Paul alignment is one of the most important steps of repair work. Before laying the finish flooring, the floor screed is performed in the apartment. During the construction of multi-storey residential buildings, a reinforced concrete slab is used as overlaps, which has a smooth surface only on one side. The smooth part always lays towards the ceiling, therefore, the side with defects serves as a floor. In this article, let's look at how to make a center of the floor in the apartment, views and rules of preparation of mixtures.

Functions tie

The screed eliminates the height difference and its defects, allows you to qualitatively lay the finish flooring. If you sit down the linoleum on the uneven floor, it crackles in times in the places of height drops.

Functions screed in the apartment:

- strengthens the concrete base;

- perceives and distributes loads arising during operation;

- increases heat and noise insulation;

- Due to the perfectly smooth surface, the floor covering from damage is prevented;

- It allows you to arrange a technological bias of the cuisine floors and a bathroom for removing water in case of flooding when the communications fails.

Using a screed, you can raise the floor level. In the course of work, you need to take into account the permissible loads on the stove. To fill the concrete more than 70 mm in thickness is not, since the overlap may not withstand the load.

Types of mixes

Often questions arise how the floor screed is done in a new building, which is better. We choose the technology of laying the base of the floor depending on the structural features of the plate.

Stages of performing dry screed

Views:

- Dry and semi-dry screed is used when drops at a height of 30-50 mm. Compared to other species, lighter materials are used, due to this, the load on the stove is reduced.

- The installation of a concrete screed is used for damaged floors with a large difference in height, increasing heat resistant and noise insulation.

- Self-leveling mixtures are used when height drops up to 30 mm. Include two stages of work: alignment with starting mixture and finishing bulk coating.

The type of screed is chosen depending on the state of the concrete slab, functional features and flooring.

Preparatory work

The floor in the new building often has to be aligned at the stage of settlement in the apartment.

Stages of preparation:

- We remove the old flooring, inspect the stove for the presence of cracks, depression, protruding reinforcement.

- Cracks are expanding with a grinder, we clean their edges, poured with concrete mortar; For better adhesion materials, the surface must be mixed.

- After soaring the cement, we remove dust from the plate with a vacuum cleaner.

- In places of floor compounds with walls, we put the damper tape. It will serve as a compensation seam when expanding concrete during drying and will protect the lower apartment from water flow.

It is recommended to perform waterproofing plates with bitumen mastic or dense polyethylene film. Rolled materials are placed on 150-200 mm.

Paul marking

Markup is performed from the lowest section of the floor

Article on the topic: how to make a closet on the loggia and the balcony of the lining

The thickness of the screed and the choice of material for its installation depends on the floor height drops.

We find the lowest and high point of the floor. We make marking with a laser or water level.

If the top point was the threshold, you can pour a concrete base. If the angles of the room are above the threshold, there are two algorithms for action:

- We dismantle the old screed to the plate, pour a concrete, configuring under the floor level in the adjacent room;

- We pour concrete to the old basis, but we consider that the height of the floor in this room will be higher than in the adjacent one. This is justified if it is planned to make new floors in the entire apartment.

To properly designate the border of the floor, you need to place the guides at a distance of 150-200 mm in parallel from the wall. The distance between the guides should be less than the width of the tool for the distribution of the mixture.

As guides, we use T-shaped profiles intended for aligning vertical surfaces. To place them in the level we use plastic and metal strips or set lighthouses on a gypsum (cement) solution.

Cardboard, chipboard and wood applying as a support for lighthouses can not, as they lose the form from the effects of moisture.

Calculation of the number of components for concrete

The volume of the screed is measured in liters

To determine the amount of sand, cement and water, calculate the volume of the screed in liters. For this, the middle height is multiplied by the length and width of the room, we get the volume.

Suppose, taking a room in a width of 4 m and a height of 3.5 m, the screed is poured with a thickness at the bottom point 25 mm, at the highest 40 mm.

Calculate the average thickness of the concrete coating (25 + 40) / 2 = 32.5 mm.

Calculate the room area: S = length 4 m * width 3.5 m = 14 m.

Volume = 32.5 * 14 = 497 liters.

Sand will need as much as the volume of the screed. But sand weighs 1.5 times more water, therefore 497 * 1.5 = 745.5 kg.

And cement will need 1 part into 3 parts of the sand. 745.5 / 3 = 248.5 kg.

The volume of water used depends on the humidity of the sand. Water is added to the preparation of the consistency of thick sour cream.

Quality concrete solution

Mix the components in a specific order

Article on the topic: How to make a wooden chaise longue with her own hands

After marking the floor, we proceed to the preparation of concrete. The preparation scheme is standard, one part of high-quality cement (M 200) accounts for three parts of the sand.

We mix the components correctly:

- First, you need to mix dry components with each other well: cement and sand. Since the large volume of the solution is mixed, you need to prepare a drill with a special nozzle or a building mixer in advance, since it is manually to mix the components to mix well.

- To protect the surface cracking during drying and further operation, it is recommended to add plasticizers into the solution. Technology and proportions are indicated on the packaging to the composition.

- The quality of the solution is tested by squeezing in a fist handful of solution. It should not crumble when compressing and cracking.

| Brand concrete | Application | Consumption of cement in kg per 1 cube concrete |

|---|---|---|

| M100 | Minimum strength. Used in concreting road borders, fences | 165. |

| M200 | It is used when installing the floor screed in new buildings, during repair work. Suitable for the foundation device | 240. |

| M300 | It is used for the installation of foundations, overlaps, etc. | 320. |

| M400 | For the construction of structures subjected to significant loads: Bridges carrying supports on overpass | 417. |

To get a homogeneous mixture, dry components fall asleep into the water. If you do in the reverse order, the sand with cement will remain at the bottom, and it will be difficult to mix.

Concrete tie device

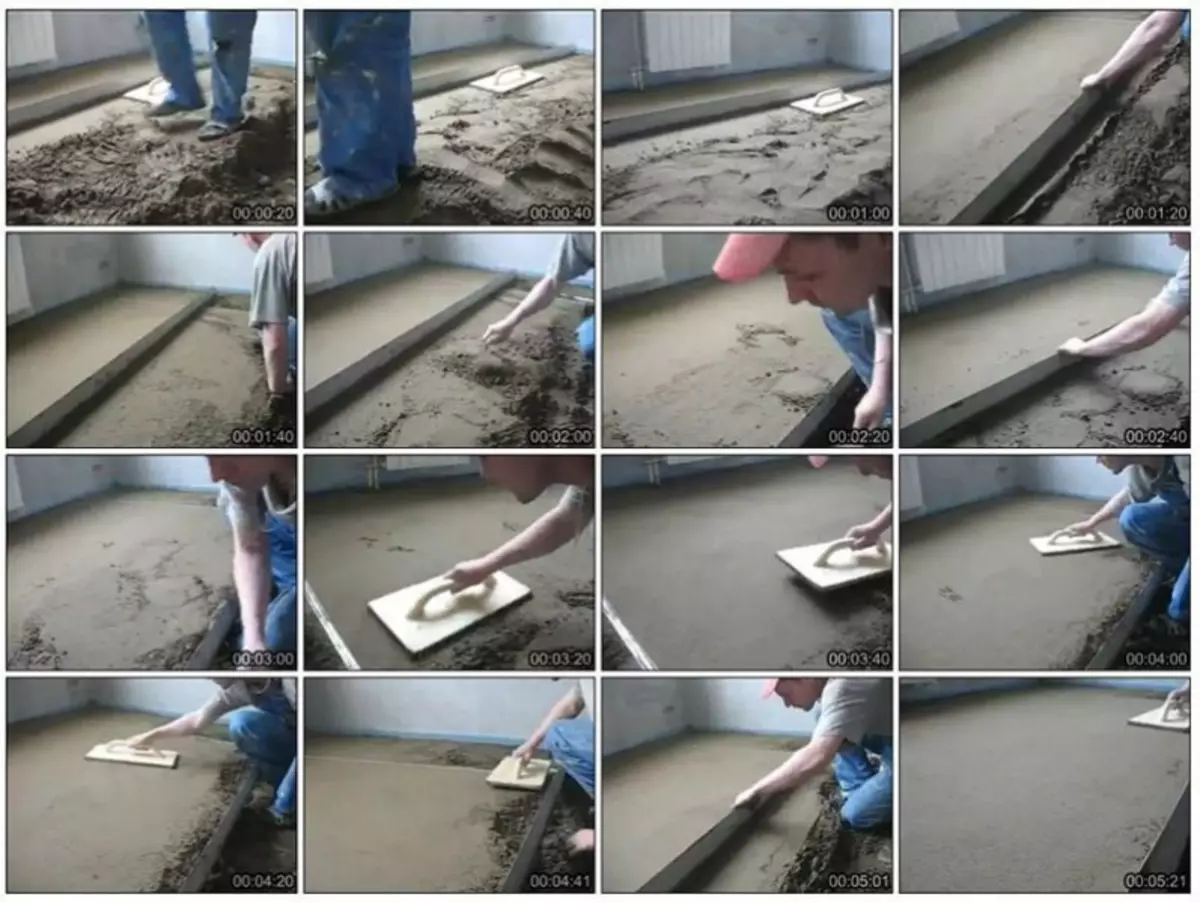

Consider how to make a light screed in the apartment. We start mounting from the long corner of the room. Floor poured into one occasion, with a large screed thickness with a fine metal mesh. See this video in this video:Stages of work:

- The solution is pouring onto the floor between the guides, spread the cells.

- With the help of the rules, moving the mixture by moving it on yourself. We compact the solution to come out, and there is no emptiness left.

- After a day, we take out the guides, poured a solution with a solution where they were.

You can walk on the floor in 4 days. Fully concrete dries and gains strength for 30 days.

The deviation in the horizontal plane should not exceed 0.2%.

At the end of the installation of the screed in the apartment, we exclude drafts, missing all the gaps, and regularly moisturize the concrete so that the coating does not crack. Finish alignment we do after complete drying screed. You can use mixtures for bulk floors.

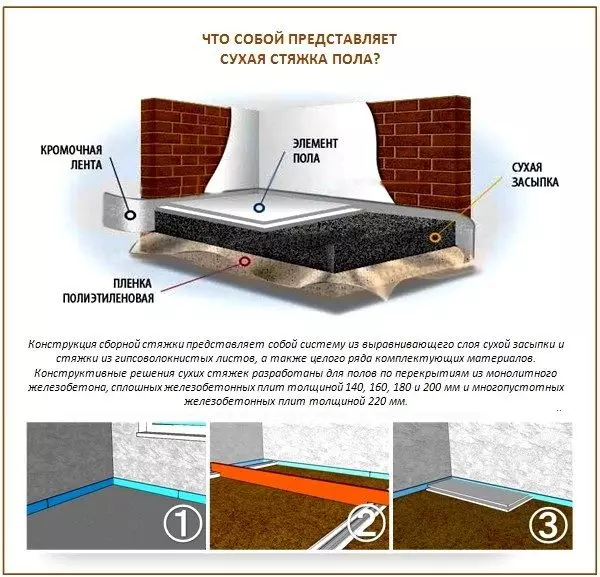

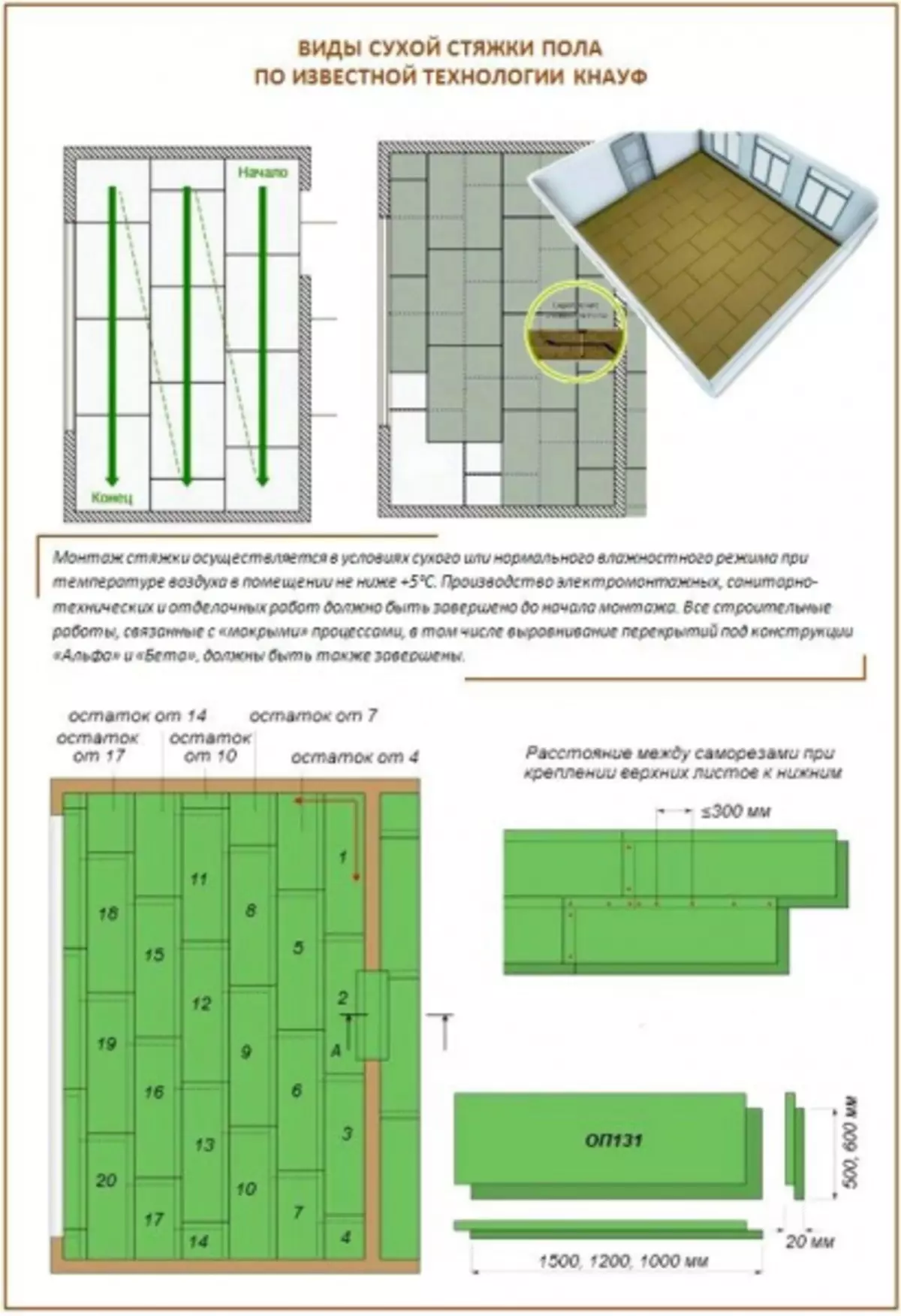

Dry screed

This type of coating facilitates the load on the stove and increases the heat insulation of the floor. The dry tie is laid using clay or other bulk material with a shallow fraction. Read more about Dry Screws See in this video:

The markup of the room and the installation of beacons is carried out according to the above-described principle.

Article on the topic: Swing do it yourself

Aligning elements for the device dry screed in the new building we select depending on the level of humidity in the room:

- Polystyrene plates ensure the maintenance of heat and sound insulation;

- wood-chipboard OSP;

- Moisture-resistant gypsum, dry-fiber sheets, plywood.

As fasting for floors, we use crumbs, quartz sand, shag of a fine-grained fraction.

Dry floor screed with their own hands provides for the following sequence of work:

- We make markup, find the bottom and top point of the screed.

- We install the guides: the first profile by the wall, the rest parallel to each other with a pitch of 1.5 m. As a support for heights, we use pieces of timber, plastic, polystyrene foam.

- Between the guards, fade by the ceramzite to the noted level, are well tamped.

- On extreme sheets, we cut off the fold so that they do not deepen in the backfill. The remaining sheets in the folding edge, which we wash the glue and fasten the screws. Stacking leveling sheets start from the entrance. Walking on sheets until the end of the work is not recommended.

Lighthouses take out as plates styling. If they leave them, the floor during operation will give a shrinkage, and the heading will remain in place.

Screed of self-leveling mixture

Actually on the first floors to install a coating that provides increased heat insulation.

With a slight difference of height, it is easy to make a tie of the floor in the apartment with your own hands using a self-leveling mixture.

Sequence of work:

- We prepare the surface of the plate, poured with a solution of cracks, chips, depressions.

- Ground floor in several layers for better adhesion materials.

- We divorce the mixture according to the instructions on the package. Installation start from a long corner.

- We stretch the solution with a needle roller.

The floor dries over 4-5 days depending on the temperature and humidity indoors.

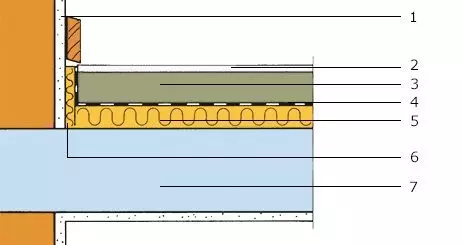

Floating screed

It is distinguished by the fact that the upper concrete coating is not fastened with the stove, since it is stacked through the film on the layer of heat-insulating material.

Scheme:

- plaster;

- Finish floor flooring;

- concrete or calcium-sulphate screed;

- The polyethylene film is placed as a barrier to the penetration of a concrete solution to thermal insulation material;

- Mineral wool or polystyrene foam;

- damper tape with a thickness of more than 10 mm;

- plate.

Dampfer tape.

Dampfer tape is fastened to laying the heat-insulating material, its height should be at least the overall thickness of the floor design: from the plate to the finish floor covering. Trimming is carried out after laying outdoor coating.

The thermal insulation material is strictly in the horizontal plane, uneven styling leads to the formation of cracks in the cement solution.

Adhering to the recommendations, it is easy to perform a tie of the floor with your own hands. Outdoor coating is permissible at the residual humidity of the screed no more than 2%.