Any overlaps is a potential source of heat loss and

Penetration of noise.

In the case of wooden beams, it can be noted that

Wood perfectly spends sound. Plus, tree beams, with time begin

make creak.

To avoid this, you need to take care timely

Proper sound insulation overlaps (noise insulation).

Soundproofing of wooden floors in the house

By nature, the sound is divided into three types:

- Shock noise. Reflects the sound of steps, drop items,

Moving furniture. Characterized by the index of the reduced level of shock noise

Lnw;

- Air (acoustic) noise. Sound waves that

Transmitted by air. The source can perform the voice of the residence, the sound of the television

and video equipment, etc. It is characterized by an RW air noise insulation index.

- Structural noise. In essence, this is a kind of shock noise, in

The difference from which the noise conductors are the Connection Places of Connection

constructions.

Select sound insulation material for overlaps

To ensure better protection against noise and vibration,

Soundproofing of inter-storey wooden floors is carried out using

several types of insulators. The main requirement is a high coefficient

Sound absorption of building materials.

Soundproofing of inter-storey wooden floors of minvatayv as the main sound insulation is better to give

Preference to fibrous materials, because their structure contributes to the fact that

Most sounds come out about it (i.e., the maximum

Sound absorption).

For example, equating, mineral and basalt wool possesses such characteristics. In addition, such a sound insulation material serves simultaneously and insulation.

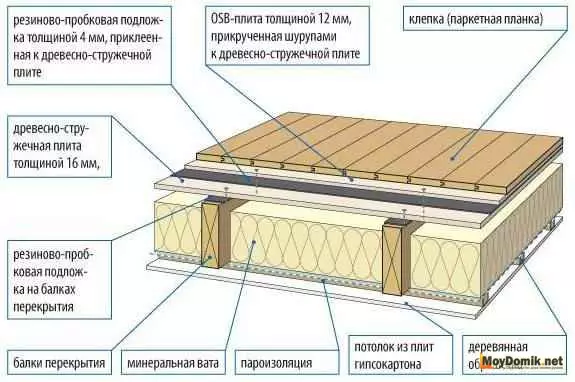

Soundproofing of wooden floors - draft floor chipboard - Speed isolation from sounds will create arrangement

draft floor from chipboard or OSB. At the same time, sheets are not attached to lags, but fixed

Between self-drawing or nails. In the beams, such a floor is held under

Own weight (on the principle of floating gender). And thanks to the absence

The hard compound with the overlap is reduced by the probability of penetration of noise

from outside.

Soundproofing between the wall and overlapping, the sound penetrated between the overlap and the bearing wall, as well as between the overlapping and chimney, it is recommended to place a roll insulation in the seam, for example, felt or in the structure of it is similar. And the location of the connection is to close the plinth. Moreover, the plinth is nailed only to the wall.

Article on the topic: Coloring of vinyl wallpaper, popular colors

Soundproofing of wooden floors - felt on the beamed felt felt on the beams also reduces the level of noise.

Soundproofing of wooden floors - substrate strokes with a polystyrene and / or foil substrate, or a substrate from a natural plug under the flooring will also reduce the level of impact noise and vibration.

It is worth noting that all types of sound insulation works

The floors must be performed at the construction stage of the building. Location scheme

Materials are presented in the figure.

Soundproofing of wooden floors between floors - norms and requirements

Despite the general approach to the selection of noise insulationMaterial, sound insulation of wooden floors of various purposes is carried out

With compliance with different requirements.

- Soundproofing overlap of non-residential attic on wooden

The beams are considered to be performed effectively, if an air noise isolation index

RW is at least 45 dB. Such protection is able to provide a layer

Mineral wool density at least 50 kg / m. Cube laid with a layer of 100 mm. If a

The height of the beams is less than this magnitude, then they can fill lags. And the next

Material layer Place between lags. In order not to be created bridges

Cold, lags need to be located perpendicular to beams. Then the place of the junctions

Watches will be closed with the following layer.

- Soundproofing of inter-storey floors will be sufficient in

Cases of using matte from mineral or basalt cotton beds

Not less than 200 mm. At a density of 50 kg / mk. If the density of the material is higher, the layer

decreases proportionally.

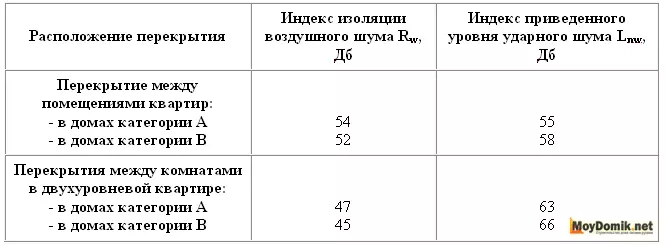

Air and shock noise insulation index

Regulatory indicators of sound insulation of floors are registered in

such standards as SNiP 23-01-2003 "Noise Protection" and SNiP II-12-77 Protection against

noise. "

Detailed data displaying the specified level index

RW shock and air noise depending on the location of the overlap

Presented in the table.

Air and Impact Noise Insulation Index - Table

At the same time, sound insulation is considered sufficient if:

- RW is equal to or exceeding the regulatory value;

- LNW is equal to or below the normative value.

It should be known that the use of sound insulation

The material does not protect the room from sounds penetrating through the walls. therefore

Soundproofing walls need to be made additionally.

Material prepared for site www.moydomik.net

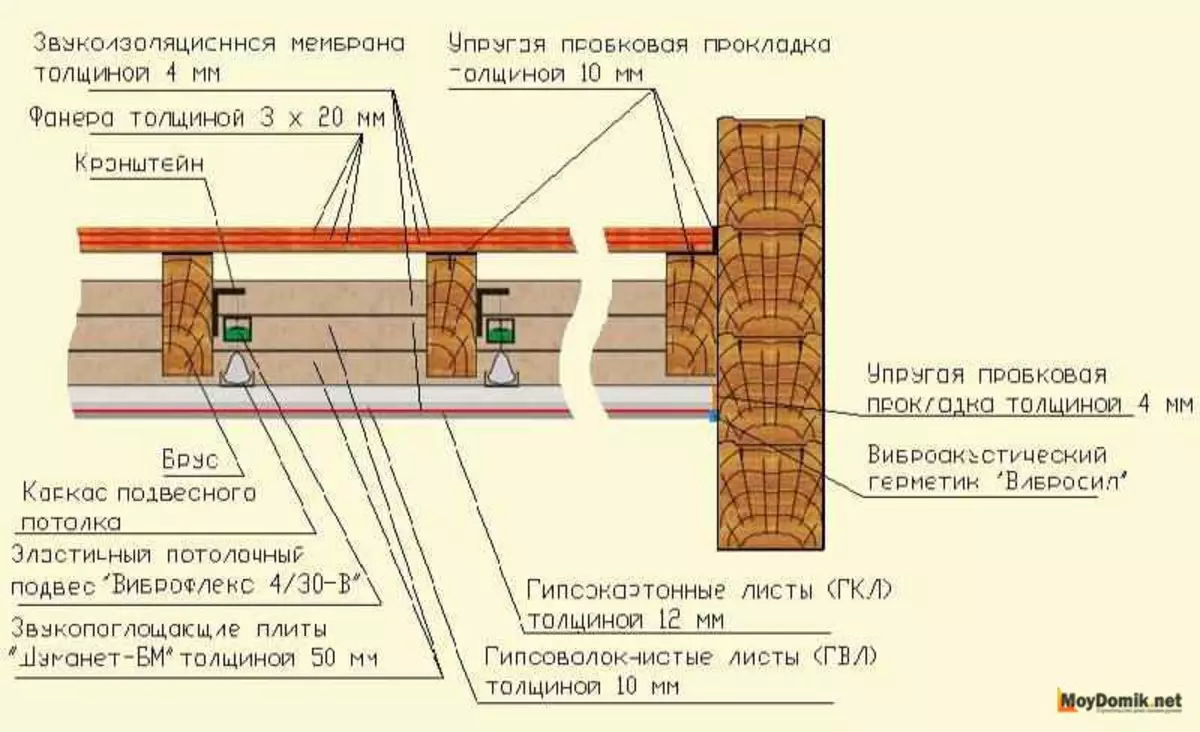

Membrane soundproofing of overlaps in a wooden house by

ceilingThe technique was described on the same construction forum,

Competent person, judging by the reviews. Who already did, say the effect

worthy.

Article on the topic: Plastic window does not close: Causes and their elimination (video)

Soundproofing of wooden beam overlaps between floors

mineral wool or mineral plates (thermal insulation plates from

mineral wool, for example, technonikol, technofas, rocklaight, ISOVER and

TD).

Acoustic insulation brand is chosen at your discretion,

The principle of all manufacturers is one. Varies size and density (thickness from

40 to 100 mm, density 30-140 kg / m3). Produced in the form of rolls or plates,

certain dimensions.

Attention!

Installation of wool is performed strictly in protective glasses and

Respirator.

The advantage of wool is excellent sound absorption, in particular,

Gas are well and partially medium frequencies. Here is the rule - than

thicker layer, the more it is able to absorb (meaning the spectrum of low

frequency). It should be understood that it is low frequencies are strongly transmitted through

Wooden overlaps and get rid of their penetration is very difficult. Why

So? Everything is simple - wooden floors have a low weight, and the tree performs in

The role of the resonator. In concrete floors to achieve sound insulation easier, in mind

Constructive features of the concrete slab and its properties.

However, if desired, you can significantly reduce the transfer

Noise through wood overlap. To do this, make a sound absorber,

Presenting a membrane type pie.

Soundwork membrane device

Pie is made of sheet material, as an option,

OSB or plywood (not thinner than 10 mm). Inside (between sheets) stacked

Soundproofer. As a sound absorber can be used:

- Mineral Wat (Minvata)

- Basalt fiber

- Madelita

- Building felt (technical)

If applying mineral wool material, then with density is not

Less than 30 kgm3 (the higher the density and thicker, the better).

Felt construction is characterized by high parameters

sound absorption, but inclined to water absorption and fire hazardous (although high quality

Antiseptic impregnation reduces the probability of fire, i.e. open does not burn

And tolets).

Construction (technical) felt - dense material from

Wool or synthetic fibers. Characteristics: Density - 10-80 kg / m3,

Thickness 5-40 mm, the width is different, varies from up to 2 meters,

thermal conductivity from 0.03 to 0.07 W / (M • K). Produced in rolls or in the form

cloth.

The sound absorber between the overlap and the membrane is not done

only for sound insulation, and more in order to pay off resonance,

arising between overlapping and membrane.

Article on the topic: Fabric rolets on the windows with their own hands

Soundproofing of wooden floors - the vibropodus-the achievement of the maximum soundproofing effect - the membrane (pie) should not be connected to the overlap, i.e. Must have an independent connection (attached to a separate profile at a distance of 10 cm from overlap, forming an airbag). It turns out a kind of suspended

ceiling.

Homemade vibrapropodvevoxic insulation pie is attached around the perimeter to the walls, and

In the middle of the beams only by means of amorticing mounts (elastic

Ceiling suspension), with a rare step, not less than meter. Vibropodves can be

Buy factory or make homemade vibrational suspension.

If the membrane is to fasten directly to the wooden beams of overlapping, the whole effect will be lost.

Principle of Technology - Synchronized Sound Wipes arising between

overlapping and membrane. It turns out, so to speak, the ceiling with resonant

absorber.

Soundproofing of wooden floors between floors - sound-absorbing membrane

An still possible device of such a design - Minvat is attached

grid or slats between beams of overlapping, and as a membrane (i.e. instead

HEE) Sew the ceiling of plywood or plasterboard. But they are attached not to the beams, but

Also independently (i.e. per walls), 3-5 cm below the overlap. With such

Device The role of the absorber will play minvat attached on the beams.

Soundproofing of Wooden Overlap Sand

The method is controversial. Time-consuming process, big weight and most

The main thing, the sound is partially extinguished, because The main resonance is transmitted by lags.

The principle of the device is shown in the photo.

Soundproofing of Wooden Overlap Sand

Soundproofing overlapping sand

Noise isolation of sand overlaps

Of course, it all depends on the method of the device, as the masters advise, you need to fall asleep the sand between the lags and the draft floor, and not only between the beams of the overlap, and on top to mount the floating floor system.

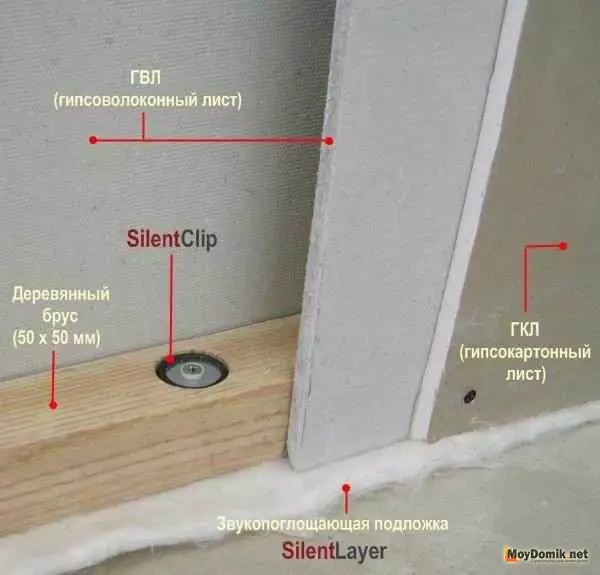

Soundproofing Soundproofing Soundproofing for Plasterboard

Soundproofing device for plasterboard

Technology of the soundproofing devices for plasterboard

Outcome

Soundproofing technology for wooden houses in

the difference from brick and concrete buildings has a number of features that

directly related to the design of the overlaps of their properties and sound conductors

characteristics. The methods described above will help isolate or significantly

reduce the penetration of sound waves between the floors in the frame cottages, and

Also in houses from a rounded log or bar.