Usually the operation of the gas column is accompanied by sounds associated with flame burning and water flow inside the machine. However, sometimes the user can hear from the equipment whistling, cotton and other extraneous noise. To understand why the column can whistle and noise, you must first learn about the device of this type of water heaters, as well as the features of the functioning of the gas columns.

Cotton when turned on

If, turning on the column, you heard cotton, this is a sign of problems with the flow of gas. Each device has a work area in which gas accumulation occurs during the equipment is turned on, as well as its gradual connection with air. In the case when the amount of accumulated gas and air meets the calculations of the manufacturer, there will be no cotton. If gas and air accumulate in excess, it becomes the cause of a small volume explosion.

It causes not just a loud clapboard sound, but also is able to damage the chimney, so it should be eliminated such a situation immediately.

The author of the next video offers its solution to this problem. Looking at his video, you can independently get rid of cotton when the gas column is turned on.

Column buzzing and noise in the process

The reason for the appearance of noise during water heating is insufficient traction. Therefore, in the noisily working equipment primarily check it. The burning match or lighter is brought to the control holes or a special hatch at the top of the column. If the flame tongue rejected towards the device, the thrust is sufficient. Otherwise, you should take care of the cleaning of the chimney channel.

Also, there may also be an insufficient air flow into the room, for example, if plastic windows were installed in the kitchen. Seals in such windows interfere with natural ventilation of the room. In this case, to eliminate noise, simply control the air flow.

Article on the topic: Pictures in the interior 55 photos

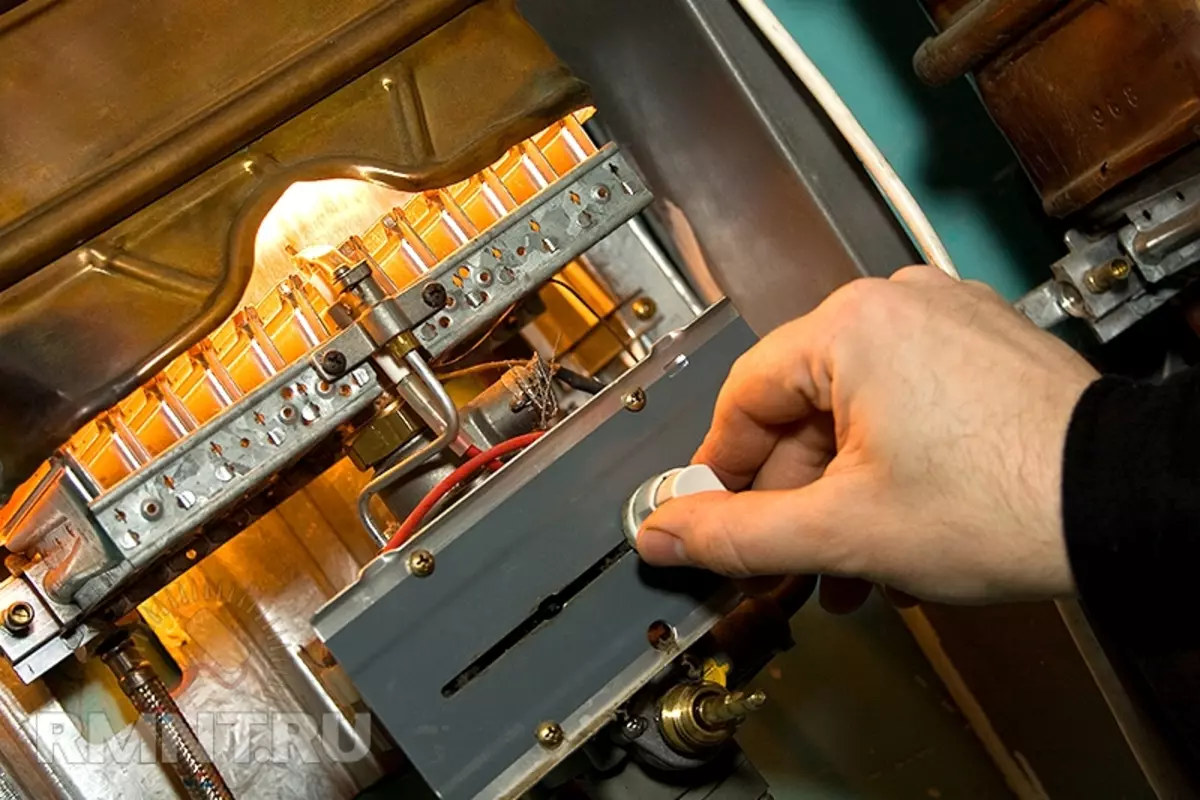

Another reason for too noisy work column consists in pollution of the wick of the ignition burner. And then to eliminate noise, it is enough to clean the jackets. Such a situation is possible and when the jets are clogged in the main burner, then after its cleaning, the hum During the operating time, the column disappears.

In modern columns, which are included with the help of electrical installation, the cause of noise when working may be like this:

- Discharged batteries. As a result, the gas-air mixture is mounted with difficulty. In such a situation, the batteries are required to replace.

- Cleaning the sensor controlling water supply. Often, its malfunction is caused by the oxidation of the contact group. Usually this sensor is unbeling, so it is replaced.

- Candle malfunction, due to which an electric spark is not created. Most often it is shifting after a variety of cooling heating cycles. Returning the candle to the nominal position, you restore the possibility of forming the spark and eliminate the outside noise.

- Problem with mechanical ignition retarder. Its presence can be determined after dismantling the node and shaking it - normally you must hear the sound of the ball movement inside the moderator. If there is no sound, it indicates the displacement of this ball. You can return it to the place with a soft wire.

Column whistite

If a monotonous loud whistle comes from the equipment, first of all, it should be determined where it appears from. To do this, overlap the gas crane, and then open the crane of hot water. Further actions depend on the resumption or absence of "TELL":

- If the whistle appeared, its occurrence is associated with a water tract. The most common cause of such a sound is in the deposits of scale in the heat exchanger or in the end of the pipe of the foreign object. In this case, the performance of the column falls. In this case, to get rid of the whistle, you need to clean the heat exchanger from scale, and the reverse stream will help flushed out of the column.

- In the absence of a whistling sound, the reason for its occurrence was problems in the gas tract. Most often they are associated with a valve defect modulating a flame power. Then the whistle appears only at a certain power, and to eliminate it, you need to adjust the power to any side. Another common reason is to clog the path. Cheerful sounds appear at any power. To identify the location of pollution, you will have to carry out extraordinary cleaning, which is best instructed by a specialist working with gas equipment.

Article on the topic: Repair of walls of a wooden house

Looking at the next video, it will be possible to clear the heat exchanger from the scale, without referring to the masters.