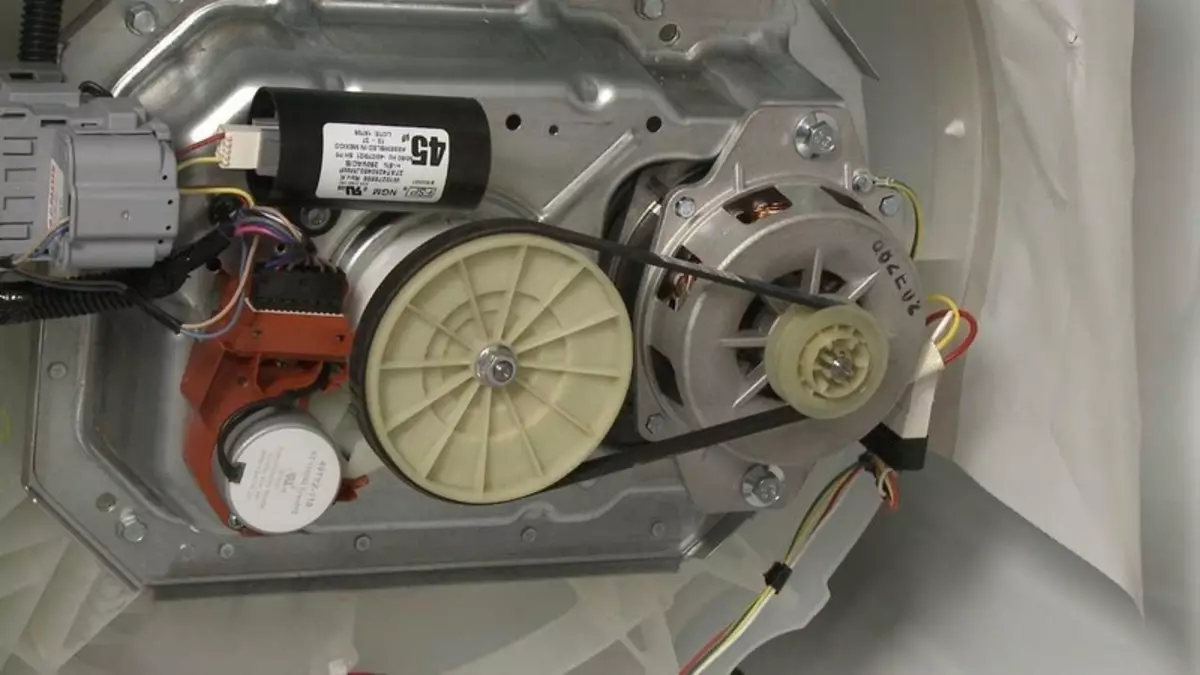

The engine is the heart of the washing machine. This device rotates the drum during washing. In the first models of machines to the drum, belts were mounted, which performed in the role of drives and ensured the movement of the container filled with linen. Since then, the developers have noticeably improved this unit that is responsible for the transformation of electricity into mechanical work.

Currently, in the production of washing equipment, three types of engines are used.

Views

Asynchronous

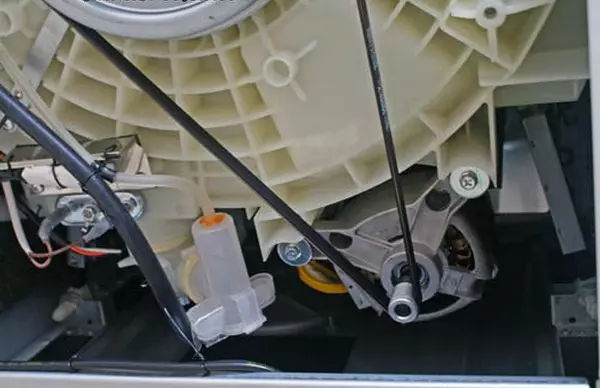

The motors of this type consist of two parts - a fixed element (stator), which performs the function of the supporting structure and serves as a magnetic pipeline, and a rotator rotor, which leads to a drum. The engine rotates as a result of the interaction of the alternating magnetic field of the stator and the rotor. Asynchronous This type of device was called because it is not able to achieve the synchronous speed of the rotating magnetic field, and follows it, as if catching up.

Asynchronous engines are found in two versions: they can be two- and three-phase. Two-phase samples are rare today, because on the threshold of the third millennium, their production has practically stopped.

The vulnerable place of such an engine is to loosen the torque. Externally, this is manifested by a violation of the trajectory of the drum movement - it is swaying without fulfilling a full turn.

The undoubted advantages of asynchronous type devices are the simpleness of the design and simplicity of service, which is the timely lubricant of the motor and replacing the predicted bearings. The asynchronous engine works quietly, and it is fairly cheap.

The disadvantages of the device include large size and low efficiency.

Typically, these engines are equipped with simple and inexpensive models that do not differ in high power.

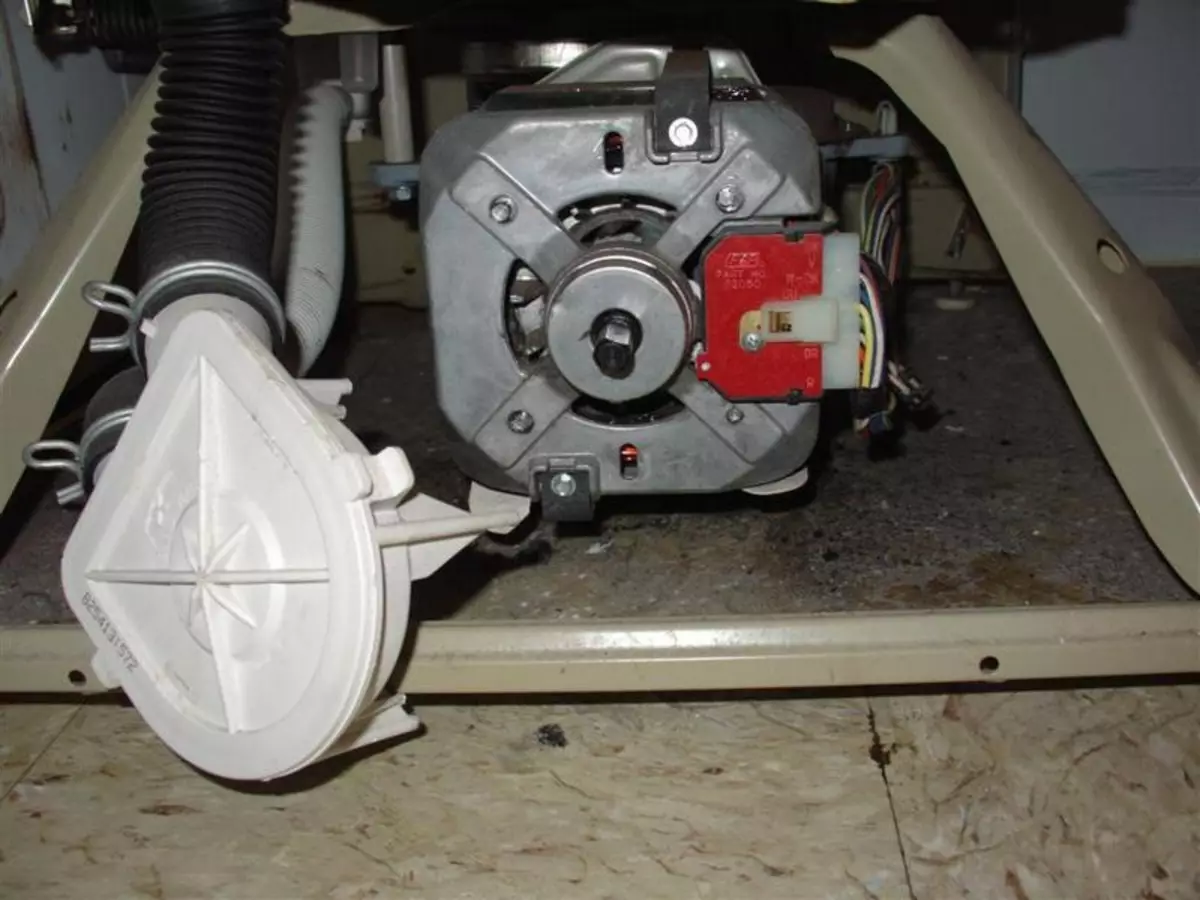

Collector

Collector engines came to replace two-phase asynchronous devices. Three quarters of household appliances are equipped with motors of this type. Their feature is the ability to operate both from alternating, and from DC.

Article on the topic: Clinker tiles for facade, base, garden tracks

To understand the principle of such an engine, briefly describe its device. The collector is a copper drum, divided into smooth rows (sections) insulating "partitions". The contacts of these sections with external electrical panels (to designate such sections in the electrician, the term "conclusions") is diametrically located on opposite sides of the circle. With conclusions, both brushes are in contact with the sliding contacts that ensure the interaction of the rotor with the engine, one on each side. As soon as any section is powered, a magnetic field appears in the coil.

With the direct turning on the stator and the rotor, the magnetic field begins to rotate the motor shaft clockwise. This happens due to the interaction of charges: the same charges are repelled, different things are attracted (for greater visibility, remember the "behavior" of ordinary magnets). Brushes gradually move from one section to another - and the movement continues. This process will not be interrupted until the network has a voltage.

To send the shaft counterclockwise, you need to change the distribution of charges on the rotor. For this, the brushes include in the opposite direction - to meet Stator. Usually, miniature electromagnetic starters (power relays) use for this.

Among the advantages of a collective engine is a high speed of rotation, a smooth change in the frequency of revolutions, which depends on the voltage change, independence from the frequency of electrical oscillations, a large starting point and compact device. Among its disadvantages, there is a relatively short service life due to the rapid wear of the brushes and the collector. The friction causes a significant increase in temperature, resulting in the destruction of the layer, insulating the collector contacts. For the same reason, an interetic closure may occur in the winding, which can cause the magnetic field weakening. The external manifestation of such a problem will be the full stop of the drum.

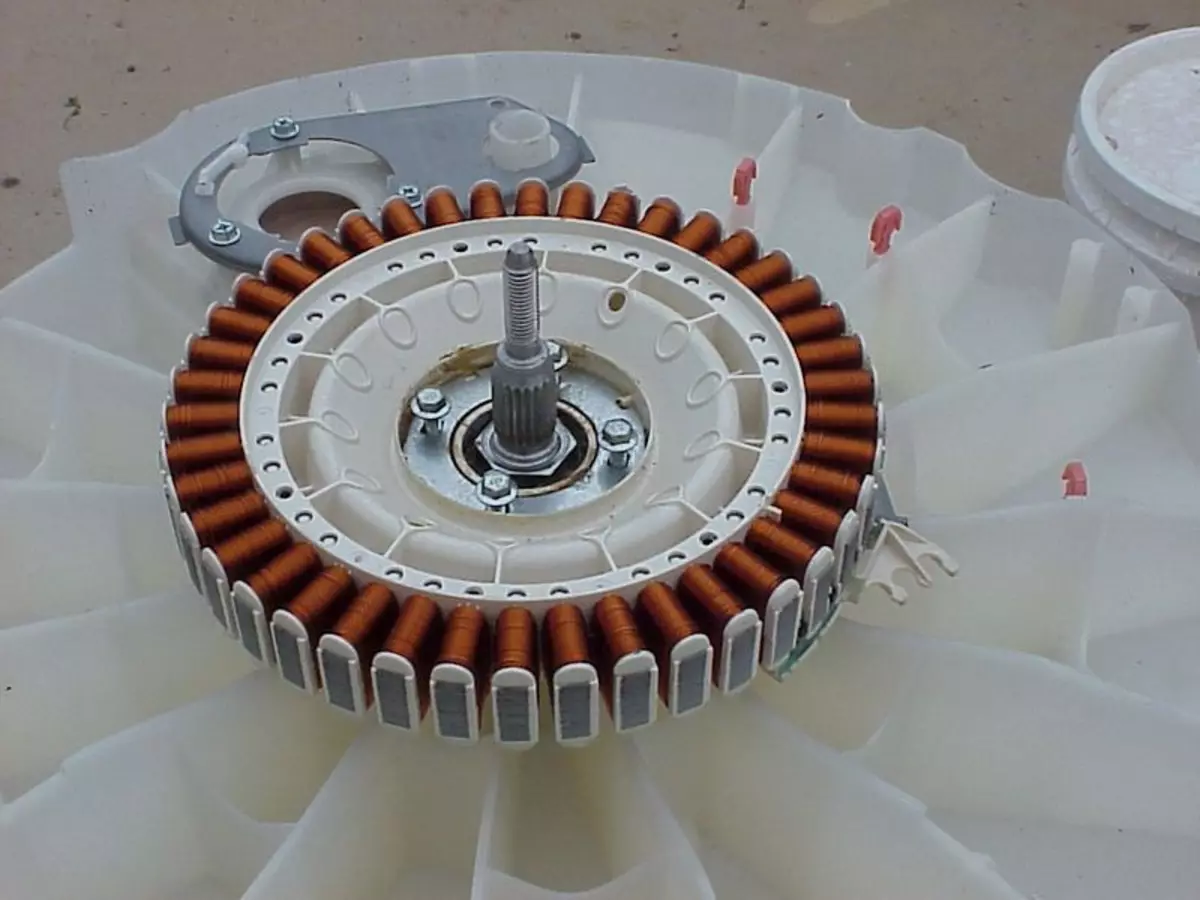

Inverter (inscoleton)

Inverter engine is a direct drive motor. This invention is a little more than 10 years. Developed by the famous Korean concern, it quickly gained popularity due to a long service life, reliability, wear resistance and its very modest dimensions.

Article on the topic: How to update the table with your own hands - instructions with photos of ideas

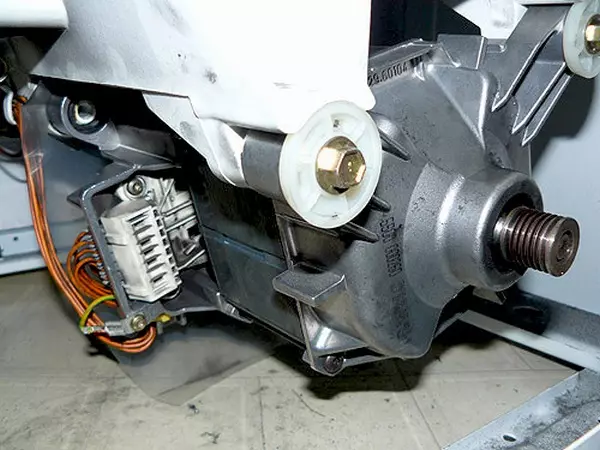

The components of this type of engine are also the rotor and the stator, but the fundamental difference is that the motor is attached to the drum directly, without using the connecting elements that fail in the first place.

Among the undoubted advantages of inverter engines are simplicity, lack of details subject to rapid wear, convenient accommodation in the body of the machine, low noise and oscillations, compactness.

The disadvantage of such a motor is the complexity - its production requires high costs and effort, which is noticeably reflected in the price of inverter cars.

Motor Connection Scheme to Network

Modern washing machine

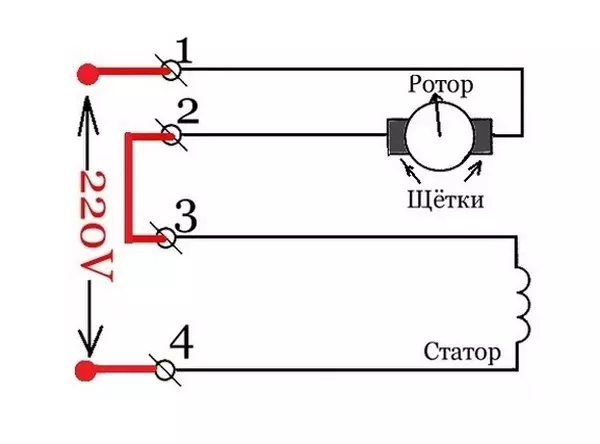

When connecting the engine of a modern washing device to the network with a voltage of 220V, it is necessary to take into account its main features:

- It works without a launcher;

- To start the motor does not need a starting capacitor.

To start the engine, you should definitely connect to the network by the wire from it. The following are the schemes for connecting collector and uncoolette electric motors.

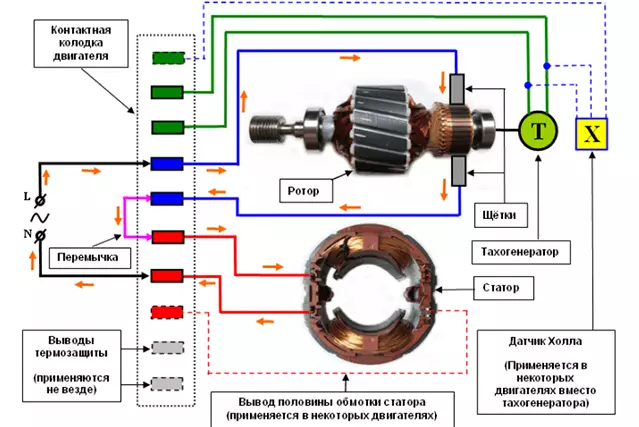

First of all, determine the "front of work", eliminating the contacts that go from the tahegererator and do not participate in the connection. They are recognized by the tester operating in the module. Fixing the tool on one of the contacts, another probe, find the pair of it. The magnitude of the resistance of the tachogenerator wires is about 70 ohms. To find a pair to the remaining contacts, call them in the same way.

Now go to the most responsible stage of work. Connect the wire 220V to one of the winding outputs. The second one is required to connect with the first brush. The second brush is connected to the remaining 220-volt wire. Turn on the motor into the network to check its operation *. If you did not allow mistakes, the rotor will start rotating. Keep in mind that with such a connection it will move only one way. If the trial starts passed without lining, the device is ready for operation.

Article on the topic: how to attach a box with wallpaper

To change the direction of movement of the engine to the opposite, the connection of the brushes should be swapped: now the first will be included in the network, and the second is connected to the winding output. Check the readiness of the motor to work described above.

Vitely the connection process you can see in the following video.

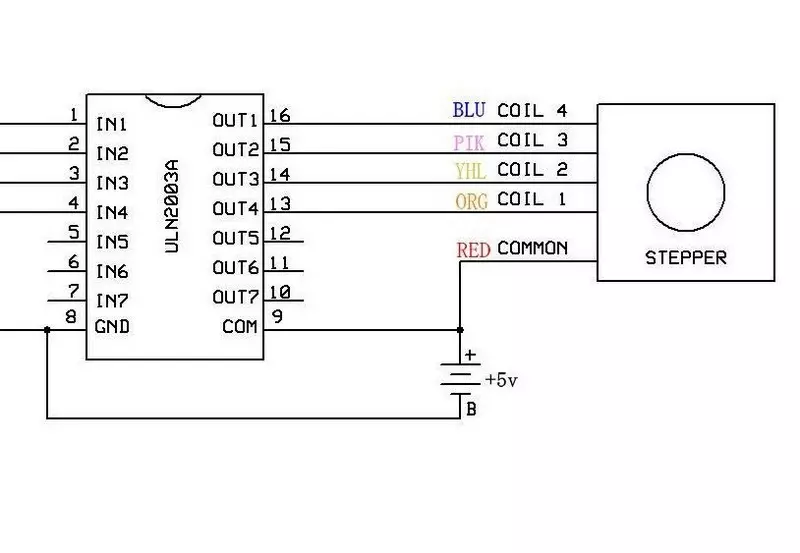

Washing machine old model

With the connection of the engine in the old sample machines, it is more complicated.

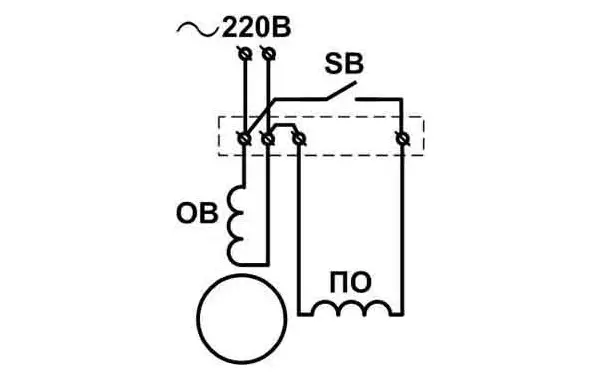

First, determine the two appropriate pairs of conclusions. To do this, use the tester (it is the multimeter). Fixing the tool on one of the winding conclusions, other probe, find the output, pair to him. The remaining contacts automatically form the second pair.

Then it should be determined where the launcher is located, and where is the working winding. Measure their resistance; Higher resistance will indicate the starting winding (software), which creates the initial torque, is lower typical for the excitation winding (s), creating a magnetic field of rotation.

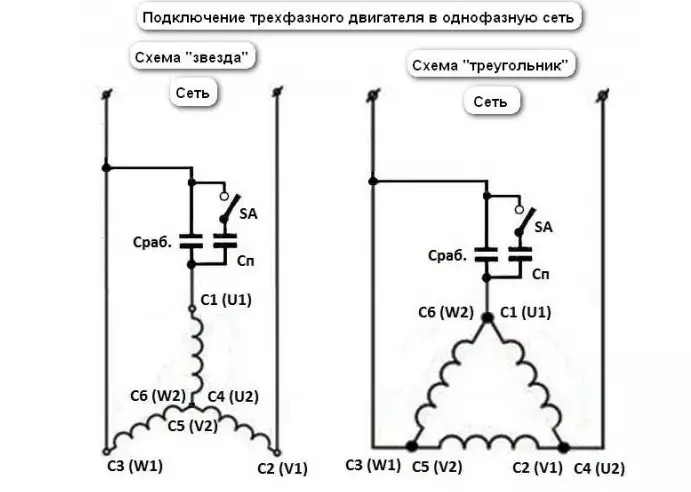

Below are possible schemes for connecting a three-phase asynchronous engine, and detailed video equipment to them.