Build a wooden garage with your own hands, and in fairly short time. It will look harmoniously at the site, on which all other structures are made of wood. It remains only to choose how to build a garage from the tree yourself.

Wooden garage will look good on the plot, where all other buildings are made of wood.

Preliminary preparation

The stage of preparation for the construction of a wooden garage includes design, calculation of materials, markup of the structure in place.

The draft garage and the calculation of building materials will allow not only to speed up the process of the construction of the garage, but also will exclude the extra cost of the purchase of wood. The project should take into account the number of machines that are planned to be placed in the garage, the presence or absence of a cargo for storing a car in the summer, as well as the construction of an attic that can be located above the garage.

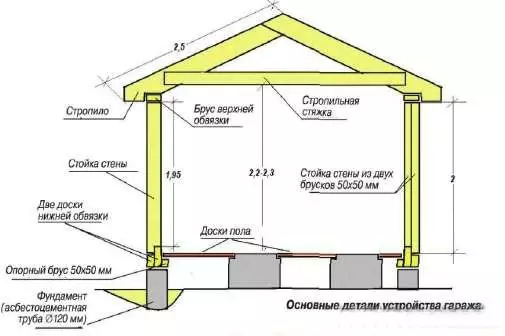

Wooden garage device diagram with dimensions.

The project can contain lighting devices around the future garage, tracks and access roads, and the trajectory of the door opening to avoid inconvenience after construction or in its process is drawn. The project reflects the type of structure - it will be this independent building or the garage will be adjusted to one of the walls of the existing home. If the garage is combined with the house, then you need to calculate building materials.

Of course, the calculation of the required number of building materials and varieties is determined depending on the chosen technology for the construction of a wooden garage. If the garage is frame, then this is a bar of different sections, OSB sheets or plywood, insulation, self-tapping screws, metal corners. If a log-made technology is taken as the basis, then these are pinned logs, insulation. At the same time, the necessary materials for the roof: boards for crates, roofing material (bituminous tile, professional flooring, metal tile).

Article on the topic: What to put near the fence in the country (20 photos)

After the calculations made, you need to mark on the spot. This can be performed using pegs and twine. In addition to build a garage, you will need:

- roulette;

- screwdriver;

- ax;

- a hammer;

- Concrete mixer and others.

Foundation and its erection nuances

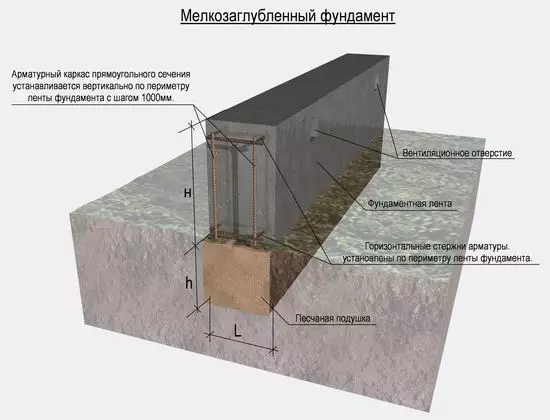

The device of a ribbon foundation under the garage.

The foundation is the basis for any building. Garage is no exception. The foundation for a wooden garage on a frame or log technology should not be very powerful, since the structure will be sufficiently easy. The monolithic design of the foundation during the construction of the garage is necessary only if the groundwater occurs at a depth of less than 10 m.

In all other cases, there will be a ribbon foundation. Its depth is 50 cm, width - 20 cm, height above the ground - not less than 20 cm. This is enough enough to withstand the upcoming load of the garage building for a long time. Drainage will serve as a pillow of gravel with a height of 5-7 cm.

For the construction of the foundation, they dig a trench on the previously applied markup on the specified dimensions. Next, formwork is installed. As it, you can use boards that are firmly connected with screwdripes to avoid possible leaks.

After that, reinforcement rods with a diameter of 10 mm, which bind with a wire or plastic locks with each other. Concrete solution, which is a mixture of cement, sand, crushed stone fraction and water, poured the foundation. During the fill, it is necessary to tribrate the solution to prevent the formation of voids. After that, it is necessary to give the foundation to completely frozen within 10-15 days.

Walls, floor, garage roof

Wooden floor in the garage laid on the lags.

Paul for a log garage can be laid on the bottom strapping. Pre-for the foundation should be put in a layer of waterproofing - ruberoid. The mortgage bar is fastened at the corners in the paw or on the radical (plug-in) spike. The selection of the mount depends on the skill and skill. The main thing - the connection must be reliable.

Article on the topic: Plinth on plastic floor

Further, lags (timber 150x100) are cut into the lower strapping, the distance between which does not exceed 50 cm. If the lags have a rather large length and in order to avoid the gear of the floor, under them at all their length it is necessary to install backups. The backups most often serve as brick columns. The distance between such columns is no more than 60 cm. They are also covered with a layer of rubberoid. It should be noted that lags, bars of the lower strapping should be processed by antiseptics.

Next, during the construction of the walls, the connection of the bar is used as the same as at the bottom strapping. The rows of each other are attached with the help of brazen - wedges of solid wood, which are clogged into a pre-drilled hole. The bells are taken to the bar in order to avoid the formation of cracks during drying.

In the upper crown, rods are performed for rafting bars.

On a wooden garage you can make a roof from the professional leaf.

The roof shape depends on the design and size of the garage. When the garage is adjusted, it is wiser to make a single-piece roof, for a separate garage - two-tie. Further, the crate, the rubberoid layer across the crate, and then the roofing material.

For floors take a circulating board, fix it on lags with nails (self-drawing). After that, the entire space inside the garage is covered with a special fire makeup. For safety, the floors can be covered with metal sheets, at least in the places of possible spill of combustible fluids.

How to build a garage of a frame: Recommendations for building

Foundation

For such a garage, a monolithic foundation is preferable. This is due to the fact that the floors are quite difficult to securely fix with very light design of the frame garage. The monolithic foundation will play the role of the floor.For a monolithic foundation, it is necessary to remove the soil on the markup and construct a 30-40 cm tool around the perimeter. The lower layer of the foundation will serve as sand with gravel, which watering water and trambed when laying. The height of the layer is 20 cm. Next, it goes a layer of waterproofing - waterproof membranes or rubberoid.

Article on the topic: The distance between the pipes of a warm floor: Tips for definition

After laying the reinforcement, its binding the foundation is poured with concrete solution. At the same time, his trambet. After the frost during the month, the construction of the garage can be continued.

Walls, roof of frame garage

On the lower strapping, which is performed from a bar of 150x100 mm, corner racks are put. However, the strapping can not be performed, but secure racks directly to the foundation using metal corners. Support beams must be exhibited by the construction level strictly vertically. Guides that are attached perpendicular to the racks can be a cross section of 100x40 mm. The distance between them does not exceed 1 m. With fixing the guides, nothing should act beyond the limits.

Slingeing beams are attached to the upper strapping in advance dirty grooves. They are fixed with metal brackets, which ensures reliability. The distance between the rafters is not more than 1 m. They are stealing the crate, then a layer of waterproofing (rubberoid), and then roofing material.

The insulation is laid between the racks - heat-insulating mats or foam. From the inside of the garage to the racks of the construction stiprole, a steam-insulating film is fixed. From the outdoor side, over the insulation, the layer is fixed at first vaporizolation, and then waterproofing. Next, the frame can be sewed by OSB sheets or plywood from the inside, siding or clapboard for outdoor work.

What the garage will end up - this is the choice of each. But the construction of a wooden garage with their own hands is a completely real event.