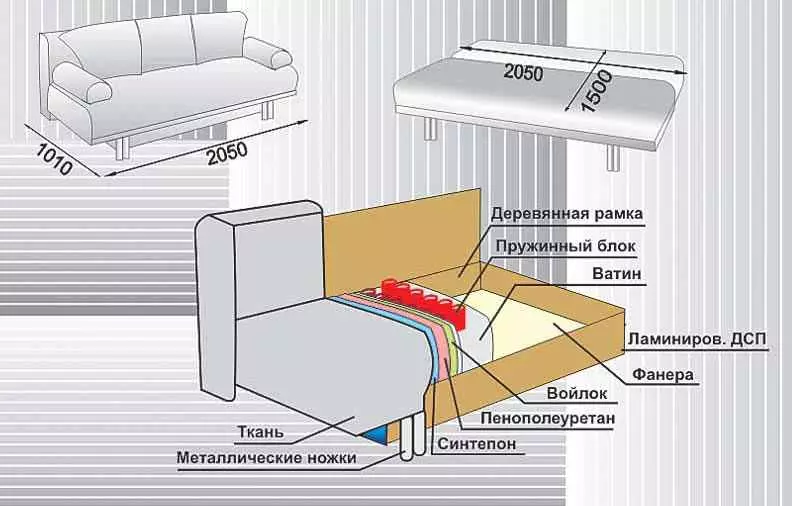

The sofa book is easily manufactured with their own hands. This will require drawing. As a collected form, the parameters of such furniture should be equal to 1x2.2 m, and in the unfounded - 1.4x2.2 m.

Sofa device diagram.

Preparatory work

To make a sofa book, you will need foam rubber, fabric, transformation mechanism, lamella, Fiberboard 1.7x2.75 mm, furniture bolts (8x120, 6x40 and 6x70), nuts, nails per 100 mm, screws (89d and 51d), brackets ( 10 and 16 mm), a bar with a cross section of 40x60 mm and a 1900x200 board. From the tools you will need:

- saw;

- screwdriver;

- pencil;

- a hammer;

- Corolnic

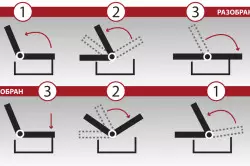

Book sofa assembly disassembly scheme.

The sofa box is made of the following materials (mm):

- 2 boards 1900x200;

- 2 boards 800x200;

- 2 boards 50x200;

- 4 bars 50x50.

To strengthen the design of the niche, you will need 2 transverse rails (1800x800 mm). The next stage provides for an assembly of the box. Furniture frame is made from a bar with a cross section of 40x60 mm, self-tapping and nails. Pre-prepared holes for fastening elements. For this, drill and drill on 3 mm are used. If nails were scored, screws 89d screws (drill on 8 mm) on the joints. The depth of each hole should be 10 mm. Wooden lamellas (to support the mattress) nourish the resulting frames.

The armrests are made of 25 mm thick chipboard and a length of 1 m. Pre-from the material cut 2 left and 2 right walls, taking into account the dimensions specified in the drawing. The length of the wooden frame for the back should be 20 mm shorter than the material itself. A holes are made in the frame using a 8.5 mm drill. They insert 8x120 mm bolts. The next stage provides for the assembly of all parts of the sofa. Transformation mechanisms are installed so that a 10 mm clearance is formed between the back and seat, the furniture should be in the unfolded state. If necessary, the backrest and seat are enhanced by wooden slats.

Article on the topic: how to install a magnetic latch on the door

For the skin of the sofa-book use foam rubber. Pre-on the lamellas are placed flizelin. From the insulation, pieces with parameters 50x95 mm are cut out. On the edge of the seat is laid in a 200 mm wide width. Similarly come with the back of the product. Top lay 2 layer of foam rubber 40 mm thick. The covers are tensioning on the furniture. On armrests make roller. Initially, the width of the foam rubber should be 150 mm, and then - 50 mm. On top lay 2 layer of this material (20 mm thick) and bend it to the foam roller. Surplus remove. Detail unfolds bolts to himself. The material is glued at 320 mm from the bottom edge of the product. Armrests are covered with cloth. Front sides are nourished with accessories. The sofa is collected.

Eurobook with your own hands

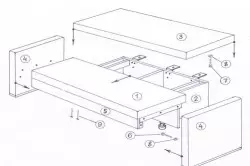

Sofa assembly scheme: 1 - seat, 2 - box, 3 - back, 4 - sidewalls, 5 - front plan, 6 - bolts 6 * 40, 7 - bolts 6 * 30, 8 - washers, 9 - screws.

Eurobook - Modern furniture consisting of the following parts:

- backs;

- seats;

- basics;

- Bals.

If desired, at the base, it is equipped with a niche for linen. The transformation mechanism of such a sofa provides for moving the seat forward (with the help of guides) and folding the back to the horizontal position.

To make an eurobook with your own hands, you will need:

- foam;

- 20 cm lightning;

- 3 zippers for 7 cm for pillows;

- material;

- metal grid;

- corner;

- bars 21x7 cm;

- Self-screws 89d.

Sofa layout diagram with book transformation mechanism.

Initially prepared the drawing of the future sofa. The sofa frame is made of bars, taking into account the parameters of the component parts of the sofa (for details, see the drawing). To do this, you will need a saw and roulette. Furniture legs are manufactured from a similar material. For mounting bars, 8x120 mm bolts are used. The next stage is the manufacture of the back. This will require a 16 mm chipboard. The resulting design is attached to the base of the sofa using thick metal corners. The tilt of the back is chosen taking into account individual preferences.

Article on the topic: Curtains on the records do it yourself: Sewing technology

The lattice for the support is made from the pacar grid. The design tasks include holding pillows for the seat. The grid is attached to the wooden base with metal brackets. To increase reliability, glue transverse elements to longitudinal frame supports. A soft upholstery of the Eurobook is created in a specific sequence. Several pieces are cut out of the foam rubber (sizes must match the backrest parameters) with a thickness of more than 15 cm.

Details are squeezed by material. For their compounds are applied lightning. The mattress can be fixed to the founding of furniture with a decorative tape. The last element is made of material and velcro. One end of the tape is attached to the frame using small nails, and the other to the sofa case. For Eurobooks will need to make 3 covers. They are stuffed with foam rubber. In this way, you can make pillows.

Shield design

In the absence of experience with the wood of the Master, it is recommended to use in the manufacture of a head sofa-book:

- metal brackets;

- 2 door flaps;

- foam

- Material for upholstery.

For the manufacture of the base and backs of the sofa-book use 2 old door flaps. Previously purify them from dirt and former coating. The surface is grouped and painted in the desired color. If desired, the coating is separated by a veneer. The sash is attached by nails on hemp. It records the 2nd item with glue and metal brackets.

The mattress for such a sofa is made by their own hands. To do this, you will need to cut the porolon of the corresponding sizes. From above it is tightened with a cloth. A high-quality fabric is stretching on the material. On the basis of the design, mattresses with pillows are placed. The transformation mechanism is set in the same way as in the first case.

With independent making of the sofa-book, special attention is paid to the reliability and durability of the frame base.

This is due to the fact that the main burden is due to this part of the furniture. Material for the manufacture of furniture is chosen taking into account the number of people in the family. The finished sofa will decorated at its discretion.

Article on the topic: Calculation of wooden and metal stairs on the second floor of the house