A homemade air recuperator is an economical heat exchanger: Returns heat that could leave during the ventilation of the room.

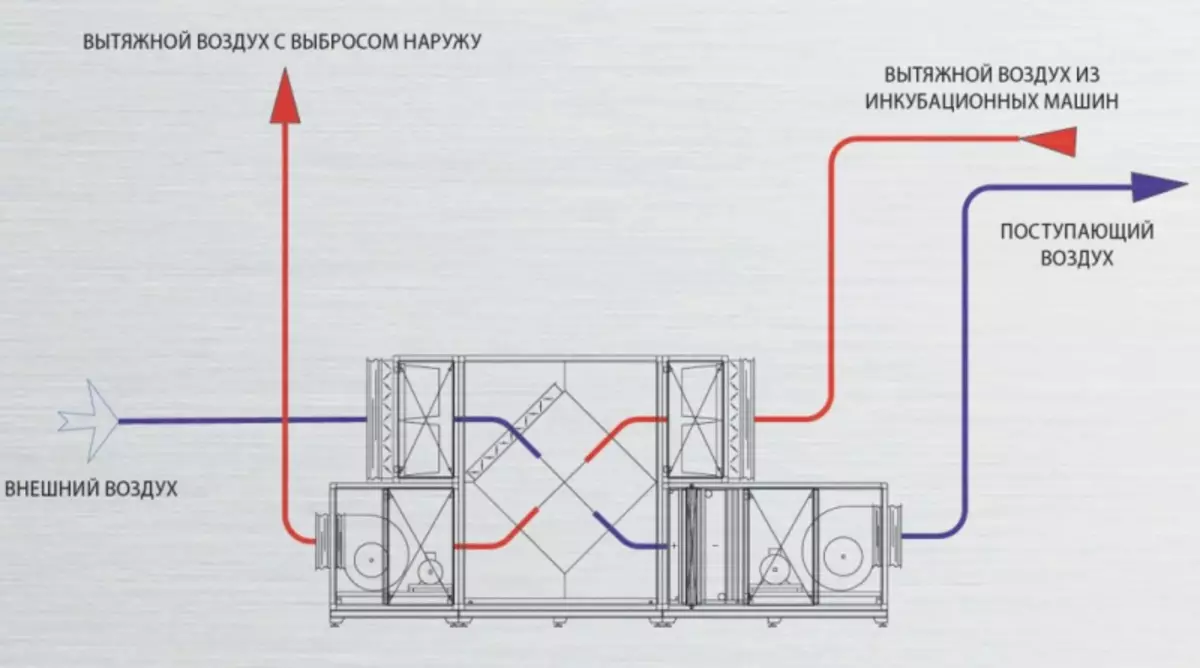

Air recovery scheme.

If we talk about basic concepts, the recuperator does not have elements that actively distinguish heat.

The heat recuperator of the ventilation air may be different for its intended purpose (decentralized or central), as well as on the principle of its action (recuperative or regenerative type).

If we talk, for example, about the garage, then it must protect your car not only from the encroachment of third-party people, but also to protect it from corrosion. If there is no ventilation in the garage, then this fact negatively affects the condition of the car. In addition, it will have an increased moisture, exhaust gases and fuel pairs will be accumulated without ventilation, which will lead to the beginning of the corrosion of the body.

Methods of air ventilation

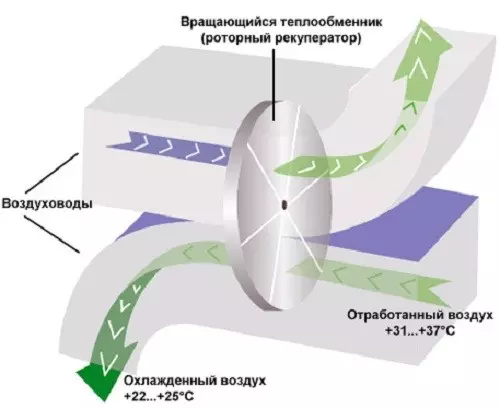

Rotary recuperator scheme.

- Natural ventilation. In this case, the opening is made at the wall at the height of 15-20 cm, the second hole is made in the wall on the contrary, and the exhaust pipe is output. In order for the ventilation to work, the height difference should be greater than 3 m from the top of the exhaust pipe to the air inlet hole. On 1 m² it is necessary 1.5 cm of the pipe diameter. Such a ventilation system is installed in an unheated room.

- Combined ventilation. To increase the heat exchange rates, use forced ventilation, but the air flow remains natural.

- Mechanical ventilation is the most efficient. In this case, the exhaust is carried out 1 unit, and the air flow is the other, they are controlled by automation. Such installations have a recuperator, which allows to transmit heat inside the air of the air, which comes from the outside. Such a heat exchanger allows you to maintain heat indoors and save electricity.

You can make a homemade air recuperator, and it is partially, and sometimes completely replaced the heating system (in the garage or utility room), will allow maintaining the temperature above + 5 ° C (even in frosts).

Article on the topic: Height of the floor of the radiator from the floor: on what to hang away

Homemade Recuperator: Design Features

So, the equipment that allows partially returning thermal energy to reuse it, is called a recuperator or heat exchanger, you can make it with your own hands. During the operation of the specified equipment, the trimmed air is heated due to the warmer exhaust air. Passing through the heat exchanger, the trim air heats up, and the heat energy is not lost during the output of the air outward.

What are the recuperators?

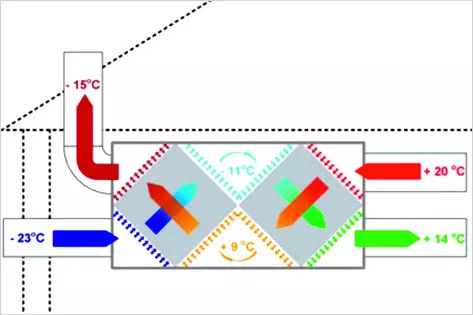

Heat recuperator scheme.

The simplest and most affordable view of the recovery, which can be made with your own hands is a plate heat exchanger. There are such types of the specified equipment:

- with a lamellar heat exchanger;

- with rotary type of heat exchanger;

- roof recovery;

- Recycling water.

For lovers, homemade is the easiest possible to make a recuperator, which has a plate heat exchanger. Make such equipment with your own hands will be able to any person who has elementary locksmith skills.

To begin with, consider the advantages of this type of equipment:

- High efficiency - 40-65%;

- A simple heat exchanger in which there are no rubbing or moving parts - it increases its reliability;

- No parts consuming electricity.

Among the shortcomings are worth noting the following:

- Since the streams of exhaust and supply air intersect, the pipes of the air ducts must be intersecting, which is sometimes quite difficult to implement;

- In winter, it is possible to frost the recuperator, so it will be necessary to sometimes turn off the trim fan or use the bypass valve;

- There is no possibility to carry out moisture transfer, only heat exchanged.

We make yourself a plate recovery

We take 4 m² of sheet material (galvanized metal or textolite) and cut it on the plate size of 200x300 mm. Thermal conductivity of the material in this case does not play a big role. The edges of the plates must be smooth, so when cutting metal, it is impossible to use scissors, it is better to use an electrolovka.

The technical cork bands are stacked between the plates, the distance between which should be at least 4 mm so that there is no high resistance of the air flow. Everything is fastened with polyurethane glue. After all the plates are folded into the stack, the slots are filled with neutral silicone sealant. If using acidic sealant, it may cause metal corrosion.

Article on the topic: Painting tiles in the bathroom - how and how to do it

After that, the package of plates must be placed in the case: it can be any rigid box of the corresponding sizes. In the box make holes in which the flanges are inserted, corresponding to the cross section of the air ducts. The area of the plates, which is in the recovery, will be about 3.3 m². Thus, at the output, the air temperature will be much higher than the air that is drawn.

In winter, such models often frost: so that this is not, the pressure drop sensor is installed in the warm part of the recovery. During the frost, the pressure drop will increase, and the trim air will go through bypass, and the calorifer will warm up with exhaust air.

To create a box, you can take polished MDF and a timber. Inside it, it is necessary to post the insulation (mineral wool 5 cm thick), the insulation is also stacked around the fan. Where the flexible air duct is connected, they make a box that is laid out with mineral wool. Thus, you reduce system noise during its work.