Owners of suburban buildings in any case are equipped with an entry open gate, but often a swing type that does not require the skill in the installation. However, the sliding valves of the gate are not difficult in creating and installing, but somewhat more practical.

Features of sliding cloths: advantages and disadvantages

Sliding gates are the optimal design with the arrangement of the space of entry into the territory, especially in conditions where this area is somewhat limited to operation. In other words, often many territories do not allow to equip the fare with a swing gate due to a small area that allows you to swallow the web, which is the basis of the installation of sliding systems.

The following indicators are admired to the positive parties to the designs of the entry overlap designs:

- In order to create a sliding canvas of the gate with their own hands and establish it at the place of operation, it does not require large specialized knowledge in the field of construction.

- The comfort of operational use of a typical gate is that even non-automated designs are quite easy to open with their own hands even children.

This fact is provided by roller systems and a high-quality guide profile. To all, the sliding doors do not require clearing the adjacent territory from the snow, in order to disclose the passage.

- The durability of the design is reduced to high-quality component elements, which will be used when creating a gate with its own hands.

- Safety of systems is enclosed in constructive stability of the canvases.

So wind exposure, atmospheric precipitation and temperature indicators will not break the sash. What you can not say about hungry.

- Saving adjacent territory.

To the sliding canvases approaching the car can stop closely.

- Universality of constructive solutions when designing.

Equipping the design of the sliding type itself, it is permissible to construct a model intended for both private use and for overlapping travel at industrial facilities. In addition, a wide range of proposed building material, it allows you to create reliable overlaps in truth.

- The aesthetics and decorativeness of the sliding systems is the type and view of the use of the material to create block blocks with their own hands.

Article on the topic: In which direction should the doors on SNiP

As a sheat, a variety of building material can be used, designed for use for outdoor work: wood, profile or sheet metal, wrought elements, sandwich panels and other products.

- The individuality of the country house may emphasize the entry overlap of the territory.

Sliding blocks are permissible to create at individual discretion and taste, which can be displayed in sizes, forms and, of course, cost.

Sliding gates, like any large-scale product, there are drawbacks, which, fortunately, just two:

- In comparison with the disintegration of entry of entry into the territory, the retractable systems are somewhat more expensive in arrangement.

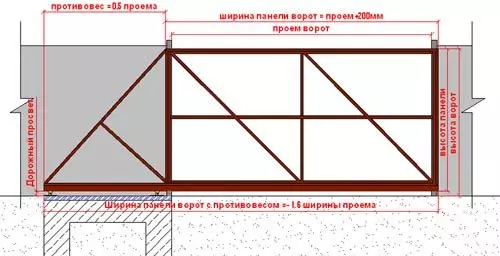

- For high-quality activities of free rolling backdrop of the canvas along the enclosing structure, some space is required, approximately equal flight width.

Package blocks and tools

The sliding design consists of such elements:

- Internal and outdoor frame, which is recommended to create from tubular rental.

- Schweller for the foundation.

- Main components Details: rollers, catchers, guides, etc.

- Automation, if the gate is created under automatic use. In other words, it is permissible to install automation and later.

- The slaughter of the frame is selected relative to personal preference. It all depends on the stylistics of the structure and the adjacent area. Often use profile sheet, fixable on the frame of self-draws.

The approximate calculation of the material being expended is permissible to reduce approximate indicators, since the volume of raw materials depends on the height and width of the future design:

№ | Material | The size | For use purposes | number |

one | Square trumpet | 20x20x2 mm | Interior Framing - Gate Frame | ~ 40 pm |

2. | Square trumpet | 60x60x2.5 mm | For pillars | ~ 10 pm |

3. | Pipe (square) | 40x20x2 mm | For outdoor carcass | ~ 40 pm |

four | Profile sheet type C-8 | 2000x1200x0.5 mm | To form a plane of cloths | ~ 7 sheets |

Stages of activity

For the beginning of independent work, it is worth deciding on the required size of the structure sufficient to enter the territory of one or other transport.

Article on the topic: Right docking parquet board and tiles

It is worth noting that the flight width plays a considerable role. So for narrow streets it is recommended to make entry wider than usual, so that the transport could be free to enter / leave.

Thoroughly determined with the width of the pass, it is worth starting the workselves:

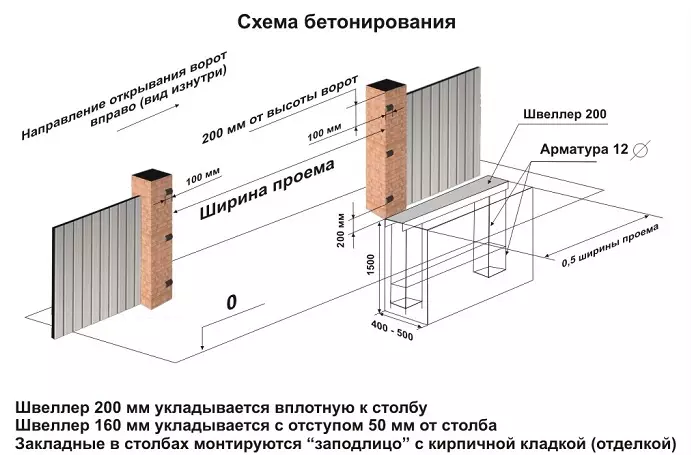

- The start of work begins with the installation at the site of the reference pillars, which can be created from brickwork, concrete or metal. Supports must be installed in the ground to the depth equal to the laundering, relative to the regional regions. Next supports concrete.

- Next, the foundation is discarded under the design, which is necessary to fix the console beams on the already installed support pillars.

With the size of the canvas, let's say 4 meters, the foundation can independently dig up 2 meters long, which will be enough. The depth of the trench under the foundation can reach 0.5 meters. Next, the trench is filled with rods of reinforcement and poured with a concrete mixture. From above, a channel is installed (mortgage), laid in terms of (down with legs), to which the retractive trolley will be fixed.

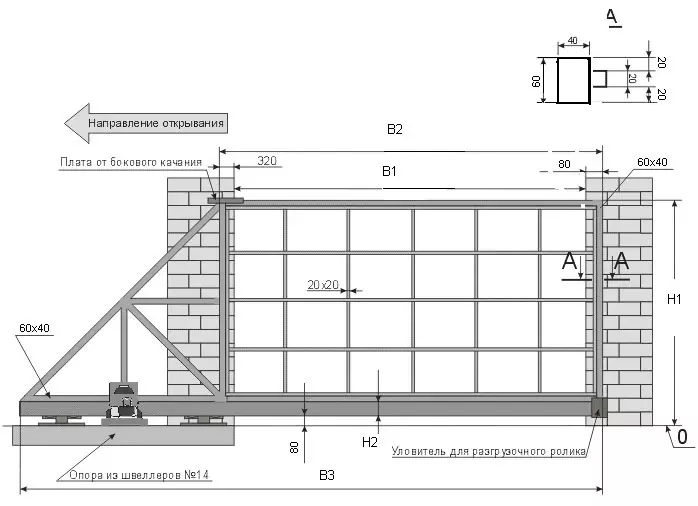

- Before starting to create a frame of the canvas with your own hands, it is worth drawing a scheme with all the necessary dimensions with the obligatory indication of the location of the rigidity ribs.

According to the drawing and the amount obtained, the profile is cut and welded in a checker order. The typical order of welding will not allow the design during the assembly process with their own hands to shift.

- Next, the collected frame side of the canvase in the welding places is seen and covered with primer.

Sewing sash frame, recommended after hanging at the place of operation, because otherwise, the design will be inbox for humans.

- Roller carriages to the channel is permissible to secure the welding joint or by using bolts.

Specialists I recommend using the welding machine in this case, because exactly the carriage is quite difficult to place the carriage, which is somewhat easier to make a welding mix. To begin with, they are worth a little to grab welding.

- Next are set to mortgages (from pipes) to secure component elements. In one parallel, it is worthwhile to be welded with the welding machine (bottom and upper), as well as the top roller systems.

- On the end of the guide profile, the rails are mounting the end roller using a special clamp.

Article on the topic: The order of installation of a wooden fence - blinds

Recommended the end parts of the rail rail to be provided with plugs, so that no atmospheric precipitates did not fall there, and the system itself was not amented by freezing.

- After checking the design on the quality of performance, roller carriages that were initially slightly grabbed with welding, it is permissible to finally weld to the desired location.

The covering of the frame side, as previously noted, is permissible to do from any building material, both on both sides and one, for example, the outside, to give the aesthetics of the sliding gate.

This shows that the sliding systems to create themselves are not so difficult and difficult, the main difficulty is in patience and accuracy of actions.