The question of how to make a folding chair, worries many homemade craftsmen who actively apply their skills and talent in the argeon of their own dwelling. Furniture of this type is often called the "transformer", and its popularity is due to a number of reasons. First of all, it is, of course, practicality: it is very convenient when one and the same thing combines two or more functions.

The advantage of folding chairs is that they can transform into bed or hammock.

In our case, the folding chair can turn into a bed or, for example, in the like hammock. The second advantage - transformer furniture allows you to save space in the room and cash of your owner, because instead of two items you can buy only one. Do not forget that the folding chairs and other furniture "with changing geometry" allow a literally one movement to transform the interior of the room, pleased with the residents of the apartment or home by a sense of novelty. After all, any, even the most stylish and spectacular situation comes with time.

If you did not turn out in the furniture stores of your city of a suitable model of a folding chair, you should not despair. If there are some experience, as well as suitable materials and tools, it is possible to make such a thing. And our advice and recommendations will help you.

Preparation for the manufacture of the chair

Production of a transformer chairs, like any other furniture item, should be started from the drawing. If you have ever done to develop more or less complex products, you will handle such a task without difficulty. If not, then you can find the drawings of a suitable model on the Internet or in books from the "DIY".

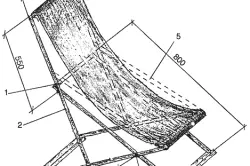

Drawing of a folding chair: 1 - Upper crossbar, 2 - Rama-back, 3 - legs-legs, 4 - lake "lamb", 5 - armrest.

Article on the topic: Variants of LED lighting with their own hands

On ready-made drawings, a specification is drawn up - a list of all products and materials, with which it will be possible to make a chair with your own hands. . For the simplest option, the master will need the following:

- boards and bars with the corresponding length in the drawing length and cross section;

- chipboard (chipboard, mdf or osb);

- foam;

- dense tissue for upholstery;

- furniture screws;

- small nails;

- Several screws or bolts with nuts;

- glue.

It is also necessary to make sure that there are such tools in the home arsenal as:

- saw;

- Topor;

- plane;

- file;

- knife;

- electrolovik;

- Corolnic;

- roulette;

- pencil or chalk;

- drill;

- Stapler.

Stages of making chair

In general terms, the instruction for making a folding chair consists of such items:

Options design folding chairs.

- Each item from the given in the drawing is drawn on the cardboard in a natural value, and then cut out, thus obtaining a pattern.

- Having attached a cardboard pattern to a board or chipboard, perform the markup of the part followed by drinking. It is most convenient to do with an electric bike. This tool allows you to easily and quickly perform the details of any complexity, for example, curly legs of any form.

- Fitting the sized cut parts are performed using a file. If the design of the chair is provided by several of the same type (the same legs, for example), then the first of them is used as a template in the manufacture of the others.

- The material for the backrest of the chair will serve the board or plate of the chipboard of 21 mm thick. After the item is cut out, it is attached to the armrests by means of a dummy (fastening element of the cylindrical shape) on one side and a row bar on the other.

- The bed of the future armchair-beds is made of three chipboard or its foreign counterparts. Between the plates are fastened with the help of furniture loops so that they can develop, forming a seat in the assembled form.

- The back of the chair, the armrests and the bed are missing with glue, after which the foam rubber sticks onto them. For a more reliable fixation of the foam pillow, it is covered with a coarse cloth, which is then fixed with a stapler to a wooden basis on the reverse side.

- Any dense fabric is suitable for the manufacture of upholstery. If such got it possible, the upholstery can be made double. It is also fixed by a stapler, feeding the brackets to the lower or internal surfaces, where they will be hidden from the eyes.

Article on the topic: Production of the rafter system with their own hands

Often those who make such a chair with their own hands, it is difficult to experience difficulties when cutting out curly legs.

In this case, you can offer an alternative option - the legs of the steel square pipe with a cross section of 25x25 mm (wall thickness - 2 mm).

If there is a different profile, such as the corner with the width of the shelf of about 25 mm, you can apply it. To the plates forming the bed of the folding chairs, the legs are fastened with furniture loops. Due to this, they can add up when the shape of the furniture object is changed.