The chimney pipe that you can see over the roof of almost every private house is only a small visible element of a complex system responsible for the gas and smoke lead. Regardless of what fuel, the heating equipment you are working, it must be supplemented with a system for removing combustion products.

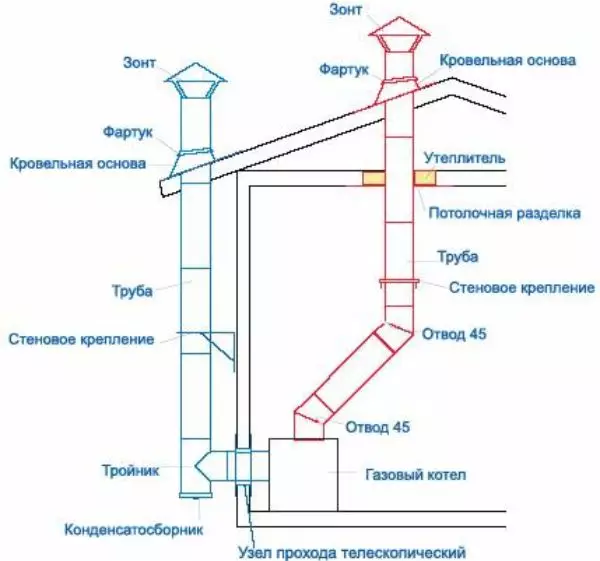

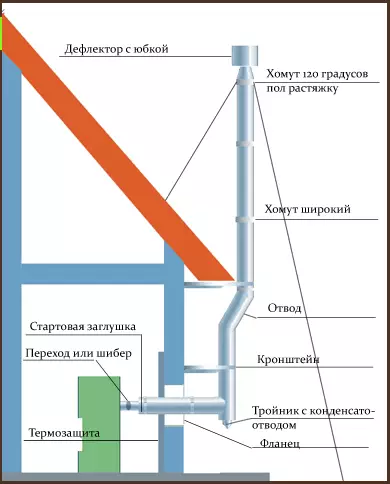

The diagram of the device of the internal chimney and the outer construction.

Each host, whose house is heated using gas equipment must have an idea of how ventilation is arranged for a gas boiler, which will allow it to properly exploit the heating system as such.

Those who can only have to solve the problems of creating ventilation for gas boilers before going to a specialized store or invite relevant specialists to themselves, you must first get acquainted with the theory. At least you need to know which hoods for gas boilers are, what are their advantages and disadvantages.

Hoods for gas boilers: Available solutions

Scheme of the chimney of the gas boiler.

Many are interested, whether it is possible to perform a chimney device for a gas boiler on its own. Can. But if you first have to do this work, the expert consultation is very desirable. First of all, you need to know which gas heating equipment schemes exist, and deal with the peculiarities of the device of various chimneys for gas boilers.

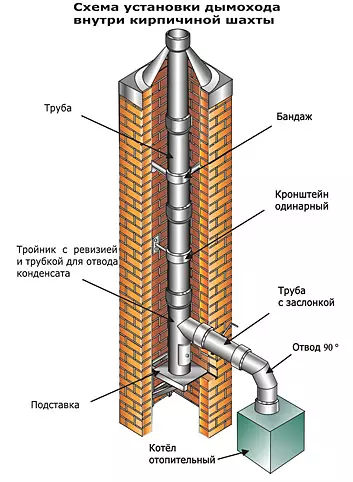

Classic, although it is extremely outdated as a modern standards option, is a brick chimney. The device of brick chimneys is characterized by the complexity of the design and the high cost, and its construction takes a lot of time. In addition, the operational characteristics of brick chimneys are worse, if you compare them with more modern designs.

The chimney device for gas boilers made of stainless steel is widespread.

The market presents a fairly rich assortment of such solutions. Among the advantages of such a solution, it is impossible not to note the high resistance to the effects of the aggressive environment and various mechanical damage.

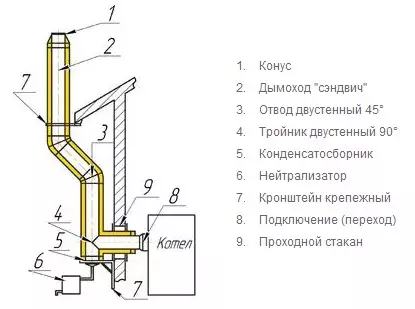

The chimney for a gas boiler, made of stainless steel, in most cases will be made in the form of a sandwich system - these are 2 different in the diameter of the pipe one in another. Between such pipes there remains empty space, which is filled with basalt cottage, resistant to high temperatures. This design is one of the most successful and modern solutions.

Article on the topic: How to put an old battery in order?

Coaxial chimney for a gas boiler can hardly be confused with any other design. A distinctive feature of such a solution is a presentable appearance. Performance characteristics are also at a very high level. Moreover, such chimney has a specific shape, on the inner walls of which condensate does not appear, which is especially important for heating systems operating on gas fuel.

Ceramic chimney - the choice of those who prefer reliability and simplicity, fire safety and ease of installation and a very affordable price.

Required chimney elements for gas boiler

The chimney device for the gas boiler.

The chimney device for gas heating boilers implies a very laborious work. First you need to consider the basic principles of the chimney installation for such equipment, which is performed in the following order:

- All pipe elements are collected;

- In places of passage of the pipe through the construction of the house, special passing elements are installed;

- isolation of all surfaces in contact with combustible materials;

- It is arranged directly chimney.

Chimney for gas heating equipment consists of the following elements:

- adapter from the boiler nozzle to the chimney pipe;

- a trial with revisions (below is equipped with a fitting room designed to remove condensate);

- Basic mounts - bracket and wall clamp;

- Tops that are used at a distance of no more than 2 m from the beginning of the chimney. Otherwise, the boiler can decrease;

- passing nozzle;

- telescopic pipes;

- Special tip having a conical shape.

The composition of the metal chimney for the boiler.

The chimney tip must be necessarily a conical shape. Ordinary umbrellas and deflectors are categorically projected. You can not put the tip at all. For the chimney device, you will need the following tools:

- Pencil.

- Drill the required diameter.

- Electric drill.

- Dowels.

- Screwdriver of the required diameter.

- Suspended corner.

- Building level.

- Set of keys of the corresponding diameters.

- Sealing material.

Chimney, in the complex with which your boiler will work, must comply with the following requirements:

Diagram of the smoke-drawing device for the gas boiler.

- The slope of some parts of the chimney should not exceed 30 degrees;

- The maximum allowable branch of the side is 100 cm;

- Maximum number of knees - 3, radius of rounding should be greater than the diameter of the pipe;

- Without narrowings of the cross section and ledges.

- In places of rotation, there must be a hatch to eliminate condensate and cleaning;

- At the bottom of the chimney, you need to provide a dropper and revision;

- One side of the smoke of the rectangular shape should not be 2 times less (more) the other, that is, the form of the design should not be elongated;

- It is impossible to allow the deflection of structural elements;

- It is impossible to leave any gaps between the connecting elements;

- Tube links need to wear one to another no less than half the diameter of the pipe;

- All items must be very tightly connected;

- In places of passage, the roof or overlap pipe should not have joints;

- The inner surface of the design elements should be perfect smooth, roughness in chimney must be absent;

- Horizontal sequins can have a total length of 3 m in buildings that are built, and not more than 6 m in the already built;

- The minimum distance between the pipe and walls and the ceiling for non-combustible materials is 5 cm, for combustible - 25 cm;

- Below the connection site of the tee must be provided for the so-called pocket with a length of at least 25 cm with a pipe cleaning hatch;

- When removing the exhaust gases from municipal equipment, it is necessary to provide dampers for boilers that operate on gas fuel - a hole with a diameter of 5 cm at the top of the damper;

- If the pipe passes through the unheated design places, it is necessary to provide a device for thermal insulation;

- Sewberry management must be taken into an affordable place;

- If the unit has a traction stabilizer, then there is no need for dampers.

Article on the topic: What are the good powder coating doors

Use additional elements and connections

Extraction assembly scheme for gas boiler.

A good thrust is the key to the effective consumption of thermal energy obtained from gas combustion. It is necessary to take care so that the extra moisture does not accumulate on the walls of the chimney channel.

You do not need to install fungi, deflectors, etc., and pr. These elements reduce the effectiveness of the output of combustion products, and the probability of carbon monoxide appears inside the room.

When performing installation work, you must adhere to the recommendations and execute the installation rules. A special emphasis should be done on the density of fitting details of the design in places of compounds, that is, it is necessary to take care of the achievement of maximum tightness. It will not give hot gases to penetrate the chimney borders. It is allowed to use common connecting chimensing pipes for several aggregates.

The chimney device for boilers in the house and outside the house

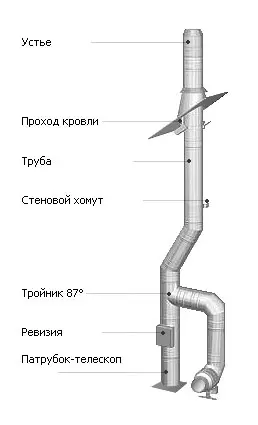

Chimney for the gas boiler outside the house is suitable as follows.

First, the passage element is joined to the nozzle, which will pass through the wall. Before cutting out the opening in the wall, you need to apply the correct markup and re-send a couple of times. After preparation, the chimney is displayed outside. Hole in the wall and plot of pipes need to isolate. Then the tee is fastened with revisions and put on the plug. The pipe is increasing by attaching links and is attached to the wall of the house with the help of brackets with a step of at least 2 m.

After the calculated height of the chimney is typed, the cone-shaped tip joins. All joints are enhanced by clamps that need to be pulled with wire or bolts. The pipe is desirable to paint the heat-resistant paint, which will protect material from corrosion.

If you do not want to use as a material for a device of a sandwich panel, do not forget to perform the heat insulation of the structure.

The chimney device in the house begins with preparatory work. First, the markup is applied for the holes for the pipe in the floors and the roof. The applied marks must be removed several times with the size of the passing pipe. The necessary opening is cut under the chimney, after which the pipe mounting begins.

Article on the topic: Warm floor in the bath from the stove: do it yourself, the scheme

Gas chimney installation scheme.

From the gas boiler leaves the nozzle. It is necessary to connect a transition adapter with it. Next joins the tee and revision (for cleaning the pipes), the steel sheet is attached and the main bracket is installed.

The pipe is increasing, if necessary, you can use the so-called knee. When passing overlaps, use a special nozzle. Then the leaf of galvanized steel with a hole is slightly larger than the diameter of the pipe itself on the pipe. The sheet is attached to overlapping on both sides.

All joints are enhanced by clamps, pulled bolts or wire. The chimney fastening is performed using brackets (every 4 m) and clamps (every 2 m).

The design is completed with a special cone-shaped tip, which will protect the chimney from strangling wind and atmospheric precipitation.

All contacting pieces of pipe and flammable designs need to be isolated. For this, the passage is covered from all sides by a foil basalt insulator (mat) with refractory mastic. On the perimeter of the opening of the floors can be laid mineral wool.