Plastic in the modern house is found everywhere. It is often subjected to shocks and cracks are formed on the surface. Do not rush to throw out equipment and furniture. Putty for plastic can be fired dents, close the cracks, gluing their edges and even close the holes. Only not always you can buy a putty you need in a construction store.

We restore plastic parts with a putty

Plastic presents special requirements for putty

Putty for plastic parts

Plastic is rarely colored from above in different colors, usually a tonality is created in the manufacture and for the entire depth. It has a glossy surface, contains dyes in the composition and does not require additional decorative appearance. Differs from most materials used in the interior:

- pushes water and does not absorb her;

- does not react to oil, domestic acids and alkali;

- flexible and plastic;

- Small specific weight - light;

- hardness below brick and stone;

- Bad adhesion with most finishing materials;

- Quickly erases, covered with scratches and cracks.

Applying putty for plastic

The decorativeness and ease of plastic rated furniture manufacturers, creating a collection of mobile sets for cottages and dining rooms. The enclosures of the instruments and equipment for the kitchen and bathroom are strong and beautifully look. Pressing plastic betray the most complex form.

Throwing away a mixer or coffee maker, due to the appearance of cracks in the case, it is not worth it. The position will fix the putty for plastic and skillful hands.

Large selection of putty for plastic parts not in building stores

Close up of bumper cracks using putty

In construction stores, various putty for plastic stands separately from the rest. Their choice is often limited. But on the showcases of goods for cars you will find the goods you need. The bulk of plastic parts is on passenger cars.

Article on the topic: How to make a shower cabin in the bathroom with your own hands - expert advice

Pay attention to polymer putty, or rather polyester. Among them are a large selection of two-component compositions created for the repair of the body, the bumper, the base for the tank, the air filter housing and many other details. Separately are colored compositions. The choice is small, it repeats the tonality of the main parts of the machine.

The basis of plastic spacure is:

- epoxy resin;

- fillers;

- plasticizers;

- Dyes.

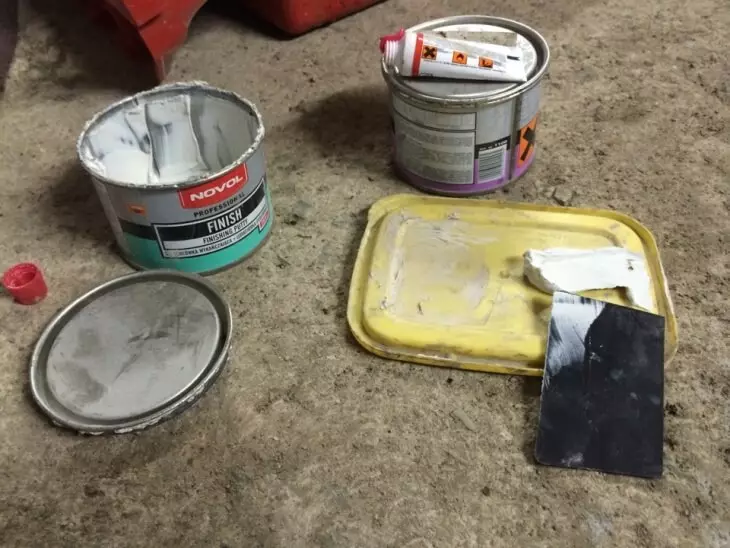

Putty for plastic

The hardener is packed in a separate tube and is added before applying in a ratio of 2 - 3% to the bulk. Time frozen from 6 to 8 minutes. It is necessary to work quickly. The layer thickness can be up to 2 mm, provided that the first is much thinner.

To obtain a smooth and smooth surface, putty on the plastic is applied by a rubber spatula and each layer is cleaned. For independent work I recommend choosing mixes with high softness. The parts made of plastic are mainly rounded surfaces, the form of which repeats the tool when sliding and equalizing the composition. Metal canvas can scratch a softer part surface.

Grinding putty on plastic is performed manually. Insert the skirt in a special device. First large, then small. We do not recommend using machine and water. The first of its vibration can destroy the item. Water will make a putty viscous and worsen processing, may even remove the whole composition.

Polymer putty with fiberglass

Repair of plastic parts with putty

For climbing cracks and defects on internal parts that are exposed to loads and vibrations, I recommend using reinforcing plastic wipers with fiberglass. The polymer composition on a latex basis is sold in a ready-to-use form. It can be applied with a layer of 2 mm. The disadvantage in the impossibility of grinding and creating a smooth surface. The position corrects the use of finishing compositions without additives.

After grinding the surface of the putty, requiring staining, is covered with primer mineral, acrylic. Accelerate the drying of materials can be lamp. Temperature should not exceed 60 degrees. The minimum should be no lower than ten.

Article on the topic: Installation of plastic doors with your own hands: Instruction (photo and video)

The advantages of reinforcing materials with fiberglass in the ability to bend along with the detail and high vibration resistance and dynamic loads.

Preparation of the surface and application of fiberglass

Putclone for restoring plastic bumper

Before aligning the surface, it should:

- wash

- degrease

- Clean the shallow eye to create roughness that improves grip with nanosimy materials.

Gasoline after drying leaves traces of oil and fat that contains. Therefore, it is better to use solvents. You can dry with a hairdryer with a low temperature setting or removing it to the distance from the part.

We restore the bumper

To close the holes in plastic and wide cracks, which will not be able to tighten the putty, I recommend using the glasswork. It passes on the surface and holds the material. For this, the surface must be projected and coated with glue composition or diluted PVA water. After that, mount the grid and give the mixtures to completely dry before putty.