Today, quite often people are trying to make double beds. If you do everything correctly, you can save a considerable amount of cash.

Double bed can be made from materials of several types: MDF, laminated chipboard, metal or wood.

Double bed with their own hands can be made approximately 10 days. This is due to the need to make technological breaks.

Bed will be manufactured from environmentally friendly materials. For fastening design elements will be used PVA glue, which is harmless.

How are double beds?

An example of making a design in which there are no visible compounds will be considered.Materials for work

Such elements will be needed:

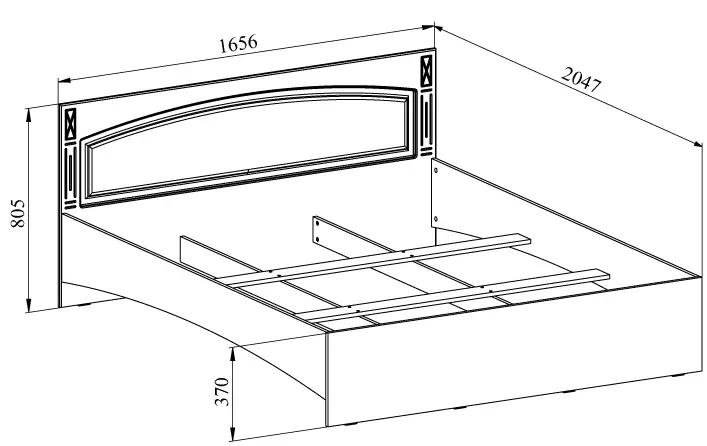

Double bed diagram with dimensions.

- Braided.

- PVA glue.

- Saws.

- Bar.

- Plywood sheets.

- Nails.

- Steel corners.

- Bed scheme.

The outer elements of the double bed are made from MDF 2-3 cm thick. You can also use laminate, but it is recommended to apply MDF, because it will not be necessary to laminate, as a result of which you can do without toxic nitrolee. Internal elements can be made of wood or plywood sheets with a thickness of 1-2 cm.

MDF blanks are recommended to be ordered in any furniture workshop. The sheets themselves are better not to buy sheets for retail prices, because it will take to spend more money. On the furniture workshop will be able to cut down and accurately in size and cover all the elements. The thickness of the edge must be about 0.5-2 mm.

From sawn timber will need to be purchased:

Double bed chart with dimensions.

- 8 m timber cross section 5x5 cm.

- Several boards 3x10 cm 2 m long.

- 10-20 2x10 cm boards for 1.5 m long.

All sawn timber must be edged. The tree of wood is suitable any. It will only be necessary to cut into the size of the board and choose the grooves.

If you plan to make a bed with your hands with drawers, then you will need to buy chipboard sheets. In this case, you can use any budget options.

It will take to pick up and fasteners. In such a design, expensive fasteners are not used.

Such a fastener will be needed:

- A large number of self-tapping screws 6 mm.

- Nails 6-7 cm.

- Corners with rigid ribs made of steel.

Article on the topic: Wallpapers

All connections will be made with sickness, therefore it is recommended to acquire phosphatated screws. The smooth fasteners of PVA glue will go worse.

It is important to pay attention to the corners. Stiffness ribs must have a large width. The base of folds should be smooth. If burrs are present, this suggests that the metal was raw and treated subsequently. Such corners can begin to crack after a while.

Preparatory stage of work

On flat reasons it will be necessary to apply glue zigzag, after which it is possible to distribute it with a toothed spatula. After that, you need to withstand glue to liquid lowlight (approximately 5-10 minutes). In the end, the details should be collected into the node and pull fastener from the metal using the glue.

Under the solemnosis will be needed to pre-drill holes. The depth of the holes is 2/3 of the length of the self-tapping screw. To ensure accurate interface of the openings in the prefabricated nodes, the connected elements must be temporarily made on the clamps.

In the holes, you need to let the small amount of the polymer emulsion on the water. After it is absorbed, it is necessary to wash the PVA with a thin stick from the inside. A glue is applied on the basis, parts are compressed by clamps and screws robbed. No need to apply glue on the thread - when turning it, it will be squeezed out on the thread outward. In the hole, the adhesive solution will drive into the tree of self-tapping screw. Clamps will need to be dismantled 24 hours after the assembly.

Required bed assembly tools.

It should be noted that the polymer emulsion on the water is sold only in large packages. For the bed you will need only 1-1.5 glasses. In order not to buy an emulsion, you can breed PVA-glue with water 1 to 4. Cooking fine portions, because the homemade emulsion will not be able to be stored even in a closed packaging.

No need to drill anything: the parts are glued in clamps, after which nails are fixed. Nuances should be known:

- Nails must have an annular notch.

- It is necessary to knock down the nails 14-16 hours after gluing the elements, without removing the clamp.

How to determine the size of the bed?

It is recommended to do the length of the bed 2 m and the width of 1.6 m. If there is a desire, they can be increased to 2.4x2 m. If you need to make a bed of even large sizes, then this can be performed only with the help of special materials and technological methods.The base of the base of the design layout is 35-50 cm. It all depends on the growth and features of the owner.

Article on the topic: Is it useful to sleep on the floor: opinions and advice of experts

The height of the bed can be distributed as follows: 18-30 cm Mattress, 15-20 cm - Tsargi, everything else - space under the bed. If it is close to 0, then the bed with drawers will not work. It is recommended to make a subcreational space with a height of 8 cm or more that the design is ventilated below.

Quite a large amount of money will need to spend on the mattress. Because of it, problems may appear in the process of independent construction of the bed.

If you do a bed with your own hands, it is recommended to purchase a road mattress.

It can be done by himself, but it will only suit people over 25 years old who will no longer grow bones.

Design elements: manufacturing technology

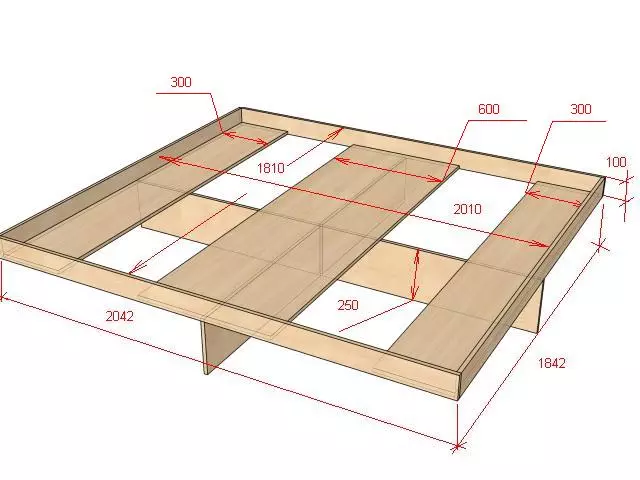

When looking outside the bed is a frame of a rectangular shape from the head of the head of the head, squaring and side elements (CARG). The carrier frame from the bar will be located inside. If you plan to make a bed of a large width, then you need to install additional stiffeners - spars. The frame of the bar is covered with boards or plywood sheets, resulting in a sun bed. It should be opening for ventilation.

How is the back of the back?

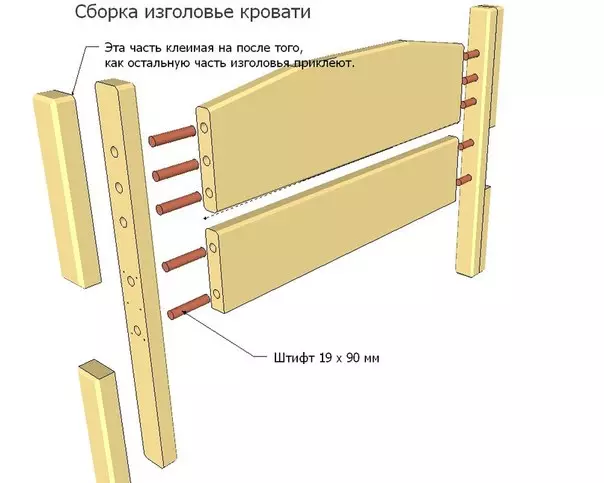

Bed headboard assembly scheme.

The transverse timber 5x5 cm is fixed with adhesive mortar and self-pressing. In the center there are cuts under the mustache of the spar. The distance between the edges of the cuts is 4-5 cm. It all depends on which trimming will be used to communicate the rigidity of the spar.

The back thickness should be 2.5-4 cm. It is assembled by a two-shield plywood 2 cm thick. In the board boards should be perpendicular to each other. After applying glue, it is necessary to dry the design of about 1 week. You need to dry under the total weight of 80 kg allocated throughout the base. As paint, you should use a veil or drive.

The length of the first timber will depend on the size and method of installing the mattress. If it is planned to be laid in the lodgment, then the length is equal to the width of the mattress plus 7-9 mm. The width of the back for the headboard can be done any. The width is equal to the width of the mattress and the double thickness of the Tsarg. If the squirrel is wounded, it will worsen the convenience of the design. If there is a desire, you can make a population high.

Installation legs are optional. If you want to install them, then they must be substituted under the corners of the frame from the bar, using glue.

Article on the topic: Children's rooms 8 and 9 square meters. M.

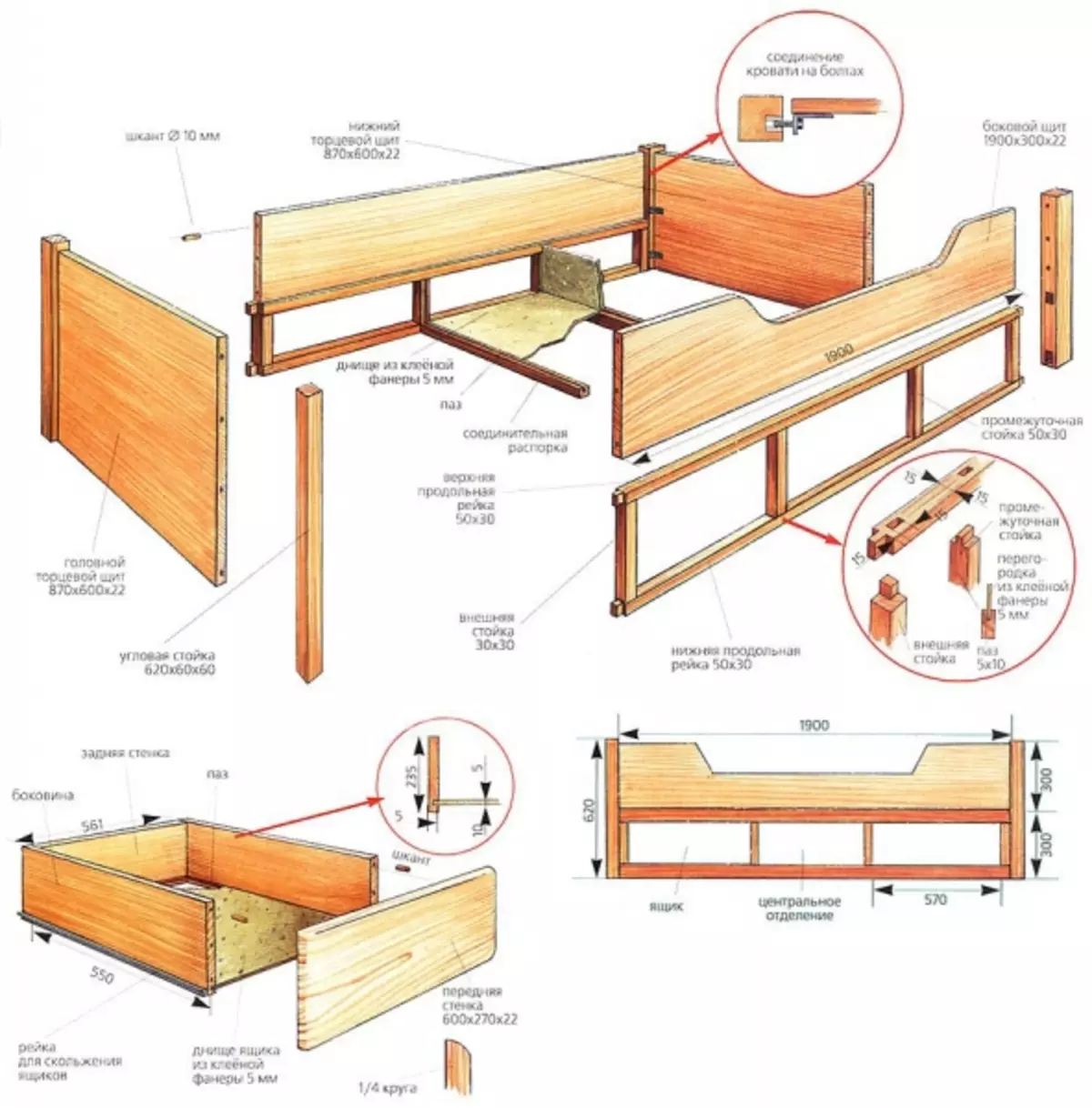

How to make kings and a spar?

Double bed assembly scheme.

The design of the Tsargi is a T-shaped beam from a 50 mm bar and a 30-40 mm boards. During the construction of the construction, the adhesive solution is used, the mount is made by self-drawing. The length of the bar and the boards should be the same. For the Tsarg Board, you can not cut out the furnitureeers. Cutting boards are 15-20 cm wide. They will need to paint in advance by the verse. From the inside it is better not to paint so that the bed can breathe.

There are two options for placing a bar in height. If the mattress is in the lifestuent, the vertex of the vertex bar from the top of the board should be 50-70 mm. If the mattress is located on the sun bed, then the indent from the top of the board should be equal to the thickness of the flooring.

Holes for fixators must be done at the base of the sun bed. To ensure a reliable connection, you need to make 4 openings in the corners and 2 between the elements of the spar. Clamps for a mattress in the lodge do not need to do. In most cases, 3 beds are installed in the bed. 4x10 cm. Inserts of rigidity between the shelves are made from unnecessary elements of the board or bar from the frame. They will be approximately 5-6 along the length of the spar. The top of the spar shelves and the frame bars should form a single plane.

Collect the spar is needed using nails and adhesive mixtures. 4 nails are installed on each of the inserts.

How to collect a bed?

The backs are installed vertically, after which they are supported by stools. Next, the tsargs are superimposed and the rectangle of the frame level is checked. The assembly is winding up with a rope, after which the diagonal is once again checked and the frame is leveling.

Next, places under the brazening, which will connect the chambers of the CARG with the backs. From the inside the lines are stuck.

Next, the kings are removed and the holes in the end parts of the boards are drilled. The ends are smeared with paint, the backs are moved, the kings are invested in place, after which the backs are tightly compressed.

Next, the holes in the backs are made and the base with the bonding bonding is assembled. After installing the frame, it must be dried.

Sunbed can be combined with a frame with an adhesive mixture and nails. The mattress is installed last, after 24-48 hours.

Bed to make it easily, if you know the manufacturing technology and have all the necessary materials.