In a country house and on the household plot, it is impossible to do without an inlet staircase, because this tool is an indispensable assistant during construction and repair work. Such a product may be needed when there is a need to get into the attic, attic or climb onto the roof. Gardeners are also not bypassed without an inlet staircase, because it is easier to process trees and collect harvest.

Most often, such a design is made of wood or metal, a variety of models of various configurations are presented on the market - these are ladder-ladder, and folding options, comfortable in everyday life. Aluminum mobile structures are most popular. But why buy such a product and spend money when you can make your own hands with a wooden downtal staircase?

Pros and cons of the wooden stairs

The staircase of the bottom type is one of the simplest types of products of this category. The design is two wooden strips, which are connected by narrow steps similar to the crossbar. The sidewalls are two components, they are also called the growths, perform the main reference element.

The wooden panel ladder has many advantages, they all relate to the main material of manufacturing - wood. The pluses include the following:

- Wood - Environmentally friendly natural material.

- Even inexperienced master can make the staircase from the tree.

- The material is easy to handle, and the product obtained has a small weight.

- There are no many means for processing, just one layer of varnish or paint.

- It is impossible not to note the beauty of the material - the natural texture of wood.

Despite all the advantages, the inlet staircase has both negative sides. And first of all, it is necessary to note the briefness of the material. The tree does not like high humidity and dampness, therefore it is prone to rotting, over time heats up, which leads to the appearance of unpleasant creaks when using the stairs.

In order for the product as long as possible, it is best to take high-quality wood products for its manufacture. And this, again, comes down to one more minus - high cost. But even stairs from the most expensive tree breeds over the years lose their presentable appearance. The most durable material for manufacture - aluminum.

Article on the topic: How to separate the staircase in the house: Choosing a facing material | +65 photos

For the preservation of the wooden structure, we recommend using it indoors with low humidity level and moderate temperatures.

Type of construction

Outwardly, the dormitory staircase is represented in the form of an unbeling structure. This means that it will not need any additional fasteners or hinge mechanisms for its manufacture. In contrast to transformer stairs, such a model is not intended for different positions and is installed strictly vertically at an angle of 60-75 degrees.

In the modern market, you can find mobile stairs from wood that can be folded and transferred - in folded form they are compact and do not occupy a lot of space.

The portable aluminum model is an excellent replacement for a wooden simple staircase, but it will be hidden. To save, it is still trying to make a wood ladder yourself. Making a simple model will not need a lot of time or special knowledge, it is enough just to stock up a small list of tools that will be found in every home.

On video: Overview of multifunctional transformer stairs.

Set of necessary materials and tools

The simplest solution for beginners and inexperienced in the joinery business is to make a staircase from the bar. The consumables must be selected especially carefully, because from the quality and breed of wood will depend on the reliability of the future product and its safe operation.

Brussia from coniferous woods is most popular - this is a fairly economical option, while the wood itself does not lose in strength. However, experts still recommend paying attention to such rocks such as oak and maple - they are more reliable, and the staircase from such wood will last much longer.

When selecting sawn timber, such requirements should be taken into account:

- The manufacture of a stepladder with a height of more than three meters is needed a bars with a cross section of 40x80 mm, if less than three meters - 40x50 mm.

- For the manufacture of steps it is better to use bars from coniferous wood, the optimal section is 35x40 mm.

- The consumable material must be high quality. Not allowing the presence of bitch and cracks, the bars must be perfectly smooth.

Important! After purchasing wooden parts for the future staircase, it is necessary to handle the antiseptic - this will prevent the appearance of fungus and mold, as well as extend the life of the product.

To work, you also need to prepare the following list of tools:

- hacksaw (can be licked);

- hammer and a small hatch;

- Drill and screwdriver;

- For fastening - nails or screws;

- Plancock and grinding;

- Cornel, roulette and pencil.

Article on the topic: Types and advantages of wooden stairs [Stage Performance Options]

Requirements for construction

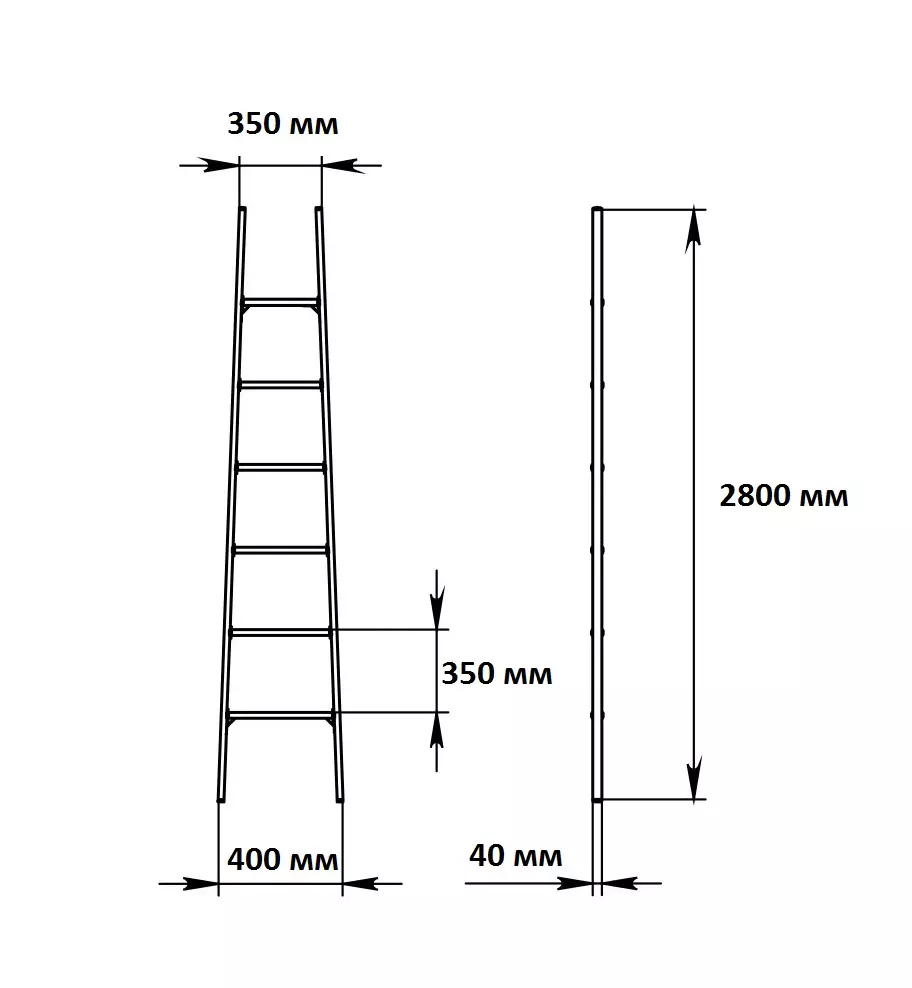

Before you start making a portable staircase from a tree, you need to create a project on paper, more precisely compile a scheme of the future product. The drawing shows not only the design itself, but also the sizes selected for it. Just to take the parameters from the head, since it is necessary to take into account the requirements that are retractable for this design.

What needs to be considered:

- The ladders of the appartible type should not be longer than 5 m.

- The optimal distance between the steps (step) is 30-35 cm.

- Supports must be fastened with screeds with an interval of 2 m.

- The crossbars must be attached in the grooves on the growths, the size of the grooves depend on the width of the steps.

In addition to the standard requirements, the presence of special nozzles is mandatory. Regardless of the type of stairs and the material of its manufacture, whether it is a wooden or aluminum portable model, linings are installed on the legs. When the tool must be fixed on the loose soil, pins are attached to the legs, with the help of which the staircase will be planted incubated. In the case of a smooth surface on the supports, rubber shoes against sliding are put on.

To reduce the risk of falling, the upper part of the stairs is equipped with removable hooks. It is with their help that you can fix the position of the product.

Calculation and assembly of stairs

To compile a detailed drawing with dimensions, it is important to conduct preliminary calculations. And first of all, you need to think about the supports. The donkey staircase should be designed in such a way that its bottom is a little wider than the top. The optimal distance between the assets below is 40 cm, at the top - 30 cm.

To determine the number of steps, the length of the future product is taken as the basis. Divide the visually length on the segments equal to the distance from the floor to the raised foot when the leg bent in the knee. As a rule, this value lies in the range of 25-30 cm. So, if the string in length is 300 cm, and the step of steps is 30 cm, we obtain the amount equal to 10.

Now consider the approximate process, how to make an appropriate staircase with your own hands. All work consists of the following steps:

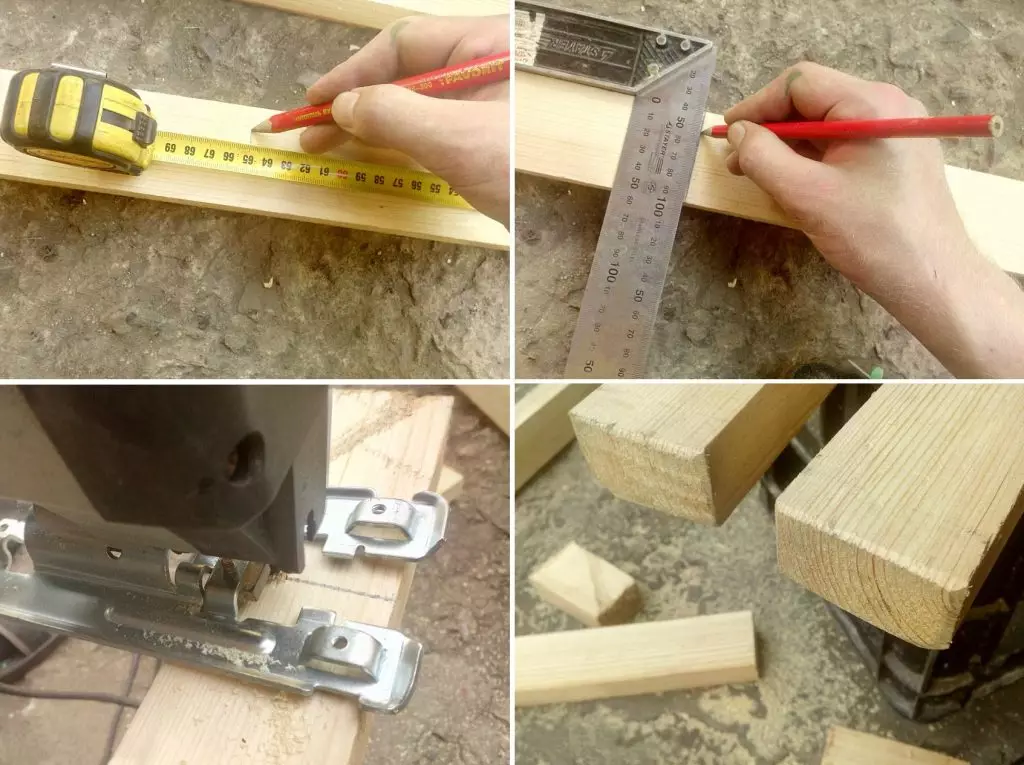

1. On the supporting bars you need to make labels - fastening places of steps. The size of the grooves corresponds to the width of the steps, for example, 50 mm. Similar labels we make on the side of the side - it will be a scour, its depth should be 15-20 mm. According to the outlined lines, we carry out the groove with the help of a hatch, the resulting SCOS, if necessary, pour and grind.

Article on the topic: Chair with transformation in the stairs: types of structures and features of independent manufacture

2. Now go to steps. It should be started from the manufacture of the upper and lower crossbar, while remembering that the ladder should be slightly wider than the top. So the lower step should be longer. With the help of the square, draw the edge cut line, dug out the unnecessary part.

3. The resulting ends need to be treated with grinding. Recovering the edge of about 2 cm. Design the line with the help of the square and tick the center on it - it will be the place of fastening of the steps. In the center point, drill the hole for the self-tapping screw.

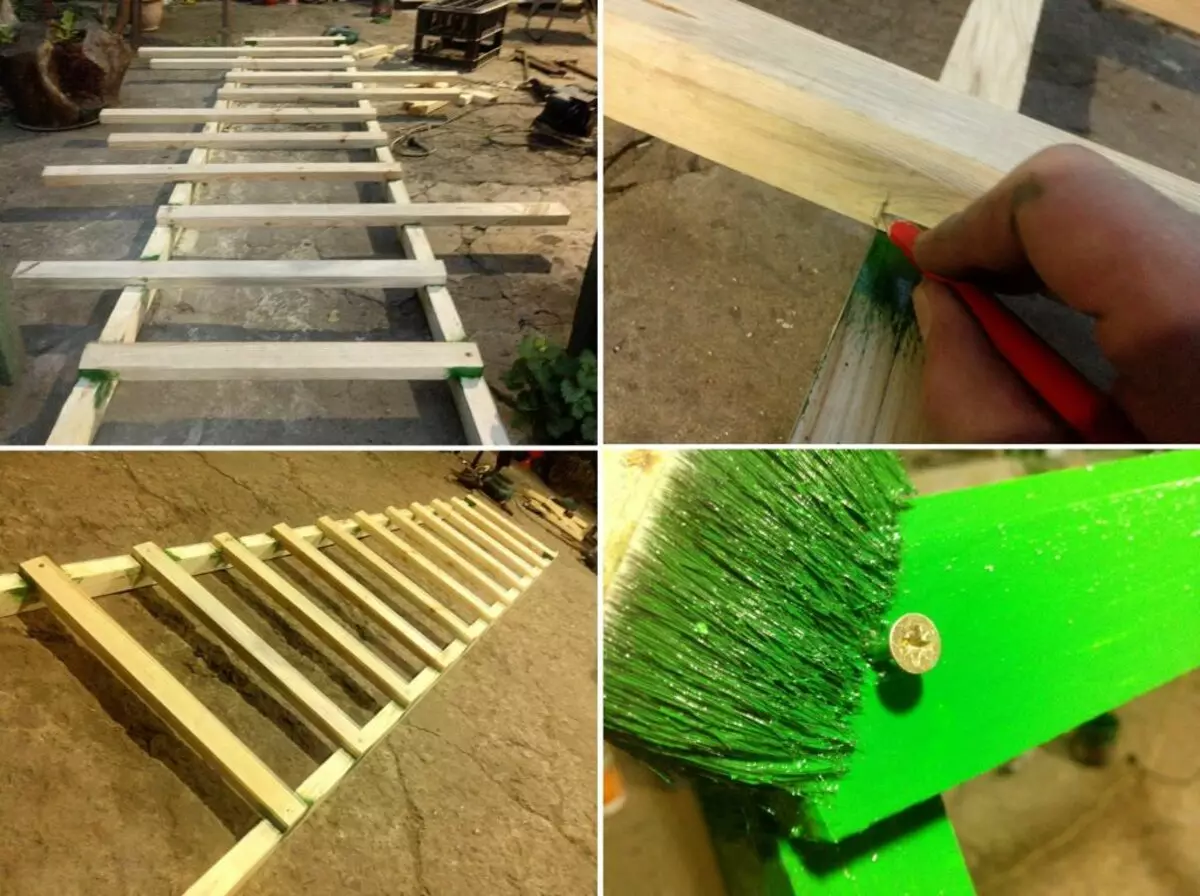

4. Go to the assembly. To do this, first the supports in the places of hell paint in a bright color (in our example it is green). Install the upper and lower steps on the supports in the groove, leve the entire design at the skewers. Remove the corresponding holes in the places of scubons and secure the steps with the help of screws.

5. Next, you need to make the remaining steps. Their length is measured in accordance with the distance between the supports - along the entire length, this value will be different. We make markers, drills, install, screw the last crossbars and our stepladder is ready.

On video: Wooden staircase in 30 minutes with the help of a grinder.

Painting + coating with special compositions

In order for the finished product to get a gladly appearance and served as long as possible, it should be covered with a special composition. It can be impregnation, ordinary painting or varnishing. When choosing a second option, it is strictly not recommended to use oil paint, since this composition can make steps very slippery.

The best option will be the application of olifa. Such a coating will protect the wood and give it the gloss, besides, it will reduce the consumption of paint or varnish.

As you can see, to build the staircase of the bottom type with your own hands is quite simple. If there is a bars of high-quality drying, a minimum of tools and free time you can get a reliable stepladder. Such an assistant you will be useful for both in the house and outside.

Staircase + stepladder in one (2 video)

Different models of inlet stairs (44 photos)