The most applied material in order to make furniture with their own hands, it is LDSP, or laminate. This is a chipboard covered with one or two sides with a varnish veneer.

Laminate can be used to make a variety of furniture species, including a wardrobe.

The properties of this material allow it to apply it for a wide variety of furniture types: ranging from the kitchen headset and ending with a living room. Positive properties of laminate:

- It can withstand elevated temperatures;

- There are moisture-proof samples of LDSP;

- has a large color gamut with a huge variety of shades;

- easily processed;

- can withstand heavy loads, which allows you to apply it as a finishing material;

- The price of LDSP is quite accessible.

It has the following disadvantages:

- From the laminate it is impossible to create curly parts;

- In case of water, the non-fatty view of this material is deformed (swelling).

Before using LDSP to create furniture with your own hands, it is necessary to take into account some nuances of working with him. The main thing is to cut the material so as not to damage its lacquer coating. You can do it yourself, but since the sheets have large sizes, then make them in the apartment, put and handle quite difficult. To get rid of this problem, you need to contact a special firm that, according to the drawings you have brought qualitatively collapsing the material on the appropriate equipment and processes the ends of the parts.

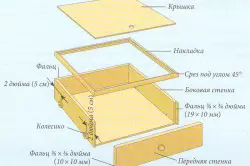

Box under bed from LDSP

When drilling a plate, it must be positioned on a solid surface and grip tightly - this reduces the number of chips during processing.

LDSP is sold at any construction market or in the stores of the same profile. The fittings and components needed to create furniture can be purchased in the same place. The following components can be used for fastening details of homemade furniture:

- plastic or metal squares;

- Screws or screws.

The plastic corners are produced in different colors, which makes it possible to accurately choose them under the colors of homemade furniture. In the construction market you can buy special screws for furniture heads.

Article on the topic: How to make a dressing room: layout and filling

For the processing of LDSP, you will need a tool - an electric drill with a set of drills and a cutter. A set of screwdrivers useful, and if you have the opportunity, you can buy a screwdriver - it will save time.

How to make laminate furniture?

To do this, first make up the drawing of the future subject or headset (for example, kitchen). Then draw individual details on Watman sheets with all sizes. If you do this case, you can take ready-made drawings, but then you will need to bind them to the size of your apartment.

Drawing of the built-in closet.

After the end of this work on the construction market, they buy the necessary material, accessories, components and fasteners to make furniture from laminate. Specialists will dry up LDSP in size specified on your drawings.

When creating future furniture, all the details must be placed in order of their assembly. On one side of the workplace, sheets of material, fasteners and other parts are placed, and on the other - a working and marking tool. Such an arrangement of the workplace can significantly speed up the assembly process and not waste time search for the desired details or tools.

If you need a markup on the details of the laminate with your own hands, then we use roulette and pencil. In the right places on the surface of the material there are future holes. They should be at a distance of 5-6 cm from the edge of the sheet, and their location in height depends on the amount of shelves in the closet. If the assembly uses special screws for furniture, then for the drowning of their heads in the material, the drill is used with a diameter of 8-8.5 mm, and for the threaded part - 6-6.2 mm.

In order for no distortion, the metal coal is checking the correct angles of the assembled walls of the product.

All the details of the cabinets twist together according to the drawings. If you need to install the rear wall, then it is cut on the desired dimensions from the DVP using the jigsaw or hacksaws. Then this sheet is either screwed to the cabinet with screws, or nail with small nails from the back side. The ends of the entire door of the cabinets should be punched with a thin veneer, which should be coincided with the color of the base material.

Article on the topic: What can replace tile in the bathroom - Alternative to Tile

Hinges are installed on the cabinet. If they need to be recessed, it is used for the creation of a recess with a cutter with a diameter of 32-32 mm. Future facades are installed accessories - handles and other elements. Doors are hung on the cabinets that must be pre-installed in place. On this, the process of creating furniture is finished with their own hands.

List of materials and tools for laminate processing with their own hands

- LDSP sheets cut in size;

- furniture handles;

- loops for facades;

- Corners connecting plastic or metal;

- Guides for drawers (if there are in the furniture you made);

- DVO sheets;

- Cabinet legs;

- thin veneer;

- Furniture screws;

- screws or minor nails;

- Electric drill with drill set;

- clamps;

- milling cutter;

- a hammer;

- iron;

- Lobzik or hacksaw;

- Roulette or metal line;

- screwdriver or screwdriver set;

- Metal coolel;

- Pencil and Watman Sheets.

The furniture made with your own hands should fit into the overall interior of your apartment. It is advisable to first take care of the combination of the color gamut of the made cabinet or kitchen set with the floor and walls in the room where it is planned to put the furniture made with your own hands. In compliance with the above recommendations and the selection of high-quality material, it can even make a wardrobe.