Installation of warm water floors is a rather time-consuming process. In addition, the cost of acquiring consumables is large enough. But as for exploitation, the more economical system does not exist today.

Installation of the system involves the installation of the pump. Despite the fact that the pricing policy of this element is not particularly large compared to the rest, it is a very important part of the water floor. If the pump is selected correctly, the system will function effectively.

Why do we need a pump

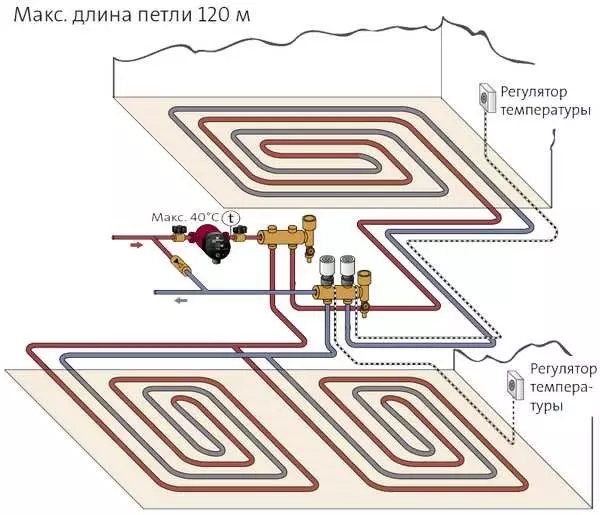

The peculiarity of the water floor is that the length of the pipe can exceed 1 m with a diameter of a maximum of 2 cm. There are several circuits in the system. It makes it difficult to circulate liquids and turns, which are quite a lot in the system. It is possible to provide good circulation only to equip the water warm floor of the pump. Let us dwell on how to choose the right pump, and at what moments should pay special attention.

Manufacturers offer a variety of models. They are characterized by functionality and, naturally, pricing policies. Do not stop at budget versions. They do not have additional features and, as a rule, are not durable.

It is desirable that the pump for a warm floor has a speed switching function. The optimal option is a three-speed pump. This will allow you to maintain the desired temperature in the system. Water is supplied to the system at a certain speed. Naturally, the movement on the system is carried out at the same speed.

When a decrease in the room temperature, the coolant will give more heat, and, therefore, cool faster. And the temperature of the fluid in the pipes will drop. That this does not happen to increase the feed rate of the coolant into the system. This type of device can be managed manually.

If you want to do everything so that the system functions independently, you can automate the mechanism. Today there is everything you need.

Article on the topic: Technology for replacing the crowns of a wooden house

As for the type of equipment, it is better to purchase a circulation pump for water floors. Such a device supplies fluid into the system at a given speed. It does not form redundant pressure.

There are pumps with a wet and dry rotor. The first does not differ in high power. Therefore, for a large room will not fit. Maximum quadrature, which forces them - 400 sq.m. The advantages of this type of equipment include low electricity consumption and reliability. It should also be noted that the pumps with a wet rotor work very quietly.

If the area of the room exceeds 400 square meters. m., then the system needs to be equipped with a dry rotor. During the operation of such an aggregate, it is necessary to systematically carry out maintenance. Namely, clean and lubricate.

Another point to pay attention to when choosing a device is the presence of an outlet valve. If the warm floor system is equipped with cranes for air shutting, then the presence of the valve is not mandatory. If not, the air caught in the pipe will interfere with water circulation.

The pumps are distinguished not only by their characteristics, type and functional features, but also appearance. Manufacturers offer pumps whose housings are made in cast iron, stainless steel or polymer material. If the system is completely sealed, then by and large, you can choose any option. If there are doubts about tightness, then the cast-iron option will not fit. Under the influence of air, the metal will begin to oxidize, which will lead to the malfunction of the unit.

Special attention should be paid to the labeling of the device and its dimensions. Marking of pumps involves the presence of two digits written through the fraction. The first indicates the diameter of the input or outlet holes. Values are indicated in millimeters. The second digit indicates the height of the lift. In the labeling there is another figure written through the Defis from the first two. It indicates a mounting length.

Article on the topic: Polyurethane floors: bulk coating, cement and polymer, two-component photos, plates and technology

Well, of course, it is worth talking about manufacturers. European firms have proven itself best. You do not have to save on the equipment. It is the pump that the system can be called "heart". Therefore, it makes sense to acquire equipment from German manufacturers.

Pump parameters

In addition to the presence of additional functions and type, the pumps are characterized by source parameters. Namely, productivity and pressure. Since the system needs to be supplied, the performance will be equal to the division of the power of the heating circuit multiplied by 0.86 and the difference in the flow temperature and temperature of the coolant in the return. This difference is, as practice shows, 500.

If there are several contours in the system, it is necessary to determine the performance of each of them and summarize the results obtained.

The generated pressure depends on the hydraulic resistance of the pipe, its length and the power supply coefficient. To calculate the pressure, it is necessary to fold the product of the hydraulic resistance of one meter of the pipe at its length with the power reserve coefficient and divide everything per 1000. The pressure is necessary for normal circulation of the coolant in the system.

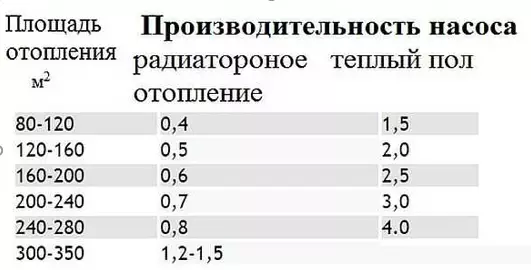

Such a parameter as power depends on the quadrature. There are tables of matching the heated area and the required power of the pump. When calculating them, it is believed that the house is normally insulated and is not much north or south of the middle strip. Experts recommend adding about 20% in case of severe frost to this parameter.

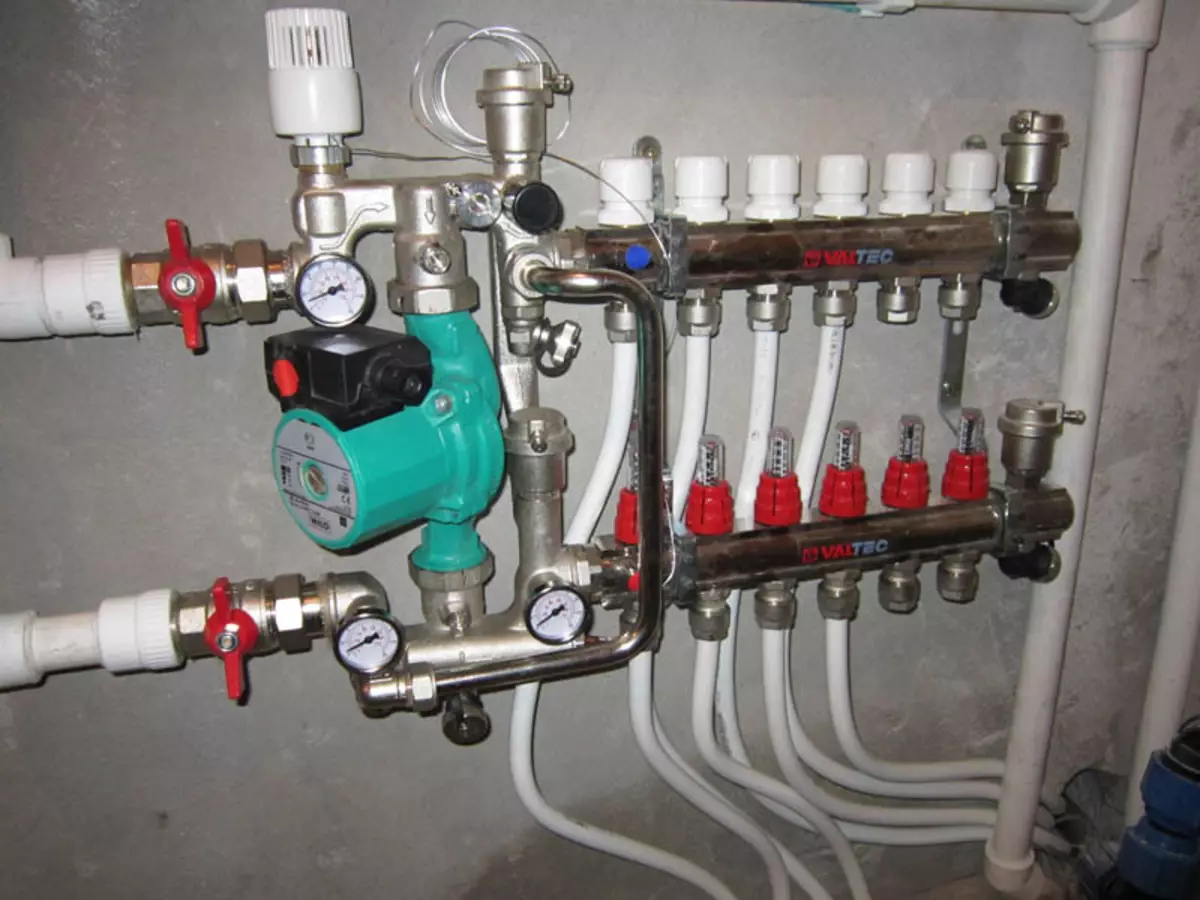

Mounting pump

Set the pump in such a way that the rotor is located horizontally. For the duration of the operational period and the efficiency of the unit, the vertical installation will not affect any way. But expect the power specified in the technical passport, not worth it. Losses can be up to 30%. And this is quite a lot.

Install the pump is advisable on the feed pipe. It is necessary to have it after the mixing site.

But these provisions are not fundamental. Some pump connection schemes suggest its location on the return pipe. If the water floor system is located in a house that has several floors, then the pumps need to be installed several. Each level is desirable to equip the device. This will make the system more manageable.

Article on the topic: The porch of the terraced boards: Decing Montage Technology

Trouble-shooting

The quality of tap water, namely it is used in a warm floor system, leaves much to be desired. After some time after using the pump on its elements in contact with water, salts are postponed. If the pump is working continuously, there will be no problems. In the summer months, a warm floor is usually disconnected.

And so, after trying to inclusion, problems begin. The pump simply refuses to "swing water." At the same time, he bursts, which indicates the working state of the unit. The coolant does not enter the system, because the rotor cannot turn. It is necessary using a screwdriver, scroll the impeller two or three times. If the unit did not start working, then you need to contact a specialist.

When choosing a pump for a warm floor, you need to pay attention to many factors: type of equipment, manufacturer, parameters, functionality, etc. If you take the choice with a certain share of negligence, the system can not work as much as it would like it.