You can give the doors an attractive appearance in different ways: to paint into another color or use crackering, fasten carvings or forged decorative parts, use photo printing or apply the old tested method - trim in various panels. The latter option is most common in many reasons.

Writing materials

Purely decorative techniques are not suitable for the restoration of the door surface, as they are cosmetic, especially if we are talking about the inlet doorway, exposed to the maximum intense effect of temperatures and moisture. The decoration of the sash with the corresponding materials will not only allow to restore the attractiveness of the product, but also to improve its sound and thermal insulation properties.- Laminate - finishing boards with a thickness of 7-8 mm are made of high-density wood-fiber plates. From the wrong side of the lamella is covered with a layer of waterproof paper, with a facial - moistureproof film and a decorative layer. Laminate imitates the type of wood, stone, ceramics, which allows you to choose options according to any interior. The material is characterized by good sound and thermal insulation properties, but rather hygroscopic, therefore it is used more often for the inner skin.

Finishing lamellae acquired great popularity due to the very affordable cost and durability. In care, they are extremely undemanding - enough wiping with water or weak detergent.

- Lining - non-screensy wooden lamellas with special grooves for durable and light fastening. The thickness of the product ranges from 6 to 20 mm, the length is 1.5, 3 and 6 m. In the manufacture, they are processed by antiseptic and means. The level of sound and thermal insulation of the lining is significantly higher, and the hygroscopicity is lower.

For external work it is recommended to use boards of coniferous wood - pines, larches, more valuable breeds - cedar, ash, beech. The products retain the natural color and drawing of the tree, which adds a lot of inlet door to the beauty.

- MDF - panels are obtained by pressing fine wood chips. To cover the door leaf, a stove is 16 mm thick, coated with a polyvinyl chloride film or anti-vandal. The material is characterized by mechanical strength and high indicators on heat and sound insulation, is not subject to the action of fungi and resistant to moisture.

- Plastic - non-fragrance lamellas are made of polyvinyl chloride with special additives that increase the stability of the material to the action of low temperatures, moisture and ultraviolet. The panels are extremely undemanding in care, durable and easy mounted. However, the mechanical strength of the material is small, so it is recommended to use it during internal work.

Article on the topic: Universal self-adhesive wallpapers - a guarantee of high-quality repair

The panels are available in two versions: seamless and suture, in the form of lining.

How to sheathe laminate doors

You can see the door leaf with laminate very quickly and easily, since the material simplicity passes on the surface of the sash.

- The door is removed from the loops - for convenience in operation, and is placed on a flat surface.

- Temporarily remove locks, door handles and eyes, if any.

- Laminate boards are cut in size of the canvas.

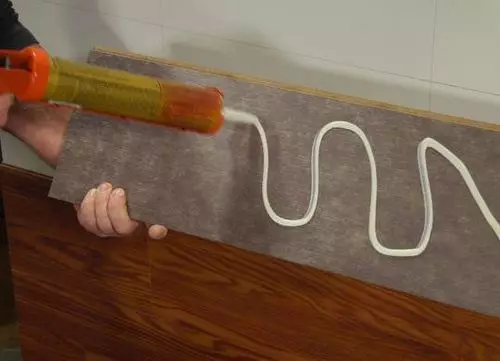

- Adhesive composition is applied to the surface of each lamellae - liquid nails or "moment" glue, for example. The lamellas are placed on the canvas, slightly appreciated and remain until a complete set.

It should be paid to the fact that the material itself does not ensure the overlap of the gap between the sash and the door frame. If the sealing material was placed around the perimeter of the canvas, then it should be restored.

The video demonstrates a roller with instructions.

How to shelter MDF plates

This is the most expensive finish method, however, the most durable. It is used, as a rule, when decorating steel entrance doors. MDF panels can be installed both directly on the surface of the steel sheet and the existing trim - dermatin, for example.- The holes are drilled around the perimeter of the action - the part of the sash that covers the door frame. The step is 20 cm.

- On the perimeter of the canvase itself, a number of through through, through both steel sheets, holes in 20 cm increments are drilled. The diameter is 3 mm, as in the previous case.

- The inner MDF-pad is recorded, and then external. The length of the screw must be a pair of millimeters less than the thickness of the canvas.

- Mounted door accessories, removed during operation.

Since the MDF panel is usually the entire facade of the door, it is recommended to invite assistants to install it.

Article on the topic: Making a wall lamp do it yourself

How to sew the door with lining

It is recommended to pre-hold the material in the room 2-3 days for acclimatization.

- The door flap is removed from the loops and stacked on a flat surface. Remove accessories.

- The lining is cut in accordance with the door parameters and the laying method: vertically, horizontally, diagonally or even in the form of some picture.

- The trim starts from the edge - depending on the method, connecting the elements in each other and fixing the finish nails.

- After the installation is completed, the surface of the material is covered with varnish.

If the metal canvas should be seduced, then at the first stage it is necessary to attach the crate. Non-screensy wooden rails are fixed with self-drawing, and wooden lamellas are mounted on them. You can use special adhesives for fastening the panel to the surface of the steel sheet, but this method fixes the liner enough, and subsequently the material may be deformed.

How to shepherd plastic

It is made approximately the same way as the facing of wooden slats. The elements are sequentially placed on the doorway, according to the laying method, are connected to each other, and then attach to the door. Since the vinyl panels - the material is very light and does not differ in great strength, then for fasteners it is recommended to use construction brackets.

http://www.youtube.com/watch?v=YDRQU_2ZA-W.

Cases when the metal door is discharged with plastic panels, extremely rare: material refers to the category of budget, and the finish of it is such a costly product produces a strange impression.