Radiators and their repair

In the modern world, radiators perform the heating and cooling functions. They emit thermal waves and dispel heat in the air. Devices made from various metals and their alloys. Radiators more often have such a fault as a crack, through which it begins to flow. This breakdown is eliminated by different ways, the most reliable of which will be welding and soldering.

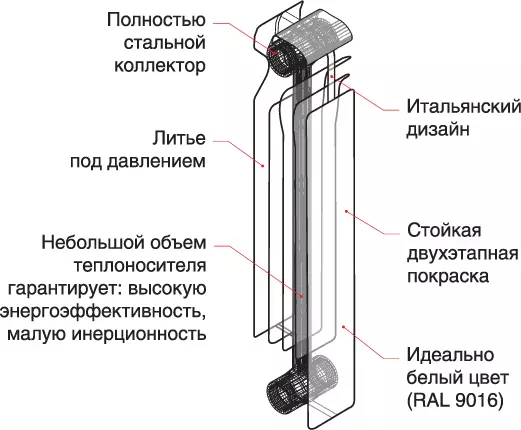

Aluminum radiator device.

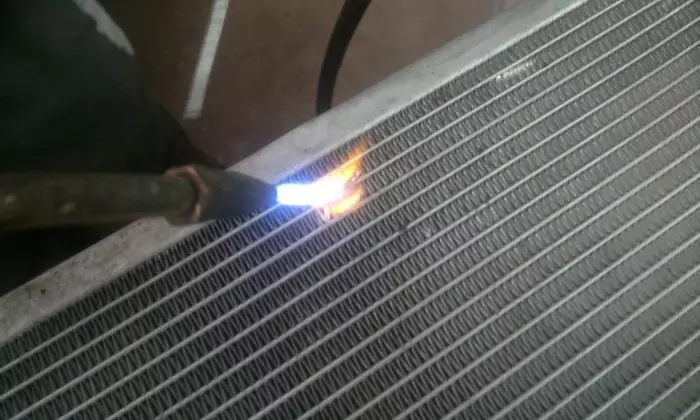

Welding (argon) requires professionalism, experience, equipment, applicable only for thick sheets of metal, and, therefore, it is difficult to recommend it for self-repair of radiators. While soldering (the connection of the desired parts with solder) is a procedure that is available for execution. This repair of copper and aluminum devices is well done by the technologies already proven.

Repair aluminum radiator

The use of the radiator is possible, for example, to cool the car engines, the heating of the cabin in the car, for the heating of apartments and other premises. Use aluminum radiators quite often, as the heat transfer in aluminum is high and, therefore, the devices are cooled faster and heated, they are compact and their weight is small.

Aluminum radiators (in contrast to brass products) It is not easy to pour, because their surface is quickly oxidized and is covered with a sturdy inert film that prevents the solder on the metal.

Radiator section.

Before repairing the radiator, you need to remove and drain the liquid, dry well. The soldering of aluminum devices should be produced, having tools:

- ceramic crucible;

- file;

- sandpaper;

- Soldering iron (from 100 W).

And materials:

- rosin;

- Special solder (for example, P150A, P250A, P300A);

- iron sawdust (bed);

Next, we carry out the instructions in detail.

- We prepare the place of the soldering, cleaning it with sandpaper but, without scratching the surface.

- We melt in the crucible rosin and prepare the mixture (rosin 2 parts and sawdust 1 part), which we will use (after cooling) as a flux.

- Cold soldering iron Clean the salty file and turn on the network. Now heating the place that is repaired, with the help of a heated soldering iron, causing a mixture from rosin. We apply a rosin on a warm surface, and not on a soldering iron, as it can start charring (at 315 ° C) and lose the properties of the flux.

- Ludim surface, rubbing it and making circular movements.

- Seeing that the rosin spreads, we continue to brow, adding a gram of solder (lead-tin), to which the iron sawdust is noticed, picking it up with a sore soldering iron. The sawmills purify the surface from the oxide film, destroying it (then the tin forms a connection with aluminum), and the rosin, protecting the surface from the air, protects it from oxidation.

- Next we sear the crack of the solder.

Article on the topic: Laying of electric heating floor under laminate and tile

Diagonal diagram of connecting heating radiators.

In this way, it is possible to close a small crack in aluminum radiators, but if it is large, the high-strength seam can be obtained using a tin mixture with a bismuth using a slim instead of a flux. Cooking solder: we melt in a crucible, mixing, bismuth and tin (5 and 95 parts). We make glasses: grind separately, then mixing them, such ingredients:

- Potassium chloride (56%);

- cryolite (10%);

- chloride of lithium (23%);

- 6.5% cook salt;

- Sodium sulphate (4%).

The vessel with a mixture is tightly clocked, as it quickly absorbs moisture. Now you need to apply a slope for the entire working plot, warm the surface with a soldering iron, and to solder, adding a solder portion that will close the hole.

We use another option soldering

The damaged area before applying the soldering can be closed with a layer of copper. Prepare tools:

- soldering iron;

- sandpaper;

- Battery.

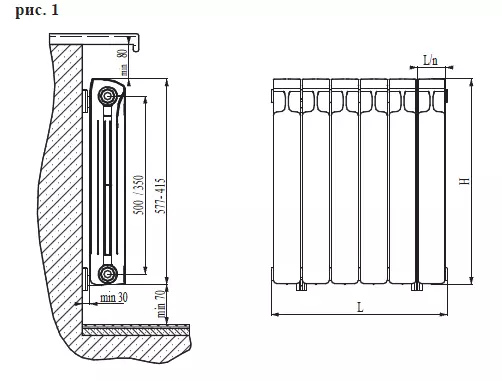

The dimensions of the aluminum radiator.

Materials are needed:

- copper sulfate solution (CUSO4);

- copper wire;

- flux;

- solder.

They act like this:

- Well cleaned the place to be sought.

- Then carefully dripped at it a bit of a mood (solution) to form a large "drop".

- The negative pole of the battery is connected to the radiator (for example, from a pocket lantern), and its positive pole is connected to a wire piece (1 mm diameter) from copper without insulation.

- Another end of the wire should be diveling in the "drop" of the vapor, but not to touch the metal. Shortly under the drop, on the surface of the radiator, a thin layer will appear red copper, located from a mood.

- Next, the surface is washed and dried, and then they produce a tinsel to a soldering iron and a conventional solder using solder. Now the crack will be closed securely, as the solder goes well on the copper surface.

The need to repair the radiator on their own forces may appear if this type of work is not carried out professionally, if the defect is small, as well as in the event of a time deficit. Spinning an aluminum radiator independently, thereby get a qualitatively renovated product, extended its life, save funds on the repair and purchase of new equipment. It is also important that the skills gained during the repair, helping to make a soldering of such a "complex" metal, like aluminum, have quite real value and can be useful in the future.

Article on the topic: Ready design projects of three-room apartments