The screed on the wooden floor under the tile can serve as a good solution for those who want to equip the bathroom or kitchen, and will also be relevant in the equipment of underground heating.

Couch on the wooden floor – Not the best construction solution, but with the right approach and compliance with certain conditions, you can successfully use a similar connection in a wooden house.

What are the ties?

Screed is the top layer on a wooden or concrete floor, which is further fried by flooring.

There are the following types:

- Dry.

- Cement.

In the first case, when using this type of screed, the surface acquires resistance to various loads and becomes high strength.

It is performed from drywall, moisture-resistant plywood or PVC sheets by laying on clay and quartz sand. This type of overlap is the most suitable for the wooden floor.

The cement or concrete screed on the wooden floor is used as a base for polymer coating or ceramic tiles.

Thanks to it, there is a process of alignment of the floor from the tree. The owner of the room can pour it on their own.

Pros and Cons

Dry screed will fix errors

Dry screed has a number of benefits:

- simple manufacture;

- With its availability, it is convenient to put communication;

- easy to correct errors;

- No need to wait for drying.

However, it has some imperfections:

- There is a significant thickness, the height of the room decreases;

- There is an increase in the cost of material.

With the concrete tie, the consumption of the material is small, but it is necessary to wait for it for a long time.

In any case, it is worth making a choice towards a particular material. The correct decision will avoid further problems with the rest of the coatings.

Working conditions

How to make a screed competent and keep all the stages of its construction? Concrete filling under ceramics on wooden floors is supplied in the correct sequence.

Article on the topic: Why do not work speakers on the computer

This should occur if there is a strong flooring from a tree. On the dilapidated and unstable coating, the tile will crack and collapse over time.

It makes it possible that the screed on the wooden floor must be masked undesirable, it is better to raise the flooring, the gap between the beams from the tree is to fill in the clamzite, to put the plates from cement and chips on them, then fill the screed.

The fill procedure can be carried out directly on the wooden floors. With this installation there are some specific features.

Characteristic steps before filling

Before the fill, check the wooden floors, repair the defective places.

An indispensable condition for the manufacture of a cement screed on the floor and the application of the tile is to identify the life of the tree, which should be at least three years.

The reason for this - the ability of the tree with time to dying and deform. It will take from 2.5 to 3 years to "soothe". Movement can occur after this period, but not so clearly.

Option, if the floor is not new, provides:

- Careful inspection of floors and the floor itself;

- identifying weak points and thorough faults;

- selective shift of spoiled parts;

- Climbing cracks and cracks with special means;

- Removing the plinth and replacing it with wooden slats;

- Grinding floor and garbage cleaning.

After pouring an ordinary screed and drying it, it becomes monolith, which cannot be argued about the concrete on wooden floors. Remove unevenness and increase the strength of the gender will succeed, but it will not be possible to free themselves from the main flaws.

What is the way it is better to apply?

Between the tree and monolith, it is necessary to pave a moisture insulating layer

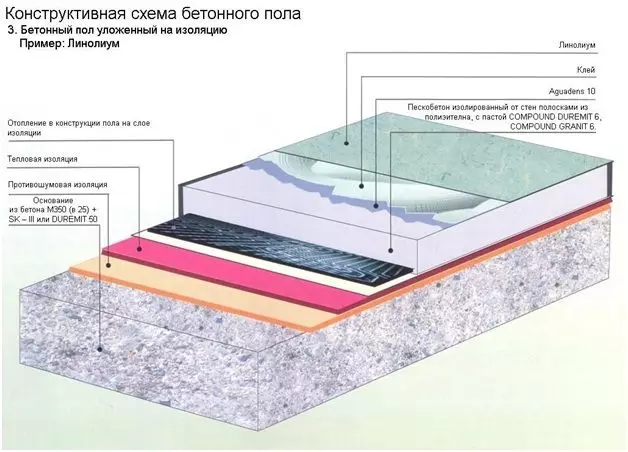

For greater reliability, the method of "unconnected" screed for the wooden floor is used. At the same time, it is an isolated from the floor covering and walls.

Pre-floor is leveling. A waterproof obstacle is created between a moving part of the floor and monolith.

To do this is used:

- dense polyethylene film;

- The material in the form of a damper tape, which is fixed at the bottom of the wall and floor;

- foamed polystyrene;

- Ruberoid;

- The material impregnated with bitumen.

Article on the topic: Picnic gazebo: Stages of the device and necessary materials

Wood must be treated with an antiseptic and apply a layer of waterproofing preferably from bitumen mastic. Then you can put the film, leaving the protrusion of 20 cm on the walls and necessarily making trays. They are sick with scotch, achieve a complete absence of joints, holes and wrinkles. On how to make a screed on a wooden base, see this video:

The advantages of the "incoherent" screed

Such a moisture insulation plate:- is floating;

- cut off from the dumping base;

- Makes a screed independent of temperature and humidity drops.

What should be the solution?

Use the screed mark M 400

Self-leveling mixtures should be included in the concrete solution for the screed on the wooden floor. But the basis, of course, constitute cement and sand M400 brand.

Pouring stages:

- 25 kg of dry mix pour 6 liters of water;

- Stir manually or using a mixer;

- achieve homogeneous mass;

- comply with the desired solution temperature, it must be no less than 10-15 degrees;

- You can use warm water if the room is cold;

To achieve strength and waterproof solution, you can add special plasticizers in the proportions specified on the package. This will also suit the option with the addition of a simple washing powder on one handstone per 100 liters of water.

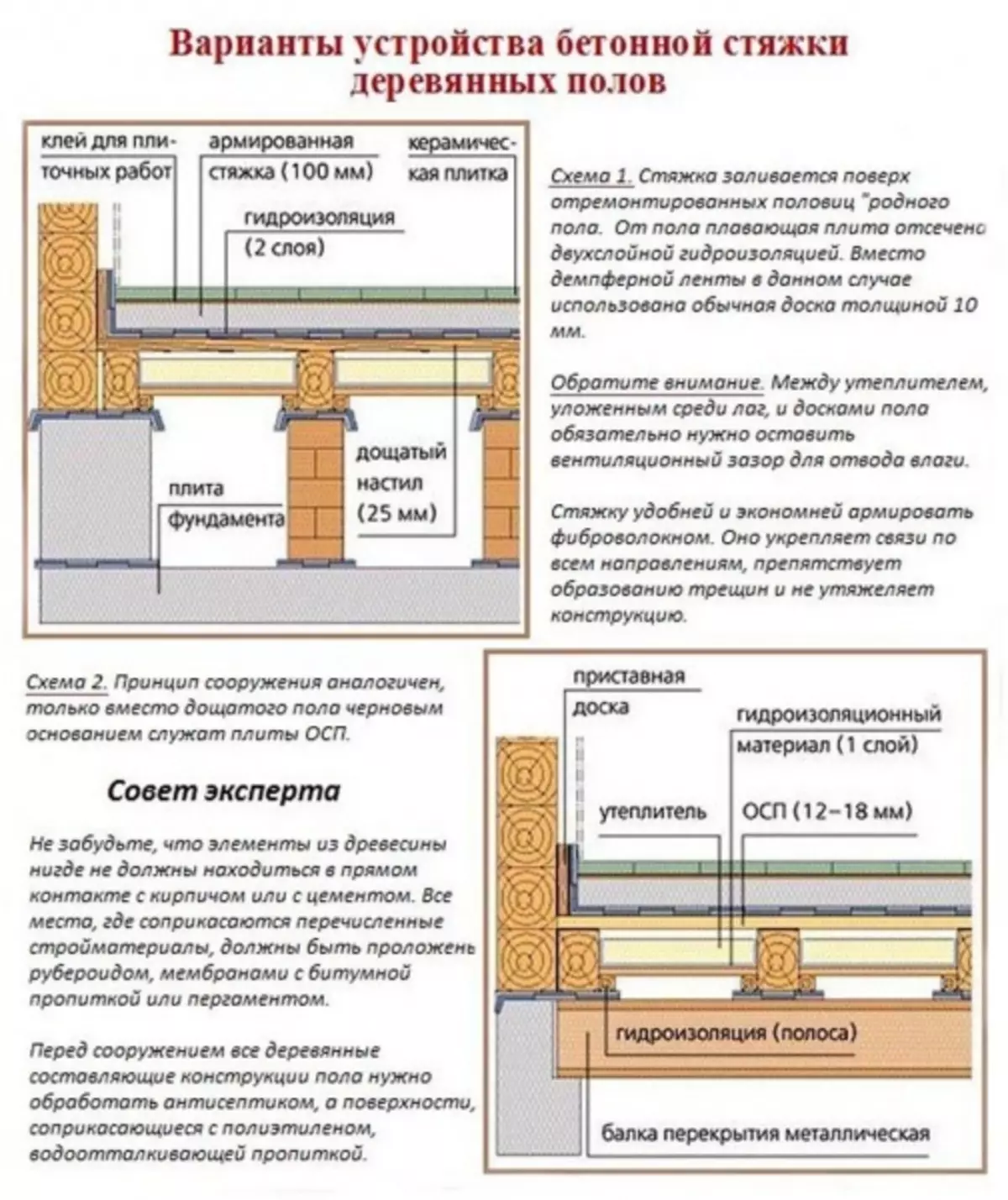

The process of the implementation of the cement screed on wooden lagas

Sometimes in wooden houses or old apartments, a concrete screed on wooden lags is needed.

Due to the fragility of the tree, the designs need to be strengthened.

This is due to the installation of a metal frame or grid, as well as a chapellery.

Before building a frame in the space between lags, the insulation of the ceramzite, perlite or other materials with low thermal conductivity is covered.

A sufficient density and elasticity of the solution should be achieved by adding polystyrene, plant fibers and other necessary components. Such additives will also perform the role of sound insulation.

Article on the topic: Wall decoration MDF panels

Sequence of work

Spend water insulation

First, the base spread the polyethylene film, and then placed insulation. The channel is attached to the lags, the reinforcing mesh is mounted, you can even in two layers.

It must be at some distance from the insulation. Approximately five fixators per 1 sq.m. are used to determine the correct interval.

After installing the frame and reinforcement, you can fill the floor with concrete. It is best to do on pre-installed beacons.

Following the application of the mixture, it is necessary to align it with vibration. In this case, air bubbles are removed, due to the strength of monolith.

Caring for tie

A day after the fill, the screed is subjected to abundant moisture.

Subsequently, for a week, it should be sprayed with water during the week, as well as a few days, the new concrete floor is covered with a film for uniform moisture.

It is still necessary to monitor the temperature background and the percentage of air humidity.

After complete drying of the solution, it is grinding, as a result of which a smooth surface is created.

Some nuances

Is it possible to create a fortress of screed to refuse the use of reinforcement and apply simpler materials? Definitely yes. After all, the period of drying the screed using fittings can be up to a month, and then you will need to wait for the same after the completion of all works. On how to make a screed on wooden beams, look at this useful video:

To avoid similar procedures, in order to strengthen the fiber fiber. Disordered placement of polymer fibers guarantees strong bundles in all directions, the mass of the screed itself will also decrease.

Competently equipped screed on the wooden floor will be an excellent base for laying such a coating as a ceramic tile.