There is nothing easier than the incarnation of a joinery project. However, he, like other undertakings, requires indicative planning and drawing up the estimate. Manufacturing shelves with their own hands requires similar planning. Almost any blackboard, which has a pair of support points, can be successfully called the shelf. In this case, the question always arises what material it is better to use.

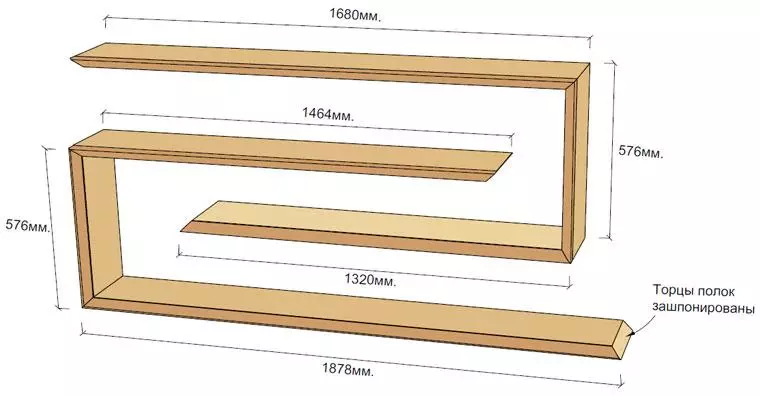

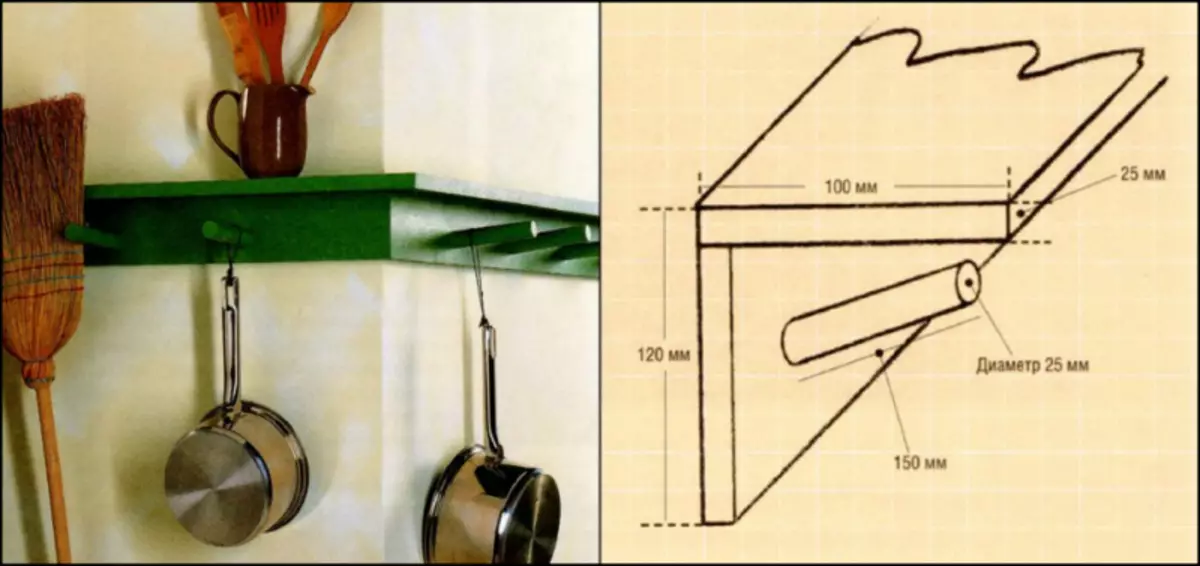

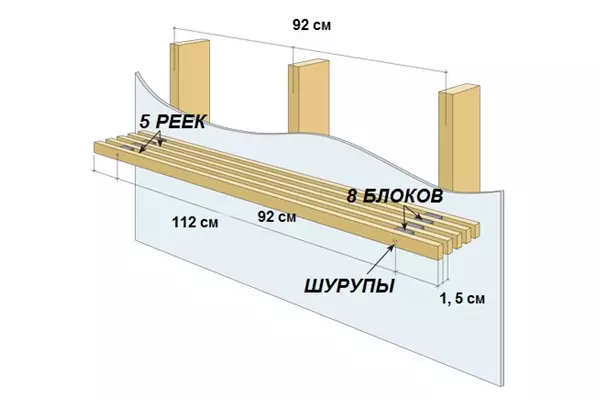

Wall-mounted shelf size scheme.

What dimensions for such a product will be the best? What material must be used to make supports? How to make a wardrobe or shelf so that they look beautiful and well fit into an existing interior? To do this, you need to familiarize yourself with the advice of experienced professionals, which will explain in detail how it is necessary to make a choice of material, what should be the dimensions, the methods of mounting the shelves.

Also prepare and tools:

- hacksaw;

- screwdriver;

- chisel;

- roulette;

- Corolnic

Determine the width of the shelves, calculate its height, find the optimal distance between several shelves.

Some features

Naturally, the regiment can keep the most different documentation, various items. When the size of the shelf is selected, you need to take the assignment of the repository as a basis. To change the height of the shelves, it is necessary to use shelf tires having brackets. Apply special pinholders that have several drilled holes.

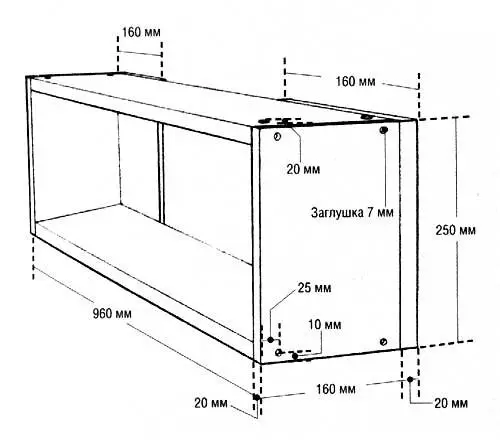

Scheme of mounted shelf.

It is very important during the manufacturer to calculate the exact depth of the shelf. This value is directly dependent on the part that will be installed on it. To determine the width, the shelves can be used by special tables, where the width of the radio equipment, television, etc. is indicated.

When installing the shelf, the height should be chosen in such a way that there is easily accessibility for a specific category of users:

- Designed for adults - approximately 1725 mm.

- For young men of 10-11 class - approximately 1550 mm.

- For students of 6-8 class - approximately 1400 mm.

- For students of junior classes - about 1295 mm.

- Shelf for small children - about 1220 mm.

Article on the topic: Mailbox do it yourself

In the manufacture of the shelf, on which electronic equipment will be installed, it is necessary to provide a special place where the electric pipes and cables will be. Each shelf must have drilled holes to skip the cable for inclusion in the common network. So that the fork of the wire has free access to the outlet, the hole diameter is necessary to drill in size more than 32 mm.

How the appearance made of the front edge affects the estimate of the shelf

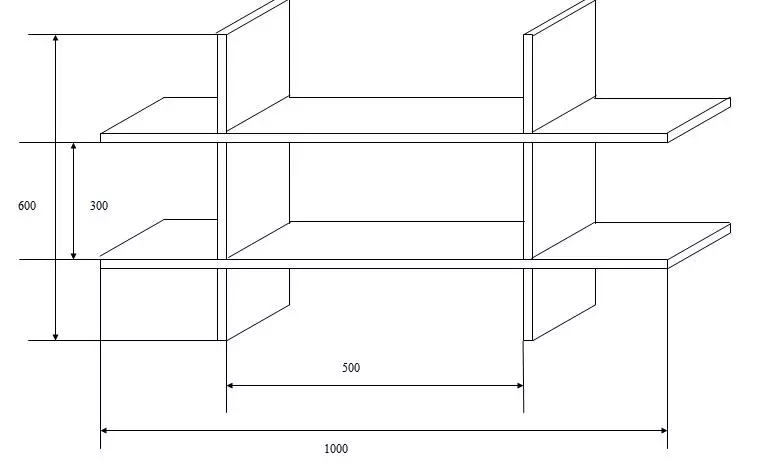

Television shelves scheme.

To finish the edge, you must have the appropriate materials. Front and pad made of wood glued together. The product becomes much stronger. If the main material of the shelf is plywood, then due to the lining the edge becomes much more beautiful. Wide pad, which performs a little behind the dimensions of the shelf, visually increases the volume. Racks for books acquire a massive view.

For the manufacture of edge overlays, it is best to use boards with a thickness of about 19 mm, configuring them to the desired width. The strength of the shelf depends on it. A wide shelf is usually the most durable.

High reliability has an adhesive cover with the edge of the shelf, if such an operation was performed using the newest PVA glue. Such a pad should close the top of the shelf slightly. After the final drying of the adhesive, the flush is aligned. This operation is performed by the edge cutter.

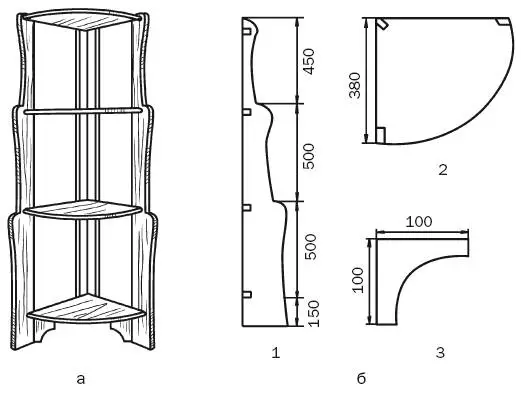

Making corner shelves.

When the shelf material serves a glued shield, the original appearance will create a glued decorative profile. Ordinary rounding turns the appearance of the made shelf in a softer. The chamfer will give it a special appeal. To make original products, it is better to use the shaped cutter that has a profile that meets the style of the intended project. Profile milling is carried out for several passes.

To rapid decoration of plywood shelves, you need to stick flexible brass strips on the edges. In addition, you can use a special edge ribbon. To do this, with the help of a heated home iron, you need to press the adhesive layer of the melamine strip to the edge of the shelf.

Article on the topic: Decorative plaster for the bathroom do it yourself

The iron temperature pointer must be set to the average heating temperature. Slowly moving, Iron melts glue, which tightly grab the melamine strip. After cooling the adhesive, it is necessary to cut the resulting sinks with a special tool. Of course, such materials do not affect the increase in the strength of the shelf, but they help hide the coarse edges.

Handling wooden shelf

Scheme of a wooden angular wall shelf.

The main thing is when the manufacture of shelves is made - this is the processing of sandpaper outer angles. To achieve smoothness, the shelf must be grinding the skin with grain №100. Grinding should be performed along the fibers. Practical experience has shown that small graininess for grinding is not suitable, especially if the shelf is subsequently covered with varnish.

It must be said that abroad often used bookshelves made from a board that has not been treated. With long-term operation, the rough surface becomes smooth from constant touches. The structure of the tree is not broken, the board acquires a noble view.

Assembly work: nuances

To the shelf tightly lying on the steel brackets, it must be fixed by conventional screws for wood.

Scheme of mounted shelf.

Applied furniture shields are fixed with special furniture screeds of different dimensions. Similar screeds are screwed into the edge of the boards. They are used in the production of complex furniture, such as writing tables, more complex racks, etc.

When the screws are applied, you need to know several characteristic nuances.

Self-tapping screws are often confused, designed for wood, with special self-drawing created for screwing into a chipboard. Such self-tapping screws have a short threaded step, they are poorly held in the present tree. Other screws intended for wood have a big threaded step. The outer diameter of such fasteners is very different from the internal, as a result, the self-tapping screws are firmly screwed into the wood.

Sometimes it is very difficult to find the self-desired length of the desired length, especially when thin shields are applied. In such cases, the excess length is simply biled with nippers.

Article on the topic: Linoleum laying technology and the production of linoleum plinth

In order not to split the board, you need to pre-drill small holes.

The diameter of the hole should be slightly less than the inner diameter of the self-press.

Fastening shelves to the wall

When hanging a closet or shelf, it is necessary to use the level. It will help even secure the design. This operation is the most responsible, since unreliable mount may not withstand and injure residents at home.

In a wooden house, it will be quite enough to fasten the shelf with long self-drawing.

If the walls are brick, concrete or plasterboard, then the best fastening will be dowels. Currently, the dowel is a metal rod, equipped with ribs that play the role of retire and metal self-press. To secure the dowel, you need to drill the hole of the desired diameter, then drive the plastic rod into the hole and screw the screws.