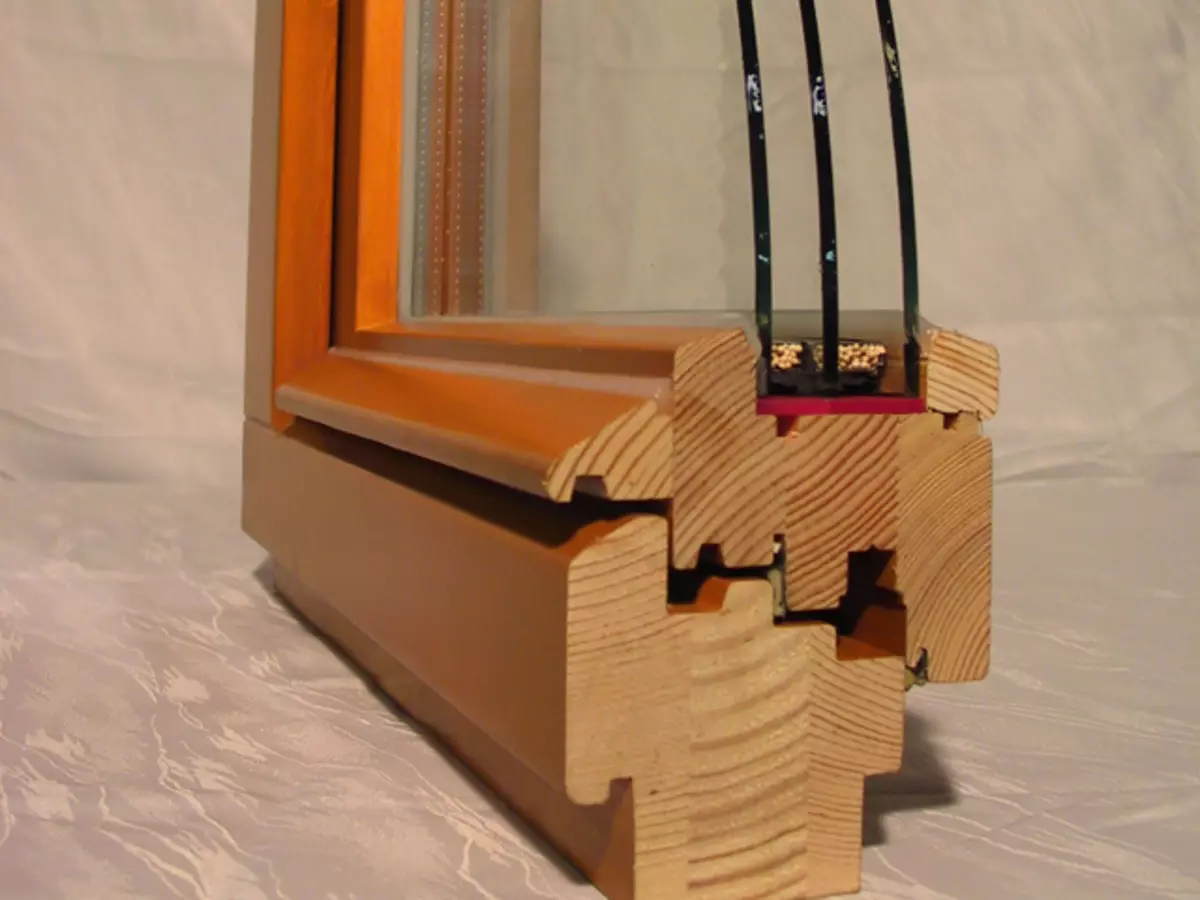

Wooden double-glazed windows: Build construction

Cutting glass should be made on dry, clean glass, is made in one movement.

First you need to carry out the fitting and fit. To do this, stick the glass in the frame, browse and make minor adjustments if necessary. Glass is removed from the frame and laid sealant. Then the glass is again placed in the frame and fix the stroke. After that, on the same principle insert the second and, if there is, the third glass.

In industrial production, material with a large number of minor pores is used as a desiccant. The molecular sieve task is to absorb moisture from the air or gas, which is inside the window between the glasses. To do this, use silica gel in granules. However, the granular silica gel can also be purchased in stores. This material is placed between the glasses.

Article on the topic: How to cover brick on the balcony is best?

The window inside itself is filled with air, since it is impossible to fill with gas in the manufacture of a wooden double-glazed glass, as in industrial production, it is impossible. However, if there is a compressor, the space between the glasses can be filled with dry air.

After that, you can paint the window or give the desired tone using the veil. After drying, it is possible to cover it with varnish, which will protect the wooden double-glazed glass from the penetration of moisture. Most often lacqued several times.

Handles, which are suitable for the room style. Special recesses for fastening the closing mechanism in the sash are cut in advance.

If this was not done or its size does not match the fastening, then the chisel is neatly done deepening. In this case, the frame itself should not be damaged. Wooden double-glazed box, made with your own hands, can be placed in the window box.

Useful advice

When using an electrolybiz, it is better to take a small pylon for it, then the edge will be smooth, without chipping.

If necessary, you can attach a rubber seal to the outer part of the window, which will allow the window to close the denser.

Surplus sealant, putty, which are used in the process of how the double-glazed windows are mounted, should be removed neatly immediately after their detection. Otherwise, after their frost, it will be very problematic.