Each home master once faces the task of how to make a double bed with your own hands, so that it is convenient, reliably and eco. For this there are many ways, but each of them is associated with a number of complications, so you should choose the one that is closer to the soul, and perform.

A double bed can be made of several types of material: a cutboard - one of the economical options, LDSP is the most common material and furniture shield - expensive and reliable.

What materials are better to use?

There are only 3 material that is used at home, in the manufacture of a double bed with their own hands.

Edged board is an economy class. It's easy to work with her, but for a very long time. The final quality depends on many factors, up to the method of drying wood, because of which it remains to be hoped only for good luck. If the material is selected correctly, all the steps of the work are fulfilled correctly, then as a result, the quality will be quite decent.

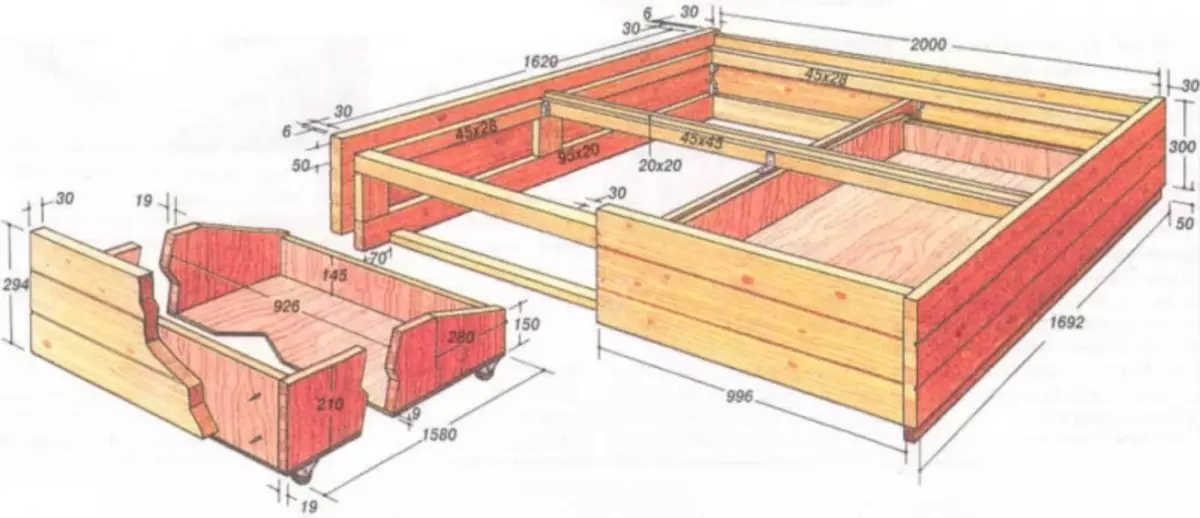

Double bed diagram with dimensions.

LDSP is a classic. Laminated plates are used at each step, because Their price is low enough, they are convenient at work and at the same time are available anywhere in the world. This material has a number of minuses - toxicity (if you do not close all open areas), the impossibility of performing complex ideas at home (curly cutting), color gamut (the number of colors is almost unlimited, but they all look too unatail) and low resistance when lateral pressure (you can compensate, using more durable options). However, a small number of weighty advantages (price, durability and simplicity in work) are doing their job, therefore among all the analogues of LDSP - the leader.

Furniture shield - expensive and angry. This material is used not particularly because of the price, but the result of the work is always on the glory, for a really high-quality product from the tree always makes an eye, and at the same time improves the quality of rest. Pros of material in its environmental friendliness, ease of work, reliability, possibilities of any processing (regarding wood) and velocity speed. Among the minuses is a very high price, and you can get far from every city in the world. The bed is from this material will be considered, and its thickness will be 25 mm.

Article on the topic: Interesting device for ESM. Video camp

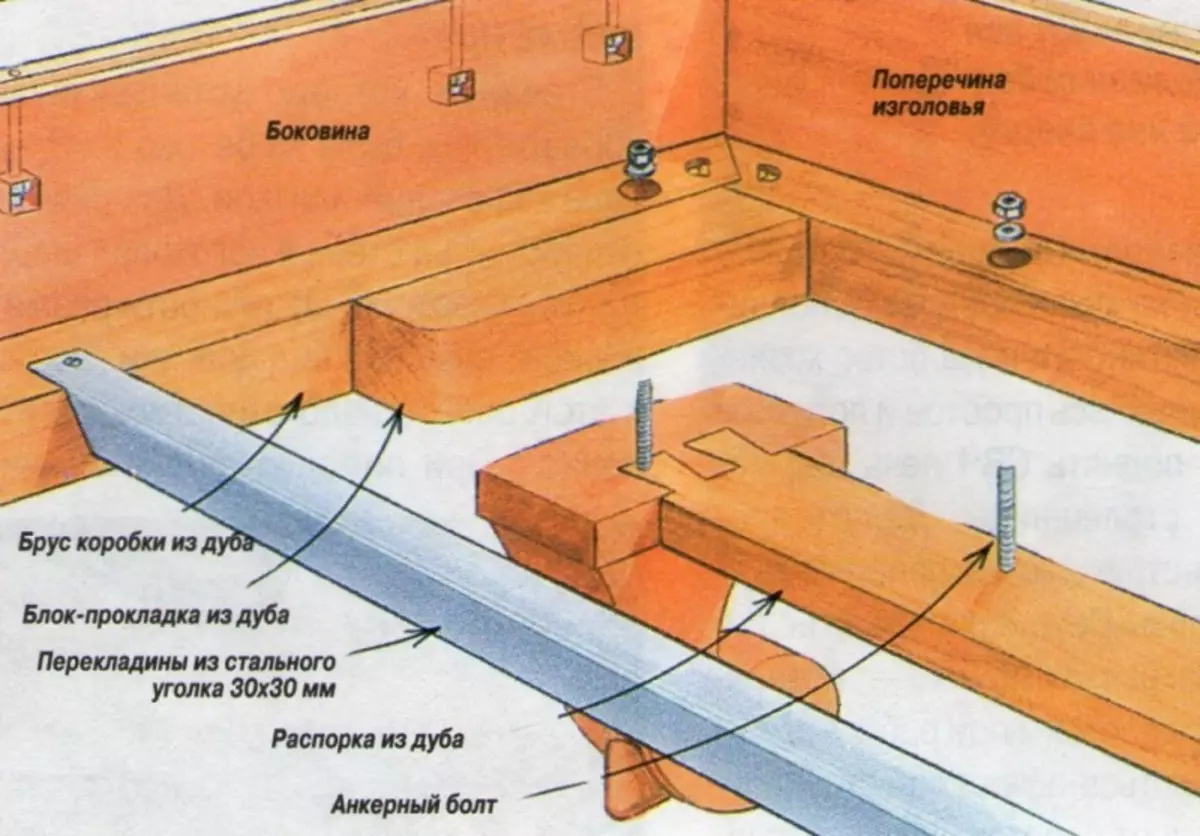

Bed framework

Tools and materials:

Required tools and materials for mounting a double bed.

- electrolovik;

- Screwdriver (drill);

- roulette;

- pencil;

- chisel;

- furniture shield;

- bar.

At this stage, you can use ready-made drawings, and you can make your own. The standard double bed has a width of 1.4-1.7 m, and with its own manufacturer it is better not to regret the materials and make the maximum width. Length, in turn, 2-2.2 m, and here it is necessary to focus exclusively on the growth of vacationers, because With an increase in 1.6 m, a particularly long bed is not necessary, whereas at 2 m will have to lengthen the design to at least 2.3 m. The total height is desirable to keep in the 0.4 m area.

Now you can begin to make a bed with your own hands, the drawings in which are ready. For the start, the plates are cut:

- 1 PC. 1550 * 250 mm - location in the legs;

- 1 PC. 1600 * 700 mm - is in the headboard;

- 2 pcs. 2100 * 250 mm - side panels.

Then 2 bars are cut with a cross section of 40 * 40 mm for a length of 200 mm - it will be legs. The width of the legs can be arbitrarily increased, which will give a greater margin of safety, but cannot be reduced in any way.

That panel, which serves as a headboard, at the bottom doubts the edges of 200 mm of 200 mm and marked with a simple pencil (no marker, because it is then very problematic to remove it). Between the 2-marked points, an arc section is made, reaching at a peak of 30-50 mm, thanks to which the legs are formed on the sides, and at the same time the installation appears even on a not particularly smooth surface (it will not "roll out" from side to side).

Between the panels are connected as follows:

Double bed mounting circuit.

- Between the side panels, the foot (1550 * 250 mm) is installed, which is screwed with furniture screws. To do this, the through hole is made through the plane of the side panels in the rear edge. Depth depends exclusively on the length of the screws used, and the diameter should be slightly smaller to provide high-quality fixation. It is advisable to the chisel to make a deepening under the hat or use special drills with a similar refinement. Each edge includes 2 screws to ensure sufficient reliability.

- From the inside the corners are filled 2 legs and fastened in a similar way, only already from the inside. To enter the legs will be inside the bed only 50 mm. Through each leg drilled 2 perpendicular holes (at different levels). They will go into wooden panels only to a depth of 23 from the total, but in no case can you allow the drill to exit the outside. To do this, you can use the tape to establish an improvised limiter on the drill.

- At the very end, the head restraint is assigned to the resulting design and is screwed in a known manner, only screws are screwed into the edges of the side panels through the head restraint.

Article on the topic: Curtains with lambrene: Benefits, species and tips on the choice

This framework is completed on this, but before the end of the work itself there is still a lot of time.

Strengthening the system and making a magnetic

Tools and materials:

Double bed diagram with drawers.

- electrolovik;

- screwdriver;

- roulette;

- pencil;

- bar;

- Edged board;

- construction level;

- Level water.

To make a bed with their own hands not only interesting appearance, but also in quality, you need to carry out small improvements:

- 3 bars (40 * 40 mm) are cut down the width of the inner wall (in this case, 2075 mm). It should not be afraid that they may not be included because of such accuracy, for you have to push, attaching some power.

- Install 2 bars along the side panels. For fixing, furniture screws are again used, only this time the step should be supported in 40 cm, since the load from above will be large. The lower emphasis is provided on the legs in the back of the structure, which in this case serve as an excellent benchmark of the lower border. In the legs, you also need to fly 1 screw, and the caps are hiding in a mandatory order. When installing, you need to use a building level that will provide perfect evenness.

- With a water level (transparent water hose), another 1 bar between 2 rows at their own level is installed. It is fixed only to the foot and headrest, and for fixation in this case, aluminum corners will be required (2 on each side). It sometimes occurs difficulty, because It is not easy to find a furniture screw in 10 mm, so you can put short bars, and only then apply corner to the sides and fixation.

With the magnifier, everything is much easier:

Makeup assembly scheme.

- The bar is laid 50 * 50 mm on the inner perimeter of the bed on top of fixed bars. But you need to take only 1 cm from the length and width to ensure the possibility of installing and removing the design in the future. The perimeter is connected by screws.

- Another 1 bar is screwed to the resulting frame, which will go smoothly through the central part over the fixed.

- A cutting board with a cross section of 15 * 100 mm is fixed from above, and the length is exactly the width of the frame. The step between the boards is 90-110 mm, but you need to remember that the magazine should not be too tough, but also impossible to fall through it.

Article on the topic: Box in the plumbing with your own hands

Now you can try to connect the entire design together. If everything fell into place, the magazine is extracted.

Latest touches in work and summing up

Tools and materials:

Wooden furniture painting options.

- brush;

- Varnish and Morilka;

- Furniture plugs;

- PVA and sawdust.

After the magazine is separated from the main structure, they need to be thoroughly lighted with sandpaper (zero) or grinding. This will remove all excess from the material that can be visible at the very end. The remaining dust is removed with a wet (not wet) sponge, after which it is necessary to give time to dry (2-3 hours there is enough for the eyes).

Now all visible screws of screws are closed with a tape, because They should not get a veil and varnish, which will be covered by a tree. From the inside the bed do not need to be varnished, because It will be an empty translation of materials. After completing the work, the tree is left in a ventilated room for 36 hours, and only after this time can be used to use (it is not necessary to hope that the solidified 5-6 hours of the lacquer will be safe, because it throws in 3 hours Air harmful substances).

At the very end, the tape is removed (or what the screws were covered) and they are closed with special furniture plugs. If you want to achieve the maximum effect, then you need to mix the sawdust with PVA glue to mix and sweep the screws from above. Such a putty for the tree to create the visibility of the integrity of the structure, but in the future it will be impossible to disassemble it even with a special desire.

The performance scheme is always the same, regardless of whether it will be a single bed, two-way or even a square.

It is very important to perform each element with maximum accuracy to get a really reliable result as a result.